Auxetics

From HandWiki - Reading time: 6 min

From HandWiki - Reading time: 6 min

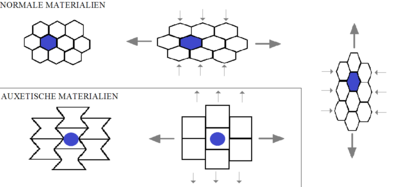

Auxetics are structures or materials that have a negative Poisson's ratio. When stretched, they become thicker perpendicular to the applied force. This occurs due to their particular internal structure and the way this deforms when the sample is uniaxially loaded. Auxetics can be single molecules, crystals, or a particular structure of macroscopic matter.[1][2]

Such materials and structures are expected to have mechanical properties such as high energy absorption and fracture resistance. Auxetics may be useful in applications such as body armor,[3] packing material, knee and elbow pads, robust shock absorbing material, and sponge mops.

History

The term auxetic derives from the Greek word auxetikos (αὐξητικός) which means 'that which tends to increase' and has its root in the word auxesis (αὔξησις), meaning 'increase' (noun). This terminology was coined by Professor Ken Evans of the University of Exeter.[4][2] One of the first artificially produced auxetic materials, the RFS structure (diamond-fold structure), was invented in 1978 by the Berlin researcher K. Pietsch. Although he did not use the term auxetics, he describes for the first time the underlying lever mechanism and its non-linear mechanical reaction so he is therefore considered the inventor of the auxetic net. The earliest published example of a material with negative Poisson's constant is due to A. G. Kolpakov in 1985, "Determination of the average characteristics of elastic frameworks"; the next synthetic auxetic material was described in Science in 1987, entitled "Foam structures with a Negative Poisson's Ratio"[1] by R.S. Lakes from the University of Wisconsin Madison. The use of the word auxetic to refer to this property probably began in 1991.[5] Recently, cells were shown to display a biological version of auxeticity under certain conditions. [6]

Designs of composites with inverted hexagonal periodicity cell (auxetic hexagon), possessing negative Poisson ratios, were published in 1985.[7]

Properties

Typically, auxetic materials have low density, which is what allows the hinge-like areas of the auxetic microstructures to flex.[8]

At the macroscale, auxetic behaviour can be illustrated with an inelastic string wound around an elastic cord. When the ends of the structure are pulled apart, the inelastic string straightens while the elastic cord stretches and winds around it, increasing the structure's effective volume. Auxetic behaviour at the macroscale can also be employed for the development of products with enhanced characteristics such as footwear based on the auxetic rotating triangles structures developed by Grima and Evans[9][10][11] and prosthetic feet with human-like toe joint properties.[12]

Auxeticity is also common in biological materials. The origin of auxeticity is very different in biological materials than the materials discussed above. One of the example is nuclei of mouse embryonic stem cells in transition state. A model has been developed by Tripathi et. al [13] to explain it.

Examples

Examples of auxetic materials include:

- Auxetic polyurethane foam[14][15]

- Nuclei of mouse embryonic stem cells in exiting pluripotent state [13]

- α-Cristobalite.[16]

- Certain states of crystalline materials: Li, Na, K, Cu, Rb, Ag, Fe, Ni, Co, Cs, Au, Be, Ca, Zn, Sr, Sb, MoS, BAsO and other.[17][18][19]

- Certain rocks and minerals[20]

- Graphene, which can be made auxetic through the introduction of vacancy defects[21][22]

- Carbon diamond-like phases[23]

- Noncarbon nanotubes[24][25]

- Living bone tissue (although this is only suspected)[20]

- Tendons within their normal range of motion.[26]

- Specific variants of polytetrafluorethylene polymers such as Gore-Tex[27]

- Several types of origami folds like the Diamond-Folding-Structure (RFS), the herringbone-fold-structure (FFS) or the miura fold,[28][29] and other periodic patterns derived from it.[30][31]

- Tailored structures designed to exhibit special designed Poisson's ratios.[33][34][35][36][37][38]

- Chain organic molecules. Recent researches revealed that organic crystals like n-paraffins and similar to them may demonstrate an auxetic behavior.[39]

See also

- Acoustic metamaterial

- Mechanical metamaterial

- Metamaterial

- Parallelogon

- Zetix, a type of commercially manufactured auxetic material

References

- ↑ 1.0 1.1 Lakes, R.S. (27 February 1987), "Foam structures with a negative Poisson's ratio", Science 235 (4792): 1038–40, doi:10.1126/science.235.4792.1038, PMID 17782252, Bibcode: 1987Sci...235.1038L.

