Small modular reactor

Topic: Engineering

From HandWiki - Reading time: 35 min

From HandWiki - Reading time: 35 min

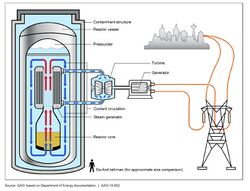

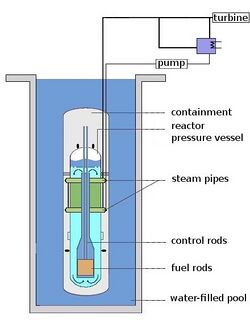

Small modular reactors (SMRs) are a class of small nuclear fission reactors, designed to be built in a factory, shipped to operational sites for installation and then used to power buildings or other commercial operations. The first commercial SMR was invented by a team of nuclear scientists at Oregon State University (OSU) in 2007.[1] Working with OSU's prototype, NuScale Power developed the first working model, available to the US market, in 2022.[2] The term SMR refers to the size, capacity and modular construction. Reactor type and the nuclear processes may vary. Of the many SMR designs, the pressurized water reactor (PWR) is the most common. However, recently proposed SMR designs include: generation IV, thermal-neutron reactors, fast-neutron reactors, molten salt, and gas-cooled reactor models.[3]

Military specified small reactors were first designed in the 1950s to power ballistic missile submarines and ships (aircraft carriers and ice breakers) with nuclear propulsion.[4] The electrical output for modern naval reactors are generally limited to less than 165 MWe and dedicated to powering turboshaft props rather than delivering commercial electricity. In addition, there are many more safety controls absent from naval reactors due to the space limitations these reactors were designed for.

Commercial SMRs can be designed to deliver an electrical power output as low as 5 MWe (electric) or a maximum of 1000 MWe. SMRs may also be designed purely for desalinization or facility heating rather than electricity. These SMRs are measured in megawatt thermals MWt. Many SMR designs rely on a modular system, allowing customers to simply add modules to achieve a desired megawatt output (MWe). Some SMR designs[which?], typically those using Generation IV reactors technologies, aim to secure additional economic advantage through improvements in electrical generating efficiency from much higher temperature steam generation. Ideally, modular reactors are expected to reduce on-site construction, increase containment efficiency, and claim to enhance safety. However, other SMR manufacturers claim greater safety should come through the application of passive safety features that operate without human intervention. Passive safety is a concept already implemented in some conventional nuclear reactor types. SMRs should also help reduce power plant staffing costs, as their operation is fairly simple.[5][6] and are claimed to have the ability to bypass financial and safety barriers that inhibit the construction of conventional reactors.[6][7]

As of 2023, only China and Russia have successfully built operational SMRs. The US Department of Energy had estimated the first SMR in the United States would be completed by NuScale Power around 2030,[8] but this deal has since fallen through after the customers backed out due to rising costs.[9] There are more than 80 modular reactor designs under development in 19 countries.[10] Russia has been operating a floating nuclear power plant Akademik Lomonosov, in Russia's Far East (Pevek), since October 2022. The floating plant is the first of its kind in the world. China's pebble-bed modular high-temperature gas-cooled reactor HTR-PM was connected to the grid in 2021.[10]

SMRs differ in terms of staffing, safety and deployment time.[11] US government studies to evaluate SMR-associated risks are claimed to have slowed the licensing process.[12][13][14] One main concern with SMRs and their large number, needed to reach an economic profitability, is preventing nuclear proliferation.[15][16]

Background

Hope of enhanced safety and reduced costs

Economic factors of scale mean that nuclear reactors tend to be large, to such an extent that size itself becomes a limiting factor. The 1986 Chernobyl disaster and the 2011 Fukushima nuclear disaster caused a major set-back for the nuclear industry, with worldwide suspension of development, cutting down of funding, and closure of reactor plants.

In response, a new strategy was introduced by American SMR manufacturer, NuScale Power, aimed at building smaller reactors, which were expected to be faster to fabricate, safer to operate, and operate at lower cost per reactor. Despite the loss of scale advantages and considerably less power output, funding was expected to be easier thanks to the introduction of modular construction and projects with anticipated shorter timescales. The generic SMR proposal is to swap the economies of unit scale for the economies of unit mass production.[17][18]

Proponents claim that SMRs would be less expensive due to the use of standardized modules that could be industrially produced off-site in a dedicated factory.[19] SMRs do, however, also have economic disadvantages.[20] Several studies suggest that the overall costs of SMRs are comparable with those of conventional large reactors. Moreover, extremely limited information about SMR modules transportation has been published.[21] Critics say that modular building will only be cost-effective for a high number of the same SMR type, given the still remaining high costs for each SMR.[22] A high market share is thus needed to obtain sufficient orders.

Contribution to the net zero emissions pathways

In her global pathway to reach net zero emissions by 2050, the International Energy Agency (IEA) considers that the worldwide nuclear power should be multiplied by two between 2020 and 2050.[23] Antonio Vaya Soler, an expert from the Nuclear Energy Agency (NEA), also acknowledges that if the renewable energies are an essential component to fight global warming, they will not be sufficient for achieving the net zero CO

2 emissions targets. To reach the objectives, the nuclear energy capacity should at least be doubled from the current level to be consistent with the net zero pathway.[24]

To produce the same electrical power than the ~ 400 large nuclear power reactors presently in operation in the world today, BASE, the German Federal Office for the Safety of Nuclear Waste Management also estimates that it would be necessary to build several thousands to tens of thousands SMRs.[4][25]

So, several fleets of SMR reactors of exactly the same type, and industrially manufactured in large series through factory production, should be rapidly and massively deployed worldwide to deliver a sufficient power output to significatively contribute to the net zero emissions of CO

2. The Nuclear Energy Agency (NEA) has launched at the COP 28 a new initiative "Accelerating SMRs for Net Zero" to foster collaborations between research organizations, nuclear industry, safety authorities, and governments, in order to rapidly reduce carbon emissions for reaching the net zero emissions targets required before 2050 to limit the Earth global surface temperature increase.[26][27][28]

Future challenges

Proponents say that nuclear energy with proven technology would be safe; the nuclear industry contends that smaller size will make SMRs even safer than larger conventional plants. Critics say that many more[4] small nuclear reactors pose a higher risk, requiring more transportation of nuclear fuel and also increasing the production of radioactive waste.[29] SMRs require new designs with new technology, the safety of which has yet to be proven.

Until 2020, no truly modular SMRs had been commissioned for commercial use.[30] In May 2020, the first prototype of a floating nuclear power plant with two 30 MWe reactors – the type KLT-40 – started operation in Pevek, Russia.[31] This concept is based on the design of nuclear icebreakers.[32] The operation of the first commercial land-based, 125 MWe demonstration reactor ACP100 (Linglong One) is due to start in China by the end of 2026.[33]

To cope with the 2050 targets of net zero CO

2 emissions without wasting time, a rapid and massive deployment of a large number of SMRs (several thousands to tens of thousands of units)[4] is critical and represents an unprecedented challenge for the nuclear industry, the safety authorities, and the civil society (acceptance by the public, the politicians, and the governments in the larger countries), in the short time frame considered.

Designs

SMRs are envisioned in multiple designs. Some are simplified versions of current reactors, others involve entirely new technologies.[34] All proposed SMRs use nuclear fission with designs including thermal-neutron reactors and fast-neutron reactors.

Thermal-neutron reactors

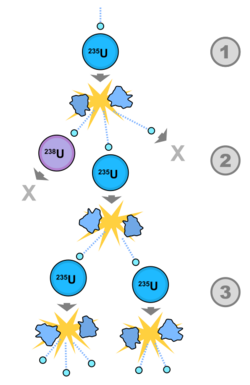

Thermal-neutron reactors rely on a moderator (water, graphite, beryllium...) to slow neutrons and generally use 235U as fissile material. Most conventional operating reactors are of this type.

Fast reactors

Fast reactors don't use moderators. Instead they rely on the fuel to absorb fast neutrons. This usually means changing the fuel arrangement within the core, or using different fuels. E.g., 239Pu is more likely to absorb a fast neutron than 235U.

