Solar simulator

Topic: Astronomy

From HandWiki - Reading time: 15 min

From HandWiki - Reading time: 15 min

A solar simulator (also artificial sun or sunlight simulator) is a device that provides illumination approximating natural sunlight. The purpose of the solar simulator is to provide a controllable indoor test facility under laboratory conditions. It can be used for the testing of any processes or materials that are photosensitive, including solar cells,[1] sun screen,[2] cosmetics,[3] plastics, aerospace materials,[4] skin cancer,[5] bioluminescence,[6] photosynthesis,[7] water treatment,[8] crude-oil degradation,[9] and free radical formation.[10] Solar simulators are used in a wide range of research areas including photobiology,[11] photo-oxidation,[12] photodegradation,[13] photovoltaics,[14] and photocatalysis.[15]

Classification

The standards specifying performance requirements of solar simulators used in photovoltaic testing are IEC 60904-9,[16] ASTM E927-19,[17] and JIS C 8912.[18] These standards specify the following dimensions of control for light from a solar simulator:

- spectral content (quantified as spectral match)

- spatial uniformity

- temporal stability

- Spectral Coverage (SPC) (IEC 60904-9:2020 only)

- Spectral Deviation (SPD) (IEC 60904-9:2020 only)

A solar simulator is specified according to its performance in the first three of the above dimensions, each in one of three classes: A, B, or C. (A fourth classification, A+, was introduced by the 2020 edition of IEC 60904-9 and only applies for solar simulators evaluated in the spectral range of 300 nm to 1200 nm.[16]) For ASTM E927-19, if a solar simulator falls outside the A, B, C criteria, it is considered Class U (unclassified).[17] Although these standards were originally defined specifically for photovoltaic testing, the metrics they introduced have become a common way of specifying solar simulators more broadly in other applications and industries.[19][20][21]

The ASTM E927-19 specifications required for each class and dimension are defined in Table 1 below. A solar simulator meeting class A specifications in all three dimensions is referred to as a Class AAA solar simulator (referring to the first three dimensions listed above).[17]

| Classification | Spectral Match (all intervals) | Spatial Non-uniformity of irradiance | Temporal Instability of irradiance | Applicable Standards |

|---|---|---|---|---|

| Class A+ | 0.875–1.125 | 1% | 1% | IEC 60904-9:2020, from 300 nm–1200 nm |

| Class A | 0.75–1.25 | 2% | 2% | IEC 60904-9, ASTM E927, JIS C 8912 |

| Class B | 0.6–1.4 | 5% | 5% | IEC 60904-9, ASTM E927, JIS C 8912 |

| Class C | 0.4–2.0 | 10% | 10% | IEC 60904-9, ASTM E927, JIS C 8912 |

| Class U (unclassified) | > 2.0 | > 10% | > 10% | ASTM E927 |

The ASTM E927-19 standard specifies that whenever this triple-letter format is used to describe a solar simulator, it needs to be made clear which classification applies to each solar simulator metric[17] (e.g. a Class ABA solar simulator needs to make clear which parameter(s) are Class A vs. B).

The IEC 60904-9 standard specifies that the three letters must be in order of spectral match, non-uniformity, and temporal instability.[16]

Spectral match

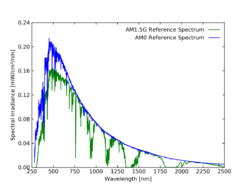

A solar simulator’s spectral match is computed by comparing its output spectrum to the integrated irradiance in several wavelength intervals. The reference percentage of total irradiance is shown below in Table 2 for the standard terrestrial spectra of AM1.5G and AM1.5D, and the extraterrestrial spectrum, AM0. Below is a plot of these two spectra.

