Manufacture of the International Space Station

Topic: Astronomy

From HandWiki - Reading time: 13 min

From HandWiki - Reading time: 13 min

The project to create the International Space Station required the utilization and/or construction of new and existing manufacturing facilities around the world, mostly in the United States and Europe. The agencies overseeing the manufacturing involved NASA, Roscosmos, the European Space Agency, JAXA, and the Canadian Space Agency. Hundreds of contractors[1] working for the five space agencies were assigned the task of fabricating the modules, trusses, experiments and other hardware elements for the station.

The fact that the project involved the co-operation of sixteen countries working together created engineering challenges that had to be overcome: most notably the differences in language, culture and politics, but also engineering processes, management, measuring standards and communication; to ensure that all elements connect together and function according to plan. The ISS agreement program also called for the station components to be made highly durable and versatile — as it is intended to be used by astronauts indefinitely. A series of new engineering and manufacturing processes and equipment were developed, and shipments of steel, aluminium alloys and other materials were needed for the construction of the space station components.

History and planning

The project began as Space Station Freedom, a US only effort, but was long delayed by funding and technical problems. Following the initial 1980's authorization (with an intended ten year construction period) by Ronald Reagan, the Station Freedom concept was designed and renamed in the 1990s to reduce costs and expand international involvement. In 1993, the United States and Russia agreed to merge their separate space station plans into a single facility integrating their respective modules and incorporating contributions from the European Space Agency and Japan.[2] In later months, an international agreement board recruited several more space agencies and companies to collaborate to the project. The International Organization for Standardization played a crucial role in unifying and overcoming different engineering methods (such as measurements and units), languages, standards and techniques to ensure quality, engineering communication and logistical management across all manufacturing activities of the station components.[citation needed]

Engineering designs

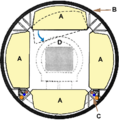

Engineering diagrams of various elements of the ISS, with annotations of various parts and systems on each module.

Technical schematics

Manufacturing Information and Processes

List of factories and manufacturing processes used in the construction and fabrication of the International Space Station modular components:[citation needed]

| Space Station component | Overseeing agency and contractor(s) | Manufacturing facility |

Materials used |

Manufacturing date | Mass (kg) |

Manufacturing Processes | Factory view | |

|---|---|---|---|---|---|---|---|---|

| Zarya (FGB)[3] | NASA, Roscosmos

|

Khrunichev State Research and Production Space Center | 1994 | 19,323 |

|

| ||

| Unity (Node 1),[4] PMA-1 & PMA-2 | NASA | Marshall Space Flight Center |

|

June 6, 1997 | 11,612 |

|

| |

| Zvezda (Service Module)[5] | Roscosmos | Khrunichev State Research and Production Space Center | February 1985 | 19,051 |

|

| ||

| Z1 Truss & PMA-3 | NASA | Michoud Assembly Facility

|

|

1999 | 8,755 (Z1) |

|

| |

| P6 Truss & Solar Arrays | NASA | Michoud Assembly Facility |

Truss

Solar Arrays

|

1999/2000 | 15,824 |

|

| |

| Destiny (US Laboratory)[6] | NASA | Marshall Space Flight Center | December 12, 1997 | 14,515 |

|

| ||

| External Stowage Platform-1 | NASA

|

Goddard Space Flight Center[7] | Steel | 2000 | 5,760 |

|

||

| Canadarm2 (SSRMS) | Canadian Space Agency |

|

Titanium | 2000/01 | 4,899 |

|

| |

| Quest (Joint Airlock)[8] | NASA | Marshall Space Flight Center |

|

2000 | 6,064 |

|

| |

| Pirs (Docking Compartment & Airlock) | RKK Energia | Korolyov, Moscow Oblast | 1998 | 3,580 |

|

| ||

| S0 Truss[9] | NASA | Michoud Assembly Facility

|

1998/2000 | 13,970 |

|

| ||

| Mobile Base System | NASA

|

Northrop Grumman factory in Carpinteria, CA |

|

2001 | 1,450 |

|

| |

| S1 Truss and Radiators | NASA | Michoud Assembly Facility |

|

June 2002 | 14,120 |

|

| |

| P1 Truss and Radiators | NASA | Michoud Assembly Facility |

|

July 2002 | 13.748 | same as S1 Truss |

| |

| ESP-2 | NASA

|

Goddard Space Flight Center |

|

October 2005 | 2,676 |

|

| |

| P3/P4 Truss & Solar Arrays[10] | NASA | Michoud Assembly Facility

|

Truss Solar Arrays

|

2005/06 | 15,900 |

|

| |

| P5 Truss[11] | NASA | Operations and Checkout Building | Anodized steel | February 2007 | 1,818 |