Fast reactors can be breeder reactors. These reactors release enough neutrons to transmute non-fissionable elements into fissionable ones. A common use for a breeder reactor is to surround the core by a "blanket" of 238U, the most easily available isotope. Once the 238U undergoes a neutron absorption reaction, it becomes 239Pu, which can be removed from the reactor during refueling, and subsequently reprocessed and used as fuel.[35]

Technologies

Coolant

Conventional light-water reactors typically use water as a coolant and neutron moderator.[36] SMRs may use water, liquid metal, gas and molten salt as coolants.[37][38] Coolant type is determined based on the reactor type, reactor design, and the chosen application. Large-rated reactors primarily use light water as coolant, allowing for this cooling method to be easily applied to SMRs. Helium is often elected as a gas coolant for SMRs because it yields a high plant thermal efficiency and supplies a sufficient amount of reactor heat. Sodium, lead, and lead-bismuth eutectic (LBE) are liquid metal coolants studied for 4th generation SMRs. There was a large focus on sodium during early work on large-rated reactors which has since carried over to SMRs to be a prominent choice as a liquid metal coolant.[39] SMRs have lower cooling water requirements, which expands the number of sites where a SMR could be built, including remote areas typically incorporating mining and desalination.[40]

Thermal/electrical generation

Some gas-cooled reactor designs could drive a gas turbine, rather than boiling water, such that thermal energy can be used directly. Heat could also be used in hydrogen production and other industrial operations,[37] such as desalination and the production of petroleum derivative (extracting oil from oil sands, making synthetic oil from coal, etc.).[41]

Load following

SMR designs are generally expected to provide base load electrical power; some proposed designs are aimed to adjust their power output based on electricity demand.[citation needed]

Another approach, especially for SMRs designed to provide high temperature heat, is to adopt cogeneration, maintaining consistent heat output, while diverting otherwise unneeded heat to an auxiliary use. District heating, desalination and hydrogen production have been proposed as cogeneration options.[42]

Overnight desalination requires sufficient freshwater storage capacity to deliver water at times other than when it is produced.[43] Reverse osmosis membrane and thermal evaporators are the two main techniques for seawater desalination. The membrane desalination process uses only electricity to power water pumps and is the most employed of the two methods. In the thermal process, the feed water stream is evaporated in different stages with continuous decreases in pressure between the stages. The thermal process directly uses thermal energy and avoids the conversion of thermal power into electricity. Thermal desalination is further divided into two main technologies: the multi-stage flash distillation (MSF) and the Multi-Effect Desalination (MED).[44]

Nuclear safety

A report by the German Federal Office for the Safety of Nuclear Waste Management (BASE) considering 136 different historical and current reactors and SMR concepts stated: "Overall, SMRs could potentially achieve safety advantages compared to power plants with a larger power output, as they have a lower radioactive inventory per reactor and aim for a higher safety level especially through simplifications and an increased use of passive systems. In contrast, however, various SMR concepts also favour reduced regulatory requirements, for example, with regard to the required degree of redundancy or diversity in safety systems. Some developers even demand that current requirements be waived, for example in the area of internal accident management or with reduced planning zones, or even a complete waiver of external emergency protection planning. Since the safety of a reactor plant depends on all of these factors, based on the current state of knowledge it is not possible to state, that a higher safety level is achieved by SMR concepts in principle."[45][46][20]

Negative temperature coefficients in the moderators and the fuels keep the fission reactions under control, causing the reaction to slow as temperature increases.[47]

Some SMR designs proposes cooling systems only based on thermoconvection – natural circulation – to eliminate cooling pumps that could break down. Convection can keep removing decay heat after reactor shutdown. However, some SMRs may need an active cooling system to back up the passive system, increasing cost.[48]

Some SMR designs feature an integral design of which the primary reactor core, steam generator and the pressurizer are integrated within the sealed reactor vessel. This integrated design allows for the reduction of a possible accident as contamination leaks could be contained. In comparison to larger reactors having numerous components outside the reactor vessel, this feature increases the safety by decreasing the risks of an uncontained accident. Some SMR designs also envisage to install the reactor and the spent-fuel storage pools underground.[49]

Radioactive waste

The backend of the nuclear fuel cycle of SMR is a complex and challenging issue remaining disputed. The quantity and the radiotoxicity of the radioactive waste produced by SMR mainly depend on their design and the related fuel cycle. As the notion of SMR encompasses a broad spectrum a nuclear reactor types, no simple answer can be easily given to the question. SMR may comprise small light water reactors of third generation as well as small fast neutron reactors of fourth generation.

Often, the startup companies developing unconventional SMR prototypes advocate waste reduction as an advantage of the proposed solution and even sometimes claim that their technology could eliminate the need for a deep geological repository to dispose of high-level and long-lived radioactive waste. This is especially the case for companies studying fast neutron reactors of 4th generation (molten salts reactors, metal-cooled reactors (sodium-cooled fast reactor, or lead-cooled fast reactor).

Fast breeder reactors "burn" 235U (0.7% of natural uranium), but also convert fertile materials such as 238U (99.3% of natural uranium) into fissile 239Pu that can be used as nuclear fuel.[35]

The traveling wave reactor proposed by TerraPower is aimed to immediately "burn" the fuel that it breeds without requiring its removal from the reactor core and its further reprocessing.[50]

The design of some SMR reactors is based on the thorium fuel cycle, which is considered by their promotors as a way to reduce the long-term waste radiotoxicity compared to the uranium cycle.[51] However, using the thorium cycle also presents big operational challenges because of the production and the use of 232U and long-lived fertile 233U, both radioisotopes emitting strong gamma rays. So, the presence of these radionuclides seriously complicates the radiation shielding of the fresh nuclear fuel and the long-term storage and disposal of their spent nuclear fuel.

A study of 2022 made by Krall, Macfarlane and Ewing is more critical and reports that some types of SMR could produce more waste per unit of output power than conventional reactors, in some cases more than 5× the number of spent fuel per kilowatt, and as much as 35× for other waste produced by neutron activation, such as activated steel and graphite.[52][53][54][29]

These authors have identified the neutron leakage as the first issue for SMRs because they have a higher surface area with respect to their core volume. They have calculated that the neutron leakage rates are much higher for SMRs, because in smaller reactor cores, emitted neutrons have fewer chances to interact with the fissile atoms present in the fuel and to produce nuclear fission. Instead, neutrons exit the reactor core without interacting with the nuclear fuel, and they are absorbed outside the core by the materials used for the neutron reflectors and the shielding (thermal and gamma shields), turning them as radioactive waste (activated steel and graphite).

Reactor designs using liquid metal coolants (molten sodium, lead, lead-bismuth eutectic, LBE) also become radioactive and contains activated impurities.

Another issue pinpointed by Krall et al. (2022)[29] related to the higher neutron leakage in SMR is that a lower fraction of their nuclear fuel is consumed, leading to a lower burnup and to more fissile materials left over in their spent fuel, therefore increasing the waste volume. To sustain the nuclear chain reactions in the core of a smaller reactor, an alternative is to use nuclear fuel more enriched in 235U. This could increase the risks of nuclear proliferation and could require more stringent safeguard measures to prevent it (see also IAEA safeguards).

If higher concentrations of fissile materials subsist in the spent fuel, the critical mass needed to sustain a nuclear chain reaction is also lower. As a direct consequence, the number of spent fuels present in a waste canister will also be lower and a larger number of canisters and overpacks will be necessary to avoid criticality accidents and to guarantee nuclear criticality safety in a deep geological repository. This also contributes to increase the total waste volume and the number of disposal galleries in a geological repository.

Given the potential technical and economical importance of SMRs to supply zero-carbon electrical energy needed to fight climate change and the long-term and social relevance of the study to adequately manage and dispose of radioactive waste without imposing a negative burden onto the future generations, the publication of Krall et al. (2022) in the prestigious PNAS journal has attracted many reactions ranging from criticisms on the quality of their data and hypotheses[55] to international debates on radioactive waste produced by SMRs and their decommissioning.[56]

In an interview with François Diaz-Maurin, the associate editor of the Bulletin of the Atomic Scientists, Lindsay Krall, the lead author of the study and a former MacArthur postdoctoral fellow at Stanford's Center for International Security and Cooperation (CISAC) answered to questions and criticisms, amongst others, those raised by the NuScale reactor company.[57] One of the main concerns Krall expressed in this interview is that:

- "There's definitely a disconnect between the people working on the back end of the fuel cycle—especially with geologic repository development—and those actually designing reactors. And, there is not a lot of motivation for these reactor designers to think about the geologic disposal aspects because the NRC's new reactor design certification application does not have a chapter on geologic disposal..."

The critical study of Krall et al. (2022) has the merit to have raised relevant questions that cannot be ignored by reactor designers, or decision-makers, and to have triggered open and fresh discussions on important outcomes for SMRs and radwaste management in general. Amongst the various types of SMR projects initiated today by many start-up companies, only those correctly addressing these questions and really contributing to minimize the radioactive waste they produce have a chance to be supported by the public and governmental organisations (nuclear safety authorities and radioactive waste management organisations) and their research to be funded by long-term national policies.

The high diversity of SMR reactors and their respective fuel cycles may also require more diverse waste management strategy to recycle, or to safely dispose, their nuclear waste.[52][29] A larger number of spent fuel types will be more difficult to manage than only one type as it is presently the case with light water reactors only.