- ↑ 2.0 2.1 Evans, Ken (1991), "Auxetic polymers: a new range of materials.", Endeavour 15 (4): 170–174, doi:10.1016/0160-9327(91)90123-S.

- ↑ "Hook's law". The Economist. 1 December 2012. https://www.economist.com/news/technology-quarterly/21567203-materials-auxetic-substances-which-get-fatter-rather-thinner-when-stretched. Retrieved 1 March 2013.

- ↑ Quinion, Michael (9 November 1996), Auxetic, http://www.worldwidewords.org/turnsofphrase/tp-aux1.htm.

- ↑ Evans, Ken (1991), "Auxetic polymers: a new range of materials", Endeavour 15 (4): 170–174, doi:10.1016/0160-9327(91)90123-S.

- ↑ Morrish, RB (2019), "Single Cell Imaging of Nuclear Architecture Changes", Front. Cell Dev. Biol. 7: 141, doi:10.3389/fcell.2019.00141, PMID 31396512.

- ↑ Kolpakov, A.G. (1985). "Determination of the average characteristics of elastic frameworks". Journal of Applied Mathematics and Mechanics 49 (6): 739–745. doi:10.1016/0021-8928(85)90011-5. Bibcode: 1985JApMM..49..739K.

- ↑ A stretch of the imagination – 7 June 1997 – New Scientist Space

- ↑ Grima, JN; Evans, KE (2000). "Auxetic behavior from rotating squares". Journal of Materials Science Letters 19 (17): 1563–1565. doi:10.1023/A:1006781224002.

- ↑ Grima, JN; Evans, KE (2006). "Auxetic behavior from rotating triangles". Journal of Materials Science 41 (10): 3193–3196. doi:10.1007/s10853-006-6339-8. Bibcode: 2006JMatS..41.3193G.

- ↑ "Nike Free 2016 product press release". http://news.nike.com/news/nike-free-2016-running-training.

- ↑ Hong, Woolim; Kumar, Namita Anil; Patrick, Shawanee; Um, Hui-Jin; Kim, Heon-Su; Kim, Hak-Sung; Hur, Pilwon (2022). "Empirical Validation of an Auxetic Structured Foot With the Powered Transfemoral Prosthesis". IEEE Robotics and Automation Letters 7 (4): 11228–11235. doi:10.1109/LRA.2022.3194673. ISSN 2377-3766. https://ieeexplore.ieee.org/document/9844236.

- ↑ 13.0 13.1 Tripathi, Kamal; Menon, Gautam I. (2019-10-28). "Chromatin Compaction, Auxeticity, and the Epigenetic Landscape of Stem Cells". Physical Review X 9 (4): 041020. doi:10.1103/PhysRevX.9.041020. https://link.aps.org/doi/10.1103/PhysRevX.9.041020.

- ↑ Li, Yan; Zeng, Changchun (2016). "On the successful fabrication of auxetic polyurethane foams: Materials requirement, processing strategy and conversion mechanism". Polymer 87: 98–107. doi:10.1016/j.polymer.2016.01.076.

- ↑ Li, Yan; Zeng, Changchun (2016). "Room‐Temperature, Near‐Instantaneous Fabrication of Auxetic Materials with Constant Poisson's Ratio over Large Deformation". Advanced Materials 28 (14): 2822–2826. doi:10.1002/adma.201505650. PMID 26861805.