| ||

| S3/S4 Truss & Solar Arrays | NASA | Michoud Assembly Facility

|

Same as P3/P4 trusses | May 12, 2005 | 15,900 | Same as P3/P4 trusses |

| |

| S5 Truss and ESP-3 | NASA | Operations and Checkout Building | Steel (some anodized) | 2007 | 13.795 | Same as P5 and ESP-1 and 2 |

| |

| Harmony (Node 2) Relocation of P6 Truss |

European Space Agency, Italian Space Agency | Thales Alenia Space factory in Turin, Italy |

|

May 2003 | 14,288 |

|

| |

| Columbus (European Laboratory)[12] | European Space Agency

|

European Space Research and Technology Centre

|

April 2006 | 12,800 |

|

| ||

| Dextre | Canadian Space Agency

|

MacDonald Dettwiler (now MDA Space Missions) factory in Brampton Ontario |

|

2004 | 1,734 |

|

| |

| Japanese Logistics Module (ELM-PS) | JAXA | Tsukuba Space Center | April 2, 2007 | 8,386 |

|

| ||

| Japanese Pressurized Module (JEM-PM) JEM Robotic Arm (JEM-RMS)[14][15] |

JAXA (formerly NASDA) | Tsukuba Space Center | November 2005 | 15,900 (JEM-PM) |

|

| ||

| S6 Truss & Solar Arrays | NASA | Michoud Assembly Facility | same as P4/S4 truss and solar arrays | 2006/07 | 15,900 | same as P4/S4 truss and solar arrays | ||

| Japanese Exposed Facility (JEM-EF) | JAXA | Tsukuba Space Center | May 28, 2003 | 4,100 |

|

| ||

| Poisk (MRM-2)[16][17] | Roscosmos

|

Khrunichev State Research and Production Space Center |

|

2008/09 | 3,670 | same as Pirs |

| |

| ExPRESS Logistics Carriers 1 & 2 | NASA | All three contracting facilities | 2008/09 | 6,277 |

|

| ||

| Tranquility (Node 3) | NASA, European Space Agency

|

Cannes Mandelieu Space Center | Stainless steel | April 2005 | 12,247 |

|

| |

| Cupola | NASA, European Space Agency

|

|

|

2003/07 | 1,800 |

|

| |

| Rassvet (MRM-1)[18] | Roscosmos, NASA

|

Khrunichev State Research and Production Space Center

|

|

July 2009 | 5,075 |

| ||

| Leonardo (PMM) | Italian Space Agency, NASA |

|

Stainless steel | 2000/01 | 9,896 |

|

| |

| EXPRESS Logistics Carrier 3 | NASA | Goddard Space Flight Center |

|

2010/11 | 6,637 | Same as ELC 1 & 2 |

| |

| EXPRESS Logistics Carrier 4 | NASA | Goddard Space Flight Center |

|

2010/11 | 6,731 | Same as ELC 1 & 2 |

| |

| Alpha Magnetic Spectrometer | CERN

|

CERN, Geneva Switzerland |

|

August 2010 | 6,731 | Spectrometer development and assembly |

| |

| Bigelow Expandable Activity Module[19] | NASA

|

Bigelow Aerospace factory in Las Vegas, Nevada[20] | March 12, 2015 | 3.2 | Composite lamination |

|

||

| NanoRacks Airlock Module | NanoRacks | Thales Alenia Space factory[21] |

|

2017-20 | 325 kg |

|

| |

| Nauka (MLM) European Robotic Arm[22] |

Roscosmos | Khrunichev State Research and Production Space Center | Same as Zarya | 2005/18 | 20,300 | Same as Zarya, with additions |

| |

| Prichal | Roscosmos

|

Khrunichev State Research and Production Space Center | Same as Poisk | 2017/20 | 3,890 | Same as Poisk |

| |

| Roll Out Solar Arrays | NASA | Deployable Space Systems, Inc. (DSSI) |

|

2014-present | 1,002 |

|

| |

| Space Station component | Overseeing agency and contractor(s) | Manufacturing facility |

Materials used |

Manufacturing date | Mass (kg) |

Manufacturing Processes | Factory view |

Decommissioned Components are shown in gray.