As previously stressed by Krall and Macfarlane (2018),[58] some types of SMR spent fuels, or coolants, (highly reactive and corrosive uranium fluoride (UF

4) from molten salt reactors, or pyrophoric sodium from liquid metal cooled fast breeders) cannot be directly disposed of in a deep geologic repository because of their chemical reactivity in the underground environment (deep clay formations, crystalline rocks, or rock salt). To avoid to exacerbate spent fuel storage and disposal issues it will be mandatory to reprocess and to condition them in an appropriate and safe way before final geological disposal.

A study made by Keto et al. (2022) at the VTT Technical Research Centre of Finland also addressed the management of spent nuclear fuel (SNF) and low- and intermediate-level waste (LILW) from a possible future deployment of SMRs in Finland . It also indicates that larger masses (per GWe-year) of SNF and other HLW and larger volumes (per GWe-year) of LLW would be produced by a light water SMR compared to a large NPP.[59]

A report by the German Federal Office for the Safety of Nuclear Waste Management (BASE) found that extensive interim storage and fuel transports are still required for SMRs. A deep geological repository is still unavoidable in any case because of the presence of highly mobile long-lived fission products that, due to their too low neutron cross section, cannot be efficiently transmuted, as it is the case with dose-dominating radionuclides such as 129I, 99Tc and 79Se (soluble anions that are not sorbed onto the negatively charged minerals and are not retarded in geological media).[20]

Nuclear proliferation

Nuclear proliferation, or the use of nuclear materials to create weapons, is a concern for small modular reactors. As SMRs have lower generation capacity and are physically smaller, they are intended to be deployed in many more locations than conventional plants.[60] SMRs are expected to substantially reduce staffing levels. The combination creates physical protection and security concerns.[15][36]

SMRs can be designed to use unconventional fuels allowing for higher burnup and longer fuel cycles.[7] Longer refueling intervals could contribute to decrease the proliferation risks. Once the fuel has been irradiated, the mixture of fission products and fissile materials is highly radioactive and requires special handling, preventing casual theft.

Contrasting to conventional large reactors, SMRs can be adapted to be installed in a sealed underground chamber; therefore, "reducing the vulnerability of the reactor to a terrorist attack or a natural disaster".[49] New SMR designs enhance the proliferation resistance, such as those from the reactor design company Gen4. These models of SMR offer a solution capable of operating sealed underground for the life of the reactor following installation.[49][61]

Some SMR designs are designed for one-time fueling. This improves proliferation resistance by eliminating on-site nuclear fuel handling and means that the fuel can be sealed within the reactor. However, this design requires large amounts of fuel, which could make it a more attractive target. A 200 MWe 30-year core life light water SMR could contain about 2.5 tonnes of plutonium at end of life.[36]

Furthermore, many SMRs offer the ability to go periods of greater than 10 years without requiring any form of refueling therefore improving the proliferation resistance as compared to conventional large reactors of which entail refueling every 18–24 months.[49]

Light-water reactors designed to run on thorium offer increased proliferation resistance compared to the conventional uranium cycle, though molten salt reactors have a substantial risk.[62][63]

SMRs are transported from the factories without fuel, as they are fueled on the ultimate site, except some microreactors.[64] This implies an independent transport of the fuel to the site and therefore increases the risk of nuclear proliferation.

Licensing process

Licensing is an essential process required to guarantee the safety, security and safeguards of a new nuclear installation.[65] Only NuScale Power's VOYGR SMR is fully licensed for use in the United States.[66] However, not all countries follow the NRC or IAEA licensing standards. In the United States and IAEA adhering countries, the licensing is based on a rigorous, independent analysis and reviewing work of all structures, systems and components critical for the nuclear safety under normal and accidental conditions on the whole service life of the installation including the long-term management of radioactive waste.[67] Licensing is based on the examination and scrutiny of the risk assessment studies and safety files elaborated by the fabricant and the exploitant of the SMR in the frame of the safety case they have to submit to the safety authority (regulatory body) when applying for a licence to construct and safely exploit the installation.[68] For NRC and IAEA licensing, the safety and feasibility cases of nuclear installations have to take into account all processes and elements important for the operational safety, its security (access protection), the nuclear safeguard (risk of proliferation), the proper conditioning of radioactive waste under a stable physico-chemical form, and the long-term safety related to the final disposal of the different types of radwaste produced, including all the waste produced during dismantling operations after decommissioning of the installation.[67][69][70] A particularly important point of attention for the backend of the nuclear fuel cycle is to avoid to producing poorly conditioned waste, or waste types without sustainable final destination or susceptible to generating unexpected reprocessing and disposal costs.

The most common licensing process, applied by existing commercial reactors, is for the operation of light water reactors (PWR and BWR). Early designs date back to the 1960s and 1970s during the construction of the nuclear reactor fleet currently in service. Some adaptations of the original licensing process by the US's Nuclear Regulatory Commission (NRC) have been repurposed to better correspond to the specific characteristics and needs of the deployment of SMR units.[71] In particular, the US Nuclear Regulatory Commission process for licensing has focused mainly on conventional reactors. Design and safety specifications, human and organizational factors (including staffing requirements) have been developed for reactors with electrical output of more than 700 MWe.[72][73]

To ensure adequate guidelines for the nuclear safety, while helping the licensing process, the IAEA has encouraged the creation of a central licensing system for SMRs.[74] A workshop in October 2009 and another in June 2010 considered the topic, followed by an US congressional hearing in May 2010.

The NRC and the United States Department of Energy) are working to define SMR licensing. The challenge of facilitating the development of SMRs is to prevent a weakening of the safety regulations: the risk of lightened regulations adopted more rapidly is to lower the safety characteristics of SMRs.[75][76][77] While deploying identical systems built in manufacturing plants with an improved quality control can be considered an advantage, SMRs remain nuclear reactors with a very high energy density and their smaller size is not per se an intrinsic guarantee for a better safety. Any severe accident with external radioactive contamination release could have potential serious consequences not so different from that of a large LWR reactor. It would also probably signify the final rejection of nuclear energy by the public and the end of the nuclear industry. The potential "proliferation" of large SMR fleets and the high diversity of their design also complicate the licensing process. The nuclear safety cannot be sacrificed for industrial or economical interests and the risk of nuclear accident increases with the number of reactors in service, small or large unit.

The U.S. Advanced Reactor Demonstration Program was expected to help license and build two prototype SMRs during the 2020s, with up to $4 billion of government funding.[78]

Flexibility

Small nuclear reactors, in comparison to conventional nuclear power plants, offer potential advantages related to the flexibility of their modular construction.[49] It would be possible to incrementally connect additional units to the grid in the event electrical load increases. Additionally, this flexibility in a standardized SMRs design revolving around modularity could allow for a faster production at a decreasing cost following the completion of the first reactor on site.[49][61]

The hypothesised flexibility and modularity of SMR is intended to allow additional power generation capability to be installed at existing power plants. A site could host several SMRs, one going off-line for refueling while the other reactors stay online as it is presently already the case for conventional larger reactors.[49]

When electrical energy is not needed, some SMR designs foresee the direct use of thermal energy, minimizing so the energy loss. This includes "desalination, industrial processes, hydrogen production, shale oil recovery, and district heating", uses for which the present conventional larger reactors are not designed.[49][79]

Economics

A key driver of interest in SMRs is the claimed economies of scale in production, due to volume manufacture in an offsite factory. Some studies instead find the capital cost of SMRs to be equivalent to larger reactors.[81] Substantial capital is needed to construct the factory – ameliorating that cost requires significant volume, estimated to be 40–70 units.[82][83]

Another potential advantage is that a future power station using SMRs can begin with a single module and expand by adding modules as demand grows. This reduces startup costs associated with conventional designs.[84] Some SMRs also have a load-following design such that they could produce less electricity when demand is low.

According to a 2014 study of electricity production in decentralized microgrids, the total cost of using SMRs for electricity generation would be significantly lower compared to the total cost of offshore wind power, solar thermal energy, biomass, and solar photovoltaic electricity generation plants.[85]

Construction costs per SMR reactor were claimed in 2016 to be less than that for a conventional nuclear plant, while exploitation costs might be higher for SMRs due to low scale economics and the higher number of reactors. SMR staff operating costs per unit output can be as much as 190% higher than the fixed operating cost of fewer large reactors.[86] Modular building is a very complex process and there is "extremely limited information about SMR modules transportation", according to a 2019 report.[21]

A production cost calculation done by the German Federal Office for the Safety of Nuclear Waste Management (BASE), taking into account economies of scale and learning effects from the nuclear industry, suggests that an average of 3,000 SMR would have to be produced before SMR production would be worthwhile. This is because the construction costs of SMRs are relatively higher than those of large nuclear power plants due to the low electrical output.[87]

In 2017, an Energy Innovation Reform Project (EIRP) study of eight companies looked at reactor designs with capacity between 47.5 MWe and 1,648 MWe.[88] The study reported average capital cost of $3,782/kW, average operating cost total of $21/MWh and levelized cost of electricity (LCOE) of $60/MWh.

