Propulsion transmission

Topic: Engineering

From HandWiki - Reading time: 25 min

From HandWiki - Reading time: 25 min

Propulsion transmission is the mode of transmitting and controlling propulsion power of a machine. The term transmission properly refers to the whole drivetrain, including clutch, gearbox, prop shaft (for rear-wheel drive vehicles), differential, and final drive shafts. In the United States the term is sometimes used in casual speech to refer more specifically to the gearbox alone, and detailed usage differs. The transmission reduces the higher engine speed to the slower wheel speed, increasing torque in the process. Transmissions are also used on pedal bicycles, fixed machines, and where different rotational speeds and torques are adapted.

Often, a transmission has multiple gear ratios (or simply "gears") with the ability to switch between them as the speed varies. This switching may be done manually (by the operator) or automatically (by a control unit). Directional (forward and reverse) control may also be provided. Single-ratio transmissions also exist, which simply change the speed and torque (and sometimes direction) of motor output. Conventional gear/belt transmissions are not the only mechanism for speed/torque adaptation. Alternative mechanisms include torque converters and power transformation (e.g. diesel-electric transmission and hydraulic drive system). Hybrid configurations also exist. Automatic transmissions use a valve body to shift gears using fluid pressures in response to engine RPM, speed, and throttle input.

Often the term 5-speed transmission refers simply to the gearbox, that uses gears and gear trains to provide speed and torque block conversions from a rotating power source to another device.[1][2] The most common use is in motor vehicles, where the transmission adapts the output of the internal combustion engine to the drive wheels. Such engines need to operate at a relatively high rotational speed, which is inappropriate for starting, stopping, and slower travel. In motor vehicles, the transmission generally is connected to the engine crankshaft via a flywheel or clutch or fluid coupling, partly because internal combustion engines cannot run below a particular speed. The output of the transmission is transmitted via the driveshaft to one or more differentials, which drive the wheels. While a differential may also provide gear reduction, its primary purpose is to permit the wheels at either end of an axle to rotate at different speeds (essential to avoid wheel slippage on turns) as it changes the direction of rotation.

Explanation

Early transmissions included the right-angle drives and other gearing in windmills, horse-powered devices, and steam engines, in support of pumping, milling, and hoisting.

Most modern gearboxes are used to increase torque while reducing the speed of a prime mover output shaft (e.g. a motor crankshaft). This means that the output shaft of a gearbox rotates at a slower rate than the input shaft, and this reduction in speed produces a mechanical advantage, increasing torque. A gearbox can be set up to do the opposite and provide an increase in shaft speed with a reduction of torque. Some of the simplest gearboxes merely change the physical rotational direction of power transmission.

Many typical automobile transmissions include the ability to select one of several gear ratios. In this case, most of the gear ratios (often simply called "gears") are used to slow down the output speed of the engine and increase torque. However, the highest gears may be "overdrive" types that increase the output speed.

Uses

Gearboxes have found use in a wide variety of different—often stationary—applications, such as wind turbines.

Transmissions are also used in agricultural, industrial, construction, mining and automotive equipment. In addition to ordinary transmission equipped with gears, such equipment makes extensive use of the hydrostatic drive and electrical adjustable-speed drives.

Simple

The simplest transmissions, often called gearboxes to reflect their simplicity (although complex systems are also called gearboxes in the vernacular), provide gear reduction (or, more rarely, an increase in speed), sometimes in conjunction with a right-angle change in direction of the shaft (typically in helicopters, see picture). These are often used on PTO-powered agricultural equipment, since the axial PTO shaft is at odds with the usual need for the driven shaft, which is either vertical (as with rotary mowers), or horizontally extending from one side of the implement to another (as with manure spreaders, flail mowers, and forage wagons). More complex equipment, such as silage choppers and snowblowers, have drives with outputs in more than one direction. So too helicopters use a split-torque gearbox where power is taken from the engine in two directions for the different rotors.

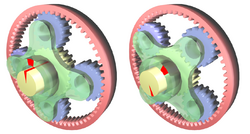

The gearbox in a wind turbine converts the slow, high-torque rotation of the turbine into much faster rotation of the electrical generator. These are much larger and more complicated than the PTO gearboxes in farm equipment. They weigh several tons and typically contain three stages to achieve an overall gear ratio from 40:1 to over 100:1, depending on the size of the turbine. (For aerodynamic and structural reasons, larger turbines have to turn more slowly, but the generators all have to rotate at similar speeds of several thousand rpm.) The first stage of the gearbox is usually a planetary gear, for compactness, and to distribute the enormous torque of the turbine over more teeth of the low-speed shaft.[3] Durability of these gearboxes has been a serious problem for a long time.[4]

Regardless of where they are used, these simple transmissions all share an important feature: the gear ratio cannot be changed during use. It is fixed at the time the transmission is constructed.

