Space Launch System

Topic: Astronomy

From HandWiki - Reading time: 50 min

From HandWiki - Reading time: 50 min

SLS Block 1 with the Orion spacecraft launching from Pad 39B | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Function | Super heavy-lift launch vehicle | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Manufacturer | Aerojet Rocketdyne Northrop Grumman Boeing United Launch Alliance | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Country of origin | United States | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Project cost | US$23.8 billion nominal[1] | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Cost per launch | Over US$2 billion excluding development (estimate) [note 1][2][3]:23–24[4][1] | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Cost per year | US$2.555 billion for FY 2021[5] | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Size | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Height | Block 1 Crew: 322 ft (98 m) Block 2 Cargo: 365 ft (111 m) | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Diameter | 27.6 ft (8.4 m), Core stage [6] 16.7 ft (5.1 m), ICPS [7] | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Mass | 5,750,000 lb (2,610 t)[8] | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Stages | 2.5 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Thrust | 39,000,000 N (39 MN; 4,000 tf; 8,800,000 lbf) (Total first stage thrust.)[9] | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Capacity | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Payload to LEO [note 2] | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Payload to trans-lunar injection | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Associated rockets | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Comparable |

| ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Launch history | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Status | Active | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Launch sites | Kennedy Space Center, LC-39B | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Total launches | 1 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Successes | 1 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| First flight | 16 November 2022, 1:47:44 am EST (6:47:44 am UTC)[17] | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Notable payloads | Orion | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

The Space Launch System (SLS) is an American super heavy-lift expendable launch vehicle used by NASA. As the primary launch vehicle of the Artemis Moon landing program, SLS is designed to launch the crewed Orion spacecraft on a trans-lunar trajectory. The first SLS launch was the uncrewed Artemis 1, which took place on 16 November 2022.[25][17]

Development of SLS began in 2011, as a replacement for the retired Space Shuttle as well as the cancelled Ares I and Ares V launch vehicles.[26][27][28] As a Shuttle-derived vehicle, the SLS reuses hardware from the Shuttle program, including the solid rocket boosters and RS-25 first stage engines. A Congressionally mandated late 2016 launch was delayed by nearly 6 years.[29]

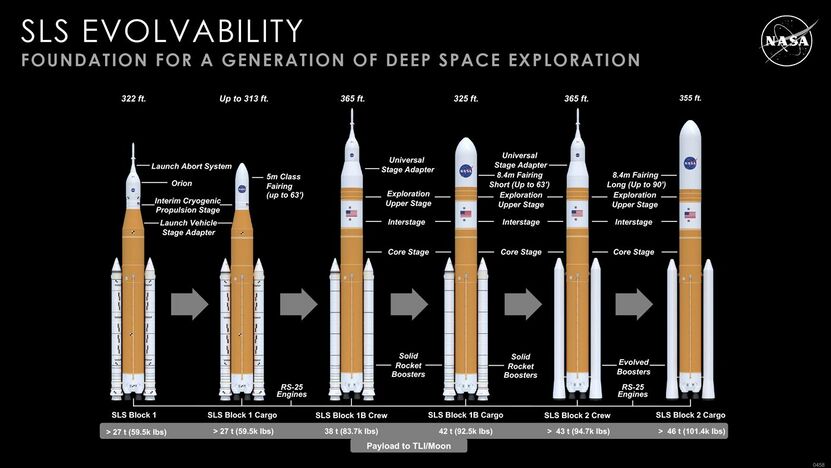

All Space Launch System flights are launched from Launch Complex 39B at the Kennedy Space Center in Florida. The first three SLS flights use the Block 1 configuration, comprising a core stage, extended Space Shuttle boosters developed for Ares I and the ICPS upper stage. An improved Block 1B configuration, with the Exploration Upper Stage, is planned to debut on the fourth flight; a further improved Block 2 configuration featuring new solid rocket boosters is planned to debut on the ninth flight.[30][31][32][33][11] After the launch of Artemis 4, NASA plans to transfer production and launch operations of SLS to Deep Space Transport LLC, a joint venture between Boeing and Northrop Grumman.[34]

Description

The SLS is a Space Shuttle-derived launch vehicle. The first stage of the rocket is powered by one central core stage and two outboard solid rocket boosters. All SLS Blocks share a common core stage design, while they differ in their upper stages and boosters.[35][36][37][38]

Core stage

Together with the solid rocket boosters, the core stage is responsible for propelling the upper stage and payload out of the atmosphere to near orbital velocity. It contains the liquid hydrogen and liquid oxygen tanks for the ascent phase, the forward and aft solid rocket booster attach points, avionics, and the Main Propulsion System (MPS), an assembly of the four RS-25 engines,[35] associated plumbing and hydraulic gimbal actuators, and equipment for autogenous pressurization of the vehicle's tanks. The core stage provides approximately 25% of the vehicle's thrust at liftoff, the rest coming from the solid rocket boosters.[39][40]

The stage measures 213 ft (65 m) long by 28 ft (8.4 m) in diameter and is visually similar to the Space Shuttle external tank.[27][41] It is made mostly of 2219 aluminium alloy,[42] and contains numerous improvements to manufacturing processes, including friction stir welding for the barrel sections, and integrated milling for the stringers.[43][44] The first four flights will each use and expend four of the remaining sixteen RS-25D engines previously flown on Space Shuttle missions.[45][46][47] Aerojet Rocketdyne refits these engines with modernized engine controllers, higher throttle limits, as well as insulation for the high temperatures the engine section will experience due to their position adjacent to the solid rocket boosters.[48] Later flights will switch to a RS-25 variant optimized for expended use, the RS-25E, which will lower per-engine costs by over 30%.[49][50] The thrust of each RS-25D engine has been increased from 492,000 lbf (2,188 kN), as on the Space Shuttle, to 513,000 lbf (2,281 kN) on the sixteen modernized engines. The RS-25E will further increase per-engine thrust to 522,000 lbf (2,321 kN).[51][52]

Solid Rocket Boosters

Blocks 1 and 1B of the SLS will use two five-segment solid rocket boosters. They use casing segments that were flown on Shuttle missions as parts of the four-segment Space Shuttle Solid Rocket Boosters. They possess an additional center segment, new avionics, and lighter insulation, but lack a parachute recovery system, as they will not be recovered after launch.[53] The propellants for the solid rocket boosters are aluminum powder, which is very reactive, and ammonium perchlorate, a powerful oxidizer. They are held together by a binder, polybutadiene acrylonitrile (PBAN). The mixture has the consistency of a rubber eraser and is packed into each segment.[54] The five-segment solid rocket boosters provide approximately 25% more total impulse than the Shuttle Solid Rocket Boosters.[55][56]

The stock of SLS Block 1 to 1B boosters is limited by the number of casings left over from the Shuttle program, which allows for eight flights of the SLS.[57] On 2 March 2019, the Booster Obsolescence and Life Extension program was announced, with the goal of developing new solid rocket boosters for SLS Block 2. These boosters will be built by Northrop Grumman Space Systems, and will be derived from the composite-casing solid rocket boosters then in development for the canceled OmegA launch vehicle, and are projected to increase Block 2's payload to 290,000 lb (130 t) to LEO and at least 101,000 lb (46 t) to trans-lunar injection.[58][59][60] (As of July 2021), the BOLE program is under development, with first firing expected in 2024.[58]

Upper stages

The Interim Cryogenic Propulsion Stage (ICPS) is the upper stage of SLS Block 1, and first flew on Artemis 1. It is planned to fly again on Artemis 2 and 3 with its last flight on SLS being for Artemis 3.[61] It is a stretched and human-rated Delta IV 16 ft (5 m) Delta Cryogenic Second Stage powered by a single RL10 engine. The Artemis 1 ICPS used the RL10B-2 variant, while the ICPS for Artemis 2 and Artemis 3 will use the RL10C-2 variant.[62][63][64] Block 1 is intended to be capable of lifting 209,000 lb (95 t) to low Earth orbit (LEO) in this configuration, including the weight of the ICPS as part of the payload.[11] At the time of SLS core stage separation, Artemis 1 was travelling on an initial 1,806 by 30 km (1,122 by 19 mi) transatmospheric orbital trajectory. This trajectory ensured safe disposal of the core stage.[65] ICPS then performed orbital insertion and a subsequent translunar injection burn to send Orion towards the Moon.[66] The ICPS will be human-rated for the crewed Artemis 2 and 3 flights.[61]

The Exploration Upper Stage (EUS) is planned to first fly on Artemis 4. The EUS will complete the SLS ascent phase and then re-ignite to send its payload to destinations beyond LEO.[67] It is expected to be used by Block 1B and Block 2. The EUS shares the core stage diameter of 8.4 meters, and will be powered by four RL10C-3 engines.[68] It will eventually be upgraded to use four improved RL10C-X engines.[69] (As of March 2022), Boeing is developing a new composite-based fuel tank for the EUS that would increase Block 1B's overall payload mass capacity to TLI by 40 percent.[70] The improved upper stage was originally named the Dual Use Upper Stage (DUUS, pronounced "duce"),[67] but was later renamed the Exploration Upper Stage (EUS).[71]

Block 1 interstage

The SLS Block 1 has a conical frustrum-shaped interstage called the Launch Vehicle Stage Adapter between the core stage and the ICPS. It consists of sixteen aluminum-lithium panels made of 2195 aluminium alloy. Teledyne Brown Engineering is its builder.[72] The first one cost $60 million, and the next two cost $85 million together.[73]