In 2020, Energy Impact Center founder Bret Kugelmass claimed that thousands of SMRs could be built in parallel, "thus reducing costs associated with long borrowing times for prolonged construction schedules and reducing risk premiums currently linked to large projects."[89] GE Hitachi Nuclear Energy Executive Vice President Jon Ball agreed, saying the modular elements of SMRs would also help reduce costs associated with extended construction times.[89]

In October 2023, an academic paper published in Energy collated the basic economic data of 19 more developed SMR designs, and modeled their costs in a consistent manner. A Monte Carlo simulation showed that none were profitable or economically competitive. For the closer to market PWR SMRs the median LCOEs ranged from $218/MWh to $614/MWh (in 2020 US dollars), with lower first quartile estimates from $188/MWh to $385/MWh. The three high-temperature gas-cooled reactor designs, which needed more development time, had lower median LCOEs from $116/MWh to $137/MWh.[90]

The first SMR deployment project in the US was the Carbon Free Power Project, which planned to deploy six 77 MWe NuScale reactors, reduced from twelve in earlier plans. Estimated target electricity generation price after subsidies was $89/MWh in 2023, an increase from $58/MWh in 2021. The increased generation cost led to the decision to cancel the project in November 2023.[80] Before its cancellation, the project received a $1.355 billion cost-share award toward construction costs from the US government in 2020[91] plus an estimated $30/MWh generation subsidy from the 2020 Inflation Reduction Act.[92] Unsubsidized cost estimates at cancellation were a capital cost of $20,139/kW and generating cost of $119/MWe.[93] This raised concerns about the commercial prospects in the U.S. of the other SMR designs.[94]

List of reactor designs

Numerous reactor designs have been proposed. Notable SMR designs:

{{#section-h::List of small nuclear reactor designs|Summary table}}

Siting/infrastructure

SMRs are expected to require less land, e.g., the 470 MWe 3-loop Rolls-Royce SMR reactor should take 40,000 m2 (430,000 sq ft), 10% of that needed for a traditional plant.[95] This unit is too large to meet the definition[citation needed] of a small modular reactor and will require more on-site construction, which calls into question the claimed benefits of SMRs. The firm is targeting a 500-day construction time.[96]

Electricity needs in remote locations are usually small and variable, making them suitable for a smaller plant.[97] The smaller size may also reduce the need to access to a large grid to distribute their output.

Proposed sites

Argentina

In February 2014, the CAREM SMR project started in Argentina with the civil engineering construction of the containment building of a prototype reactor. The CAREM acronym means Central ARgentina de Elementos Modulares. The National Atomic Energy Commission (Spanish: Comisión Nacional de Energía Atómica, CNEA), the Argentina government agency in charge of nuclear energy research and development and Nucleoeléctrica Argentina (es), the national nuclear energy company, are cooperating to achieve the realization of the project.[98]

CAREM-25 is a prototype of 25 MWe, the first nuclear power plant completely designed and developed in Argentina.[98] The project was suspended several times before being resumed. In October 2022, CNEA expected that the civil construction works would be finished by 2024. If construction continues according to plan, the first criticality of CAREM-25 is foreseen by the end of 2027.[98]

Canada

In 2018, the Canadian province of New Brunswick announced it would invest $10 million for a demonstration project at the Point Lepreau Nuclear Generating Station.[99] It was later announced that SMR proponents Advanced Reactor Concepts[100] and Moltex[101] would open offices there.

On 1 December 2019, the Premiers of Ontario, New Brunswick and Saskatchewan signed a memorandum of understanding (MoU) [102] "committing to collaborate on the development and deployment of innovative, versatile and scalable nuclear reactors, known as Small Modular Reactors (SMRs)."[103] They were joined by Alberta in August 2020.[104] With continued support from citizens and government officials have led to the execution of a selected SMR at the Canadian Nuclear Laboratory.[39]

In 2021, Ontario Power Generation announced they plan to build a BWRX-300 SMR at their Darlington site to be completed by 2028. A licence for construction still had to be applied for.[105]

On 11 August 2022, Invest Alberta, the Government of Alberta's crown corporation signed a MoU with Terrestrial Energy regarding IMSR in Western Canada through an interprovincial MoU it joined earlier.[106]

China

In July 2019, China National Nuclear Corporation announced it would build an ACP100 SMR on the north-west side of the existing Changjiang Nuclear Power Plant at Changjiang, in the Hainan province by the end of the year.[107] On 7 June 2021, the demonstration project, named the Linglong One, was approved by China's National Development and Reform Commission.[108] In July, China National Nuclear Corporation (CNNC) started construction,[109] and in October 2021, the containment vessel bottom of the first of two units was installed. It is the world's first commercial land-based SMR prototype.[33]

In August 2023, the core module was installed. The core module includes an integrated pressure vessel, steam generator, primary pump receiver. The reactor's planned capacity is 125 MWe.[110]

France

At the beginning of 2023, Électricité de France (EDF) created a new subsidiary to develop and construct a new SMR: Nuward. It is a 340 MWe power plant with two independent light water reactors of 170 MWe. The twin reactors are sheltered in a single containment building and share most of their equipment.[111] In August 2023, EDF submitted a safety case for Nuward to the autorité de sûreté nucléaire (ASN), the French safety authority.[112]

Poland

Polish chemical company Synthos declared plans to deploy a Hitachi BWRX-300 reactor (300 MW) in Poland by 2030.[113] A feasibility study was completed in December 2020 and the licensing process started with the Polish National Atomic Energy Agency.[114]

In February 2022, NuScale Power and the large mining conglomerate KGHM Polska Miedź announced signing of contract to construct a first operational reactor in Poland by 2029.[115]

Romania

On the occasion of 2021 United Nations Climate Change Conference, the state-owned Romanian nuclear energy company Nuclearelectrica and NuScale Power signed an agreement to build a power plant with six small-scale nuclear reactors at the Doicești power station, on the site of a former coal power plant, located near the village of Doicești, Dâmbovița county, 90 km North of Bucharest. The project is estimated to be completed by 2026–2027, which will make the power plant the first of its kind in Europe. The power plant is expected to generate 462 MWe, securing the consumption of about 46.000 households and would help to avoid the release of 4 million tons of CO

2 per year.[116][117][118]

Russia

Russia has started to deploy on its arctic coast small nuclear reactors embarked on board icebreakers. In May 2020, the first prototype of a floating nuclear power plant with two 30 MWe reactors – the type KLT-40 – started operation in Pevek, Russia.[31] This concept is based on the design of nuclear icebreakers.[32]

United Kingdom

In 2016, it was reported that the UK Government was assessing Welsh SMR sites – including the former Trawsfynydd nuclear power station – and on the site of former nuclear or coal-fired power stations in Northern England. Existing nuclear sites including Bradwell, Hartlepool, Heysham, Oldbury, Sizewell, Sellafield, and Wylfa were stated to be possibilities.[119] The target cost for a 470 MWe Rolls-Royce SMR unit is £1.8 billion for the fifth unit built.[120][121] In 2020, it was reported that Rolls-Royce had plans to construct up to 16 SMRs in the UK. In 2019, the company received £18 million to begin designing the modular system.[122] An additional £210 million was awarded to Rolls-Royce by the British government in 2021, complemented by a £195 million contribution from private firms.[123] In November 2022, Rolls-Royce announced that the sites at Trawsfynydd, Wylfa, Sellafield and Oldbury would be prioritised for assessment as potential locations for multiple SMRs.[124]

The British government launched Great British Nuclear in July 2023 to administer a competition to create SMRs, and will co-fund any viable project.[125]

United States

Standard Power, a provider of infrastructure as a service to advanced data processing companies, has chosen to work with NuScale Power and ENTRA1 Energy to develop SMR-powered facilities in Pennsylvania and Ohio that will together produce nearly two gigawatts of clean, reliable energy.[126]

NuScale Power is working with Wisconsin's Dairyland Power to evaluate VOYGR™ SMR power plants for potential deployment. The US leader in SMR technology believes its load-following capabilities can be used to support Dairyland’s existing renewables portfolio, as well as facilitate growth. Additionally, VOYGR plants are well-suited for replacing Dairyland’s retiring coal plant sites, preserving critical jobs and helping communities transition to a decarbonized energy system.[127]

NuScale Power is working with Associated Electric Cooperative Inc. (Associated) in Missouri to evaluate deployment of VOYGR™ SMR power plants as part of Associated’s due diligence to explore reliable, responsible sources of energy.[128]

NuScale had planned to build an SMR project in the US, the Carbon Free Power Project, but this was canceled in November 2023 for cost reasons.[80] NuScale said in January 2023 the target price for power from the plant was $89 per megawatt hour, up 53% from the previous estimate of $58 per MWh, raising concerns about customers' willingness to pay.[129] Still, increased cost estimates remain well below traditional nuclear power used for commercial facilities and most other less reliable and more environmentally hazardous forms of power production.[130]

The Utah Associated Municipal Power Systems (UAMPS) had partnered with Energy Northwest to explore siting a NuScale Power reactor in Idaho, possibly on the Department of Energy's Idaho National Laboratory.[131] The project was cancelled in 2023 due to increased costs.[80]

The Galena Nuclear Power Plant in Galena, Alaska was a proposed micro nuclear reactor installation. It was a potential deployment for the Toshiba 4S reactor.[132] The project was "effectively stalled." Toshiba never began the expensive process for approval that is required by the U.S. Nuclear Regulatory Commission.