For transmission types that overcome this issue, see Continuously variable transmission, also known as CVT.

Multi-ratio systems

Many applications require the availability of multiple gear ratios. Often, this is to ease the starting and stopping of a mechanical system, though another important need is that of maintaining good fuel efficiency.

Automotive basics

The need for a transmission in an automobile is a consequence of the characteristics of the internal combustion engine. Engines typically operate over a range of 600 to about 7000 rpm (though this varies, and is typically less for diesel engines), while the car's wheels rotate between 0 RPM and around 1800 RPM.

Furthermore, the engine provides its highest torque and power outputs unevenly across the rev range resulting in a torque band and a power band. Often the greatest torque is required when the vehicle is moving from rest or traveling slowly, while maximum power is needed at high speed. Therefore, a system is required that transforms the engine's output so that it can supply high torque at low speeds, but also operate at highway speeds with the motor still operating within its limits. Transmissions perform this transformation.

The dynamics of a car vary with speed: at low speeds, acceleration is limited by the inertia of vehicular gross mass; while at cruising or maximum speeds wind resistance is the dominant barrier.

Many transmissions and gears used in automotive and truck applications are contained in a cast iron case, though more frequently aluminium is used for lower weight especially in cars. There are usually three shafts: the main shaft, a countershaft, and an idler shaft.

The main shaft extends outside the case in both directions: the input shaft towards the engine, and the output shaft towards the rear axle (on rear-wheel-drive cars. Front-wheel-drive vehicles generally have the engine and transmission mounted transversely, the differential being part of the transmission assembly.) The shaft is suspended by the main bearings, and is split towards the input end. At the point of the split, a pilot bearing holds the shafts together. The gears and clutches ride on the main shaft, the gears being free to turn relative to the mainshaft except when engaged by the clutches.

Manual

Manual transmissions come in two basic types:

- A simple but rugged sliding-mesh or unsynchronized/non-synchronous system; where straight-cut spur gear sets spin freely and must be synchronized by the operator matching engine revs to road speed, to avoid noisy and damaging clashing of the gears

- The now ubiquitous constant-mesh gearboxes; which can be/include unsynchronized/non-synchronized, or synchronized/synchromesh systems, where typically diagonal-cut helical (or sometimes either straight-cut, or double-helical) gear sets are constantly "meshed" together, and a dog clutch is used for changing gears. On synchromesh 'boxes, friction cones or "synchro-rings" are used in addition to the dog clutch to closely match the rotational speeds of the two sides of the (declutched) transmission before making a full mechanical engagement.

The former type was standard in many vintage cars (alongside; e.g., epicyclic and multi-clutch systems) before the development of constant-mesh manuals and hydraulic-epicyclic automatics, older heavy-duty trucks, and can still be found in use in some agricultural equipment. The latter is the modern standard for on- and off-road transport manual and automated manual transmissions, although it may be found in many forms; e.g., non-synchronized straight-cut in a racetrack or super-heavy-duty applications, non-synchro helical-cut in the majority of heavy-trucks and motorcycles, and in certain classic cars (e.g., the Fiat 500), and partly- or fully-synchronized helical in almost all modern manual-shift passenger cars and light trucks.

Manual transmissions are the most common type outside North America and Australia. They are cheaper, lighter, usually give better performance, but the newest automatic transmissions and CVTs give better fuel economy.[5][6] It is customary for new drivers to learn, and be tested, on a car with a manual gear change. In Malaysia and Denmark all cars used for testing (and because of that, virtually all those used for instruction as well) have a manual transmission. In Japan, the Philippines, Germany, Poland, Italy, Israel, the Netherlands, Belgium, New Zealand, Austria, Bulgaria, the UK,[7] Ireland, Sweden, Norway, Estonia, France, Spain, Switzerland, the Australian states of Victoria,[8] Western Australia and Queensland, Finland, Latvia,[9] Lithuania and the Czech Republic, a test pass using an automatic car does not entitle the driver to use a manual car on the public road; a test with a manual car is required.[citation needed] Manual transmissions are much more common than automatic transmissions in Asia, Africa, South America and Europe.

Manual gearboxes can include both synchromesh engagement and plain tooth to tooth engagement. For example, reverse gear is usually without synchromesh, as the driver is only expected to engage it when the vehicle is at a standstill. Many older (up to 1970s) cars also lacked synchromesh on first gear (for various reasons—cost, typically "shorter" overall gearing, engines typically having more low-end torque), meaning it also could only be used for moving away from a stop unless the driver became adept at double-declutching and had a particular need to regularly downshift into the lowest gear.