Block variants

| Flight # | Block | Core stage engines | Boosters | Upper stage | Liftoff Thrust | Payload mass to... | ||

|---|---|---|---|---|---|---|---|---|

| Low Earth orbit (LEO) | Trans-lunar injection (TLI) | Heliocentric orbit (HCO) | ||||||

| 1 | 1 | RS-25D[45] | 5-segment Shuttle-derived boosters | Interim Cryogenic Propulsion Stage (ICPS) with RL10B-2[64] | 8,800,000 lbf (39 MN)[15] | 209,000 lb (95 metric tons)[11] | >59,500 lb (27 metric tons)[74][15][16] | Not known |

| 2, 3 | Interim Cryogenic Propulsion Stage (ICPS) with RL10C-2[62] | |||||||

| 4 | 1B | Exploration Upper Stage (EUS) | 231,000 lb (105 metric tons)[12] | 92,500 lb (42 metric tons)[74][15][16] | ||||

| 5, 6, 7, 8 | RS-25E[50] | |||||||

| 9, ... | 2 | Booster Obsolescence and Life Extension (BOLE)[57] | 9,200,000 lbf (41 MN)[15] | 290,000 lb (130 metric tons)[14] | >101,400 lb (46 metric tons)[74][15][16] | 99,000 lb (45 metric tons)[11] | ||

Development

Funding

During the joint Senate-NASA presentation in September 2011, it was stated that the SLS program had a projected development cost of United States dollar 18 billion through 2017, with $10 billion for the SLS rocket, $6 billion for the Orion spacecraft, and $2 billion for upgrades to the launch pad and other facilities at Kennedy Space Center.[75][76] These costs and schedules were considered optimistic in an independent 2011 cost assessment report by Booz Allen Hamilton for NASA.[77] An internal 2011 NASA document estimated the cost of the program through 2025 to total at least $41 billion for four 209,000 lb (95 t) launches (1 uncrewed, 3 crewed),[78][79] with the 290,000 lb (130 t) version ready no earlier than 2030.[80] The Human Exploration Framework Team estimated unit costs for 'Block 0' at $1.6 billion and Block 1 at $1.86 billion in 2010.[81] However, since these estimates were made the Block 0 SLS vehicle was dropped in late 2011, and the design was not completed.[35]

In September 2012, an SLS deputy project manager stated that $500 million is a reasonable target average cost per flight for the SLS program.[82] In 2013, the Space Review estimated the cost per launch at $5 billion, depending on the rate of launches.[83][84] NASA announced in 2013 that the European Space Agency will build the Orion service module.[85] In August 2014, as the SLS program passed its Key Decision Point C review and was deemed ready to enter full development, costs from February 2014 until its planned launch in September 2018 were estimated at $7.021 billion.[86] Ground systems modifications and construction would require an additional $1.8 billion over the same time.[87]

In October 2018, NASA's Inspector General reported that the Boeing core stage contract had made up 40% of the $11.9 billion spent on the SLS as of August 2018. By 2021, development of the core stage was expected to have cost $8.9 billion, twice the initially planned amount.[88] In December 2018, NASA estimated that yearly budgets for the SLS will range from $2.1 to $2.3 billion between 2019 and 2023.[89]

In March 2019, the Trump administration released its fiscal year 2020 budget request for NASA, which notably proposed dropped funding for Block 1B and Block 2 variants of SLS. Congressional action ultimately included the funding in the passed budget.[90] One Gateway component that had been previously planned for the SLS Block 1B is expected to fly on the Falcon Heavy.[91][needs update]

On 1 May 2020, NASA awarded a contract extension to Aerojet Rocketdyne to manufacture 18 additional RS-25 engines with associated services for $1.79 billion, bringing the total RS-25 contract value to almost $3.5 billion.[92][50]

Budget

For fiscal years 2011 through 2022, the SLS program had expended funding totaling $23.8 billion in nominal dollars. This is equivalent to $27.5 billion in 2022 dollars using the NASA New Start Inflation Indices.[93]

| Fiscal year | Funding | Source | |

|---|---|---|---|

| Nominal (millions) |

In 2022[93] (millions) | ||

| 2011 | $1,536.1 | $1,985.7 | Actual[94][lower-alpha 1] |

| 2012 | $1,497.5 | $1,915.4 | Actual[96] |

| 2013 | $1,414.9 | $1,783.0 | Actual[97] |

| 2014 | $1,600.0 | $1,977.4 | Actual[98] |

| 2015 | $1,678.6 | $2,033.6 | Actual[99] |

| 2016 | $1,971.9 | $2,360.4 | Actual[100] |

| 2017 | $2,127.1 | $2,493.1 | Actual[101] |

| 2018 | $2,150.0 | $2,457.6 | Actual[102] |

| 2019 | $2,144.0 | $2,404.3 | Actual[103] |

| 2020 | $2,528.1 | $2,773.6 | Actual[104] |

| 2021 | $2,555.0 | $2,707.2 | 2021 Spend Plan[105] |

| 2022 | $2,600.0 | $2,600.0 | 2022 Spend Plan[106] |

| Total 2011–2022 | $23,803 | $27,485 | |

Included in the above SLS costs above are (1) the Interim Cryogenic Propulsion Stage (ICPS), a $412 million contract[107] and (2) the costs of developing the Exploration Upper Stage (below).

Excluded from the SLS cost above are the costs to assemble, integrate, prepare and launch the SLS and its payloads, funded separately in the NASA Exploration Ground Systems, currently at about $600 million per year,[108][109] and anticipated to stay there through at least the first four launches of SLS.[3] Also excluded are payloads that launch on the SLS, such as the Orion crew capsule. Also excluded are predecessor programs that contributed to the development of the SLS, such as the Ares V Cargo Launch Vehicle project, funded from 2008 to 2010 for a total of $70 million,[110] and the Ares I Crew Launch Vehicle, funded from 2006 to 2010 for a total of $4.8 billion[110][111] in development, including the 5-segment Solid Rocket Boosters used on the SLS.[112]

| Fiscal year | Funding for EUS development | |

|---|---|---|

| Nominal (millions) |

In 2022[93] (millions) | |

| 2016 | $85.0[113] | $101.7 |

| 2017 | $300.0[114][101] | $351.6 |

| 2018 | $300.0[115][102] | $342.9 |

| 2019 | $150.0[116][117] | $168.2 |

| 2020 | $300.0[104] | $329.1 |

| 2021 | $400.0[105][note 3] | $422.9 |

| 2022 | $636.7[106] | $636.7 |

| 2023 | $600.0[118] | $575.5 |

| Total: 2016–2023 | $2,772.0 | $2,928.7 |

Early plans

File:Space Launch System Booster Passes Major Ground Test.webm File:KSC-20210610-MH-FMX01-0001-Artemis I SLS Core Stage Lift Ops TIMELAPSE-3278141~orig-trimmed.webm

The SLS was created by an act of Congress in the NASA Authorization Act of 2010, Public Law 111–267, in which NASA was directed to create a system for launching payloads and crew into space that would replace the capabilities lost with the retirement of the Space Shuttle.[29] The act set out certain goals, such as being able to lift 70-100 tons into low earth orbit with evolvability to 130 tons, a target date of December 31, 2016 for the system to be fully operational, and a directive to use "to the extent practicable" existing components, hardware, and workforce from the Space Shuttle and from Ares I.[29]:12

On 14 September 2011, NASA announced their plan to meet these requirements: the design for the SLS, with the Orion spacecraft as payload.[119][120][121][122]

The SLS has considered several future development routes of potential launch configurations, with the planned evolution of the blocks of the rocket having been modified many times.[112] Many options, all of which just needed to meet the congressionally mandated payload minimums,[112] were considered, including a Block 0 variant with three main engines,[35] a variant with five main engines,[112] a Block 1A variant with upgraded boosters instead of the improved second stage,[35] and a Block 2 with five main engines plus the Earth Departure Stage, with up to three J-2X engines.[38]

In the initial announcement of the design of the SLS, NASA also announced an "Advanced Booster Competition", to select which boosters would be used on Block 2 of the SLS.[119][123][40][124] Several companies proposed boosters for this competition, all of which were indicated as viable:[125] Aerojet and Teledyne Brown proposed three booster engines each with dual combustion chambers,[126] Alliant Techsystems proposed a modified solid rocket booster with lighter casing, more energetic propellant, and four segments instead of five,[127] and Pratt & Whitney Rocketdyne and Dynetics proposed a liquid-fueled booster named Pyrios.[128] However, this competition was planned for a development plan in which Block 1A would be followed by Block 2A, with upgraded boosters. NASA canceled Block 1A and the planned competition in April 2014, in favor of simply remaining with the Ares I's five-segment solid rocket boosters, themselves modified from the Space Shuttle's solid rocket boosters, until at least the late 2020s.[112][129] The overly powerful advanced booster would have resulted in unsuitably high acceleration, and would need modifications to LC-39B, its flame trench, and Mobile Launcher.[130][112]

On 31 July 2013, the SLS passed Preliminary Design Review. The review included not only the rocket and boosters but also ground support and logistical arrangements.[131]

On 7 August 2014, the SLS Block 1 passed a milestone known as Key Decision Point C and entered full-scale development, with an estimated launch date of November 2018.[86][132]

EUS options

In 2013, NASA and Boeing analyzed the performance of several EUS engine options. The analysis was based on a second-stage usable propellant load of 105 metric tons, and compared stages with four RL10 engines, two MARC-60 engines, or one J-2X engine.[133][134] In 2014, NASA also considered using the European Vinci instead of the RL10, which offered the same specific impulse but with 64% greater thrust, which would allow for the same performance at a lower cost.[135]

In 2018, Blue Origin submitted a proposal to replace the Exploration Upper Stage with a cheaper alternative to be designed and fabricated by the company, but it was rejected by NASA in November 2019 on multiple grounds; these included lower performance compared to the existing EUS design, incompatibility of the proposal with the height of the door of the Vehicle Assembly Building being only 390 feet (120 m), and unacceptable acceleration of Orion components such as its solar panels due to the higher thrust of the engines being used for the fuel tank.[136][137]:7–8

SRB tests

From 2009 to 2011, three full-duration static fire tests of five-segment solid rocket boosters were conducted under the Constellation Program, including tests at low and high core temperatures, to validate performance at extreme temperatures.[138][139][140] The 5-segment solid rocket booster would be carried over to SLS.[112] Northrop Grumman Innovation Systems has completed full-duration static fire tests of the five-segment solid rocket boosters. Qualification Motor 1 was tested on 10 March 2015.[141] Qualification Motor 2 was successfully tested on 28 June 2016.[142]

Launch costs

Estimates of the per launch costs for the SLS have varied widely, partly due to uncertainty over how much the program will expend during development and testing before the operational launches begin, and partly due to various agencies using differing cost measures; but also based on differing purposes for which the cost estimates were developed. For example, a marginal cost per one additional launch ignores the development and annual recurring fixed costs, whereas a total cost per launch includes recurring costs but excludes development.