- ↑ Yeganeh-Haeri, Amir; Weidner, Donald J.; Parise, John B. (31 July 1992). "Elasticity of α-Cristobalite: A Silicon Dioxide with a Negative Poisson's Ratio" (in en). Science 257 (5070): 650–652. doi:10.1126/science.257.5070.650. ISSN 0036-8075. PMID 17740733. Bibcode: 1992Sci...257..650Y.

- ↑ Goldstein, R.V.; Gorodtsov, V.A.; Lisovenko, D.S. (2013). "Classification of cubic auxetics" (in en). Physica Status Solidi B 250 (10): 2038–2043. doi:10.1002/pssb.201384233.

- ↑ Gorodtsov, V.A.; Lisovenko, D.S. (2019). "Extreme values of Young's modulus and Poisson's ratio of hexagonal crystals" (in en). Mechanics of Materials 134: 1–8. doi:10.1016/j.mechmat.2019.03.017.

- ↑ Grima-Cornish, JN; Vella-Zarb, L; Grima, JN (2020). "Negative Linear Compressibility and Auxeticity in Boron Arsenate". Annalen der Physik 532 (5): 1900550. doi:10.1002/andp.201900550. Bibcode: 2020AnP...53200550G.

- ↑ 20.0 20.1 Burke, Maria (7 June 1997), "A stretch of the imagination", New Scientist 154 (2085): 36, https://www.newscientist.com/article/mg15420854.200-a-stretch-of-the-imagination.html

- ↑ Grima, J. N.; Winczewski, S.; Mizzi, L.; Grech, M. C.; Cauchi, R.; Gatt, R.; Attard, D.; Wojciechowski, K.W. et al. (2014). "Tailoring Graphene to Achieve Negative Poisson's Ratio Properties". Advanced Materials 27 (8): 1455–1459. doi:10.1002/adma.201404106. PMID 25504060.

- ↑ Grima, Joseph N.; Grech, Michael C.; Grima‐Cornish, James N.; Gatt, Ruben; Attard, Daphne (2018). "Giant Auxetic Behaviour in Engineered Graphene" (in en). Annalen der Physik 530 (6): 1700330. doi:10.1002/andp.201700330. ISSN 1521-3889. Bibcode: 2018AnP...53000330G.

- ↑ Rysaeva, L.Kh.; Baimova, J.A.; Lisovenko, D.S.; Gorodtsov, V.A.; Dmitriev, S.V. (2019). "Elastic properties of fullerites and diamond-like phases" (in en). Physica Status Solidi B 256 (1): 1800049. doi:10.1002/pssb.201800049. Bibcode: 2019PSSBR.25600049R.

- ↑ Goldstein, R.V.; Gorodtsov, V.A.; Lisovenko, D.S.; Volkov, M.A. (2014). "Negative Poisson's ratio for cubic crystals and nano/microtubes" (in en). Physical Mesomechanics 17 (2): 97–115. doi:10.1134/S1029959914020027.

- ↑ Bryukhanov, I.A.; Gorodtsov, V.A.; Lisovenko, D.S. (2019). "Chiral Fe nanotubes with both negative Poisson's ratio and Poynting's effect. Atomistic simulation" (in en). Journal of Physics: Condensed Matter 31 (47): 475304. doi:10.1088/1361-648X/ab3a04. PMID 31398716. Bibcode: 2019JPCM...31U5304B.

- ↑ "Negative Poisson's ratios in tendons: An unexpected mechanical response". Acta Biomater. 24: 201–208. 2015. doi:10.1016/j.actbio.2015.06.018. PMID 26102335. http://eprints.staffs.ac.uk/3517/1/AA_Negative_Possionsratio_Paper_M.pdf.

- ↑ Auxetic materials, 9 March 2001, http://www.azom.com/details.asp?ArticleID=168.

- ↑ Mark, Schenk (2011). Folded Shell Structures, PhD Thesis. University of Cambridge, Clare College. http://www.markschenk.com/research/files/PhD%20thesis%20-%20Mark%20Schenk.pdf.