Some manual gearboxes have an extremely low ratio for first gear, Referred to in the UK as a crawler gear but some know it as a creeper gear or granny gear. Such gears are usually not engaged via a synchromesh mechanism. This feature is used on larger and heavier vehicles (Goods vehicles, coaches or those made for trailer-towing, farming, or construction-site work. During normal on-road use, the truck is usually driven without using the creeper gear at all, and second gear is used from a standing start. Some off-road vehicles, most particularly the Willys Jeep and its descendants, also had transmissions with "granny first's" either as standard or an option, but this function is now more often provided for by a low-range transfer gearbox attached to a normal fully synchromeshed gearbox.

Non-synchronous

Some commercial applications use non-synchronized manual transmissions that require a skilled operator. Depending on the country, many local, regional, and national laws govern the operation of these types of vehicles (see Commercial Driver's License). This class may include commercial, military, agricultural, or engineering vehicles. Some of these may use combinations of types for multi-purpose functions. An example is a power take-off (PTO) gear. The non-synchronous transmission type requires an understanding of gear range, torque, engine power, and multi-functional clutch and shifter functions. Sequential manual transmissions, which are commonly used in motorcycles and race cars, are a form of non-synchronous manual transmission.

Automatic

Most modern North American and some European and Japanese cars have an automatic transmission that selects an appropriate gear ratio without any operator intervention. They primarily use hydraulics to select gears, depending on pressure exerted by fluid within the transmission assembly. Rather than using a clutch to engage the transmission, a fluid flywheel, or torque converter is placed in between the engine and transmission. It is possible for the driver to control the number of gears in use or select reverse, though precise control of which gear is in use may or may not be possible.

Automatic transmissions are easy to use. However, in the past, some automatic transmissions of this type have had a number of problems; they were complex and expensive, sometimes had reliability problems (which sometimes caused more expenses in repair), have often been less fuel-efficient than their manual counterparts (due to "slippage" in the torque converter), and their shift time was slower than a manual making them uncompetitive for racing. With the advancement of modern automatic transmissions, this has changed.[10]

Attempts to improve the fuel efficiency of automatic transmissions include the use of torque converters that lock up beyond a certain speed or in higher gear ratios, eliminating power loss, and overdrive gears that automatically actuate above certain speeds. In older transmissions, both technologies could be intrusive, when conditions are such that they repeatedly cut in and out as speed and such load factors as grade or wind vary slightly. Current computerized transmissions possess complex programming that both maximizes fuel efficiency and eliminates intrusiveness. This is due mainly to electronic rather than mechanical advances, though improvements in CVT technology and the use of automatic clutches have also helped. A few cars, including the 2013 Subaru Impreza[11] and the 2012 model of the Honda Jazz sold in the UK, actually claim marginally better fuel consumption for the CVT version than the manual version.

For certain applications, the slippage inherent in automatic transmissions can be advantageous. For instance, in drag racing, the automatic transmission allows the car to stop with the engine at a high rpm (the "stall speed") to allow for a very quick launch when the brakes are released. In fact, a common modification is to increase the stall speed of the transmission. This is even more advantageous for turbocharged engines, where the turbocharger must be kept spinning at high rpm by a large flow of exhaust to maintain the boost pressure and eliminate the turbo lag that occurs when the throttle suddenly opens on an idling engine.

Continuously variable

The continuously variable transmission (CVT) is a transmission in which the ratio of the rotational speeds of two shafts, as the input shaft and output shaft of a vehicle or other machine, can be varied continuously within a given range, providing an infinite number of possible ratios. The CVT allows the driver or a computer to select the relationship between the speed of the engine and the speed of the wheels within a continuous range. This can provide even better fuel economy if the engine constantly runs at a single speed. The transmission is, in theory, capable of better user experience, without the rise and fall in the speed of an engine, and the jerk felt when changing gears poorly.

CVTs are increasingly found on small cars and especially high-gas-mileage or hybrid vehicles. On these platforms, the torque is limited because the electric motor can provide torque without changing the speed of the engine. By leaving the engine running at the rate that generates the best gas mileage for the given operating conditions, overall mileage can be improved over a system with a smaller number of fixed gears, where the system may be operating at peak efficiency only for a small range of speeds. CVTs are also found in agricultural equipment; due to the high-torque nature of these vehicles, mechanical gears are integrated to provide tractive force at high speeds. The system is similar to that of a hydrostatic gearbox, and at 'inching speeds' relies entirely on a hydrostatic drive. German tractor manufacturer Fendt pioneered the technology, developing its 'Vario - YouTube' transmission.

Electric variable

The Electric Variable Transmission (EVT or e-CVT) are used in hybrid vehicle combines the output of an electric motor and a gasoline engine, and like a CVT, provides continuously varied gear ratios.

