Knitting machine

Topic: Engineering

From HandWiki - Reading time: 4 min

From HandWiki - Reading time: 4 min

A knitting machine is a device used to create knitted fabrics in a semi or fully automated fashion.

There are numerous types of knitting machines, ranging from simple spool or board templates with no moving parts to highly complex mechanisms controlled by electronics. All, however, produce various types of knitted fabrics, usually either flat or tubular, and of varying degrees of complexity. Pattern stitches can be selected by hand manipulation of the needles, or with push-buttons and dials, mechanical punch cards, or electronic pattern reading devices and computers.

Process

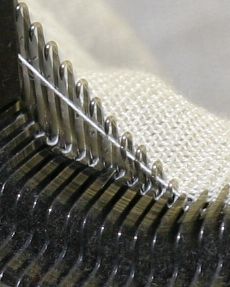

Early flat bed stocking frames had low carbon steel bearded needles where the tips were reflexed and could be depressed onto a hollow closing the loop. The needles were supported on a needle bar that passed back and forth, to and from the operator. The beards were simultaneously depressed by a presser bar.[1]

- The needle bar goes forward- the open needles clear the web

- The weft thread is laid on the needles

- The weft thread falls loosely

- The needle bar draws back, the weft is pulled in the open needles

- The needle bar draws back, the presser bar drops, the needle loops close and the weft is drawn back through the web

- The needles open, a new row has been added to the web which drops under gravity

This basic process can still be recognised in all machines, but it has been refined as new technologies have become available.

Types

A few simple devices permit knitting without needles for toy or hobby purposes. The simplest of these is spool knitting, followed by knitting boards or knitting looms, which consist of two rows of pins mounted in two parallel rows approximately 0.5 inches (1.3 cm) apart. Yarn is wound around the pins; various patterns of winding produce different textured knitting. A needle or special tool is then used to transfer the loops of yarn from around the pins, either off the pins or to other pins, to produce the knitting. Knitting boards can produce complex designs. Other semi-mechanical knitting devices are available.

To produce larger and more complex knitted items, such as garments, domestic and industrial machines, with either flat or circular beds, producing rectangular or tubular fabrics, respectively, are needed. Double bed machines have two flat beds facing each other, in order to produce purl and plain rib fabrics plus a variety of multi patterns. Ribbing attachments can be added to single bed machines to achieve a similar result.[2]

Late 20th century domestic/studio models typically use up to 200 latch-hook needles to hold the stitches in fine, standard, mid-gauge or bulky gauge needle. A carriage or cam box is passed across the bed of needles causing the needle movements required to produce each next stitch. By means of various selection methods, e.g. punch cards, particular needles can be caused to travel by alternate pathways through the cam box. Thus needles will knit or not, and the unknitted yarn portions will lie under (slip stitch) or over the needle or be held in the needle hook (tuck stitch). Needles can be placed in holding position to allow short row shaping.[2] In the most modern machines, punchcards have been replaced by computer control.

Automatic patterning machines can knit two-colour Fair Isle patterns automatically, and have machine stitch patterning features such as plating and knitweaving. Plating refers to knitting with two strands of yarn that are held in such a way that one is in front of the other. Plated effects can be particularly striking in a ribbed fabric. Knitweaving refers to a technique in which a separate piece of yarn, often heavier than the knitted fabric, is carried along and caught between stitches to produce an effect like weaving. With knitwoven fabric, the purl side (usually the wrong side) is the right side of the fabric. The fine and standard gauge models have the option of a lace carriage, where stitches can be transferred from one needle to the next. The yarn passes through a tensioning mechanism and down through the knit carriage, which feeds the yarn to the needles as they knit.

Domestic knitting machines use the weft knitting method which produces a fabric similar to hand knitting. Knitting proceeds more quickly than in hand knitting, where (usually two) straight needles are held in the hand and each stitch is manipulated individually across the row. Knitting machines work an entire row of loops in a single movement.

-

A hobbyist spool knitting machine operates on a crank.

-

A flatbed home knitting machine.

-

A sock-knitting machine in use.

-

A circular knitting machine

-

Circular Knitic open source hardware knitting machine

-

Knitting machine yarn bobbins

Comparison to hand knitting

The fabric produced using a knitting machine is of a more even texture than hand-knitted fabric, which is particularly noticeable on large areas of plain stockinette stitch, and can be an advantage. Some stitch patterns (e.g., tuck stitches) are much easier to produce with a knitting machine. Others (e.g. garter stitch) can also be produced with machine knitting but can take a little longer but still much faster than hand knitting. The standard gauge 200-needle machine can knit the finest yarns up to a good sport-weight, while the heavier yarns knit better on a mid-gauge or bulky knitting machine.

Machine knitting saves a considerable amount of time but does require learning to operate the machines correctly. Most if not all hand knitting patterns can be worked up on a machine, either identically or in a similar design. Hand knitting patterns are designed to "flip" the fabric on every row so that the knitter consistently uses the dominant hand. However, machine knitting is consistently knit with the fabric facing the same way. Flat Bed machines knit back and forth and Circular machines knit continuously in the round.

See also

- History of knitting

- Stocking frame – an antique type of knitting machine

- Luddites – a social movement of English textile artisans in the early 19th century

- Textile manufacturing

References

- ↑ Earnshaw 1986, pp. 12–13.

- ↑ 2.0 2.1 Hand Manipulated Stitches for Machine Knitters, Susan Gaugliumi (1990) p. 9

- Bibliography

- Earnshaw, Pat (1986). Lace Machines and Machine Laces. Batsford. ISBN 0713446846.

- Kinder, K. A Resource Book for Machine Knitters, self-published, 1989.

- Lewis, S. A Machine Knitter's Guide to Creating Fabrics, Sterling Publishing Company, 1986.

- Norbury, J. and Agutter, M. Odhams Encyclopaedia of Knitting, Odhams Press Ltd, (undated, c.1950).

- Taylor, C. Machine Knitting Encyclopedia, Concord Press, 1974.

- Thomas, M. Mary Thomas's Knitting Book, Hodder & Stoughton, 1938.

- Candee, Richard M. The Hand Cranked Knitter and Sock Machine, Cottonwood Hill Publishing, 2005

External links

KSF

KSF