There are no official NASA estimates for how much the SLS will cost per launch, nor for the SLS program annual recurring costs once operational. Cost per launch is not a straightforward figure to estimate as it depends heavily on how many launches occur per year.[1] For example, similarly, the Space Shuttle was estimated, in 2012 dollars, to cost $576 million per launch had it been able to achieve 7 launches per year, while the marginal cost of adding a single additional launch in a given year was estimated to be less than half of that, at just $252 million of marginal cost. However, at the rate that it flew, the final cost was $1.64 billion per Space Shuttle launch, including development.[143]:III−490

NASA associate administrator William H. Gerstenmaier said in 2017 that there would be no official per flight cost estimates of any variety provided by NASA for the SLS.[144] Other bodies, such as the Government Accountability Office (GAO), the NASA Office of Inspector General, the Senate Appropriations Committee, and the White House Office of Management and Budget have put out cost per launch figures, however. Several internal NASA programs and project concept study reports have released proposed budgets that include future SLS launches. For example, a concept study report for a space telescope stated it was advised by NASA HQ in 2019 to budget $500 million for an SLS launch in 2035.[145] Another study in 2019 also proposing a space telescope assumed a budget for their launch of $650 million in current-day dollars, or $925 million for when the launch would occur, also in the "mid-2030s".[146]

Europa Clipper launch cost

Europa Clipper is a NASA scientific mission that was initially required by Congress to launch on SLS. Oversight bodies both internal and external to NASA disagreed with this requirement. First, NASA's Inspector General office published a report in May 2019[147][148] that stated Europa Clipper would need to give up $876 million for the "marginal cost" of its SLS launch. An addendum to the letter published in August 2019 increased the estimate and stated that switching to a commercial rocket would save over $1 billion.

A JCL (Joint Cost and Schedule Confidence Level) analysis cited in that letter put the cost savings at $700 million, with the SLS at $1.05 billion per launch and the commercial alternative at $350 million.[149][150] Finally, a letter from the White House Office of Management and Budget (OMB) to the Senate Appropriations Committee in October 2019 revealed that SLS's total cost to the taxpayer was estimated at "over $2 billion" per launch after development is complete; said development has cost $23 billion in 2021 dollars.[2][note 4] The letter suggested Congress remove this requirement, agreeing the NASA Inspector General, adding that using a commercial launch vehicle for Europa Clipper instead of the SLS would save $1.5 billion overall. NASA did not deny this $2 billion cost of launch and an agency spokesperson stated it "is working to bring down the cost of a single SLS launch in a given year as the agency continues negotiations with Boeing on the long-term production contract and efforts to finalize contracts and costs for other elements of the rocket".[1]

Ultimately, Europa Clipper was rebooked in 2021 to launch on a Falcon Heavy for a contract price of $178 million — saving $2 billion in launch costs compared to SLS.[151][152] The move was done not only for cost reasons but also due to unacceptably high vibration loads on SLS, and concerns over the availability of spare SLS vehicles from the Artemis program.[153][154]

Launch Cost, Generally

The 2019 OMB figure above is dependent on the rate of construction, so building more SLS rockets faster could decrease the per-unit cost.[1] For example, Exploration Ground Systems – whose only role is to support, assemble, integrate, and launch SLS – has separately budgeted fixed costs of $600 million per year on facilities, spread across however many rockets launch that year.[108] Then, in December 2019, NASA Administrator Jim Bridenstine shared informally that he disagrees with the $2 billion figure since the marginal cost of an SLS launch should decrease after the first few, and is expected to end up around $800 million to $900 million, although contract negotiations were only just beginning for those later cores.[155]

In November 2021 a new NASA Office of Inspector General audit was released, which estimated that, at least for the first four launches of SLS, the per-launch production and operating costs would be $2.2 billion for SLS, plus $568 million for Exploration Ground Systems. Additionally, since the first four missions are under the Artemis program, the payload would cost $1 billion for Orion and $300 million for the ESA service module.[3]:23

Operation

Construction

(As of 2020), three SLS versions are planned: Block 1, Block 1B, and Block 2. Each will use the same Core stage with its four main engines, but Block 1B will feature the Exploration Upper Stage (EUS), and Block 2 will combine the EUS with upgraded boosters.[156][12][157]

The ICPS for Artemis 1 was delivered by ULA to NASA about July 2017[158] and was housed at Kennedy Space Center as of November 2018.[159]

Construction of core stage

In mid-November 2014, construction of the first core stage hardware began using a new friction stir welding system in the South Vertical Assembly Building at NASA's Michoud Assembly Facility.[44][42][43] Between 2015 and 2017, NASA test fired RS-25 engines in preparation for use on SLS.[49]

The core stage for the first SLS, built at Michoud Assembly Facility by Boeing,[160] had all four engines attached in November 2019,[161] and it was declared finished by NASA in December 2019.[162]

The first core stage left Michoud Assembly Facility for comprehensive testing at Stennis Space Center in January 2020.[163] The static firing test program at Stennis Space Center, known as the Green Run, operated all the core stage systems simultaneously for the first time.[164][165] Test 7 (of 8), the wet dress rehearsal, was carried out in December 2020 and the fire (test 8) took place on 16 January 2021, but shut down earlier than expected,[166] about 67 seconds in total rather than the desired eight minutes. The reason for the early shutdown was later reported to be because of conservative test commit criteria on the thrust vector control system, specific only for ground testing and not for flight. If this scenario occurred during a flight, the rocket would have continued to fly normally. There was no sign of damage to the core stage or the engines, contrary to initial concerns.[167] The second fire test was completed on 18 March 2021, with all four engines igniting, throttling down as expected to simulate in-flight conditions, and gimballing profiles. The core stage was shipped to Kennedy Space Center to be mated with the rest of the rocket for Artemis 1. It left Stennis on April 24 and arrived at Kennedy on April 27.[168] It was refurbished there in preparation for stacking.[169] On 12 June 2021, NASA announced the assembly of the first SLS rocket was completed at the Kennedy Space Center. The assembled SLS was used for the uncrewed Artemis 1 mission in 2022.[170]

The first SLS, for Artemis 1, launched an Orion spacecraft into a lunar orbit on a test flight in fall 2022,[171] and NASA and Boeing are constructing the next three rockets for Artemis 2, Artemis 3, and Artemis 4.[172] Boeing stated in July 2021 that while the COVID-19 pandemic had affected their suppliers and schedules, such as delaying parts needed for hydraulics, they would still be able to provide the Artemis 2 SLS core stage per NASA's schedule, with months to spare.[172] The spray-on foam insulation process for Artemis 2 was automated for most sections of the core stage, saving 12 days in the schedule.[173][172] The Artemis 2 forward skirt, the foremost component of the core stage, was affixed on the liquid oxygen tank in late May 2021.[172] By 25 September 2023 the core stage was functionally complete, as all sections were assembled and the four RS-25 engines had been installed.[174] (As of May 2023), the complete core stage is set to ship to NASA in late fall 2023,[175][176] eight months later than was predicted originally.[177] For Artemis 3, assembly of elements of the thrust structure began at Michoud Assembly Facility in early 2021.[172] The liquid hydrogen tank for Artemis 3 was originally planned to be the Artemis 1 tank, but it was set aside as the welds were found to be faulty.[178]:2 Repair techniques were developed, and the tank re-entered production and will be proof tested for strength, for use on Artemis 3.[178]:2

Construction of EUS for Block 1B

As of July 2021, Boeing is also preparing to begin construction of the Exploration Upper Stage (EUS), which is planned to debut on Artemis 4.[172]

Launches

Originally planned for late 2016, the uncrewed first flight of SLS slipped more than twenty-six times and almost six years.[note 5] As of earlier that month, the first launch was originally scheduled for 8:30 am EDT, 29 August 2022.[216] It was postponed to 2:17 pm EDT (18:17 UTC), 3 September 2022, after the launch director called a scrub due to a temperature sensor falsely indicating that an RS-25 engine's hydrogen bleed intake was too warm.[206][207] The 3 September attempt was then scrubbed due to a hydrogen leak in the tail service mast quick disconnect arm, which was fixed; the next launch option was at first a period in late[212][213] October and then a launch in mid-November, due to unfavorable weather during Hurricane Ian.[211][217][209] It launched on November 16.[218]