In the common implementation, a gasoline engine is connected to a traditional transmission, which is in turn connected to an epicyclic gear system's planet carrier. An electric motor/generator is connected to the central "sun" gear, which is normally un-driven in typical epicyclic systems. Both sources of power can be fed into the transmission's output at the same time, splitting power between them. In common examples, between one-quarter and half of the engine's power can be fed into the sun gear. Depending on the implementation, the transmission in front of the epicyclic system may be greatly simplified or eliminated. EVTs are capable of continuously modulating output/input speed ratios like mechanical CVTs, but offer the distinct benefit of being able to also apply power from two different sources to one output, as well as potentially reducing overall complexity dramatically.

In typical implementations, the gear ratio of the transmission and epicyclic system is set to the ratio of the common driving conditions, say highway speed for a car, or city speeds for a bus. When the driver presses on the gas, the associated electronics interpret the pedal position and immediately set the gasoline engine to the RPM that provides the best gas mileage for that setting. As the gear ratio is normally set far from the maximum torque point, this set-up would normally result in very poor acceleration. Unlike gasoline engines, electric motors offer efficient torque across a wide selection of RPM and are especially effective at low settings where the gasoline engine is inefficient. By varying the electrical load or supply on the motor attached to the sun gear, additional torque can be provided to make up for the low torque output from the engine. As the vehicle accelerates, the power to the motor is reduced and eventually ended, providing the illusion of a CVT.

The canonical example of the e-CVT is Toyota's Hybrid Synergy Drive. This implementation has no conventional transmission, and the sun gear always receives 28% of the torque from the engine. This power can be used to operate any electrical loads in the vehicle, recharging the batteries, powering the entertainment system, or running the air conditioning system. Any residual power is then fed back into a second motor that powers the output of the drivetrain directly. At highway speeds, this additional generator/motor pathway is less efficient than simply powering the wheels directly. However, during acceleration, the electrical path is much more efficient than an engine operating so far from its torque point.[12] GM uses a similar system in the Allison Bus hybrid powertrains and the Tahoe and Yukon pick-up trucks, but these use a two-speed transmission in front of the epicyclic system, and the sun gear receives close to half the total power.

Automated manual

Automated manual transmission (AMT) denotes a type of multi-speed motor vehicle transmission system that is closely based on the mechanical design and build of a conventional manual transmission,[13][14][15][16][17] but uses automation to control either the clutch, and/or the gear shifting.

Modern versions of these systems began to appear on mass-production automobiles in the mid-1990s, and are fully-automatic in operation. Tradenames include Selespeed and Easytronic, and they can control both the clutch operation and the gear shifts automatically, by means of an ECU, therefore requiring no manual intervention or driver input over gear changes.[18][19]

The usage of modern computer-controlled AMTs in passenger cars increased during the mid-1990s, as a more sporting alternative to the traditional hydraulic automatic transmission. During the 2010s, AMTs were largely replaced by the increasingly widespread dual-clutch transmission design.

Clutchless manual / Semi-automatic

Semi-automatic transmission denotes a multi-speed motor vehicle transmission where part of its operation is automated (usually the clutch actuation), but the driver's input is still required to manually change gear ratios. Most semi-automatic transmissions used in cars and motorcycles are based on conventional manual transmissions or a sequential manual transmission, but use an automatic clutch system. Occasionally, however, some semi-automatic transmissions have also been based on standard hydraulic automatic transmissions, with a fluid coupling or torque converter, and using a planetary gearset.[20][21]

Names for specific types of semi-automatic transmissions include clutchless manual,[22][23] auto-manual,[24] auto-clutch manual,[25][26] and paddle-shift transmissions.[27][28][29] These systems facilitate gear shifts for the driver by operating the clutch system automatically, usually by means, or under control of an actuator or servo, and sensors, while still requiring the driver to manually shift gears

The first usage of semi-automatic transmissions was in automobiles, increasing in popularity in the mid-1930s when they were offered by several American car manufacturers. Less common than traditional (hydraulic) automatic transmissions, semi-automatic transmissions have nonetheless been made available on various car and motorcycle models, and currently remain in production. Semi-automatic transmissions with paddle-shift operation have been used in various racing cars, and were first introduced to control the electro-hydraulic gear shift mechanism of the Ferrari 640 Formula One race car in 1989.[30] These systems are currently used on a variety of top-level racing car classes; including Formula One, Indycar, and Touring car racing.[31][32] Other applications include motorcycles, trucks, buses, and railway vehicles.