A solar simulator’s spectral match ratio, (i.e. ratio of spectral match), is its percentage output irradiance divided by that of the reference spectrum in that wavelength interval. For example, if a solar simulator emits 17.8 percent of its total irradiance in the 400 nm–500 nm range, it would have a in that wavelength interval of 0.98. If a solar simulator achieves a spectral match ratio between 0.75 and 1.25 for all wavelength intervals, it is considered to have class A spectral match.

| Wavelength Interval [nm] | AM1.5D[22] | AM1.5G[22] | AM0[23] |

|---|---|---|---|

| 300–400 | no spec | no spec | 4.67% |

| 400–500 | 16.75% | 18.21% | 16.80% |

| 500–600 | 19.49% | 19.73% | 16.68% |

| 600–700 | 18.36% | 18.20% | 14.28% |

| 700–800 | 15.08% | 14.79% | 11.31% |

| 800–900 | 12.82% | 12.39% | 8.98% |

| 900–1100 | 16.69% | 15.89% | 13.50% |

| 1100–1400 | no spec | no spec | 12.56% |

These wavelength intervals were primarily intended for the solar simulator application of testing silicon photovoltaics, hence the spectral range over which the intervals were defined was limited mainly to the originally-developed absorption region of crystalline silicon (400 nm–1100 nm).

The solar simulator standards have some requirements for where the illumination spectrum must be measured. For example, the IEC 60904-9 standard requires that the spectrum be measured at four different locations in a pattern given below.[16]

Recent material science developments have expanded the spectral responsivity range of c-Si, multi-c-Si and CIGS solar cells to 300 nm–1200 nm.[16] Therefore, in 2020, the IEC 60904-9 standard introduced a new table of wavelength intervals (given in Table 3 below) aimed to match solar simulator output to the present needs of a wide variety of photovoltaic devices.[16]

| Wavelength Interval [nm] | Percentage of Total Irradiance [%] |

|---|---|

| 300–470 | 16.61 |

| 470–561 | 16.74 |

| 561–657 | 16.67 |

| 657–772 | 16.63 |

| 772–919 | 16.66 |

| 919–1200 | 16.69 |

While the above definition of spectral range is adequate for addressing the testing needs of many photovoltaic technologies, including thin film solar cells constructed from CdTe or CIGS, it is not sufficient for testing multi-junction solar cells using high-efficiency III-V semiconductors that have wider absorption bandwidths from 300–1800 nm.

For accurate spectral data outside the above-mentioned ranges, the data tables in ASTM G173 (for AM1.5G and AM1.5D)[22] and ASTM E490 (for AM0)[23] can be used as reference, but the specifications of solar simulators do not yet apply to anything outside 300 nm to 1200 nm for AM1.5G, and 300 nm to 1400 nm for AM0. Many solar simulator manufacturers produce light outside these regions, but the classification of light in these external regions is not yet standardized.

Spatial non-uniformity

A solar simulator’s spatial non-uniformity is computed via the following equation, with the result being a percentage:[17]

Here, is the array of normalized short-circuit current values detected by a solar cell or array of solar cells. The three solar simulator standards have slightly different requirements for how the array of measurements is gathered for computing spatial non-uniformity. ASTM E927-19 specifies that the illumination field must be measured at a minimum of 64 positions. The area of each test position, , is the illumination test area divided by the number of positions. The area of the detector used must be between 0.5 and 1.0 of .[17]

Temporal instability

A solar simulator’s temporal instability of irradiance is computed via the following equation, with the result being a percentage:[17]

Here, is the array of measurements gathered over the period of data acquisition. The solar simulator standards do not specify the required time interval or sampling frequency in absolute terms.

Spectral coverage

The 2020 update to the IEC 60904-9 standard introduced the spectral coverage (SPC) metric, an additional way of qualifying solar simulators.[16] The value of a solar simulator’s spectral coverage does not currently impact its classification, but is requested to be reported under IEC 60904-9:2020. SPC is calculated as follows, and refers to the percentage of a solar simulator’s emission that is at least 10 percent of the reference irradiance at a given wavelength:

Spectral deviation

The 2020 update to the IEC 60904-9 standard introduced the spectral deviation (SPD) metric, an additional way of qualifying solar simulators.[16] The value of a solar simulator’s spectral deviation does not currently impact its classification, but is requested to be reported under IEC 60904-9:2020.