Although the SMR now under consideration has yet to be NRC licensed, the Tennessee Valley Authority was authorized to receive an Early Site Permit (ESP) by the Nuclear Regulatory Commission for siting an SMR at its Clinch River site in Tennessee in December 2019.[133] This ESP is valid for 20 years, and addresses site safety, environmental protection and emergency preparedness. This ESP is applicable for any light-water reactor SMR design under development in the United States.[134]

References

- ↑ "Oregon State-NuScale partnership powers the future of nuclear energy". https://advantage.oregonstate.edu/feature-story/oregon-state-nuscale-partnership-powers-future-nuclear-energy.

- ↑ Musto, Julia. "NuScale Power secures NRC certification for its SMR design". FOX News. https://www.foxnews.com/tech/u-s-approves-first-small-modular-nuclear-reactor-design.

- ↑ Berniolles, Jean-Marie (2019-11-29). "De-mystifying small modular reactors" (in en-GB). https://www.sustainability-times.com/low-carbon-energy/de-mystifying-small-modular-reactors/.

- ↑ 4.0 4.1 4.2 4.3 BASE, the German Federal Office for the Safety of Nuclear Waste Management (2023-01-15). "Small Modular Reactors (SMR)". https://www.base.bund.de/EN/ns/ni-germany/smr/small-modular-reactors_node.html.

- ↑ "The Galena Project Technical Publications", p. 22, Burns & Roe

- ↑ 6.0 6.1 "Small Modular Reactors: Nuclear Energy Market Potential for Near-term Deployment". 2016. https://www.oecd-nea.org/ndd/pubs/2016/7213-smrs.pdf.

- ↑ 7.0 7.1 Furfari, Samuele (2019-10-31). "Squaring the energy circle with SMRs" (in en-GB). https://www.sustainability-times.com/uncategorized/squaring-the-energy-circle-with-smrs/.

- ↑ "Technology Deployment". US Department of Energy. https://www.iea.org/energy-system/electricity/nuclear-power#tracking.

- ↑ https://www.science.org/content/article/deal-build-pint-size-nuclear-reactors-canceled

- ↑ 10.0 10.1 Perera, Judith (18 January 2023). "IAEA ups support for SMRs". Nuclear Engineering International. https://www.neimagazine.com/features/featureiaea-ups-support-for-smrs-10528638/.

- ↑ "Licensing Small Modular Reactors: An Overview of Regulatory and Policy Issues". 2015. https://www.hoover.org/sites/default/files/research/docs/ostendorff_licensingsmrs_2rs_reduced_4_0.pdf.

- ↑ Cite error: Invalid

<ref>tag; no text was provided for refs namedauto - ↑ "Small isn't always beautiful". Union of Concerned Scientists. 2013. https://www.ucsusa.org/sites/default/files/legacy/assets/documents/nuclear_power/small-isnt-always-beautiful.pdf.

- ↑ Mignacca, Benito; Locatelli, Giorgio; Sainati, Tristano (20 Jun 2020). "Deeds not words: Barriers and remedies for Small Modular nuclear Reactors". Energy 206: 118137. doi:10.1016/j.energy.2020.118137.

- ↑ 15.0 15.1 Greneche, Dominique (18 June 2010) (presentation), Proliferation issues related to the deployment of Small & Medium Size reactors (SMRs), Areva, http://bnrc.berkeley.edu/documents/forum-2010/Presentations/S-Session-III/Dominique_Greneche_NuclearConsulting_Pres.pdf

- ↑ Trakimavičius, Lukas (Nov 2020). "Is Small Really Beautiful? The Future Role of Small Modular Nuclear Reactors (SMRs) In The Military" (in en). https://www.enseccoe.org/data/public/uploads/2020/11/02.-solo-article-lukas-smr-eh-15-web-version-final.pdf.

- ↑ "Chasing Cheap Nuclear: Economic Trade-Offs for Small Modular Reactors" (in en). https://nae.edu/239267/Chasing-Cheap-Nuclear-Economic-TradeOffs-for-Small-Modular-Reactors.

- ↑ Mignacca, B.; Locatelli, G. (2020-02-01). "Economics and finance of Small Modular Reactors: A systematic review and research agenda". Renewable and Sustainable Energy Reviews 118: 109519. doi:10.1016/j.rser.2019.109519. ISSN 1364-0321. https://www.sciencedirect.com/science/article/pii/S1364032119307270.

- ↑ Trakimavičius, Lukas. "Is Small Really Beautiful? The Future Role of Small Modular Nuclear Reactors (SMRs) in the Military" (in en). https://www.enseccoe.org/data/public/uploads/2020/11/02.-solo-article-lukas-smr-eh-15-web-version-final.pdf.

- ↑ 20.0 20.1 20.2 Bundesamt für die Sicherheit der nuklearen Entsorgung (2021-03-10). "Small Modular Reactors - Was ist von den neuen Reaktorkonzepten zu erwarten?" (in de). https://www.base.bund.de/DE/themen/kt/kta-deutschland/neue_reaktoren/neue-reaktoren_node.html.

- ↑ 21.0 21.1 Mignacca, Benito; Hasan Alawneh, Ahmad; Locatelli, Giorgio (27 Jun 2019). "Transportation of small modular reactor modules: What do the experts say?". 27th International Conference on Nuclear Engineering. https://www.researchgate.net/publication/330823799.

- ↑ Boarin, Sara; Ricotti, Marco E. (2014-08-05). "An Evaluation of SMR Economic Attractiveness" (in en). Science and Technology of Nuclear Installations 2014: e803698. doi:10.1155/2014/803698. ISSN 1687-6075.

- ↑ "Nuclear power can play a major role in enabling secure transitions to low emissions energy systems". 2022-06-30. https://www.iea.org/news/nuclear-power-can-play-a-major-role-in-enabling-secure-transitions-to-low-emissions-energy-systems.

- ↑ Vaya Soler, Antonio (2024). Chapter 23 – The future of nuclear energy and small modular reactors. In: Living with Climate Change. Elsevier. p. 465–512. doi:10.1016/B978-0-443-18515-1.00012-5. ISBN 9780443185151. https://www.sciencedirect.com/science/article/abs/pii/B9780443185151000125. Retrieved 2023-12-13.

- ↑ Öko-Institut (10 March 2021). "Sicherheitstechnische Analyse und Risikobewertung einer Anwendung von SMR-Konzepten (Small Modular Reactors)" (in de). https://www.base.bund.de/SharedDocs/Downloads/BASE/DE/berichte/kt/gutachten-small-modular-reactors.html;jsessionid=268D8A1B8EE5F6F621FDBCF3A5817292.internet992.

- ↑ ""Accelerating SMRs for Net Zero" initiative launched at COP28". 2023-12-05. https://www.oecd-nea.org/jcms/pl_88887/-accelerating-smrs-for-net-zero-initiative-launched-at-cop28.

- ↑ "Accelerating SMRs for Net Zero". 2023-12-05. https://www.oecd-nea.org/jcms/pl_88539/accelerating-smrs-for-net-zero.

- ↑ Nuclear Energy Agency (NEA) (November 2023). "Small Modular Reactors (SMRs) for Net Zero". https://www.oecd-nea.org/upload/docs/application/pdf/2023-12/smrs_for_net_zero.pdf.

- ↑ 29.0 29.1 29.2 29.3 Krall, Lindsay M.; Macfarlane, Allison M.; Ewing, Rodney C. (2022-06-07). "Nuclear waste from small modular reactors" (in en). Proceedings of the National Academy of Sciences 119 (23): e2111833119. doi:10.1073/pnas.2111833119. ISSN 0027-8424. PMID 35639689. Bibcode: 2022PNAS..11911833K.

- ↑ Mignacca, Benito; Locatelli, Giorgio (1 Nov 2019). "Economics and finance of Small Modular Reactors: A systematic review and research agenda". Renewable and Sustainable Energy Reviews 118: 109519. doi:10.1016/j.rser.2019.109519.