Early semi-automatic systems used a variety of mechanical, electrical, pneumatic, and hydraulic systems—including centrifugal clutches, vacuum-operated clutches, torque converters, electro-pneumatic clutches, electro-mechanical (and even electrostatic) and servo/solenoid-controlled clutches, and control schemes—automatic clutching when moving the gearshift, pre-selector controls, centrifugal clutches with drum-sequential-shift, requiring the driver to lift the throttle for a successful shift, etc.—and some were little more than regular lock-up torque converter automatics with manual gear selection. Semi-automatic transmission systems on motorcycles generally use a centrifugal clutch.

An example of this transmission type in automobiles is the VW Autostick semi-automatic transmission; a conventional 3-speed manual transmission, with a vacuum-operated automatic clutch, plus a torque converter (like in a regular automatic), and a standard gear shifter.[33]

Semi-automatic transmissions on motorcycles and ATVs still require the driver to manually shift gears, and generally use a conventional sequential manual foot-shift lever, coupled with an automatic centrifugal clutch, so there is no manually-operated clutch lever on the handlebar for the driver to use, as it is a fully-automated clutch system.

Sequential manual

A sequential manual transmission (like the kind of gearbox used on a fully-manual motorcycle) is a type of multi-speed non-synchronous manual transmission, which only allows the driver to select either the next gear (e.g., shifting from second gear to first gear) or the previous gear (e.g. shifting from second gear to third gear), in a successive order. This restriction avoids accidentally selecting the wrong gear, however, it also prevents the driver from deliberately "skipping" gears. The clutch in a sequential manual transmission is only needed when going from a standstill (i.e., stationary; neutral) into first gear, after which the gears are forced into place by the dogs. This contrasts with a conventional manual transmission, which uses synchromesh for smooth gear shifts.[34] The use of dog-clutches (rather than synchromesh) results in faster shift speeds than a manual transmission.[35]

Sequential manual transmissions use the rotation of a drum and selector forks to switch gears, like what is used on a fully-manual motorcycle transmission.[36] The shift-drum mechanism is connected and rotated in a fore-and-aft motion by either a mechanical linkage (e.g., shift lever) or via an electro-pneumatic or electro-hydraulic control system, which typically will mechanically connect to the shift forks and dog clutches, and is operated with paddle-shifters, behind the steering wheel. They can also be designed with manual or automatic clutch systems. Semi-automatic sequential transmissions (with automatic clutches) may be found both in automobiles (mainly track and some rally racecars, e.g. paddle-shift), motorcycles (typically light "step-thru" type city utility bikes, e.g.; the Honda Super Cub) and quad bikes (often with a separately engaged reversing gear), the latter two normally using a scooter-style centrifugal clutch.

On a sequential manual transmission, the shift lever operates a ratchet mechanism that converts the fore and aft motion of the shift lever into rotation of a selector drum (sometimes called a barrel) which has three or four tracks machined around its circumference.[37] Selector forks are guided by the tracks, either directly or via selector rods. The tracks deviate around the circumference and as the drum rotates, the selector forks are moved to select the required gear.[38]

Bicycle gearing

Bicycles usually have a system for selecting different gear ratios. There are two main types: derailleur gears and hub gears. The derailleur type is the most common, and the most visible, using sprocket gears. Typically there are several gears available on the rear sprocket assembly, attached to the rear wheel. A few more sprockets are usually added to the front assembly as well. Multiplying the number of sprocket gears in front by the number to the rear gives the number of gear ratios, often called "speeds".

Several attempts have been made to fit bicycles with an enclosed gearbox, giving obvious advantages for better lubrication, dirt-sealing and shifting. These have usually been in conjunction with a shaft drive, as a gearbox with a traditional chain would (like the hub gear) still have many of the derailleur's disadvantages for an exposed chain. Bicycle gearboxes are enclosed in a box replacing the traditional bottom bracket. The requirement for a modified frame has been a serious drawback to their adoption. One of the most recent attempts to provide a gearbox for bicycles is the 18 speed Pinion P1.18.[39][40][41] This gives an enclosed gearbox, but still a traditional chain. When fitted to a rear suspension bike, it also retains a derailleur-like jockey cage chain tensioner, although without the derailleur's low ground clearance.

Causes for failure of bicycle gearing include worn teeth, damage caused by a faulty chain, damage due to thermal expansion, broken teeth due to excessive pedaling force, interference by foreign objects, and loss of lubrication due to negligence.

Uncommon types

Dual-clutch transmission

A dual-clutch transmission (DCT) (sometimes referred to as a twin-clutch transmission, or a double-clutch transmission) is a type of multi-speed vehicle transmission system, that uses two separate clutches for odd and even gear sets.[42] The design is often similar to two separate manual transmissions with their respective clutches contained within one housing, and working as one unit.[43][44] In car and truck applications, the DCT functions as an automatic transmission, requiring no driver input to change gears.