SPD is calculated as follows, and refers to the total percentage deviation between a solar simulator’s emitted spectrum and a reference spectrum:

Types of solar simulators

Solar simulators can be divided into two categories according to their emission duration: continuous (or steady-state) and flashed (or pulsed). Solar simulators are also sometimes categorized according to the number of lamps used to generate the spectrum: single-lamp or multi-lamp.[24]

Continuous simulators

The first type is a familiar form of light source in which illumination is continuous in time, also known as steady-state. The specifications discussed in the previous sections most directly relate to this type of solar simulator. This category is most often used for low intensity testing, from less than 1 sun up to several suns. The total integrated irradiance for the AM1.5G spectrum is 1000.4 (280 nm to 4000 nm bandwidth)[22] which is often referred to as ‘1 sun’. Continuous light (or Continuous-Wave, CW) solar simulators may have several different lamp types combined—such as an arc source and one or more halogen lamps—to extend the spectrum far into the infrared. [25]

Flashed solar simulators

The second type of solar simulator, also known as a pulsed simulator, is qualitatively similar to flash photography and uses flash tubes. With typical durations of several milliseconds, very high intensities of up to several thousand suns are possible. This type of equipment is often used to prevent unnecessary heat build-up in the device under test. However, due to the rapid heating and cooling of the lamp, the intensity and light spectrum are inherently transient, making repeated reliable testing more technically challenging. Solid-state lamp technology such as LEDs mitigate some of these heating and cooling concerns in flash solar simulators.[26] The solar simulator standards provide guidance for steady-state compared to flashed solar simulators. For example, ASTM E927 section 7.1.6.3 provides guidance on temporal instability measurements for flashed solar simulators.[17]

Solar simulator construction

A solar simulator consists of three main parts:[1]

- Light sources (lamps) and power sources

- Optics and optical filters, to alter the beam and obtain desired properties

- Control elements for operation

Types of lamps

Several types of lamps have been used as the light sources within solar simulators. The lamp type is arguably the most important determining factor of a solar simulator’s performance limits with respect to intensity, spectral range, illumination pattern, collimation and temporal stability.[1]

Argon arc lamps

Argon arc lamps were used in early solar simulation studies (1972) and have a high color heat emission of 6500 K, well-matched to the sun’s blackbody temperature, with a relatively broad spectral emission from 275 nm to 1525 nm.[1] High-pressure argon gas cycles between an anode and a cathode, with a water vortex flowing along the inside quartz tube wall to cool the arc edge.[14] Argon arc lamps carry the disadvantages of short lifetimes and poor reliability.[1][28]

Carbon arc lamps

Carbon arc lamps have an emission similar to AM0 and are therefore used for solar simulators designed to produce extrasolar spectra.[1] (They were used for NASA’s first space simulators.[30]) Carbon arc lamps benefit from higher-intensity UV emission. However, they have the disadvantage of being generally weaker in intensity than similar xenon arc lamps.[1] In addition, they have a short lifetime, are unstable during operation and emit high-intensity blue light mismatched to the solar spectrum.[1]

Light-emitting diodes

Since approximately the year 2000, Light-emitting diodes (LEDs) have become commonly used in PV solar simulators.[24] LEDs emit light when electron-hole pairs recombine.[31][circular reference] They are low-cost and compact with low power consumption.[1] They typically have narrow bandwidths of the order of 10 nm–100 nm, so multiple LEDs must be combined in a solar simulator.[32] As such, the spectral match of an LED solar simulator is largely determined by the number and types of LEDs used in its design. LEDs can be accurately controlled to time windows less than a millisecond for steady or flashed solar simulator applications.[1] Additionally, LEDs have a relatively long life cycle compared to all other solar simulator lamp types, and are very efficient in energy conversion.[1] Ongoing research and development on LEDs is continually driving down their cost[1] and expanding their spectral coverage,[32] allowing them to be increasingly employed in wider-spectrum solar simulators. LED solar simulators are unique in that their spectra can be tuned electrically (by increasing or decreasing the intensity of various LEDs) without the need for optical filters.[33] Compared to xenon arc lamps, LEDs have demonstrated equivalent results in IV testing of photovoltaic modules with better stability, flexibility and spectral match.[34] Because LED emission is somewhat sensitive to junction temperature, LEDs have the disadvantage of requiring adequate thermal management.[35][33][36]

