Bio-energy with carbon capture and storage

Topic: Earth

From HandWiki - Reading time: 13 min

From HandWiki - Reading time: 13 min

Bio-energy with carbon capture and storage (BECCS) is a potential greenhouse gas mitigation technology which produces negative carbon dioxide emissions by combining bioenergy (energy from biomass) use with geologic carbon capture and storage.[1] The concept of BECCS is drawn from the integration of trees and crops, which extract carbon dioxide (CO2) from the atmosphere as they grow, the use of this biomass in processing industries or power plants, and the application of carbon capture and storage via CO2 injection into geological formations.[2] There are other non-BECCS forms of carbon dioxide removal and storage that include technologies such as biochar, carbon dioxide air capture and biomass burial[3] and enhanced weathering.

According to a recent Biorecro report, there is 550 000 tonnes CO2/year in total BECCS capacity currently operating, divided between three different facilities (as of January 2012).[2][4][5][6][7]

In the IPCC Fourth Assessment Report by the Intergovernmental Panel on Climate Change (IPCC), BECCS was indicated as a key technology for reaching low carbon dioxide atmospheric concentration targets.[8] The negative emissions that can be produced by BECCS has been estimated by the Royal Society to be equivalent to a 50 to 150 ppm decrease in global atmospheric carbon dioxide concentrations[9] and according to the International Energy Agency, the BLUE map climate change mitigation scenario calls for more than 2 gigatonnes of negative CO2 emissions per year with BECCS in 2050.[10] According to Stanford University, 10 gigatonnes is achievable by this date.[11]

The Imperial College London, the UK Met Office Hadley Centre for Climate Prediction and Research, the Tyndall Centre for Climate Change Research, the Walker Institute for Climate System Research, and the Grantham Institute for Climate Change issued a joint report on carbon dioxide removal technologies as part of the AVOID: Avoiding dangerous climate change research program, stating that "Overall, of the technologies studied in this report, BECCS has the greatest maturity and there are no major practical barriers to its introduction into today’s energy system. The presence of a primary product will support early deployment."[12]

According to the OECD, "Achieving lower concentration targets (450 ppm) depends significantly on the use of BECCS".[13]

Negative emission

The main appeal of BECCS is in its ability to result in negative emissions of CO2. The capture of carbon dioxide from bioenergy sources effectively removes CO2 from the atmosphere.[14]

Bio-energy is derived from biomass which is a renewable energy source and serves as a carbon sink during its growth. During industrial processes, the biomass combusted or processed re-releases the CO2 into the atmosphere. The process thus results in a net zero emission of CO2, though this may be positively or negatively altered depending on the carbon emissions associated with biomass growth, transport and processing, see below under environmental considerations.[15] Carbon capture and storage (CCS) technology serves to intercept the release of CO2 into the atmosphere and redirect it into geological storage locations.[16] CO2 with a biomass origin is not only released from biomass fuelled power plants, but also during the production of pulp used to make paper and in the production of biofuels such as biogas and bioethanol. The BECCS technology can also be employed on such industrial processes.[17]

It is argued that through the BECCS technology, carbon dioxide is trapped in geologic formations for very long periods of time, whereas for example a tree only stores its carbon during its lifetime. In its report on the CCS technology, IPCC projects that more than 99% of carbon dioxide which is stored through geologic sequestration is likely to stay in place for more than 1000 years. While other types of carbon sinks such as the ocean, trees and soil may involve the risk of negative feedback loops at increased temperatures, BECCS technology is likely to provide a better permanence by storing CO2 in geological formations.[2][18]

The amount of CO2 that has been released to date is believed to be too much to be able to be absorbed by conventional sinks such as trees and soil in order to reach low emission targets.[19] In addition to the presently accumulated emissions, there will be significant additional emissions during this century, even in the most ambitious low-emission scenarios. BECCS has therefore been suggested as a technology to reverse the emission trend and create a global system of net negative emissions.[1][8][19][20][21] This implies that the emissions would not only be zero, but negative, so that not only the emissions, but the absolute amount of CO2 in the atmosphere would be reduced.