- ↑ 31.0 31.1 Akademik Lomonosov-1, Power Reactor Information System (PRIS), International Atomic Energy Agency, 2020-09-13.

- ↑ 32.0 32.1 "Russia connects floating plant to grid". 2019-12-19. http://www.world-nuclear-news.org/Articles/Russia-connects-floating-plant-to-grid. "Alexey Likhachov, director general of state nuclear corporation Rosatom, said Akademik Lomonosov had thus becomes the world's first nuclear power plant based on SMR technology to generate electricity."

- ↑ 33.0 33.1 Installation of containment starts at Chinese SMR. WNN, 25 Oct 2021

- ↑ INEA, NEA, IEA. "Innovative Nuclear Reactor Development: Opportunities for International Co-operation", OECD Nuclear Energy Agency

- ↑ 35.0 35.1 Carlson, J. "Fast Neutron Reactors" , World Nuclear Association

- ↑ 36.0 36.1 36.2 Glaser, Alexander (5 November 2014) (presentation), Small Modular Reactors - Technology and Deployment Choices, NRC, https://www.nrc.gov/reading-rm/doc-collections/commission/slides/2014/20141105/glaser-11-05-14.pdf

- ↑ 37.0 37.1 Wilson, P.D. "Nuclear Power Reactors" , World Nuclear Association

- ↑ brian wang (13 October 2011). "Flibe Energy Liquid Flouride [sic] Thorium Reactor Company". Nextbigfuture.com. http://nextbigfuture.com/2011/10/flibe-energy-liquid-flouride-thorium.html.

- ↑ 39.0 39.1 Carelli, Mario D., Ingersoll, D. T. (22 October 2020). Handbook of small modular nuclear reactors. Woodhead. ISBN 978-0-12-823917-9. OCLC 1222802880. http://worldcat.org/oclc/1222802880.

- ↑ "Small nuclear power reactors - World Nuclear Association". https://www.world-nuclear.org/information-library/nuclear-fuel-cycle/nuclear-power-reactors/small-nuclear-power-reactors.aspx.

- ↑ "Nuclear Process Heat for Industry" , World Nuclear Association

- ↑ Locatelli, Giorgio; Fiordaliso, Andrea; Boarin, Sara; Ricotti, Marco E. (1 May 2017). "Cogeneration: An option to facilitate load following in Small Modular Reactors". Progress in Nuclear Energy 97: 153–161. doi:10.1016/j.pnucene.2016.12.012. http://eprints.whiterose.ac.uk/110233/1/Load%20Following%20by%20Cogeneration%20V27%20to%20deposit.pdf.

- ↑ Locatelli, Giorgio; Boarin, Sara; Pellegrino, Francesco; Ricotti, Marco E. (1 February 2015). "Load following with Small Modular Reactors (SMR): A real options analysis". Energy 80: 41–54. doi:10.1016/j.energy.2014.11.040. http://eprints.whiterose.ac.uk/91139/1/Accpeted%20version.pdf.

- ↑ Locatelli, Giorgio; Boarin, Sara; Pellegrino, Francesco; Ricotti, Marco E. (2015). "Load following with Small Modular Reactors (SMR): A real options analysis". Energy 80: 41–54. doi:10.1016/j.energy.2014.11.040. ISSN 0360-5442. http://dx.doi.org/10.1016/j.energy.2014.11.040.

- ↑ Sicherheitstechnische Analyse und Risikobewertung einer Anwendung von SMR-Konzepten (Small Modular Reactors). BASE, März 2021

- ↑ Für die Zukunft zu spät. Süddeutsche Zeitung, 9. März 2021

- ↑ DOE-HDBK-1019 1993, pp. 23–29

- ↑ "Small Modular Reactors: Safety, Security and Cost Concerns (2013)" (in en). https://www.ucsusa.org/nuclear-power/nuclear-power-technology/small-modular-reactors.

- ↑ 49.0 49.1 49.2 49.3 49.4 49.5 49.6 49.7 Cunningham, Nick (2012). Small modular reactors : a possible path forward for nuclear power. American Security Project. OCLC 813390081. http://worldcat.org/oclc/813390081.

- ↑ Wald, M. "TR10: Traveling Wave Reactor" , Technology Review

- ↑ Section 5.3, WASH 1097 "The Use of Thorium in nuclear power reactors", available as a PDF from Liquid-Halide Reactor Documents database: http://www.energyfromthorium.com/pdf/

- ↑ 52.0 52.1 Barber, Gregory. "Smaller reactors may still have a big nuclear waste problem" (in en-US). Wired. ISSN 1059-1028. https://www.wired.com/story/smaller-reactors-may-still-have-a-big-nuclear-waste-problem/. Retrieved 2022-08-03.

- ↑ Vaughan, Adam (2022-05-30). Mini nuclear power stations may produce more waste than large ones. https://www.newscientist.com/article/2322252-mini-nuclear-power-stations-may-produce-more-waste-than-large-ones/. Retrieved 2023-12-03.

- ↑ Stanford University (2022-05-30). "Small modular reactors produce high levels of nuclear waste". https://news.stanford.edu/2022/05/30/small-modular-reactors-produce-high-levels-nuclear-waste/#:~:text=%E2%80%9CWe%20found%20that%20small%20modular,%2C%20which%20will%20be%20expensive.%E2%80%9D.

- ↑ "Stanford's questionable study on spent nuclear fuel for SMRs". 2022-05-31. https://neutronbytes.com/2022/05/31/stanfords-questionable-study-on-spent-nuclear-fuel-for-smrs/.

- ↑ "Management of spent fuel, radioactive waste and decommissioning in SMRs or advanced reactor technologies. 7-10 November 2022, Ottawa, Canada. Workshop programme". https://www.oecd-nea.org/upload/docs/application/pdf/2022-11/smr_programme_final.pdf.

- ↑ Diaz-Maurin, François (2022-06-17). "Interview: Small modular reactors get a reality check about their waste". https://thebulletin.org/2022/06/interview-small-modular-reactors-get-a-reality-check-about-their-waste/.

- ↑ Krall, Lindsay M.; Macfarlane, Allison M. (2018-08-31). "Burning waste or playing with fire? Waste management considerations for non-traditional reactors". Bulletin of the Atomic Scientists (Routledge) 74 (5): 326–334. doi:10.1080/00963402.2018.1507791. Bibcode: 2018BuAtS..74e.326K. https://www.tandfonline.com/doi/full/10.1080/00963402.2018.1507791. Retrieved 2023-12-03.

- ↑ Keto, Paula; Juutilainen, Pauli; Schatz, Timothy; Naumer, Sami; Häkkinen, Silja (2022-02-28). "Waste Management of Small Modular Nuclear Reactors in Finland". VTT Technical Research Centre of Finland. https://cris.vtt.fi/en/publications/waste-management-of-small-modular-nuclear-reactors-in-finland.

- ↑ Trakimavičius, Lukas (Nov 2020). "Is Small Really Beautiful?The Future Role of Small Modular Nuclear Reactors (SMRs) In The Military" (in en). https://www.enseccoe.org/data/public/uploads/2020/11/02.-solo-article-lukas-smr-eh-15-web-version-final.pdf.

- ↑ 61.0 61.1 Ingersoll, D.T. (2009). "Deliberately small reactors and the second nuclear era". Progress in Nuclear Energy 51 (4–5): 589–603. doi:10.1016/j.pnucene.2009.01.003. ISSN 0149-1970. http://dx.doi.org/10.1016/j.pnucene.2009.01.003.

- ↑ Kang, J.; Von Hippel, F. N. (2001). "U‐232 and the proliferation‐resistance of U‐233 in spent fuel". Science & Global Security 9 (1): 1–32. doi:10.1080/08929880108426485. Bibcode: 2001S&GS....9....1K. "Archived copy". http://www.torium.se/res/Documents/9_1kang.pdf.

- ↑ Ashley, Stephen (2012). "Thorium fuel has risks". Nature 492 (7427): 31–33. doi:10.1038/492031a. PMID 23222590. Bibcode: 2012Natur.492...31A.

- ↑ Office of Nuclear Energy. "What is a Nuclear Microreactor?". Office of Nuclear Energy. https://www.energy.gov/ne/articles/what-nuclear-microreactor. Retrieved 2022-08-18.

- ↑ Williams, Adam David; Osborn, Douglas; Cohn, Brian (2019). "Security Safety and Safeguards (3S) risk analysis for small modular reactors. Report No. SAND2019-6657C. Sandia National Laboratory (SNL-NM), Albuquerque, New mexico (United States)". https://www.osti.gov/biblio/1640767.