-

The simulated spectral output of an LED solar simulator, showing relatively lower spectral match because of the LEDs used[33]

-

The simulated spectral output of an LED solar simulator, showing relatively higher spectral match because of the LEDs used[37]

Metal halide arc lamps

Metal Halide arc lamps were primarily developed for use in film and television lighting, where a high temporal stability and daylight colour match are required. However, for these same properties, metal halide arc lamps are also used in solar simulation. These lamps produce light through a high-intensity discharge (HID) by passing an electric arc through vapourized high-pressure mercury and metal halide compounds.[14] Their disadvantages include high power consumption,[1] high electronic driver costs,[1] and short life cycles.[1] However, they have the benefit of relatively low costs,[14] and because of this low cost, many large-area solar simulators have been built with this technology.[39][40]

Quartz-tungsten halogen lamps

Quartz-tungsten halogen lamps (QTH lamps) offer spectra which very closely match black body radiation, although typically with a lower color temperature than the sun.They are a type of incandescent lamp where a halogen such as bromine or iodine surrounds a heated tungsten filament.[14] Their disadvantage is that they have a maximum color temperature of 3400 K, meaning they produce less UV and more IR emission than sunlight.[14] They are high-intensity.[1] and low-cost,[1] and are widely used in less spectrum-sensitive applications such as concentrated solar collector testing.[14]

Supercontinuum laser

A super continuum laser is a source of high-power, broadband light that can range from the visible range to the IR.[1] Lasers are high-intensity and easy to focus, but have the disadvantage of only illuminating very small areas.[1] Their high intensities, however, allow for testing of photovoltaic modules in solar concentrator applications.

Xenon arc lamps

Xenon arc lamps are the most common type of lamp both for continuous and flashed solar simulators. They are a type of high-intensity discharge (HID) lamp where light is produced from an electric arc through ionized, high-pressure xenon gas.[14] These lamps offer high intensities and an unfiltered spectrum which matches reasonably well to sunlight. Furthermore, these lamps exhibit no significant spectral balance shift due to differences in power, reducing the need for power source stability.[1] Because they emit high intensities from a single bulb, a collimated high-intensity beam can be produced from a xenon arc lamp.[14] However, the xenon arc lamp spectrum is characterized by many undesirable sharp atomic transitional peaks, as well as generally stronger emission in the infrared,[14] making the spectrum less desirable for some spectrally sensitive applications. These emission peaks are typically filtered using glass filters.[1] Xenon lamps carry many disadvantages, including a high power consumption,[1] a need for constant maintenance,[1] a short life cycle,[1] a high cost,[14] an output sensitivity to power supply instabilities,[14] a risk of bulb explosion due to their operation via high-pressure gas,[14] and an ozone respiratory hazard due to ozone production from UV radiation.[14]

-

Example schematic of a Xenon Arc Lamp Solar Simulator[34]

-

The spectral output of a xenon arc lamp, after passing through an optical filter to achieve better spectral match to AM1.5G[34]

References

- ↑ 1.00 1.01 1.02 1.03 1.04 1.05 1.06 1.07 1.08 1.09 1.10 1.11 1.12 1.13 1.14 1.15 1.16 1.17 1.18 1.19 1.20 1.21 1.22 1.23 Esen, Vedat; Sağlam, Şafak; Oral, Bülent (September 2017). "Light sources of solar simulators for photovoltaic devices: A review". Renewable and Sustainable Energy Reviews 77: 1240–1250. doi:10.1016/j.rser.2017.03.062.