Transportation

Once manufactured or fabricated sufficiently, most of the space station elements were transported by aircraft (usually the Airbus Beluga or the Antonov An-124) to the Kennedy Space Center Space Station Processing Facility for final manufacturing stages, checks and launch processing. Some elements arrived by ship at Port Canaveral.[23][24]

Each module for aircraft transport was safely housed in a custom-designed shipping container with foam insulation and an outer shell of sheet metal, to protect it from damage and the elements. At their respective European, Russian and Japanese factories, the modules were transported to their nearest airport by road in their containers, loaded into the cargo aircraft and were flown to Kennedy Space Center's Shuttle Landing Facility for unloading and final transfers to the SSPF and or the Operations and Checkout Building in the KSC industrial area. The American and Canadian-built components such as the US lab, Node 1, Quest airlock, truss and solar array segments, and the Canadarm-2 were either flown by the Aero Spacelines Super Guppy to KSC, or transported by road and rail.[25]

After final stages of manufacturing, systems testing and launch checkout, all ISS components are loaded into a payload transfer container in the shape of the Space Shuttle payload bay. This container safely carries the component in its launch configuration until it is hoisted vertically at the launch pad gantry for transfer to the Space Shuttle orbiter for launch and in-orbit assembly of the International Space Station.[26]

Pre-launch processing and last stages of manufacturing

With the exception of all but one Russian-built module — Rassvet, all ISS components end up here at either one or both of these buildings at Kennedy Space Center.

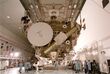

Space Station Processing Facility

At the SSPF, ISS modules, trusses and solar arrays are prepped and made ready for launch. In this iconic building are two large 100,000 class clean work environment areas.[27] Workers and engineers wear full non-contaminant clothing while working. Modules receive cleaning and polishing, and some areas are temporarily disassembled for the installation of cables, electrical systems and plumbing. Steel truss parts and module panels are assembled together with screws, bolts and connectors, some with insulation. In another area, shipments of spare materials are available for installation. International Standard Payload Rack frames are assembled and welded together, allowing the installation of instruments, machines and science experiment boxes to be fitted. Once racks are fully assembled, they are hoisted by a special manually operated robotic crane and carefully maneuvered into place inside the space station modules. Each rack weighs from 700 to 1,100 kg, and connect inside the module on special mounts with screws and latches.[28]

Cargo bags for MPLM modules were filled with their cargo such as food packages, science experiments and other miscellaneous items on-site in the SSPF, and were loaded into the module by the same robotic crane and strapped in securely.

Operations and Checkout Building

Adjacent to the Space Station Processing Facility, the Operations and Checkout Building's spacecraft workshop is used for testing of the space station modules in a vacuum chamber to check for leaks which can be repaired on-site. Additionally, systems checking on various electrical elements and machines is conducted. Similar processing operations to the SSPF are conducted in this building if the SSPF area is full, or certain stages of preparation can only be done in the O&C.[29]

See also

- Assembly of the International Space Station

- Origins of the International Space Station

- Space architecture

- Aerospace engineering

- Space manufacturing

- Space Station 3D – 2002 Canadian documentary

References

- ↑ "Companies involved with ISS". https://www.esa.int/Our_Activities/Human_and_Robotic_Exploration/International_Space_Station/Companies_involved_with_ISS.

- ↑ "International Space Station | Facts, Missions, & History". https://www.britannica.com/topic/International-Space-Station.

- ↑ Wade, Mark (15 July 2008). "ISS Zarya". Encyclopaedia Astronautica. Archived from the original on 27 February 2009. https://web.archive.org/web/20090227060517/http://www.astronautix.com/craft/isszarya.htm. Retrieved 2009-03-11.

- ↑ "Unity Connecting Module: Cornerstone for a Home in Orbit". NASA. January 1999. Archived from the original on 17 March 2009. https://web.archive.org/web/20090317204752/http://spaceflight.nasa.gov/spacenews/factsheets/pdfs/unity.pdf. Retrieved 2009-03-11.

- ↑ "Zvezda Service Module". NASA. 11 March 2009. Archived from the original on 23 March 2009. https://web.archive.org/web/20090323030726/http://www.nasa.gov/mission_pages/station/structure/elements/sm.html. Retrieved 2009-03-11.

- ↑ "US Destiny Laboratory". NASA. 26 March 2007. Archived from the original on 9 July 2007. https://web.archive.org/web/20070709153924/http://www.nasa.gov/mission_pages/station/structure/elements/destiny.html. Retrieved 2007-06-26.

- ↑ NASA.gov Techs_working_on_ELC_1019.jpg

- ↑ "Space Station Extravehicular Activity". NASA. 4 April 2004. Archived from the original on 3 April 2009. https://web.archive.org/web/20090403213449/http://spaceflight.nasa.gov/station/eva/outside.html. Retrieved 2009-03-11.

- ↑ "Space Station Assembly: Integrated Truss Structure". NASA. Archived from the original on 7 December 2007. https://web.archive.org/web/20071207081810/http://www.nasa.gov/mission_pages/station/structure/elements/its.html. Retrieved 2007-12-02.

- ↑ "P3 and P4 to expand station capabilities, providing a third and fourth solar array". Boeing. July 2006. http://www.boeing.com/defense-space/space/spacestation/components/docs/P3-P4.pdf. Retrieved 2007-12-02.