Application

| Source | CO2 Source | Sector |

|---|---|---|

| Electrical power plants | Combustion of biomass or biofuel in steam or gas powered generators releases CO2 as a by-product | Energy |

| Heat power plants | Combustion of biofuel for heat generation releases CO2 as a by-product. Usually used for district heating | Energy |

| Pulp and paper mills |

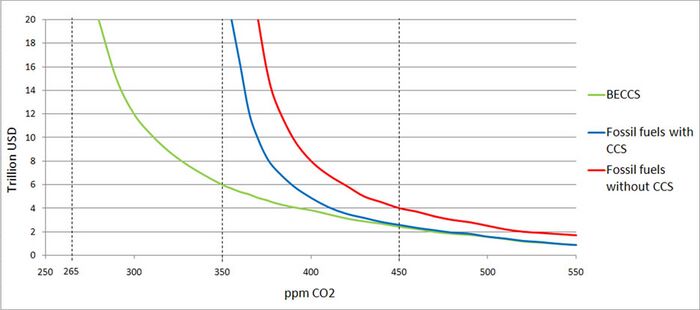

|

Industry |

| Ethanol production | Fermentation of biomass such as sugarcane, wheat or corn releases CO2 as a by-product | Industry |

| Biogas production | In the biogas upgrading process, CO2 is separated from the methane to produce a higher quality gas | Industry |

Technology

The main technology for CO2 capture from biotic sources generally employs the same technology as carbon dioxide capture from conventional fossil fuel sources. Broadly, three different types of technologies exist: post-combustion, pre-combustion, and oxy-fuel combustion.[23]

Cost

The sustainable technical potential for net negative emissions with BECCS has been estimated to 10 Gt of CO

2 equivalent annually, with an economic potential of up to 3.5 Gt of CO

2 equivalent annually at a cost of less than 50 €/tonne, and up to 3.9 Gt of CO

2 equivalent annually at a cost of less than 100 €/tonne.[24]

Currently, most schematic BECCS systems are not cost-efficient compared to normal CCS. The IPCC states that estimations for BECCS cost range from $60-$250 per ton of CO2.[25] On the other hand, "normal" CCS (from coal and natural gas processing) costs have been decreasing to less than $35 per ton.[26] With limited large-scale testing, BECCS faces many challenges to be a financially viable alternative.

Policy

Based on the current Kyoto Protocol agreement, carbon capture and storage projects are not applicable as an emission reduction tool to be used for the Clean Development Mechanism (CDM) or for Joint Implementation (JI) projects.[27] Recognising CCS technologies as an emission reduction tool is vital for the implementation of such plants as there is no other financial motivation for the implementation of such systems. There has been growing support to have fossil CCS and BECCS included in the protocol. Accounting studies on how this can be implemented, including BECCS, have also been done.[28]

Techno-economics of BECCS and the TESBiC Project

The largest and most detailed techno-economic assessment of BECCS was carried out by cmcl innovations and the TESBiC[29] group (Techno-Economic Study of Biomass to CCS) in 2012. This project recommended the most promising set of biomass fueled power generation technologies coupled with carbon capture and storage (CCS). The project outcomes lead to a detailed “biomass CCS roadmap” for the U.K..

Environmental considerations

Some of the environmental considerations and other concerns about the widespread implementation of BECCS are similar to those of CCS. However, much of the critique towards CCS is that it may strengthen the dependency on depletable fossil fuels and environmentally invasive coal mining. This is not the case with BECCS, as it relies on renewable biomass. There are however other considerations which involve BECCS and these concerns are related to the possible increased use of biofuels.