- ↑ Sayre, Robert M.; Agin, Patricia Poh; LeVee, Gordon J.; Marlowe, Edward (March 1979). "A Comparison of in Vivo and in Vitro Testing of Sunscreening Formulas". Photochemistry and Photobiology 29 (3): 559–566. doi:10.1111/j.1751-1097.1979.tb07090.x. PMID 441130.

- ↑ Uhlmann, B.; Mann, T.; Gers-Barlag, H.; Alert, D.; Sauermann, G. (February 1996). "Consequences for sun protection factors when solar simulator spectra deviate from the spectrum of the sun". International Journal of Cosmetic Science 18 (1): 13–24. doi:10.1111/j.1467-2494.1996.tb00132.x. PMID 19245475.

- ↑ Gunther, Matthew (1 December 2020). "Design and Validation of an LED-Based Solar Simulator for Solar Cell and Thermal Testing". Master's Theses. https://digitalcommons.calpoly.edu/theses/2302/.

- ↑ Mabruk, Mohamed J. E. M. F.; Toh, Lim K.; Murphy, Miriam; Leader, Mary; Kay, Elaine; Murphy, Gillian M. (July 2009). "Investigation of the effect of UV irradiation on DNA damage: comparison between skin cancer patients and normal volunteers". Journal of Cutaneous Pathology 36 (7): 760–765. doi:10.1111/j.1600-0560.2008.01164.x. PMID 19519607.

- ↑ Giménez, Bárbara N.; Conte, Leandro O.; Alfano, Orlando M.; Schenone, Agustina V. (June 2020). "Paracetamol removal by photo-Fenton processes at near-neutral pH using a solar simulator: Optimization by D-optimal experimental design and toxicity evaluation". Journal of Photochemistry and Photobiology A: Chemistry 397: 112584. doi:10.1016/j.jphotochem.2020.112584.

- ↑ Herrmann, H.; Häder, D.-P.; Köfferlein, M.; Seidlitz, H.K.; Ghetti, F. (June 1996). "Effects of UV radiation on photosynthesis of phytoplankton exposed to solar simulator light". Journal of Photochemistry and Photobiology B: Biology 34 (1): 21–28. doi:10.1016/1011-1344(95)07245-4.

- ↑ Philippe, Karine K.; Timmers, Ruud; van Grieken, Rafael; Marugan, Javier (23 March 2016). "Photocatalytic Disinfection and Removal of Emerging Pollutants from Effluents of Biological Wastewater Treatments, Using a Newly Developed Large-Scale Solar Simulator". Industrial & Engineering Chemistry Research 55 (11): 2952–2958. doi:10.1021/acs.iecr.5b04927.

- ↑ D'Auria, M.; Racioppi, R.; Velluzzi, V. (1 April 2008). "Photodegradation of Crude Oil: Liquid Injection and Headspace Solid-Phase Microextraction for Crude Oil Analysis by Gas Chromatography with Mass Spectrometer Detector". Journal of Chromatographic Science 46 (4): 339–344. doi:10.1093/chromsci/46.4.339. PMID 18402726.

- ↑ Faust, Bruce C.; Allen, John M. (1 June 1993). "Aqueous-phase photochemical formation of hydroxyl radical in authentic cloudwaters and fogwaters". Environmental Science & Technology 27 (6): 1221–1224. doi:10.1021/es00043a024. Bibcode: 1993EnST...27.1221F.

- ↑ Sayre, Robert M.; Dowdy, John C. (January 2010). "Examination of Solar Simulators Used for the Determination of Sunscreen UVA Efficacy". Photochemistry and Photobiology 86 (1): 162–167. doi:10.1111/j.1751-1097.2009.00633.x. PMID 19906095.

- ↑ Thiele, Jens J.; Traber, Maret G.; Packer, Lester (May 1998). "Depletion of Human Stratum Corneum Vitamin E: An Early and Sensitive In Vivo Marker of UV Induced Photo-Oxidation". Journal of Investigative Dermatology 110 (5): 756–761. doi:10.1046/j.1523-1747.1998.00169.x. PMID 9579541.