NASA originally limited the amount of time the solid rocket boosters can remain stacked to "about a year" from the time two segments are joined.[219] The first and second segments of the Artemis 1 boosters were joined on 7 January 2021.[220] NASA could choose to extend the time limit based on an engineering review.[221] On 29 September 2021, Northrop Grumman indicated that the limit could be extended to eighteen months for Artemis 1, based on an analysis of the data collected when the boosters were being stacked;[170] an analysis weeks before the actual launch date later extended that to December 2022 for the boosters of Artemis 1, almost two years after stacking.[222]

In late 2015, the SLS program was stated to have a 70% confidence level for the first Orion flight that carries crew, the second SLS flight overall, to happen by 2023;[223][224][225] (As of November 2021), NASA delayed Artemis 2 from 2023[226] to May 2024.[227] In March 2023, NASA announced they had delayed Artemis 2 to November 2024[228] and in January 2024 the mission was further delayed to September 2025.[229] Template:SLS launches/future

Usage beyond Artemis

Although the SLS is only confirmed for use on the first few Artemis missions, several NASA mission concept studies for robotic missions considered launching on the SLS. These include: Neptune Odyssey,[230][231] Europa Lander,[232][233][234] Enceladus Orbilander, Persephone,[235] HabEx,[146] Origins Space Telescope,[145] LUVOIR,[236] Lynx,[237] and Interstellar probe.[238] These concept studies were prepared for possible recommendation by the National Academy's Decadal surveys. The Astronomy and Astrophysics Decadal Survey in 2021 recommended a smaller, merged version of HabEx and LUVOIR preceded by a technology maturation program to reduce cost and schedule risk, although the eventual mission may or may not use SLS. In 2022 the Planetary Science Decadal Survey recommended Enceladus Orbilander as the third highest priority for flagship planetary missions in the 2020s. The Heliophysics Decadal Survey, due to be completed in 2024, is considering the Interstellar Probe mission concept.

NASA is planning to turn over the SLS to contractors such as Boeing and Northtrop Grumman to find more buyers and bring down costs, hoping to reduce the rocket's price tag to $1 billion.[239] Finding a market for a large and costly rocket is difficult however, Reuters reported.[239] The DoD, seen as a potential customer, stated in 2023 that it is not interested in a partnership with NASA or the SLS as other rockets already offer them the capability that they need at an affordable price.[239]

Criticism

The SLS has been criticized based on program cost, lack of commercial involvement, and non-competitiveness of legislation requiring the use of Space Shuttle components.[240]

Funding

In 2011, Rep. Tom McClintock and other groups[who?] called on the Government Accountability Office to investigate possible violations of the Competition in Contracting Act, arguing that the requirement that Space Shuttle components be used on SLS were non-competitive and assured contracts to existing Space Shuttle suppliers.[241][242][243] In 2014, Lori Garver, a former NASA Deputy Administrator, called for cancelling the launch vehicle alongside the Mars 2020 rover.[244] In 2023, Cristina Chaplain, former assistant director of the GAO, has expressed doubts about the reduction of the rocket's cost to a competitive threshold, "just given the history and how challenging it is to build".[239]

Management

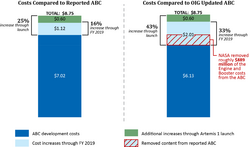

In 2019, the Government Accountability Office noted that NASA had assessed the performance of contractor Boeing positively, though the project had experienced cost growth and delay.[246][247] A March 2020 report by Office of Inspector General found NASA moved out $889 million of costs relating to SLS boosters, but did not update the SLS budget to match. This kept the budget overrun to 15% in FY 2019;[245]:22 an overrun of 30% would have required NASA to request additional funding from Congress[245]:21–23 The Inspector General report found that were it not for this "masking" of cost, the overrun would have been 33% by FY 2019.[245]:iv,23 The GAO stated "NASA's current approach for reporting cost growth misrepresents the cost performance of the program".[248]:19–20

Proposed alternatives

In 2009, the Augustine commission proposed a commercial 165,000 lb (75 t) launcher for lunar exploration.[249] In 2011–2012, the Space Access Society, Space Frontier Foundation, and The Planetary Society called for the cancellation of the project, arguing that the SLS would consume the funds for other projects from the NASA budget.[250][241][251] U.S. Representative Dana Rohrabacher and others[who?] proposed the development of an orbital propellant depot and the acceleration of the Commercial Crew Development program as an alternative to the SLS program.[250][252][253][254][255]

An unpublished NASA study[256][257] and another from the Georgia Institute of Technology found these approaches could have lower costs.[258][259] In 2012, United Launch Alliance also suggested using existing rockets with on-orbit assembly and propellant depots as needed.[260][261] In 2019, a former ULA employee alleged that Boeing viewed orbital refueling technology as a threat to the SLS and blocked investment in the technology.[262] In 2010, SpaceX's CEO Elon Musk claimed that his company could build a launch vehicle in the 310,000–330,000 lb (140–150 t) payload range for $2.5 billion, or $300 million (in 2010 dollars) per launch, not including a potential upper-stage upgrade.[263][264]

Former NASA Administrator Charlie Bolden, expressed that the SLS could be replaced in the future in an interview with Politico in September 2020. Bolden said that the "SLS will go away ... because at some point commercial entities are going to catch up." Bolden further stated, "They are really going to build a heavy-lift launch vehicle sort of like SLS that they will be able to fly for a much cheaper price than NASA can do SLS. That's just the way it works."[265]

See also

Note: This topic belongs to "Spaceflight " portal

- Austere Human Missions to Mars

- Comparison of orbital launch systems

- DIRECT, proposals prior to SLS

- Shuttle-Derived Heavy Lift Launch Vehicle, a 2009 concept launch vehicle

- Ares V, a 2000s cargo vehicle design for the Constellation Program

- National Launch System, 1990s

- Saturn (rocket family), 1960s

- Starship HLS, lunar variant of super heavy-lift vehicle Starship

- Studied Space Shuttle Variations and Derivatives

Notes

- ↑ This is for the Block 1 launch vehicle alone and does not include the Orion capsule or service module costs.[1]

- ↑ 200-km (124-mi) altitude, 28.5° inclination, circular[10]

- ↑ The FY2021 spending plan indicates that this is for "Block 1B (non-add) (including EUS)"

- ↑ See the budget table for yearly inflation-adjusted figures.

- ↑

Then-planned launch date history Date Planned launch date October 2010 31 December 2016[29][26][179][180] September 2011 2017[181][182][180] February 2012–August 2014 17 December 2017[180][183] December 2014 June–July 2018[184] 13 April 2017[inconsistent] November 2018[185] 28 April 2017 2019[186][180] November 2017 June 2020[187] December 2019 November 2020[188][189] 21 February 2020 18 April 2021[189] 28 February 2020 Mid- to late 2021[190] May 2020 22 November 2021[191][192] August 2021 December 2021[193][194] 22 October 2021 12 February 2022[195][196] 17 December 2021 March–April 2022[197] February 2022 May 2022[198] March 2022 June 2022[199] 26 April 2022 23 August 2022[200][201] 20 July 2022 8:33 am ET (12:33 UTC), 29 August 2022[202] 29 August 2022 12:48 pm ET (16:48 UTC), 2 September 2022[203][204][205] 30 August 2022 2:17 pm ET (18:17 UTC), 3 September 2022[206][207] 3 September 2022 19 September–4 October 2022[208] 8 September 2022 23 September–4 October 2022[209] 12 September 2022 27 September–4 October 2022[210] 24 September 2022 Late October 2022[211][212][213] 30 September 2022 12–27 November 2022[214] 13 October 2022 12:07 am ET (5:07 UTC), 14 November 2022[215] 8 November 2022 1:04 am ET (6:04 UTC), 16 November 2022[17]

References

- ↑ 1.0 1.1 1.2 1.3 1.4 1.5 Berger, Eric (2019-11-08). "NASA does not deny the "over US$2 billion" cost of a single SLS launch". Ars Technica. https://arstechnica.com/science/2019/11/nasa-does-not-deny-the-over-2-billion-cost-of-a-single-sls-launch/. "The White House number appears to include both the "marginal" cost of building a single SLS rocket as well as the "fixed" costs of maintaining a standing army of thousands of employees and hundreds of suppliers across the country. Building a second SLS rocket each year would make the per-unit cost "significantly less""

- ↑ 2.0 2.1 Vought, Russell T.. "Letter to the Chair and Vice Chair of the Senate Appropriations Committee with respect to 10 of the FY 2020 annual appropriations bills". p. 7. https://www.whitehouse.gov/wp-content/uploads/2019/10/shelby-mega-approps-10-23-19.pdf. "estimated cost of over US$2 billion per launch for the SLS once development is complete"

This article incorporates text from this source, which is in the public domain.

This article incorporates text from this source, which is in the public domain.

- ↑ 3.0 3.1 3.2 "NASA'S MANAGEMENT OF THE ARTEMIS MISSIONS". Office of Inspector General (United States). NASA. 15 November 2021. p. numbered page 23, PDF page 29. https://oig.nasa.gov/docs/IG-22-003.pdf. "SLS/Orion Production and Operating Costs Will Average Over $4 Billion Per Launch [...] We project the cost to fly a single SLS/Orion system through at least Artemis IV to be $4.1 billion per launch at a cadence of approximately one mission per year. Building and launching one Orion capsule costs approximately $1 billion, with an additional $300 million for the Service Module supplied by the ESA [...] In addition, we estimate the single-use SLS will cost $2.2 billion to produce, including two rocket stages, two solid rocket boosters, four RS-25 engines, and two stage adapters. Ground systems located at Kennedy where the launches will take place—the Vehicle Assembly Building, Crawler-Transporter, Mobile Launcher 1, Launch Pad, and Launch Control Center—are estimated to cost $568 million per year due to the large support structure that must be maintained. The $4.1 billion total cost represents production of the rocket and the operations needed to launch the SLS/Orion system including materials, labor, facilities, and overhead, but does not include any money spent either on prior development of the system or for next-generation technologies such as the SLS’s Exploration Upper Stage, Orion’s docking system, or Mobile Launcher 2. [...] The cost per launch was calculated as follows: $1 billion for the Orion based on information provided by ESD officials and NASA OIG analysis; $300 million for the ESA’s Service Module based on the value of a barter agreement between ESA and the United States in which ESA provides the service modules in exchange for offsetting its ISS responsibilities; $2.2 billion for the SLS based on program budget submissions and analysis of contracts; and $568 million for EGS costs related to the SLS/Orion launch as provided by ESD officials."