- ↑ "NRC Approves First U.S. Small Modular Reactor Design". Department of Energy. September 2, 2020. https://www.energy.gov/ne/articles/nrc-approves-first-us-small-modular-reactor-design.

- ↑ 67.0 67.1 "DIS-16-04, Small Modular Reactors: Regulatory Strategy, Approaches and Challenges". 2016-05-30. https://nuclearsafety.gc.ca/eng/acts-and-regulations/consultation/comment/d-16-04/index.cfm.

- ↑ Pistner, Christoph; Englert, Matthias; Wealer, Ben; Hirschhausen, Christian von; Donderer, Richard (2021-03-01). "Safety analysis and risk assessment of an application of SMR concepts (Small Modular Reactors)". https://inis.iaea.org/search/search.aspx?orig_q=RN:52097919.

- ↑ Ahonen, E., Heinonen, J., Lahtinen, N., Tuomainen, M., & Lång, O. (2020). "Preconditions for the safe use of small modular reactors: Outlook for the licensing system (STUK, Finland)". https://www.julkari.fi/bitstream/handle/10024/139290/STUK_Preconditions%20for%20the%20safe%20use%20of%20small%20modular%20reactors.pdf?sequence=1&isAllowed=y.

- ↑ WENRA RHWG (12 January 2021). "Applicability of the safety objectives to SMRs". https://www.wenra.eu/sites/default/files/publications/WENRA_RHWG_Report_on_applicability_of_safety_objectivers_to_SMR.PDF.

- ↑ Sainati, Tristano; Locatelli, Giorgio; Brookes, Naomi (15 March 2015). "Small Modular Reactors: Licensing constraints and the way forward". Energy 82: 1092–1095. doi:10.1016/j.energy.2014.12.079. http://eprints.whiterose.ac.uk/91108/1/Accepted%20version.pdf.

- ↑ Rysavy, Charles F.; Rhyne, Stephen K.; Shaw, Roger P. (December 2009). "Small Modular Reactors". pp. 1-3. http://apps.americanbar.org/environ/committees/nuclearpower/docs/SMR-Dec_2009.pdf.

- ↑ Smith, Tyson (May 25, 2012). "Special Committee on Nuclear Power, Message From The Chair". http://apps.americanbar.org/dch/committee.cfm?com=NR601577.

- ↑ Black, R.L. (2015), "Licensing of small modular reactors (SMRs)", Handbook of Small Modular Nuclear Reactors (Elsevier): pp. 279–292, doi:10.1533/9780857098535.3.279, ISBN 9780857098511, http://dx.doi.org/10.1533/9780857098535.3.279, retrieved 2022-05-01

- ↑ "Advanced Small Modular Reactors (SMRs)" (in en). https://www.energy.gov/ne/nuclear-reactor-technologies/small-modular-nuclear-reactors.

- ↑ "Small isn't always beautiful". Union of Concerned Scientists. 2013. https://www.ucsusa.org/sites/default/files/legacy/assets/documents/nuclear_power/small-isnt-always-beautiful.pdf.

- ↑ "Small modular nuclear reactors won’t solve nuclear power’s safety, security and cost problems, new report finds". 2013-09-26. https://www.ucsusa.org/about/news/nuclear-powers-safety-security-and-cost-problems.

- ↑ Cho, Adrian (20 May 2020). "U.S. Department of Energy rushes to build advanced new nuclear reactors". Science. https://www.science.org/content/article/us-department-energy-rushes-build-advanced-new-nuclear-reactors.

- ↑ Locatelli, Giorgio; Fiordaliso, Andrea; Boarin, Sara; Ricotti, Marco E. (2017). "Cogeneration: An option to facilitate load following in Small Modular Reactors". Progress in Nuclear Energy 97: 153–161. doi:10.1016/j.pnucene.2016.12.012. ISSN 0149-1970. http://dx.doi.org/10.1016/j.pnucene.2016.12.012.

- ↑ 80.0 80.1 80.2 80.3 Bright, Zach (9 November 2023). "NuScale cancels first-of-a-kind nuclear project as costs surge". Politico. https://www.eenews.net/articles/nuscale-cancels-first-of-a-kind-nuclear-project-as-costs-surge/.

- ↑ Carelli, Mario; Petrovic, B; Mycoff, C; Trucco, Paolo; Ricotti, M.E.; Locatelli, Giorgio (1 January 2007). "Economic comparison of different size nuclear reactors". Simposio LAS/ANS 2007. https://www.researchgate.net/publication/228463939.

- ↑ Harrabin, Roger (23 March 2016). "The nuclear industry: a small revolution". BBC News (British Broadcasting Corporation). https://www.bbc.co.uk/news/business-35863846.

- ↑ Mignacca, Benito; Locatelli, Giorgio; Sainati, Tristano (20 Jun 2020). "Deeds not words: Barriers and remedies for Small Modular nuclear Reactors". Energy 206: 118137. doi:10.1016/j.energy.2020.118137.

- ↑ Mignacca, B.; Locatelli, G. (2020-02-01). "Economics and finance of Small Modular Reactors: A systematic review and research agenda" (in en). Renewable and Sustainable Energy Reviews 118: 109519. doi:10.1016/j.rser.2019.109519. ISSN 1364-0321.

- ↑ Islam, Md. Razibul; Gabbar, Hossam A. (2014-06-06). "Study of small modular reactors in modern microgrids". International Transactions on Electrical Energy Systems 25 (9): 1943–1951. doi:10.1002/etep.1945. ISSN 2050-7038.

- ↑ "Small modular reactors - Can building nuclear power become more cost-effective?". Ernst & Young (gov.uk): 38. March 2016. https://assets.publishing.service.gov.uk/government/uploads/system/uploads/attachment_data/file/665300/TEA_Projects_5-7_-_SMR_Cost_Reduction_Study.pdf. Retrieved 29 February 2020.

- ↑ Bundesamt für die Sicherheit der nuklearen Entsorgung (2021-03-10). "Small Modular Reactors - Was ist von den neuen Reaktorkonzepten zu erwarten?" (in de). https://www.base.bund.de/DE/themen/kt/kta-deutschland/neue_reaktoren/neue-reaktoren_node.html.

- ↑ EIRP (2017-07-01). "What Will Advanced Nuclear Power Plants Cost?" (in en-US). https://www.innovationreform.org/2017/07/01/will-advanced-nuclear-power-plants-cost/.

- ↑ 89.0 89.1 Day, Paul (21 July 2020). "Industry heads warn nuclear costs must be slashed". Reuters. https://www.reutersevents.com/nuclear/industry-heads-warn-nuclear-costs-must-be-slashed.

- ↑ Steigerwald, Björn; Weibezahn, Jens; Slowik, Martin; von Hirschhausen, Christian (15 October 2023). "Uncertainties in estimating production costs of future nuclear technologies: A model-based analysis of small modular reactors". Energy (Elsevier) 281 (15). doi:10.1016/j.energy.2023.128204. https://www.sciencedirect.com/science/article/pii/S0360544223015980. Retrieved 12 January 2024.

- ↑ "US government backs NuScale projects at home and abroad". World Nuclear News. 19 October 2020. https://www.world-nuclear-news.org/Articles/US-government-backs-NuScale-projects-at-home-and-a.

- ↑ "Further cost refinements announced for first US SMR plant". World Nuclear News. 9 January 2023. https://www.world-nuclear-news.org/Articles/Further-cost-refinements-announced-for-first-US-SM.

- ↑ Schlissel, David (11 January 2023). "Eye-popping new cost estimates released for NuScale small modular reactor". https://ieefa.org/resources/eye-popping-new-cost-estimates-released-nuscale-small-modular-reactor.

- ↑ Cho, Adrian (10 November 2023). "Deal to build pint-size nuclear reactors canceled". Science. https://www.science.org/content/article/deal-build-pint-size-nuclear-reactors-canceled.

- ↑ Small Modular Reactors UK, promotion brochure (Report). Rolls-Royce. 2017. https://www.rolls-royce.com/~/media/Files/R/Rolls-Royce/documents/customers/nuclear/smr-brochure-july-2017.pdf. (5.5 MB)

- ↑ UK SMR – brochure with specifications (Report). Rolls-Royce. 2017. https://www.rolls-royce.com/~/media/Files/R/Rolls-Royce/documents/customers/nuclear/smr-technical-summary.pdf. (5 MB) Archived

- ↑ Report to Congress 2001, p. 8

- ↑ 98.0 98.1 98.2 "CNEA and Nucleoeléctrica sign CAREM SMR agreement : New Nuclear". 2023-10-30. https://www.world-nuclear-news.org/Articles/Argentina-s-SMR-CNEA-and-Nucleoelectrica-sign-agre#:~:text=The%20CAREM%20name%20is%20taken,be%20sourced%20from%20Argentine%20companies..