- ↑ Kohtani, Shigeru; Koshiko, Masaya; Kudo, Akihiko; Tokumura, Kunihiro; Ishigaki, Yasuhito; Toriba, Akira; Hayakawa, Kazuichi; Nakagaki, Ryoichi (November 2003). "Photodegradation of 4-alkylphenols using BiVO4 photocatalyst under irradiation with visible light from a solar simulator". Applied Catalysis B: Environmental 46 (3): 573–586. doi:10.1016/S0926-3373(03)00320-5.

- ↑ 14.00 14.01 14.02 14.03 14.04 14.05 14.06 14.07 14.08 14.09 14.10 14.11 14.12 14.13 Tawfik, M.; Tonnellier, X.; Sansom, C. (July 2018). "Light source selection for a solar simulator for thermal applications: A review". Renewable and Sustainable Energy Reviews 90: 802–813. doi:10.1016/j.rser.2018.03.059.

- ↑ Brandi, Rodolfo J.; Rintoul, Gerardo; Alfano, Orlando M.; Cassano, Alberto E. (15 November 2002). "Photocatalytic reactors: Reaction kinetics in a flat plate solar simulator" (in en). Catalysis Today 76 (2): 161–175. doi:10.1016/S0920-5861(02)00216-X. ISSN 0920-5861. https://www.sciencedirect.com/science/article/pii/S092058610200216X.

- ↑ 16.0 16.1 16.2 16.3 16.4 16.5 16.6 16.7 "IEC 60904-9:2020 | IEC Webstore | water management, smart city, rural electrification, solar power, solar panel, photovoltaic, PV, LVDC". https://webstore.iec.ch/publication/28973.

- ↑ 17.0 17.1 17.2 17.3 17.4 17.5 17.6 17.7 "ASTM E927 - 19 Standard Classification for Solar Simulators for Electrical Performance Testing of Photovoltaic Devices". https://www.astm.org/Standards/E927.htm.

- ↑ "JIS C 8912:1998". https://www.techstreet.com/standards/jis-c-8912-1998?product_id=1230810.

- ↑ Fu, Zhiwei; Vogel, Anastasia; Zwijnenburg, Martijn A.; Cooper, Andrew I.; Sprick, Reiner Sebastian (23 February 2021). "Photocatalytic syngas production using conjugated organic polymers". Journal of Materials Chemistry A 9 (7): 4291–4296. doi:10.1039/D0TA09613J.

- ↑ Ashraf, Muhammad; Khan, Ibrahim; Baig, Nadeem; Hendi, Abdulmajeed H.; Ehsan, Muhammad Fahad; Sarfraz, Nafeesa (July 2021). "A Bifunctional 2D Interlayered β‐Cu 2 V 2 O 7 /Zn 2 V 2 O 6 (CZVO) Heterojunction for Solar‐Driven Nonsacrificial Dye Degradation and Water Oxidation". Energy Technology 9 (7): 2100034. doi:10.1002/ente.202100034.

- ↑ Kim, E. J.; Kim, M. J.; Im, N. R.; Park, S. N. (1 August 2015). "Photolysis of the organic UV filter, avobenzone, combined with octyl methoxycinnamate by nano-TiO2 composites" (in en). Journal of Photochemistry and Photobiology B: Biology 149: 196–203. doi:10.1016/j.jphotobiol.2015.05.011. ISSN 1011-1344. PMID 26093231. https://doi.org/10.1016/j.jphotobiol.2015.05.011.

- ↑ 22.0 22.1 22.2 22.3 "ASTM G173 - 03(2020) Standard Tables for Reference Solar Spectral Irradiances: Direct Normal and Hemispherical on 37° Tilted Surface". https://www.astm.org/Standards/G173.htm.

- ↑ 23.0 23.1 "ASTM E490 - 00a(2019) Standard Solar Constant and Zero Air Mass Solar Spectral Irradiance Tables". https://www.astm.org/Standards/E490.htm.