A dual-clutch transmission uses two sets of internals, each with its own clutch, so that a "gearchange" actually only consists of one clutch engaging as the other disengages—providing a supposedly "seamless" shift with no break in (or jarring reuptake of) power transmission. Each clutch's attached shaft carries half of the total input gear complement (with a shared output shaft), including synchronized dog clutch systems that pre-select which of its set of ratios is most likely needed at the next shift, under command of a computerized control system. Specific types of this transmission include: Direct-Shift Gearbox and Twin-Clutch SST.

Infinitely variable

The IVT is a specific type of CVT that includes not only an infinite number of gear ratios, but an "infinite" range as well. This is a turn of phrase, it actually refers to CVTs that are able to include a "zero ratio", where the input shaft can turn without any motion of the output shaft while remaining in gear. The gear ratio, in that case, is not "infinite" but is instead zero.

Most (if not all) IVTs result from the combination of a CVT with an epicyclic gear system with a fixed ratio. The combination of the fixed ratio of the epicyclic gear with a specific matching ratio in the CVT side results in zero output. For instance, consider a transmission with an epicyclic gear set to 1:−1 gear ratio; a 1:1 reverse gear. When the CVT side is set to 1:1 the two ratios add up to zero output. The IVT is always engaged, even during its zero output. When the CVT is set to higher values it operates conventionally, with increasing forward ratios.

In practice, the epicyclic gear may be set to the lowest possible ratio of the CVT, if reversing is not needed or is handled through other means. Reversing can be incorporated by setting the epicyclic gear ratio somewhat higher than the lowest ratio of the CVT, providing a range of reverse ratios.

Direct-drive mechanism

A direct-drive mechanism is where the transmitting of mechanical power and torque from an electric motor to the output device (such as the driven wheels of a car) occurs without any gearing reductions.[45][46][47]

Several cars from the late 19th century used direct-drive wheel hub motors, as did some concept cars in the early 2000s; however, most modern electric cars use inboard motor(s), where drive is transferred to the wheels, via the driveshaft or axles.[48][49]

Non-direct

Electric

Electric transmissions convert the mechanical power of the engine(s) to electricity with electric generators and convert it back to mechanical power with electric motors. Electrical or electronic adjustable-speed drive control systems are used to control the speed and torque of the motors. If the generators are driven by turbines, such arrangements are called turbo-electric transmission. Likewise, installations powered by diesel-engines are called diesel-electric.

Diesel-electric arrangements are used on many railway locomotives, ships, large mining trucks, and some bulldozers. In these cases, each driven wheel is equipped with its own electric motor, which can be fed varying electrical power to provide any required torque or power output for each wheel independently. This produces a much simpler solution for multiple driven wheels in very large vehicles, where driveshafts would be much larger or heavier than the electrical cable that can provide the same amount of power. It also improves the ability to allow different wheels to run at different speeds, which is useful for steered wheels in large construction vehicles.

Hydrostatic

- See also Continuously variable transmission > Hydrostatic CVTs

Hydrostatic transmissions transmit all power hydraulically, using the components of hydraulic machinery. They are similar to electrical transmissions but use the hydraulic fluid as the power distribution system rather than electricity.

The transmission input drive is a central hydraulic pump and the final drive unit(s) is/are a hydraulic motor or hydraulic cylinder (see: swashplate). Both components can be placed physically far apart on the machine, being connected only by flexible hoses. Hydrostatic drive systems are used on excavators, lawn tractors, forklifts, winch drive systems, heavy lift equipment, agricultural machinery, earth-moving equipment, etc. An arrangement for motor-vehicle transmission was probably used on the Ferguson F-1 P99 racing car in about 1961.

The Human Friendly Transmission of the Honda DN-01 is hydrostatic.

Hydrodynamic

If the hydraulic pump or hydraulic motor makes use of the hydrodynamic effects of the fluid flow, i.e. pressure due to a change in the fluid's momentum as it flows through vanes in a turbine. The pump and motor usually consist of rotating vanes without seals and are typically placed in proximity. The transmission ratio can be made to vary by means of additional rotating vanes, an effect similar to varying the pitch of an airplane propeller.

The torque converter in most automotive automatic transmissions is, in itself, a hydrodynamic transmission. Hydrodynamic transmissions are used in many passenger rail vehicles, those that are not using electrical transmissions. In this application, the advantage of smooth power delivery may outweigh the reduced efficiency caused by turbulence energy losses in the fluid.

See also

Notes

References

- ↑ J. J. Uicker; G. R. Pennock; J. E. Shigley (2003). Theory of Machines and Mechanisms (3rd ed.). New York: Oxford University Press. ISBN 9780195155983.

- ↑ B. Paul (1979). Kinematics and Dynamics of Planar Machinery. Prentice Hall.