- ↑ Lv, Cheng; Krishnaraju, Deepakshyam; Konjevod, Goran; Yu, Hongyu; Jiang, Hanqing (2015). "Origami based Mechanical Metamaterials". Scientific Reports 4: 5979. doi:10.1038/srep05979. PMID 25099402.

- ↑ Eidini, Maryam; Paulino, Glaucio H. (2015). "Unraveling metamaterial properties in zigzag-base folded sheets". Science Advances 1 (8): e1500224. doi:10.1126/sciadv.1500224. ISSN 2375-2548. PMID 26601253. Bibcode: 2015SciA....1E0224E.

- ↑ Eidini, Maryam (2016). "Zigzag-base folded sheet cellular mechanical metamaterials". Extreme Mechanics Letters 6: 96–102. doi:10.1016/j.eml.2015.12.006.

- ↑ Mizzi, Luke; Salvati, Enrico; Spaggiari, Andrea; Tan, Jin-Chong; Korsunsky, Alexander M. (2020). "Highly stretchable two-dimensional auxetic metamaterial sheets fabricated via direct-laser cutting". International Journal of Mechanical Sciences 167: 105242. doi:10.1016/j.ijmecsci.2019.105242. ISSN 0020-7403. https://ora.ox.ac.uk/objects/uuid:61962177-e5f8-48c6-8eef-a3c125ec804d/download_file?safe_filename=%28aam%29Mizzi%2520-%25202D%2520auxetic%2520sheet_.pdf&file_format=application%2Fpdf&type_of_work=Journal+article.

- ↑ Tiemo Bückmann (May 2012). "Tailored 3D Mechanical Metamaterials Made by Dip-in Direct-Laser-Writing Optical Lithography". Advanced Materials 24 (20): 2710–2714. doi:10.1002/adma.201200584. PMID 22495906.

- ↑ Grima‐Cornish, James N.; Grima, Joseph N.; Evans, Kenneth E. (2017). "On the Structural and Mechanical Properties of Poly(Phenylacetylene) Truss-Like Hexagonal Hierarchical Nanonetworks" (in en). Physica Status Solidi B 254 (12): 1700190. doi:10.1002/pssb.201700190. ISSN 1521-3951. Bibcode: 2017PSSBR.25400190G.

- ↑ Cabras, Luigi; Brun, Michele (2014). "Auxetic two-dimensional lattices with Poisson's ratio arbitrarily close to −1" (in en). Proceedings of the Royal Society A: Mathematical, Physical and Engineering Sciences 470 (2172): 20140538. doi:10.1098/rspa.2014.0538. ISSN 1364-5021. Bibcode: 2014RSPSA.47040538C.

- ↑ Carta, Giorgio; Brun, Michele; Baldi, Antonio (2016). "Design of a porous material with isotropic negative Poisson's ratio" (in en). Mechanics of Materials 97: 67–75. doi:10.1016/j.mechmat.2016.02.012.

- ↑ Cabras, Luigi; Brun, Michele (2016). "A class of auxetic three-dimensional lattices" (in en). Journal of the Mechanics and Physics of Solids 91: 56–72. doi:10.1016/j.jmps.2016.02.010. Bibcode: 2016JMPSo..91...56C.

- ↑ Kaminakis, N; Stavroulakis, G (2012). "Topology optimization for compliant mechanisms, using evolutionary-hybrid algorithms and application to the design of auxetic materials". Composites Part B Engineering 43 (6): 2655–2668. doi:10.1016/j.compositesb.2012.03.018.

- ↑ Stetsenko, M (2015). "Determining the elastic constants of hydrocarbons of heavy oil products using molecular dynamics simulation approach". Journal of Petroleum Science and Engineering 126: 124–130. doi:10.1016/j.petrol.2014.12.021. https://zenodo.org/record/889919.

External links

- Materials with negative Poisson's ratio

- Auxetic foam in youtube

- General Information about Auxetic Materials

|

KSF

KSF