This article incorporates text from this source, which is in the public domain.

This article incorporates text from this source, which is in the public domain.

- ↑ "White House warns Congress about Artemis funding". SpaceNews. 2019-11-07. https://spacenews.com/white-house-warns-congress-about-artemis-funding/.

- ↑ "Updated FY 2021 Spending Plan". NASA. https://www.nasa.gov/sites/default/files/atoms/files/updated_fy_2021_spend_plan_june_2021.pdf.

This article incorporates text from this source, which is in the public domain.

This article incorporates text from this source, which is in the public domain.

- ↑ NASA (2021-10-27). "Space Launch System Core Stage" (in en-US). https://www.nasa.gov/exploration/systems/sls/fs/core_stage.html.

- ↑ NASA (2021-11-18). "Space Launch System Interim Cryogenic Propulsion Stage (ICPS)" (in en-US). https://www.nasa.gov/exploration/systems/sls/fs/ICPS.html.

- ↑ "SLS October 2015 Fact Sheet". https://www.nasa.gov/sites/default/files/files/SLS-Fact-Sheet_aug2014-finalv3.pdf#:~:text=The%20initial%20Block%201%20configuration%20of%20SLS%20will,liftoff%2C%20equivalent%20to%20more%20than%20160%2C000%20Corvette%20engines..

- ↑ NASA's Space Launch System Reference Guide v2.0 NASA pub. SLS-4071 NP-2022-08-65-MSFC. Page 5. August, 2022. Retrieved 2023-04-21.

- ↑ "2018 draft factsheet of SLS capabilities". August 20, 2018. https://www.nasa.gov/sites/default/files/atoms/files/sls_lift_capabilities_and_configurations_508_08202018_0.pdf.

- ↑ 11.0 11.1 11.2 11.3 11.4 Harbaugh, Jennifer (9 July 2018). "The Great Escape: SLS Provides Power for Missions to the Moon". NASA. https://www.nasa.gov/exploration/systems/sls/to-the-moon.html.

This article incorporates text from this source, which is in the public domain.

This article incorporates text from this source, which is in the public domain.

- ↑ 12.0 12.1 12.2 "Space Launch System". NASA. 11 October 2017. https://www.nasa.gov/sites/default/files/atoms/files/sls_fact_sheet_final_10112017.pdf.

This article incorporates text from this source, which is in the public domain.

This article incorporates text from this source, which is in the public domain.

- ↑ "NASA's Space Launch System: Exploration, Science, Security". The Boeing Company. https://www.rocket.com/sites/default/files/documents/322837_SLS%20Flip%20book_012221.pdf.

- ↑ 14.0 14.1 Creech, Stephen (April 2014). "NASA's Space Launch System: A Capability for Deep Space Exploration". NASA. p. 2. https://www.nasa.gov/sites/default/files/files/Creech_SLS_Deep_Space.pdf.

This article incorporates text from this source, which is in the public domain.

This article incorporates text from this source, which is in the public domain.

- ↑ 15.0 15.1 15.2 15.3 15.4 15.5 Mohon, Lee (2015-03-16). "Space Launch System (SLS) Overview". http://www.nasa.gov/exploration/systems/sls/overview.html.

This article incorporates text from this source, which is in the public domain.

This article incorporates text from this source, which is in the public domain.

- ↑ 16.0 16.1 16.2 16.3 "SLS Lift Capabilities and Configurations". NASA. 29 April 2020. https://www.nasa.gov/sites/default/files/atoms/files/sls_lift_capabilities_configurations_04292020_woleo.pdf.

This article incorporates text from this source, which is in the public domain.

This article incorporates text from this source, which is in the public domain.

- ↑ 17.0 17.1 17.2 "NASA Prepares Rocket, Spacecraft Ahead of Tropical Storm Nicole, Re-targets Launch". NASA. 8 November 2022. https://blogs.nasa.gov/artemis/2022/11/08/nasa-prepares-rocket-spacecraft-ahead-of-tropical-storm-nicole-re-targets-launch/.

- ↑ 18.0 18.1 "Space Launch System Solid Rocket Booster". NASA. February 2021. https://www.nasa.gov/exploration/systems/sls/fs/solid-rocket-booster.html.

This article incorporates text from this source, which is in the public domain.

This article incorporates text from this source, which is in the public domain.

- ↑ Redden, Jeremy J. (27 July 2015). SLS Booster Development. https://ntrs.nasa.gov/citations/20150016519. Retrieved 1 October 2020.

This article incorporates text from this source, which is in the public domain.

This article incorporates text from this source, which is in the public domain.

- ↑ "SLS Core Stage Fact Sheet". NASA. https://www.nasa.gov/sites/default/files/atoms/files/sls_core_stage_fact_sheet_01072016.pdf.

This article incorporates text from this source, which is in the public domain.

This article incorporates text from this source, which is in the public domain.

- ↑ 21.0 21.1 21.2 21.3 "RS-25 Engine". https://www.rocket.com/space/liquid-engines/rs-25-engine.

This article incorporates text from this source, which is in the public domain.

This article incorporates text from this source, which is in the public domain.

- ↑ "What is ICPS?". United Launch Alliance. 23 June 2021. https://www.flickr.com/photos/ulalaunch/51266939305/in/album-72157690220351103/.

This article incorporates text from this source, which is in the public domain.

This article incorporates text from this source, which is in the public domain.

- ↑ 23.0 23.1 "Space Launch System". Spaceflight Insider. 9 September 2018. https://www.spaceflightinsider.com/hangar/sls/.

- ↑ "RL10 Engine". https://rocket.com/space/liquid-engines/rl10-engine.

This article incorporates text from this source, which is in the public domain.

This article incorporates text from this source, which is in the public domain.

- ↑ Gebhardt, Chris; Burghardt, Thomas (2022-11-16). "SLS makes successful debut flight, sending Artemis I to the Moon" (in en-US). https://www.nasaspaceflight.com/2022/11/artemis-i-launch-nov/.

- ↑ 26.0 26.1 "S.3729 – National Aeronautics and Space Administration Authorization Act of 2010". United States Congress. 11 October 2010. https://www.congress.gov/bill/111th-congress/senate-bill/3729.

This article incorporates text from this source, which is in the public domain.

This article incorporates text from this source, which is in the public domain.

- ↑ 27.0 27.1 Stephen Clark (31 March 2011). "NASA to set exploration architecture this summer". Spaceflight Now. http://spaceflightnow.com/news/n1103/31slsmpcv/.

- ↑ Day, Dwayne (25 November 2013). "Burning thunder". http://www.thespacereview.com/article/2410/1.

- ↑ 29.0 29.1 29.2 29.3 "Public Law 111–267 111th Congress, 42 USC 18322. SEC. 302 (c) (2) 42 USC 18323. SEC. 303 (a) (2)". 11 October 2010. pp. 11–12. https://www.nasa.gov/pdf/649377main_PL_111-267.pdf. "42 USC 18322. SEC. 302 SPACE LAUNCH SYSTEM AS FOLLOW-ON LAUNCH VEHICLE TO THE SPACE SHUTTLE [...] (c) MINIMUM CAPABILITY REQUIREMENTS (1) IN GENERAL – The Space Launch System developed pursuant to subsection (b) shall be designed to have, at a minimum, the following: (A) The initial capability of the core elements, without an upper stage, of lifting payloads weighing between 70 tons and 100 tons into low-Earth orbit in preparation for transit for missions beyond low Earth orbit [...] (2) FLEXIBILITY [...] (Deadline) Developmental work and testing of the core elements and the upper stage should proceed in parallel subject to appro-priations. Priority should be placed on the core elements with the goal for operational capability for the core elements not later than December 31, 2016 [...] 42 USC 18323. SEC. 303 MULTI-PURPOSE CREW VEHICLE (a) INITIATION OF DEVELOPMENT (1) IN GENERAL – The Administrator shall continue the development of a multi-purpose crew vehicle to be available as soon as practicable, and no later than for use with the Space Launch System [...] (2) GOAL FOR OPERATIONAL CAPABILITY. It shall be the goal to achieve full operational capability for the transportation vehicle developed pursuant to this subsection by not later than December 31, 2016. For purposes of meeting such goal, the Administrator may undertake a test of the transportation vehicle at the ISS before that date."

- ↑ "Space Launch System". http://www.aerospaceguide.net/spacerocket/space-launch-system.html.

- ↑ Gebhardt, Chris (6 April 2017). "NASA finally sets goals, missions for SLS – eyes multi-step plan to Mars". NASASpaceFlight.com. https://www.nasaspaceflight.com/2017/04/nasa-goals-missions-sls-eyes-multi-step-mars/.