- ↑ 24.0 24.1 Gallo, Alessandro; Marzo, Aitor; Fuentealba, Edward; Alonso, Elisa (1 September 2017). "High flux solar simulators for concentrated solar thermal research: A review" (in en). Renewable and Sustainable Energy Reviews 77: 1385–1402. doi:10.1016/j.rser.2017.01.056. ISSN 1364-0321. https://doi.org/10.1016/j.rser.2017.01.056.

- ↑ Tables for Reference Solar Spectral Irradiances: Direct Normal and Hemispherical on 37 Tilted Surface. 2008. doi:10.1520/G0173-03R08.

- ↑ Bliss, M.; Betts, T. R.; Gottschalg, R. (10 September 2008). Dhere, Neelkanth G. ed. "Advantages in using LEDs as the main light source in solar simulators for measuring PV device characteristics". Reliability of Photovoltaic Cells, Modules, Components, and Systems (SPIE) 7048: 45–55. doi:10.1117/12.795428. Bibcode: 2008SPIE.7048E..07B. https://doi.org/10.1117/12.795428.

- ↑ Hirsch, D.; Zedtwitz, and , P. v.; Osinga, T.; Kinamore, J.; Steinfeld, A. (27 January 2003). "A New 75 kW High-Flux Solar Simulator for High-Temperature Thermal and Thermochemical Research". Journal of Solar Energy Engineering 125 (1): 117–120. doi:10.1115/1.1528922. ISSN 0199-6231. https://doi.org/10.1115/1.1528922.

- ↑ Hirsch, D.; Zedtwitz, and , P. v.; Osinga, T.; Kinamore, J.; Steinfeld, A. (27 January 2003). "A New 75 kW High-Flux Solar Simulator for High-Temperature Thermal and Thermochemical Research". Journal of Solar Energy Engineering 125 (1): 117–120. doi:10.1115/1.1528922. ISSN 0199-6231. https://doi.org/10.1115/1.1528922.

- ↑ Olson, Robert A.; Parker, Jack H. (1 April 1991). "Carbon arc solar simulator" (in EN). Applied Optics 30 (10): 1290–1293. doi:10.1364/AO.30.001290. ISSN 2155-3165. PMID 20582141. Bibcode: 1991ApOpt..30.1290O. https://doi.org/10.1364/ao.30.001290.

- ↑ Goggia, R. J.; Maclay, J. E. (4 June 1962). "Use of Carbon Arc Lamps as Solar Simulation in Environmental Testing" (in en). Jet Propulsion Laboratory, California Institute of Technology. https://ntrs.nasa.gov/citations/19620003906.

- ↑ "Light-emitting diode" (in en). 14 November 2021. https://en.wikipedia.org/wiki/Light-emitting_diode.

- ↑ 32.0 32.1 Kolberg, D.; Schubert, F.; Lontke, N.; Zwigart, A.; Spinner, D. M. (1 January 2011). "Development of tunable close match LED solar simulator with extended spectral range to UV and IR" (in en). Energy Procedia 8: 100–105. doi:10.1016/j.egypro.2011.06.109. ISSN 1876-6102.

- ↑ 33.0 33.1 33.2 Linden, Kurt J.; Neal, William R.; Serreze, Harvey B. (27 February 2014). Streubel, Klaus P; Jeon, Heonsu; Tu, Li-Wei et al.. eds. "Adjustable spectrum LED solar simulator". Light-Emitting Diodes: Materials, Devices, and Applications for Solid State Lighting XVIII (SPIE) 9003: 109–117. doi:10.1117/12.2035649. Bibcode: 2014SPIE.9003E..17L. https://doi.org/10.1117/12.2035649.

