Acrylate

Topic: Chemistry

From HandWiki - Reading time: 3 min

From HandWiki - Reading time: 3 min

Acrylates (IUPAC: prop-2-enoates) are the salts, esters, and conjugate bases of acrylic acid. The acrylate ion is the anion CH

2=CHCO−

2. Often, acrylate refers to esters of acrylic acid, the most common member being methyl acrylate. These acrylates contain vinyl groups. These compounds are of interest because they are bifunctional: the vinyl group is susceptible to polymerization and the carboxylate group carries myriad functionalities.[1]

Monomers

Acrylates are defined by the formula CH

2=CHCO

2R, where R can be many groups:

- Acrylic acid

- Methyl acrylate

- Ethyl acrylate

- 2-Chloroethyl vinyl ether

- 2-Ethylhexyl acrylate

- Butyl acrylate

- Trimethylolpropane triacrylate (TMPTA)

The versatility of the resulting polymers is owed to the range of R groups.

- Structures of some acrylates

-

The acrylate anion

-

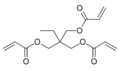

Trimethylolpropane triacrylate (TMPTA), a trifunctional acrylate ester

-

Methyl acrylate, an acrylic ester

-

Hexandiol diacrylate, a bifunctional acrylate

-

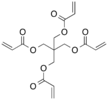

Pentaerythritol tetraacrylate (PETA), a tetrafunctional acrylate

-

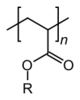

A generic polyacrylate

Acrylate derivatives

Methacrylates ( CH

2=C(CH

3)CO

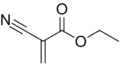

2R) and cyanoacrylates ( CH

2=C(CN)CO

2R,) are closely related to acrylates. The feature a methyl and a nitrile in place of the H alpha to the carboxy functional group. They share several properties, being polymerized by radicals and being colorless.[2]

- Structures of some important modified acrylates

-

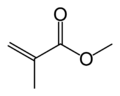

Methyl methacrylate, precursor to "perspex" (plexiglass)

-

Ethyl cyanoacrylate, precursor to "super glue"

Polymers

Some acrylate polymers (poly(methyl methacrylate) etc. not included):

Acrylate monomers are used to form acrylate polymers. Most commonly, these polymers are in fact copolymers, being derived from two monomers.[3][4]

Related polymers

In the same way that several variants of acrylic esters are known, so too are the corresponding polymers. Their properties strongly depends on the substituent.

A large family of acrylate-like polymers are derived from methyl methacrylate and many related esters, especially polymethyl methacrylate.

A second large family of acrylate-like polymers are derived from ethyl cyanoacrylate, which gives rise to cyanoacrylates.

Yet another family of acrylate-related polymers are the polyacrylamides, especially the parent derived from acrylamide.

Other uses

In addition to forming polymers, acrylate esters participate in other reactions relevant to organic chemistry. They are Michael acceptors and dienophiles. They undergo transesterification.

Production

Acrylates are industrially prepared by treating acrylic acid with the corresponding alcohol in presence of a catalyst. The reaction with lower alcohols (methanol, ethanol) takes place at 100–120 °C with acidic heterogeneous catalysts (cation exchanger). The reaction of higher alcohols (n-butanol, 2-ethylhexanol) is catalysed with sulfuric acid in homogeneous phase. Acrylates of even higher alcohols are obtainable by transesterification of lower esters catalysed by titanium alcoholates or organic tin compounds (e.g. dibutyltin dilaurate).[5]

See also

- Acrylate polymer

- Sodium polyacrylate thickeners

- Methacrylate

References

- ↑ Takashi Ohara; Takahisa Sato; Noboru Shimizu; Günter Prescher; Helmut Schwind; Otto Weiberg; Klaus Marten; Helmut Greim (2003). "Acrylic Acid and Derivatives". Ullmann's Encyclopedia of Industrial Chemistry. Weinheim: Wiley-VCH. doi:10.1002/14356007.a01_161.pub2. ISBN 3527306730.

- ↑ Veerle Coessens; Tomislav Pintauer; Krzysztof Matyjaszewski (2001). "Functional polymers by atom transfer radical polymerization". Functional polymers by atom transfer radical polymerization. 26. 337–377. doi:10.1016/S0079-6700(01)00003-X.

- ↑ Takashi Ohara; Takahisa Sato; Noboru Shimizu; Günter Prescher; Helmut Schwind; Otto Weiberg; Klaus Marten; Helmut Greim (2002). Ullmann's Encyclopedia of Industrial Chemistry. Weinheim: Wiley-VCH. doi:10.1002/14356007.a01_161.pub2. ISBN 978-3-527-30673-2.(Subscription content?)

- ↑ "Polyacrylates". http://pslc.ws/macrog/acrylate.htm.

- ↑ Arpe, Hans-Jürgen (2007). Industrielle organische Chemie: bedeutende Vor- und Zwischenprodukte. (6 ed.). Weinheim: Wiley-VCH. ISBN 978-3-527-31540-6.

|

KSF

KSF