- ↑ Harbaugh, Jennifer (12 May 2017). "NASA Continues Testing, Manufacturing World's Most Powerful Rocket". NASA. https://www.nasa.gov/exploration/systems/sls/nasa-continues-testing-manufacturing-worlds-most-powerful-rocket.

This article incorporates text from this source, which is in the public domain.

This article incorporates text from this source, which is in the public domain.

- ↑ Gebhardt, Chris (15 August 2019). "Eastern Range updates "Drive to 48" launches per year status". NASASpaceFlight.com. https://www.nasaspaceflight.com/2019/08/eastern-range-drive-48-launches-per-year-status/. "NASA, on the other hand, will have to add this capability to their SLS rocket, and Mr. Rosati said NASA is tracking that debut for the Artemis 3 mission in 2023."

- ↑ Potter, Sean Sean (27 July 2022). "NASA Prepares for Space Launch System Rocket Services Contract". NASA. https://www.nasa.gov/press-release/nasa-prepares-for-space-launch-system-rocket-services-contract.

- ↑ 35.0 35.1 35.2 35.3 35.4 Bergin, Chris (4 October 2011). "SLS trades lean towards opening with four RS-25s on the core stage". NASASpaceFlight.com. http://www.nasaspaceflight.com/2011/10/sls-trades-opening-four-rs-25s-core-stage/.

- ↑ Chris Bergin (25 April 2011). "SLS planning focuses on dual phase approach opening with SD HLV". NASASpaceFlight.com. http://www.nasaspaceflight.com/2011/04/sls-planning-dual-phase-approach-opening-sd-hlv/.

- ↑ Bergin, Chris (16 June 2011). "Managers SLS announcement after SD HLV victory". NASASpaceFlight.com. http://www.nasaspaceflight.com/2011/06/managers-sls-announcement-after-sd-hlv-victory/.

- ↑ 38.0 38.1 Bergin, Chris (23 February 2012). "Acronyms to Ascent – SLS managers create development milestone roadmap". NASASpaceFlight.com. http://www.nasaspaceflight.com/2012/02/acronyms-ascent-sls-managers-create-developmental-milestone-roadmap/.

- ↑ Harbaugh, Jennifer (2019-12-09). "NASA, Public Marks Assembly of SLS Stage with Artemis Day". NASA. https://www.nasa.gov/exploration/systems/sls/artemis-day-marks-sls-core-stage-milestone.html. "NASA and the Michoud team will shortly send the first fully assembled, 212-foot-tall core stage [...] 27.6-feet-in-diameter tanks and barrels."

This article incorporates text from this source, which is in the public domain.

This article incorporates text from this source, which is in the public domain.

- ↑ 40.0 40.1 "space launch system". 2012. http://www.nasa.gov/pdf/664158main_sls_fs_master.pdf.

This article incorporates text from this source, which is in the public domain.

This article incorporates text from this source, which is in the public domain.

- ↑ Chris Bergin (14 September 2011). "SLS finally announced by NASA – Forward path taking shape". NASASpaceFlight.com. http://www.nasaspaceflight.com/2011/09/sls-finally-announced-nasa-forward-path/.

- ↑ 42.0 42.1 Payne, Martin (February 18, 2013). "SLS takes on new buckling standards, drops Super Light alloy". https://www.nasaspaceflight.com/2013/02/sls-new-buckling-standards-drops-super-light-alloy/.

- ↑ 43.0 43.1 Burkey, Martin (June 2, 2016). "A (much) Closer Look at How We Build SLS – Rocketology: NASA's Space Launch System". https://blogs.nasa.gov/Rocketology/2016/06/02/a-much-closer-look-at-how-we-build-sls/.

- ↑ 44.0 44.1 "SLS Engine Section Barrel Hot off the Vertical Weld Center at Michoud". NASA. http://www.nasa.gov/sls/14-171.html#.VGfrNb4_ypc.

This article incorporates text from this source, which is in the public domain.

This article incorporates text from this source, which is in the public domain.

- ↑ 45.0 45.1 Evans, Ben (2 May 2020). "NASA Orders 18 More RS-25 Engines for SLS Moon Rocket, at $1.79 Billion". AmericaSpace. https://www.americaspace.com/2020/05/02/nasa-orders-18-more-rs-25-engines-for-sls-moon-rocket-at-1-79-billion/.

- ↑ Sloss, Philip (2 January 2015). "NASA ready to power up the RS-25 engines for SLS". NASASpaceFlight.com. http://www.nasaspaceflight.com/2015/01/nasa-ready-power-up-rs-25-engine/.

- ↑ Boen, Brooke (2015-03-02). "RS-25: The Clark Kent of Engines for the Space Launch System". http://www.nasa.gov/exploration/systems/sls/rs25-engine-powers-sls.html.

- ↑ Harbaugh, Jennifer (2020-01-29). "Space Launch System RS-25 Core Stage Engines". http://www.nasa.gov/exploration/systems/sls/fs/rs25_core_stage_engines.html.

- ↑ 49.0 49.1 Campbell, Lloyd (25 March 2017). "NASA conducts 13th test of Space Launch System RS-25 engine". SpaceflightInsider.com. http://www.spaceflightinsider.com/space-centers/stennis-space-center/nasa-conducts-13th-test-space-launch-system-rs-25-engine/.

- ↑ 50.0 50.1 50.2 "NASA Awards Aerojet Rocketdyne $1.79 Billion Contract Modification to Build Additional RS-25 Rocket Engines to Support Artemis Program | Aerojet Rocketdyne". https://www.rocket.com/article/nasa-awards-aerojet-rocketdyne-179-billion-contract-modification-build-additional-rs-25.

- ↑ Sloss, Philip (31 December 2020). "NASA, Aerojet Rocketdyne plan busy RS-25 test schedule for 2021". NASASpaceFlight. https://www.nasaspaceflight.com/2020/12/nasa-aerojet-plan-busy-2021-test-schedule/.

- ↑ Ballard, Richard (2017). "Next-Generation RS-25 Engines for the NASA Space Launch System". NASA Marshall Space Flight Center. p. 3. https://ntrs.nasa.gov/api/citations/20170008946/downloads/20170008946.pdf.

- ↑ "Four to Five: Engineer Details Changes Made to SLS Booster". 10 January 2016. https://www.spaceflightinsider.com/missions/human-spaceflight/four-five-engineer-details-shuttles-booster-will-used-sls/.

- ↑ Perry, Beverly (21 April 2016). "We've Got (Rocket) Chemistry, Part 2". National Aeronautics and Space Administration. https://blogs.nasa.gov/Rocketology/2016/04/21/weve-got-rocket-chemistry-part-2/.

- ↑ Priskos, Alex (7 May 2012). Five-segment Solid Rocket Motor Development Status. NASA. https://ntrs.nasa.gov/archive/nasa/casi.ntrs.nasa.gov/20120014501.pdf. Retrieved 2015-03-11.

This article incorporates text from this source, which is in the public domain.

This article incorporates text from this source, which is in the public domain.

- ↑ "Space Launch System: How to launch NASA's new monster rocket". NASASpaceFlight.com. 20 February 2012. http://www.nasaspaceflight.com/2012/02/sls-how-to-launch-nasas-new-monster-rocket/.

- ↑ 57.0 57.1 Bergin, Chris (8 May 2018). "SLS requires Advanced Boosters by flight nine due to lack of Shuttle heritage components". NASASpaceFlight.com. https://www.nasaspaceflight.com/2018/05/sls-advanced-boosters-flight-nine-shuttle-heritage/.

- ↑ 58.0 58.1 Sloss, Philip (12 July 2021). "NASA, Northrop Grumman designing new BOLE SRB for SLS Block 2 vehicle". https://www.nasaspaceflight.com/2021/07/sls-bole-srbs/.

- ↑ Tobias, Mark E.; Griffin, David R.; McMillin, Joshua E.; Haws, Terry D.; Fuller, Micheal E. (2 March 2019). Booster Obsolescence and Life Extension (BOLE) for Space Launch System (SLS). NASA. https://ntrs.nasa.gov/archive/nasa/casi.ntrs.nasa.gov/20190002126.pdf. Retrieved 15 November 2019.

This article incorporates text from this source, which is in the public domain.

This article incorporates text from this source, which is in the public domain.

- ↑ Tobias, Mark E.; Griffin, David R.; McMillin, Joshua E.; Haws, Terry D.; Fuller, Micheal E. (27 April 2020). "Booster Obsolescence and Life Extension (BOLE) for Space Launch System (SLS)". NASA. https://ntrs.nasa.gov/api/citations/20200002334/downloads/20200002334.pdf.

This article incorporates text from this source, which is in the public domain.

This article incorporates text from this source, which is in the public domain.

- ↑ 61.0 61.1 "Upper Stage RL10s arrive at Stennis for upcoming SLS launches February 2020". NASASpaceFlight.com. 3 February 2020. https://www.nasaspaceflight.com/2020/02/upper-stage-rl-10s-stennis-sls-launches/.

- ↑ 62.0 62.1 "NASA'S SPACE LAUNCH SYSTEM BEGINS MOVING TO THE LAUNCH SITE". NASA. 15 April 2020. https://ntrs.nasa.gov/api/citations/20205000944/downloads/Askins%20JANNAF%202020%20PAPER%2004152020.docx.pdf.

- ↑ Rosenberg, Zach (8 May 2012). "Delta second stage chosen as SLS interim". http://www.flightglobal.com/news/articles/delta-second-stage-chosen-as-sls-interim-371581/.

- ↑ 64.0 64.1 Henry, Kim (2014-10-30). "Getting to Know You, Rocket Edition: Interim Cryogenic Propulsion Stage". https://www.nasa.gov/sls/interim_cryogenic_propulsion_stage_141030.html.