Biomass production is subject to a range of sustainability constraints, such as: scarcity of arable land and fresh water, loss of biodiversity, competition with food production, deforestation and scarcity of phosphorus.[30] It is important to make sure that biomass is used in a way that maximizes both energy and climate benefits. There has been criticism to some suggested BECCS deployment scenarios, where there would be a very heavy reliance on increased biomass input.[31]

Large areas of land would be required to operate BECCS on an industrial scale. To remove 10 billion tons of CO2, upwards of 300 million hectares of land area (larger than India) would be required.[25] As a result, BECCS risks using land that could be better suited to agriculture and food production, especially in developing countries.

These systems may have other negative side effects. There is however presently no need to expand the use of biofuels in energy or industry applications to allow for BECCS deployment. There is already today considerable emissions from point sources of biomass derived CO2, which could be utilized for BECCS. Though, in possible future bio-energy system upscaling scenarios, this may be an important consideration.

The BECCS process allows CO2 to be collected and stored directly from the atmosphere, rather than from a fossil source. This implies that any eventual emissions from storage may be recollected and restored simply by reiterating the BECCS-process. This is not possible with CCS alone, as CO2 emitted to the atmosphere cannot be restored by burning more fossil fuel with CCS.

Current projects

Most CCS projects include adding capture to an existing power plant, usually coal or another fossil fuel.[32] With complete capture, these processes would be carbon neutral. Decatur, Illinois in the United States has many corn plants run by Archer Daniels Midland (ADM), where corn is processed into syrups and ethanol.[32] The plant emits high amounts of carbon dioxide as a byproduct of the process. With the CCS fitting, the plant ideally becomes carbon negative, since corn absorbs carbon dioxide when it grows, and all the carbon dioxide produced during processing is being captured and sequestered in the Mount Simon sandstone.[32] The project cannot be completely carbon negative, as carbon dioxide is produced during the combustion of the ethanol that is being produced. The project is one of the only CCS projects in use to not be coupled with EOR. The Southern Illinois Basin is considered one of the best injection sites, due to its sandstone composition and depth (injection site is 2,000 meters below the surface),[33] as well as its possible capacity (geologists project storage capacity of 27-109 Gt carbon dioxide).[34]

See also

- Biosequestration

- Carbon dioxide removal

- Carbon negative

- Climate change mitigation scenarios

- Climate engineering

- List of emerging technologies

- Low-carbon economy

- United Nations Environment Programme

- Virgin Earth Challenge

References

- ↑ 1.0 1.1 Obersteiner, M. (2001). "Managing Climate Risk". Science 294 (5543): 786–7. doi:10.1126/science.294.5543.786b. PMID 11681318.

- ↑ 2.0 2.1 2.2 "Global Status of BECCS Projects 2010". Biorecro AB, Global CCS Institute. 2010. http://www.globalccsinstitute.com/publications/global-status-beccs-projects-2010/online/27026. Retrieved 2011-12-09.

- ↑ Rhodes, James S.; Keith, David W. (2008). "Biomass with capture: Negative emissions within social and environmental constraints: An editorial comment". Climatic Change 87 (3–4): 321–8. doi:10.1007/s10584-007-9387-4.

- ↑ "Global Technology Roadmap for CCS in Industry Biomass-based industrial CO2 sources: biofuels production with CCS". ECN. 2011. http://www.ecn.nl/docs/library/report/2011/e11012.pdf. Retrieved 2012-01-20.

- ↑ "First U.S. large demonstration-scale injection of CO2 from a biofuel production facility begins". http://www.sequestration.org/resources/topStories.html. Retrieved 20 January 2012.

- ↑ "Ethanol plant to sequester CO2 emissions". http://www.gctelegram.com/News/ethanol-plant-carbon-sequestration-3-13-10. Retrieved 20 January 2012.

- ↑ "Production Begins at Biggest Ethanol Plant in Kansas". http://www.ksallink.com/?cmd=displaystory&story_id=2504&format=print. Retrieved 20 January 2012.