- ↑ "STS-118 MISSION OVERVIEW: BUILD THE STATION…BUILD THE FUTURE". NASA PAO. July 2007. Archived from the original on 1 December 2007. https://web.archive.org/web/20071201130531/http://www.nasa.gov/pdf/182728main_STS-118_Press_Kit.pdf. Retrieved 2007-12-02.

- ↑ "Columbus laboratory". ESA. 10 January 2009. Archived from the original on 30 March 2009. https://web.archive.org/web/20090330191925/http://www.esa.int/esaHS/ESAAYI0VMOC_iss_0.html. Retrieved 2009-03-06.

- ↑ "Stainless Steel, orbiting our planet at 17,150 miles per hour". https://www.dsmstainlessproducts.co.uk/iss.html.

- ↑ "About Kibo". JAXA. 25 September 2008. Archived from the original on 10 March 2009. https://web.archive.org/web/20090310171550/http://kibo.jaxa.jp/en/about/. Retrieved 2009-03-06.

- ↑ "Kibo Japanese Experiment Module". NASA. 23 November 2007. Archived from the original on 23 October 2008. https://web.archive.org/web/20081023071601/http://www.nasa.gov/mission_pages/station/structure/elements/jem.html. Retrieved 2008-11-22.

- ↑ Zak, Anatoly. "Docking Compartment-1 and 2". RussianSpaceWeb.com. Archived from the original on 10 February 2009. https://web.archive.org/web/20090210130224/http://www.russianspaceweb.com/iss_dc.html. Retrieved 26 March 2009.

- ↑ Bergin, Chris (9 November 2009). "Russian module launches via Soyuz for Thursday ISS docking". NASASpaceflight.com. Archived from the original on 13 November 2009. https://web.archive.org/web/20091113190354/http://www.nasaspaceflight.com/2009/11/live-russian-module-launch-towards-iss-on-soyuz/. Retrieved 10 November 2009.

- ↑ "NASA Extends Contract With Russia's Federal Space Agency" (Press release). NASA. 9 April 2007. Archived from the original on 23 June 2007. Retrieved 2007-06-15.

- ↑ "NASA to Test Bigelow Expandable Module on Space Station". NASA. 16 January 2013. http://www.nasa.gov/mission_pages/station/news/beam_feature.html. Retrieved 16 January 2013.

- ↑ NASA.gov New Expandable Addition on Space Station to Gather Critical Data for Future Space Habitat Systems 2015

- ↑ "Thales Alenia Space Joins NanoRacks on Commercial ISS Airlock Module". 5 February 2018. http://nanoracks.com/nanoracks-adds-thales-alenia-space-to-airlock/.

- ↑ "FGB-based Multipurpose Lab Module (MLM)". Khrunichev State Research and Production Space Centre. Archived from the original on 27 September 2007. https://web.archive.org/web/20070927002737/http://www.khrunichev.ru/khrunichev_eng/live/full_mks.asp?id=13190. Retrieved 2008-10-31.

- ↑ NASA.gov

- ↑ NASA.gov

- ↑ mediaarchive.ksc.nasa.gov/detail.cfm?mediaid=44772

- ↑ mediaarchive.ksc.nasa.gov/detail.cfm?mediaid=44912

- ↑ NASA.gov

- ↑ mediaarchive.ksc.nasa.gov/detail.cfm?mediaid=51708

- ↑ NASA.gov

External links

ISS space agency websites

Canadian Space Agency

Canadian Space Agency European Space Agency

European Space Agency Centre national d'études spatiales (National Centre for Space Studies)

Centre national d'études spatiales (National Centre for Space Studies) German Aerospace Center

German Aerospace Center Italian Space Agency

Italian Space Agency Japan Aerospace Exploration Agency

Japan Aerospace Exploration Agency Russian Federal Space Agency

Russian Federal Space Agency National Aeronautics and Space Administration

National Aeronautics and Space Administration

Manufacturer websites

S.P. Korolev Rocket and Space Corporation Energia

S.P. Korolev Rocket and Space Corporation Energia Boeing - International Space Station

Boeing - International Space Station Lockheed Martin Space Systems

Lockheed Martin Space Systems Thales Alenia Group

Thales Alenia Group Thales Aerospace UK

Thales Aerospace UK BSM group (stainless steel supplier)

BSM group (stainless steel supplier) MDA Space Missions

MDA Space Missions Institute of Space and Astronautical Science

Institute of Space and Astronautical Science Brazilian Space Agency

Brazilian Space Agency Bigelow Aerospace

Bigelow Aerospace Airbus space industries

Airbus space industries

|

KSF

KSF