- ↑ Stiesdal, Henrik (August 1999), The wind turbine: Components and operation, http://transmissionrepairguy.com/wp-content/uploads/2014/08/How-A-Turbine-Works.pdf, retrieved 2009-10-06

- ↑ Musial, W.; Butterfield, S.; McNiff, B. (May 2007), Improving Wind TurbineGearbox Reliability, National Renewable Energy Laboratory, http://www.nrel.gov/wind/pdfs/41548.pdf, retrieved July 2, 2013

- ↑ "Experts predict nine-, 10-speed transmissions to dominate in North America". Autoweek. May 13, 2013. http://www.autoweek.com/article/20130513/carnews/130519940.

- ↑ "Ford, GM work together on new nine-, 10-speed transmissions". Autoweek. April 15, 2013. http://www.autoweek.com/article/20130415/carnews/130419905.

- ↑ "Practical Driving Test FAQs". Dvtani.gov.uk. 2009-10-04. http://www.dvtani.gov.uk/practicaldrivingtest/carfaqs.asp#15.

- ↑ "Victorian restrictions on probationary drivers". Vicroads.vic.gov.au. 2014-01-14. http://www.vicroads.vic.gov.au/Home/Licences/GetYourPs/RestrictionsOnPs/P1andP2Probationarylicencerestrictions.htm.

- ↑ "Transportlīdzekļu vadītāja tiesību iegūšanas un atjaunošanas kārtība un vadītāja apliecības izsniegšanas, apmaiņas, atjaunošanas un iznīcināšanas kārtība" (in lv). Likumi.lv. http://www.likumi.lv/doc.php?id=205042#p51.

- ↑ "All Pro Transmissions". All Pro Transmissions. https://allpromilwaukee.com/.

- ↑ "2013 Subaru Impreza Wagon AWD". fueleconomy.gov. http://www.fueleconomy.gov/feg/PowerSearch.do?action=noform&path=7&year=2013&make=Subaru&model=Impreza%20Wagon%20AWD&srchtyp=ymm.

- ↑ "The Prius 'Continuously Variable Transmission'". Prius.ecrostech.com. 2001-10-10. http://prius.ecrostech.com/original/Understanding/ContinuouslyVariableTransmission.htm.

- ↑ (in en) 5 Transmissions - Cost, Effectiveness, and Deployment of Fuel Economy Technologies for Light-Duty Vehicles. 2015. doi:10.17226/21744. ISBN 978-0-309-37388-3. https://www.nap.edu/read/21744/chapter/7#172. Retrieved 26 July 2020.

- ↑ Yulong, Lei; Hua, Tian (11 April 2005) (in en). Research on Accurate Engagement Control of Electrohydraulic Clutch Actuator. SAE Technical Paper Series. 1. doi:10.4271/2005-01-1787. https://www.sae.org/publications/technical-papers/content/2005-01-1787/. Retrieved 26 July 2020.

- ↑ "Transmission Actuation". https://www.fte-automotive.com/fileadmin/user_upload/Valeo_Getriebe_EN_web.pdf.

- ↑ "Manual Transmission". https://www.autozine.org/technical_school/gearbox/Gearbox_Manual.html.

- ↑ "Manual vs Automatic Transmission: A Shift to Know About | RepairSmith Blog". May 6, 2020. https://www.repairsmith.com/i/blog/manual-vs-automatic-transmission-shift-know-about/.

- ↑ "Directly from the Formula 1". https://www.magnetimarelli.com/press_room/news/directly-formula-1.

- ↑ "Introduction to Automatic Transmission Systems". https://www.tranzmile.com/news/introduction-to-automatic-transmission-systems/.

- ↑ Wan, Mark (2019). "AutoZine Technical School, Manual Transmission". https://www.autozine.org/technical_school/gearbox/Gearbox_Manual.html.

- ↑ "How to Shift Gears on a Motorcycle". 21 September 2020. https://www.wikihow.com/Shift-Gears-on-a-Motorcycle.

- ↑ Hunting, Benjamin (11 December 2020). "A brief history of missing clutch pedals and almost-automatics". Hagerty. https://www.hagerty.com/media/automotive-history/a-brief-history-of-missing-clutch-pedals-and-almost-automatics/.

- ↑ "Accessing America: Shifting Gears". National Museum of American History. 2 January 2018. https://americanhistory.si.edu/america-on-the-move/shifting-gears.

- ↑ "1993 Ferrari Mondial T Cabriolet Valeo". October 2018. https://bringatrailer.com/listing/1993-ferrari-mondial-t-cabriolet-2/.

- ↑ "2021 Yamaha TT-R110E Trail Motorcycle - Photo Gallery, Video, Specs, Features, Offers, Inventory and more". https://www.yamahamotorsports.com/trail-motorcycle/models/tt-r110e.