- ↑ 8.0 8.1 Fisher, Brian; Nakicenovic, Nebojsa; Alfsen, Knut; Morlot, Jan Corfee; de la Chesnaye, Francisco; Hourcade, Jean-Charles; Jiang, Kejun; Kainuma, Mikiko et al.. "Issues related to mitigation in the long-term context". in Metz, Bert. Climate Change 2007: Mitigation of Climate Change. Working Group III contribution to the Fourth Assessment Report of the IPCC. pp. 169–250. ISBN 978-0-521-88011-4. http://www.ipcc.ch/pdf/assessment-report/ar4/wg3/ar4-wg3-chapter3.pdf.

- ↑ "Geoengineering the climate: science, governance and uncertainty". The Royal Society. 2009. http://royalsociety.org/Geoengineering-the-climate/. Retrieved 2010-08-22.

- ↑ "IEA Technology Roadmap Carbon Capture and Storage 2009". OECD/IEA. 2009. https://www.iea.org/papers/2009/CCS_Roadmap.pdf. Retrieved 2010-10-22.

- ↑ "Going negative: Stanford scientists explore new ways to remove atmospheric CO2". Stanford University. 2013. http://news.stanford.edu/pr/2013/pr-reducing-carbon-dioxide-021513.html. Retrieved 2013-03-17.

- ↑ "The Potential for the Deployment of Negative Emissions Technologies in the UK". Grantham Institute for Climate Change, Imperial College. 2010. http://www.avoid.uk.net/2010/07/avoid-1-the-potential-for-the-deployment-of-negative-emissions-technologies-in-the-uk/. Retrieved 2012-01-16.

- ↑ "OECD Environmental Outlook to 2050, Climate Change Chapter, pre-release version". OECD. 2011. http://www.oecd.org/dataoecd/32/53/49082173.pdf. Retrieved 2012-01-16.

- ↑ Read, Peter; Lermit, Jonathan (2005). "Bio-energy with carbon storage (BECS): A sequential decision approach to the threat of abrupt climate change". Energy 30 (14): 2654. doi:10.1016/j.energy.2004.07.003.

- ↑ g. Cassman, Kenneth; Liska, Adam J. (2007). "Food and fuel for all: Realistic or foolish?". Biofuels, Bioproducts and Biorefining 1: 18. doi:10.1002/bbb.3.

- ↑ Möllersten, Kenneth; Yan, Jinyue; r. Moreira, Jose (2003). "Potential market niches for biomass energy with CO2 capture and storage—Opportunities for energy supply with negative CO2 emissions". Biomass and Bioenergy 25 (3): 273. doi:10.1016/S0961-9534(03)00013-8.

- ↑ Möllersten, K.; Yan, J.; Westermark, M. (2003). "Potential and cost-effectiveness of CO2 reductions through energy measures in Swedish pulp and paper mills". Energy 28 (7): 691. doi:10.1016/S0360-5442(03)00002-1.

- ↑ IPCC, (2005)"Chapter 5: Underground geological storage" IPCC Special Report on Carbon dioxide Capture and Storage. Prepared by Working Group III of the Intergovernmental Panel on Climate Change [Metz, B., O. Davidson, H. C. De Coninck, M. Loos, and L. A. Meyer (eds.)]. Cambridge University Press, Cambridge, United Kingdom and New York, NY, USA, pp195-276.

- ↑ 19.0 19.1 Hare, Bill; Meinshausen, Malte (2006). "How Much Warming are We Committed to and How Much can be Avoided?". Climatic Change 75: 111. doi:10.1007/s10584-005-9027-9.

- ↑ 20.0 20.1 Azar, Christian; Lindgren, Kristian; Larson, Eric; Möllersten, Kenneth (2006). "Carbon Capture and Storage from Fossil Fuels and Biomass – Costs and Potential Role in Stabilizing the Atmosphere". Climatic Change 74: 47. doi:10.1007/s10584-005-3484-7.