This article incorporates text from this source, which is in the public domain.

This article incorporates text from this source, which is in the public domain.

- ↑ Batcha, Amelia L.; Williams, Jacob; Dawn, Timothy F.; Gutkowski, Jeffrey P.; Widner, Maxon V.; Smallwood, Sarah L.; Killeen, Brian J.; Williams, Elizabeth C. et al. (27 July 2020). "Artemis I Trajectory Design and Optimization". NASA. https://ntrs.nasa.gov/api/citations/20205005150/downloads/AAS20649_Artemis1_Trajectory_Design_Optimization.pdf.

This article incorporates text from this source, which is in the public domain.

This article incorporates text from this source, which is in the public domain.

- ↑ "Space Launch System Data Sheet". 27 May 2014. http://www.spacelaunchreport.com/sls0.html.

- ↑ 67.0 67.1 "SLS prepares for PDR – Evolution eyes Dual-Use Upper Stage". NASASpaceFlight.com. June 2013. http://www.nasaspaceflight.com/2013/06/sls-pdr-evolved-rocket-dual-upper-stage/.

- ↑ "NASA confirms EUS for SLS Block 1B design and EM-2 flight". NASASpaceFlight.com. 6 June 2014. http://www.nasaspaceflight.com/2014/06/nasa-confirms-eus-sls-block-ib-design-em-2-flight/.

- ↑ Sloss, Philip (4 March 2021). "NASA, Boeing looking to begin SLS Exploration Upper Stage manufacturing in 2021". https://www.nasaspaceflight.com/2021/03/nasa-boeing-begin-sls-eus-2021/.

- ↑ Gebhardt, Chris (5 March 2022). "With all-composite cryogenic tank, Boeing eyes mass-reducing space, aviation applications". https://www.nasaspaceflight.com/2022/03/boeing-all-composite-cryo-tank/.

- ↑ Bergin, Chris (28 March 2014). "SLS positioning for ARRM and Europa missions". NASASpaceflight.com. http://www.nasaspaceflight.com/2014/03/sls-positioning-arrm-europa-missions/.

- ↑ "Teledyne to Build NASA's $60 Million Launch Vehicle Stage Adapter". https://www.tbe.com/en-us/news-and-media/Pages/teledyne-to-build-nasa-60-million-launch-vehicle-stage-adapter.aspx.

- ↑ "Teledyne Brown Engineering Awarded $85 Million NASA Contract to Provide Key Stage of NASA's Space Launch System Vehicle Returning Astronauts to the Moon". https://www.teledyne.com/en-us/news/Pages/Teledyne-Brown-Engineering-Awarded-$85-Million-NASA-Contract-to-Provide-Key-Stage-of-NASA%27s-Space-Launch-System-Vehicle-Ret.aspx.

- ↑ 74.0 74.1 74.2 "Space Launch System Lift Capabilities and Configurations". 20 August 2018. https://www.nasa.gov/sites/default/files/atoms/files/sls_lift_capabilities_and_configurations_508_08202018_0.pdf.

This article incorporates text from this source, which is in the public domain.

This article incorporates text from this source, which is in the public domain.

- ↑ Smith, Marcia (14 September 2011). "New NASA Crew Transportation System to Cost US$18 Billion Through 2017". Space Policy Online. http://www.spacepolicyonline.com/news/new-nasa-crew-transportation-system-to-cost-18-billion-through-2017.

- ↑ Bill Nelson, Kay Bailey Hutchison, Charles F. Bolden (14 September 2011). Future of NASA Space Program. Washington, D.C.: Cspan.org.

- ↑ Booz Allen Hamilton (19 August 2011). "Independent Cost Assessment of the Space Launch System, Multi-purpose Crew Vehicle and 21st Century Ground Systems Programs: Executive Summary of Final Report". http://www.nasa.gov/pdf/581582main_BAH_Executive_Summary.pdf.

This article incorporates text from this source, which is in the public domain.

This article incorporates text from this source, which is in the public domain.

- ↑ Paszior, Andy (7 September 2011). "White House Experiences Sticker Shock Over NASA's Plans". https://www.wsj.com/articles/SB10001424053111903648204576555010831469864.

- ↑ "ESD Integration, Budget Availability Scenarios". Space Policy Online. 19 August 2011. http://spacepolicyonline.com/pages/images/stories/SLS_budget_Integration_2011-08.pdf.

- ↑ Smith, Marcia (9 September 2011). "The NASA Numbers Behind That WSJ Article". Space Policy Online. http://www.spacepolicyonline.com/news/the-nasa-numbers-behind-that-wsj-article.

- ↑ "HEFT Phase I Closeout". September 2010. p. 69. http://www.nasawatch.com/images/heft.presentation.pdf.

- ↑ "NASA's huge new rocket may cost US$500 million per launch". NBC News. 12 September 2012. http://www.nbcnews.com/id/49019843.

- ↑ Lee Roop (29 July 2013). "NASA defends Space Launch System against charge it 'is draining the lifeblood' of space program". http://blog.al.com/breaking/2013/07/nasa_defends_space_launch_syst.html.

- ↑ Strickland, John (15 July 2013). "Revisiting SLS/Orion launch costs". The Space Review. http://www.thespacereview.com/article/2330/1.

- ↑ "NASA Signs Agreement for a European-Provided Orion Service Module". NASA. 12 April 2015. http://www.nasa.gov/exploration/systems/mpcv/orion_feature_011613.html.

This article incorporates text from this source, which is in the public domain.

This article incorporates text from this source, which is in the public domain.

- ↑ 86.0 86.1 Foust, Jeff (27 August 2014). "SLS Debut Likely To Slip to 2018". SpaceNews. http://spacenews.com/41690sls-debut-likely-to-slip-to-2018/.

- ↑ Davis, Jason. "NASA Budget Lists Timelines, Costs and Risks for First SLS Flight". The Planetary Society. http://www.planetary.org/blogs/jason-davis/2015/20150203-budget-maiden-sls-flight.html.

- ↑ "NASA's Management of the Space Launch System Stages Contract". NASA Office of Inspector General Office of Audits. 10 October 2018. https://oig.nasa.gov/docs/IG-19-001.pdf.

This article incorporates text from this source, which is in the public domain.

This article incorporates text from this source, which is in the public domain.

- ↑ "NASA FY 2019 Budget Estimates". p. BUD-2. https://www.nasa.gov/sites/default/files/atoms/files/fy19_nasa_budget_estimates.pdf.

This article incorporates text from this source, which is in the public domain.

This article incorporates text from this source, which is in the public domain.

- ↑ Smith, Rich (26 March 2019). "Is NASA Preparing to Cancel Its Space Launch System?". https://www.fool.com/investing/2019/03/26/is-nasa-preparing-to-cancel-its-space-launch-syste.aspx.

- ↑ "NASA FY 2019 Budget Overview". https://www.nasa.gov/sites/default/files/atoms/files/nasa_fy_2019_budget_overview.pdf. Quote: "Supports launch of the Power and Propulsion Element on a commercial launch vehicle as the first component of the LOP–Gateway, (page 14)

This article incorporates text from this source, which is in the public domain.

This article incorporates text from this source, which is in the public domain.

- ↑ "NASA Commits to Future Artemis Missions with More SLS Rocket Engines" (Press release). NASA. 1 May 2020. Archived from the original on 1 May 2020. Retrieved 4 May 2020.

This article incorporates text from this source, which is in the public domain.

This article incorporates text from this source, which is in the public domain.

- ↑ 93.0 93.1 93.2 “NASA FY22 Inflation Tables - to be utilized in FY23” (Excel). NASA. Retrieved 31 October 2022. This article incorporates text from this source, which is in the public domain.

- ↑ "FY 2013 Complete Budget Estimates". NASA. https://www.nasa.gov/sites/default/files/632697main_NASA_FY13_Budget_Summary-508.pdf.

This article incorporates text from this source, which is in the public domain.

This article incorporates text from this source, which is in the public domain.

- ↑ "NASA, Assessments of Major Projects". General Accounting Office. March 2016. p. 63. http://www.gao.gov/assets/680/676179.pdf.

This article incorporates text from this source, which is in the public domain.

This article incorporates text from this source, which is in the public domain.

- ↑ "FY 2014 Complete Budget Estimates". NASA. https://www.nasa.gov/pdf/750614main_NASA_FY_2014_Budget_Estimates-508.pdf.

This article incorporates text from this source, which is in the public domain.

This article incorporates text from this source, which is in the public domain.

- ↑ "FY 2013 Operating Plan". NASA. https://www.nasa.gov/sites/default/files/files/FY_2013NASA_OperatingPlanEnclosure1_13SEP2013.pdf.

This article incorporates text from this source, which is in the public domain.

This article incorporates text from this source, which is in the public domain.

- ↑ "FY 2014 Operating Plan". NASA. https://www.nasa.gov/sites/default/files/files/FY-2014-NASA-Operating-Plan-June-2014.pdf.

This article incorporates text from this source, which is in the public domain.

This article incorporates text from this source, which is in the public domain.

- ↑ "FY 2015 Operating Plan Update (Aug. 2015)". NASA. https://www.nasa.gov/sites/default/files/atoms/files/fy_2015_opplan_update.pdf.

This article incorporates text from this source, which is in the public domain.

This article incorporates text from this source, which is in the public domain.

- ↑ "FY 2016 Operating Plan (Sept. 4 update)". NASA. https://www.nasa.gov/sites/default/files/atoms/files/fy16_operating_plan_4sept_update_0.pdf.

This article incorporates text from this source, which is in the public domain.

This article incorporates text from this source, which is in the public domain.