- ↑ 34.0 34.1 34.2 Leary, Gregory; Switzer, Gregg; Kuntz, Gene; Kaiser, Todd (June 2016). "Comparison of xenon lamp-based and led-based solar simulators". 2016 IEEE 43rd Photovoltaic Specialists Conference (PVSC). pp. 3062–3067. doi:10.1109/PVSC.2016.7750227. ISBN 978-1-5090-2724-8. https://doi.org/10.1109/PVSC.2016.7750227.

- ↑ Wang, Wujun; Bjorn, Laumert (2014). "Simulate a 'Sun' for Solar Research: A Literature Review of Solar Simulator Technology". KTH Royal Institute of Technology: Heat and Power Technology: 37. http://urn.kb.se/resolve?urn=urn:nbn:se:kth:diva-154262. Retrieved 16 November 2021.

- ↑ Plyta, Foteini (1 January 2015). Optical design of a fully LED-based solar simulator (thesis). Loughborough University. hdl:2134/19601.

- ↑ Plyta, Foteini (1 January 2015). Optical design of a fully LED-based solar simulator (thesis). Loughborough University. hdl:2134/19601.

- ↑ Roba, Jeffrey P.; Siegel, Nathan P. (15 November 2017). "The design of metal halide-based high flux solar simulators: Optical model development and empirical validation" (in en). Solar Energy 157: 818–826. doi:10.1016/j.solener.2017.08.072. ISSN 0038-092X. Bibcode: 2017SoEn..157..818R.

- ↑ Meng, Qinglong; Wang, Yuan; Zhang, Linhua (1 September 2011). "Irradiance characteristics and optimization design of a large-scale solar simulator" (in en). Solar Energy 85 (9): 1758–1767. doi:10.1016/j.solener.2011.04.014. ISSN 0038-092X. Bibcode: 2011SoEn...85.1758M. https://doi.org/10.1016/j.solener.2011.04.014.

- ↑ Bigaila, Edvinas; Rounis, Efstratios; Luk, Peter; Athienitis, Andreas (1 November 2015). "A Study of a BIPV/T Collector Prototype for Building Façade Applications" (in en). Energy Procedia 78: 1931–1936. doi:10.1016/j.egypro.2015.11.374. ISSN 1876-6102.

- ↑ Elvidge, Christopher D.; Keith, David M.; Tuttle, Benjamin T.; Baugh, Kimberly E. (April 2010). "Spectral Identification of Lighting Type and Character" (in en). Sensors 10 (4): 3961–3988. doi:10.3390/s100403961. PMID 22319336. Bibcode: 2010Senso..10.3961E.

- ↑ Dennis, Tasshi; Schlager, John B.; Bertness, Kris A. (July 2014). "A Novel Solar Simulator Based on a Supercontinuum Laser for Solar Cell Device and Materials Characterization". IEEE Journal of Photovoltaics 4 (4): 1119–1127. doi:10.1109/JPHOTOV.2014.2321659. ISSN 2156-3403.

|

KSF

KSF![The simulated spectral output of an LED solar simulator, showing relatively lower spectral match because of the LEDs used[33]](https://handwiki.org/wiki/images/thumb/d/df/Lower_Spectral_Match_LED_Solar_Simulator.png/400px-Lower_Spectral_Match_LED_Solar_Simulator.png)

![The simulated spectral output of an LED solar simulator, showing relatively higher spectral match because of the LEDs used[37]](https://handwiki.org/wiki/images/thumb/a/a4/Higher_Spectral_Match_LED_Solar_Simulator.png/400px-Higher_Spectral_Match_LED_Solar_Simulator.png)

![Example schematic of a Xenon Arc Lamp Solar Simulator[34]](https://handwiki.org/wiki/images/thumb/1/16/Xenon-solarsim.png/535px-Xenon-solarsim.png)

![The spectral output of a xenon arc lamp, after passing through an optical filter to achieve better spectral match to AM1.5G[34]](https://handwiki.org/wiki/images/thumb/8/8b/Filtered_Xenon_Arc_Lamp_Laser_Solar_Simulator.png/400px-Filtered_Xenon_Arc_Lamp_Laser_Solar_Simulator.png)