- ↑ Lindfeldt, Erik G.; Westermark, Mats O. (2008). "System study of carbon dioxide (CO2) capture in bio-based motor fuel production". Energy 33 (2): 352. doi:10.1016/j.energy.2007.09.005.

- ↑ National Research Council (U.S.). Carbon Dioxide Assessment Committee (1983) Changing climate: report of the Carbon Dioxide Assessment Committee, National Academy Press, pp 186-188

- ↑ IPCC, (2005)"Chapter 3: Capture of CO2" IPCC Special Report on Carbon dioxide Capture and Storage. Prepared by Working Group III of the Intergovernmental Panel on Climate Change [Metz, B., O. Davidson, H. C. De Coninck, M. Loos, and L. A. Meyer (eds.)]. Cambridge University Press, Cambridge, United Kingdom and New York, NY, USA, pp 105-178.

- ↑ Koornneef, Joris; can Breevoort, Pieter; Hendricks, Chris; Hoogwijk, Monique; Koops, Klaus (July 2011), Potential for Biomass and Carbon Dioxide Capture and Storage, International Energy Agency Greenhouse Gas R&D Programme(IEAGHG), http://www.eenews.net/assets/2011/08/04/document_cw_01.pdf, retrieved 2012-01-20

- ↑ 25.0 25.1 "Extracting carbon from nature can aid climate but will be costly: U.N.". Reuters. 2017-03-26. https://www.reuters.com/article/us-climatechange-ccs-idUSBREA2P1LK20140326.

- ↑ "Carbon Capture Use and Storage | Center for Climate and Energy Solutions" (in en). https://www.c2es.org/technology/factsheet/CCS.

- ↑ Emission Trading Scheme (EU ETS) from ec.europa.eu

- ↑ Grönkvist, Stefan; Möllersten, Kenneth; Pingoud, Kim (2006). "Equal Opportunity for Biomass in Greenhouse Gas Accounting of CO2 Capture and Storage: A Step Towards More Cost-Effective Climate Change Mitigation Regimes". Mitigation and Adaptation Strategies for Global Change 11 (5–6): 1083. doi:10.1007/s11027-006-9034-9.

- ↑ "Archived copy". Archived from the original on 2012-11-06. https://web.archive.org/web/20121106035708/http://www.cmclinnovations.com/TESBIC/. Retrieved 2013-01-18.[full citation needed]

- ↑ Ignacy, S.: (2007) "The Biofuels Controversy", United Nations Conference on Trade and Development, 12

- ↑ "Carbon-negative bioenergy to cut global warming could drive deforestation: An interview on BECS with Biopact's Laurens Rademakers". November 6, 2007. https://news.mongabay.com/2007/11/carbon-negative-bioenergy-to-cut-global-warming-could-drive-deforestation/.

- ↑ 32.0 32.1 32.2 "Analysis: Negative emissions tested at world's first major BECCS facility | Carbon Brief" (in en-US). Carbon Brief. 2016-05-31. https://www.carbonbrief.org/analysis-negative-emissions-tested-worlds-first-major-beccs-facility.

- ↑ "5. Decatur, Illinois, United States | Global CCS Institute" (in en). https://hub.globalccsinstitute.com/publications/global-status-beccs-projects-2010/5-decatur-illinois-united-states.

- ↑ "Illinois Industrial Carbon Capture and Storage Project | Global Carbon Capture and Storage Institute" (in en). https://www.globalccsinstitute.com/projects/illinois-industrial-carbon-capture-and-storage-project.

External links

- Biorecro

- IEA Greenhouse Gas Programme

- Grantham Institute at the Imperial College, London

- The Natural Step Intl.

- Tyndall Center

- UNIDO

- University of Edinburgh/Tyndall Center[yes|permanent dead link|dead link}}]

- Zero Emission Resource Organisation(ZERO)

KSF

KSF