- ↑ 101.0 101.1 "FY 2017 Operating Plan". NASA. https://www.nasa.gov/sites/default/files/atoms/files/fy17_iop_august_2017.pdf.

This article incorporates text from this source, which is in the public domain.

This article incorporates text from this source, which is in the public domain.

- ↑ 102.0 102.1 "FY 2018 Operating Plan". NASA. https://www.nasa.gov/sites/default/files/atoms/files/fy2018operatingplan_july2018.pdf.

This article incorporates text from this source, which is in the public domain.

This article incorporates text from this source, which is in the public domain.

- ↑ “FY 2021 President’s Budget Request Summary” (PDF). NASA. Retrieved 31 October 2022. Archived (PDF) from the original on 31 October 2022. This article incorporates text from this source, which is in the public domain.

- ↑ 104.0 104.1 "Updated FY 2020 Spending Plan". NASA. https://www.nasa.gov/sites/default/files/atoms/files/fy_2020_spend_plan_update.pdf.

This article incorporates text from this source, which is in the public domain.

This article incorporates text from this source, which is in the public domain.

- ↑ 105.0 105.1 “National Aeronautics and Space Administration FY 2021 Spending Plan” (PDF) June Update. NASA. Retrieved 03 January 2023. Archived from the original 03 January 2023. This article incorporates text from this source, which is in the public domain.

- ↑ 106.0 106.1 “National Aeronautics and Space Administration FY 2022 Spending Plan" (PDF). NASA. Retrieved 03 January 2023. Archived from the original on 03 January 2023. This article incorporates text from this source, which is in the public domain.

- ↑ "Definitive Contract NNM12AA82C". https://govtribe.com/award/federal-contract-award/definitive-contract-nnm12aa82c.

This article incorporates text from this source, which is in the public domain.

This article incorporates text from this source, which is in the public domain.

- ↑ 108.0 108.1 "NASA FY2021 budget estimates". NASA. https://www.nasa.gov/sites/default/files/atoms/files/fy_2021_budget_book_508.pdf.

This article incorporates text from this source, which is in the public domain.

This article incorporates text from this source, which is in the public domain.

- ↑ "NASA's Ground Systems Development and Operations Program Completes Preliminary Design Review". NASA. https://www.youtube.com/watch?v=yd_Bg7K6Jt0.

This article incorporates text from this source, which is in the public domain.

This article incorporates text from this source, which is in the public domain.

- ↑ 110.0 110.1 "Fiscal Year 2010 Budget Estimates". NASA. p. v. http://www.nasa.gov/pdf/345225main_FY_2010_UPDATED_final_5-11-09_with_cover.pdf.

This article incorporates text from this source, which is in the public domain.

This article incorporates text from this source, which is in the public domain.

- ↑ "FY 2008 Budget Estimates". NASA. p. ESMD-14. http://www.nasa.gov/pdf/168652main_NASA_FY08_Budget_Request.pdf.

This article incorporates text from this source, which is in the public domain.

This article incorporates text from this source, which is in the public domain.

- ↑ 112.0 112.1 112.2 112.3 112.4 112.5 112.6 Bergin, Chris (20 February 2015). "Advanced Boosters progress towards a solid future for SLS". NasaSpaceFlight.com. http://www.nasaspaceflight.com/2015/02/advanced-boosters-towards-solid-future-sls/.

- ↑ “Consolidated Appropriations Act, 2016’" (PDF). p.63. Archived from the original 31 October 2022. Retrieved 31 October 2022. This article incorporates text from this source, which is in the public domain.

- ↑ "NASA outlines plan for 2024 lunar landing". SpaceNews. 1 May 2019. https://spacenews.com/nasa-outlines-plan-for-2024-lunar-landing/.

- ↑ Berger, Eric (20 May 2019). "NASA's full Artemis plan revealed: 37 launches and a lunar outpost". Ars Technica. https://arstechnica.com/science/2019/05/nasas-full-artemis-plan-revealed-37-launches-and-a-lunar-outpost/.

- ↑ Sloss, Philip (18 December 2019). "Amid competing priorities, Boeing redesigns NASA SLS Exploration Upper Stage". NASASpaceFlight.com. https://www.nasaspaceflight.com/2019/12/amid-priorities-boeing-redesigns-nasa-sls-eus/.

- ↑ "FY 2019 Spend Plan". NASA. https://www.nasa.gov/sites/default/files/atoms/files/fy19_-_iop-2019_-_enclosure_-_1_-_2019_op_plan-with_congress_website_version.pdf.

This article incorporates text from this source, which is in the public domain.

This article incorporates text from this source, which is in the public domain.

- ↑ "H.R.2617 - Consolidated Appropriations Act, 2023". https://www.planetary.org/space-policy/nasas-fy-2023-budget.

- ↑ 119.0 119.1 "NASA Announces Design For New Deep Space Exploration System". NASA. 14 September 2011. http://www.nasa.gov/home/hqnews/2011/sep/HQ_11-301_SLS_Decision.html.

This article incorporates text from this source, which is in the public domain.

This article incorporates text from this source, which is in the public domain.

- ↑ "NASA Announces Key Decision For Next Deep Space Transportation System". NASA. 24 May 2011. http://www.nasa.gov/home/hqnews/2011/may/HQ_11-164_MPCV_Decision.html.

This article incorporates text from this source, which is in the public domain.

This article incorporates text from this source, which is in the public domain.

- ↑ "Press Conference on the Future of NASA Space Program". C-Span. 14 September 2011. http://www.c-span.org/Events/Press-Conference-on-the-Future-of-NASA-Space-Program/10737424158/.

- ↑ Kenneth Chang (14 September 2011). "NASA Unveils New Rocket Design". The New York Times. https://www.nytimes.com/2011/09/15/science/space/15nasa.html.

- ↑ Keith Cowing (14 September 2011). "NASA's New Space Launch System Announced – Destination TBD". SpaceRef. http://www.spaceref.com/news/viewnews.html?id=1567.

- ↑ Frank Morring (17 June 2011). "NASA Will Compete Space Launch System Boosters". Aviation Week. http://www.aviationweek.com/aw/generic/story_channel.jsp?channel=space&id=news/awx/2011/06/16/awx_06_16_2011_p0-337088.xml&headline=NASA%20Will%20Compete%20Space%20Launch%20System%20Boosters.

- ↑ "SLS Block II drives hydrocarbon engine research". thespacereview.com. 14 January 2013. http://www.thespacereview.com/article/2217/1.

- ↑ "NASA's Space Launch System: Partnering For Tomorrow". NASA. http://www.asee.org/Crumbly_ASEE_Final.pdf.

This article incorporates text from this source, which is in the public domain.

This article incorporates text from this source, which is in the public domain.

- ↑ "The Dark Knights – ATK's Advanced Boosters for SLS revealed". NASASpaceFlight.com. 14 January 2013. http://www.nasaspaceflight.com/2013/01/the-dark-knights-atks-advanced-booster-revealed-for-sls/.

- ↑ Lee Hutchinson (15 April 2013). "New F-1B rocket engine upgrades Apollo-era design with 1.8M lbs of thrust". Ars Technica. https://arstechnica.com/science/2013/04/new-f-1b-rocket-engine-upgrades-apollo-era-deisgn-with-1-8m-lbs-of-thrust/.

- ↑ "Second SLS Mission Might Not Carry Crew". SpaceNews. 21 May 2014. http://www.spacenews.com/article/civil-space/40647news-from-the-30th-space-symposium-second-sls-mission-might-not-carry-crew.

- ↑ "Wind Tunnel testing conducted on SLS configurations, including Block 1B". NASASpaceFlight.com. July 2012. http://www.nasaspaceflight.com/2012/07/wind-tunnel-testing-sls-configurations-block-1b/.

- ↑ "NASA's Space Launch System Program PDR: Answers to the Acronym". NASA. 1 August 2013. http://www.nasa.gov/exploration/systems/sls/sls-pdr.html.

This article incorporates text from this source, which is in the public domain.

This article incorporates text from this source, which is in the public domain.

- ↑ "NASA Completes Key Review of World's Most Powerful Rocket in Support". NASA. 15 April 2015. http://www.nasa.gov/press/2014/august/nasa-completes-key-review-of-world-s-most-powerful-rocket-in-support-of-journey-to/#.U_5UAfl7Eeg.

This article incorporates text from this source, which is in the public domain.

This article incorporates text from this source, which is in the public domain.

- ↑ Gebhardt, Chris (13 November 2013). "SLS upper stage proposals reveal increasing payload-to-destination options". NASASpaceFlight.com. http://www.nasaspaceflight.com/2013/11/sls-us-proposals-increasing-payload-destination-options/.

- ↑ Todd, David (3 June 2013). "SLS design may ditch J-2X upper stage engine for four RL-10 engines". Seradata. http://seradata.com/SSI/2013/06/sls-may-change-upper-stage-eng/.

- ↑ Todd, David (7 November 2014). "Next Steps for SLS: Europe's Vinci is a contender for Exploration Upper-Stage Engine". Seradata. http://seradata.com/SSI/2014/11/next-steps-for-sls-europes-vinci-is-a-contender-for-exploration-upper-stage-engine/.

- ↑ Berger, Eric (5 November 2019). "NASA rejects Blue Origin's offer of a cheaper upper stage for the SLS rocket". https://arstechnica.com/science/2019/11/nasa-rejects-blue-origins-offer-of-a-cheaper-upper-stage-for-the-sls-rocket/.

- ↑ "Redacted_EUS.pdf". 31 October 2019. https://sam.gov/opp/957d857a579a9c13c26c64825f82a5d5/view.