- ↑ "How to make any bike an AUTOMATIC - YouTube". https://www.youtube.com/watch?v=XC29R9CSx-M.

- ↑ "Geartronics - Sequential gearbox electronic systems - Professional paddle shift system". http://www.geartronics.co.uk/paddleshift.htm.

- ↑ "Semi-Auto Systems". https://www.hewland.com/wpcproduct/semi-auto-systems/.

- ↑ "Control components for race series reduce cost, improve competition". https://www.hewland.com/race-series-control-components/.

- ↑ "John Barnard on working for Enzo Ferrari , engineering Schumacher, and his best F1 innovations". F1. 15 April 2021. https://www.formula1.com/en/latest/article.listen-to-john-barnard-f1-podcast.BMSWfX9hs5BvvOWoM9xvF.html.

- ↑ "The history of the 'paddle shift'". 2011-02-21. https://www.lemans.org/en/news/the-history-of-the-paddle-shift/2922.

- ↑ "Ferrari F1-89". http://formula1.ferrari.com/cars/f1-89.

- ↑ Stoklosa, Alexander (16 December 2015). "The Bug's Life: A History of the Volkswagen Beetle". Car and Driver. https://www.caranddriver.com/features/g15378761/volkswagen-beetle-models-by-year/.

- ↑ "Gearbox technologies". 27 October 2016. https://drivingfast.net/gearbox-technologies-explained/.

- ↑ "How Sequential Gearboxes Work" (in en). 4 April 2003. https://auto.howstuffworks.com/sequential-gearbox.htm.

- ↑ Marshall Brain (4 April 2003). "How Sequential Gearboxes Work". Howstuffworks.com. http://auto.howstuffworks.com/sequential-gearbox.htm.

- ↑ "How Sequential Gearboxes Work" (in en). 4 April 2003. https://auto.howstuffworks.com/sequential-gearbox1.htm.

- ↑ "BMW M3 SMG - Short Take Road Test - Auto Reviews". Car and Driver. http://www.caranddriver.com/reviews/hot_lists/high_performance/german_performance/bmw_m3_smg_short_take_road_test.

- ↑ Ben Coxworth (13 March 2013). "Pinion sealed gearbox offers an alternative to those darn derailleurs". Gizmag. http://www.gizmag.com/pinion-p118-sealed-gearbox/26640/.

- ↑ Matt Wragg (6 June 2012). "Pinion P1.18 Gearbox: First Ride". Pinkbike. http://www.pinkbike.com/news/Pinion-Gearbox-First-Ride.html.

- ↑ "The Gearmakers". Pinion. http://pinion.eu/en/.

- ↑ "Powertrain — transmissions: Shift in power to the gearbox". AMS (UnofficialBMW.com). September–October 2003. http://www.unofficialbmw.com/images/SHIFT1.pdf. Retrieved 31 October 2009.

- ↑ "Automatic-shifting dual-clutch transmissions are poised to grab share from traditional transmissions thanks to their combination of efficiency and convenience". AEI-online.org (DCTfacts.com). June 2009. http://www.dctfacts.com/documents/1-117-6-20.pdf. Retrieved 31 October 2009.

- ↑ "Porsche Doppelkupplung (PDK)". Porsche.com. http://www.porsche.com/microsite/technology/default.aspx?pool=uk&ShowSingleTechterm=PTPDopKuGe&Category=&Model=&SearchedString=&SelectedVariant=.

- ↑ "What Is Direct Drive Gear?". autoblog.com. 30 November 2015. https://www.autoblog.com/2015/11/30/what-is-direct-drive-gear/.

- ↑ Vanderwerp, Dave (5 September 2019). "Why the Porsche Taycan EV's Two-Speed Transmission Is a Big Deal". Car and Driver. https://www.caranddriver.com/news/a28903274/porsche-taycan-transmission/.

- ↑ "What Is a Direct Drive Motor?". Electric Torque Machines. https://etmpower.com/learn-more/what-is-a-direct-drive-motor/.

- ↑ "In-wheel motor". Nissan Motor Corporation. https://www.nissan-global.com/EN/TECHNOLOGY/OVERVIEW/in_wheel_motor.html.

- ↑ "How Do All-Electric Cars Work?". Alternative Fuels Data Center. U.S. Department of Energy. https://afdc.energy.gov/vehicles/how-do-all-electric-cars-work.

Further reading

- Harald Naunheimer; Peter Fietkau; G Lechner (2011). Automotive transmissions : fundamentals, selection, design and application (2nd ed.). Springer. doi:10.1007/978-3-642-16214-5. ISBN 9783642162138.

External links

- Manual Transmission Operation on YouTube WeberAuto 2012-09-23

KSF

KSF