- ↑ Government of New Brunswick, Canada (26 June 2018). "$10 million committed for nuclear research cluster". https://www2.gnb.ca/content/gnb/en/news/news_release.2018.06.0832.html.

- ↑ Government of New Brunswick, Canada (9 July 2018). "Partner announced in nuclear research cluster". https://www2.gnb.ca/content/gnb/en/departments/erd/news/news_release.2018.07.0906.html.

- ↑ Government of New Brunswick, Canada (13 July 2018). "Moltex to partner in nuclear research and innovation cluster". https://www2.gnb.ca/content/gnb/en/departments/erd/news/news_release.2018.07.0930.html.

- ↑ "Collaboration memorandum of understanding". Government of Ontario. http://files.news.ontario.ca.s3-website-us-east-1.amazonaws.com/opo/en/learnmore/premier_ford_premier_higgs_and_premier_moe_sign_agreement_on_the_development_of_small_modular_reacto/2019%2011%2027%20-%20MOU%20Prov%20NB%20and%20ON%20and%20SK.pdf?_ga=2.103085056.1434873882.1575249250-931592757.1575249250.

- ↑ "Premier Ford, Premier Higgs and Premier Moe Sign Agreement on the Development of Small Modular Reactors". Government of Ontario. https://news.ontario.ca/opo/en/2019/12/premier-ford-premier-higgs-and-premier-moe-sign-agreement-on-the-development-of-small-modular-reacto.html.

- ↑ "Opinion: Small nuclear reactors can play big role in clean energy transition". https://calgaryherald.com/opinion/columnists/opinion-small-nuclear-reactors-can-play-big-role-in-clean-energy-transition.

- ↑ OPG chooses BWRX-300 SMR for Darlington new build. WNN, 2 Dec 2021

- ↑ "Pact signed to advance IMSR development in western Canada". NuclearNewswire. https://www.ans.org/news/article-4221/pact-signed-to-advance-imsr-development-in-western-canada/.

- ↑ "CNNC launches demonstration SMR project". World Nuclear News. 22 July 2019. http://www.world-nuclear-news.org/Articles/CNNC-launches-demonstration-SMR-project.

- ↑ "China approves construction of demonstration SMR : New Nuclear - World Nuclear News". https://world-nuclear-news.org/Articles/Construction-of-demonstration-Chinese-SMR-approved.

- ↑ Editing staff (2021-07-13). "China launches first commercial onshore small reactor project" (in en). Reuters. https://www.reuters.com/article/us-china-nuclearpower-idUSKBN2EJ073.

- ↑ Largue, Pamela (2023-08-11). "Core module instaled at China's Linglong One modular reactor" (in en-US). https://www.powerengineeringint.com/nuclear/reactors/core-module-instaled-at-chinas-linglong-one-modular-reactor/.

- ↑ EDF (2022-12-16). "NUWARD™ SMR, leading the way to a low‑carbon world". https://www.edf.fr/en/the-edf-group/producing-a-climate-friendly-energy/nuclear-energy/shaping-the-future-of-nuclear/the-nuwardtm-smr-solution/the-solution.

- ↑ Lopez, Alicia (2023-08-10). "Licensing process begins for Nuward Small Modular Reactor project in France". https://www.foronuclear.org/en/updates/news/licensing-process-begins-for-nuward-small-modular-reactor-project-in-france/.

- ↑ "Billionaire Pole to build nuclear reactor" (in en). https://www.thefirstnews.com/article/billionaire-pole-to-build-nuclear-reactor-8244.

- ↑ "Feasibility study completed on SMRs for Poland - Nuclear Engineering International". https://www.neimagazine.com/news/newsfeasibility-study-completed-on-smrs-for-poland-8415956.

- ↑ "NuScale, KGHM agree to deploy SMRs in Poland" (in en). February 2022. https://www.world-nuclear-news.org/Articles/NuScale,-KGHM-agree-to-deploy-SMRs-in-Poland.

- ↑ Chirileasa, Andrei (2022-05-24). "Romania, the US agree on location of first small-scale nuclear reactor". https://www.romania-insider.com/ro-us-location-small-scale-reactor-may-2022.

- ↑ "Prima centrală cu mini reactor nuclear din Europa va fi la Doicești, Dâmbovița. Cum funcționează o centrală SMR" (in ro). https://romania.europalibera.org/a/centrala-nculeara-doicesti/31917155.html.

- ↑ Agerpres. "Ghiţă (Nuclearelectrica): Suntem încrezători în potenţialul pe care amplasamentul de la.." (in ro). http://www.agerpres.ro/economic/2022/06/15/ghita-nuclearelectrica-suntem-increzatori-in-potentialul-pe-care-amplasamentul-de-la-doicesti-il-are-de-a-gazdui-primul-smr-nuscale-din-europa--934792.

- ↑ McCann, Kate (2 April 2016). "Mini nuclear power stations in UK towns move one step closer". The Sunday Telegraph. https://www.telegraph.co.uk/news/2016/04/02/mini-nuclear-power-stations-in-uk-towns-move-one-step-closer/.

- ↑ "UK confirms funding for Rolls-Royce SMR". World Nuclear News. 7 November 2019. http://www.world-nuclear-news.org/Articles/UK-confirms-funding-for-Rolls-Royce-SMR.

- ↑ Macfarlane-Smith, Sophie (8 September 2021). "Rolls-Royce SMR - Nuclear Academics Meeting". https://www.nuclearuniversities.ac.uk/wp-content/uploads/2021/09/Sophie-Macfarlane-Smith.pdf.

- ↑ "Rolls-Royce plans 16 mini-nuclear plants for UK". BBC News. 11 November 2020. https://www.bbc.co.uk/news/science-environment-54703204.

- ↑ "Rolls-Royce gets funding to develop mini nuclear reactors". BBC. 9 November 2021. https://www.bbc.co.uk/news/business-59212983.

- ↑ "Study identifies potential Rolls-Royce SMR sites". World Nuclear News. 11 November 2022. https://www.world-nuclear-news.org/Articles/Study-identifies-potential-Rolls-Royce-SMR-sites.

- ↑ "Nuclear energy: How environmentally-friendly and safe is it?". BBC News. 17 July 2023. Archived on 10 June 2023. Error: If you specify

|archivedate=, you must also specify|archiveurl=. https://www.bbc.co.uk/news/business-59212992. Retrieved 19 July 2023. - ↑ "Standard Power Ohio and Pennsylvania". NuScale Power. https://www.nuscalepower.com/en/projects.

- ↑ "Dairyland Power Cooperative WisconsinDairyland Power Cooperative Wisconsin". NuScale Power. https://www.nuscalepower.com/en/projects.

- ↑ "Associated Electric Cooperative Missouri". NuSclae Power. https://www.nuscalepower.com/en/projects.

- ↑ Gardner, Timothy. "My View Following Saved Energy Energy Grid & Infrastructure Nuclear Sustainable Markets NuScale ends Utah project, in blow to US nuclear power ambitions". Reuters. https://www.reuters.com/business/energy/nuscale-power-uamps-agree-terminate-nuclear-project-2023-11-08/.

- ↑ Fernández, Lucía. "Estimated unsubsidized levelized costs of energy generation in the United States in 2023, by technology (in U.S. dollars per megawatt hour)". Statista. https://www.statista.com/statistics/493797/estimated-levelized-cost-of-energy-generation-in-the-us-by-technology/.

- ↑ "Carbon Free". http://www.uamps.com/index.php/38-items/24-carbon-free-power-project.

- ↑ "Nuclear Power and the Perils of Pioneering" (in en). https://www.uaf.edu/acep-blog/nuclear-power-and-the-perils-of-pioneering.php.

- ↑ U.S. Nuclear Regulatory Commission (17 December 2019). "NRC to Issue Early Site Permit to Tennessee Valley Authority for Clinch River Site". https://www.nrc.gov/reading-rm/doc-collections/news/2019/19-064.pdf.

- ↑ "TVA - Small Modular Reactors". https://www.tva.gov/Energy/Technology-Innovation/Small-Modular-Reactors.

Further reading

- Daniel T. Ingersoll and Mario D. Carelli, ed (2021). Handbook of Small Modular Nuclear Reactors. Elsevier – Woodhead Publishing. doi:10.1016/c2019-0-00070-2. ISBN 978-0-12-823916-2.

- Office of Nuclear Energy, Science and Technology (January 1993). "DOE Fundamentals Handbook: Nuclear Physics and Reactor Theory". U.S. Department of Energy. http://www.hss.doe.gov/nuclearsafety/techstds/docs/handbook/h1019v2.pdf.

- Office of Nuclear Energy, Science and Technology (May 2001). "Report to Congress on Small Modular Nuclear Reactors". U.S. Department of Energy. http://www.ne.doe.gov/pdfFiles/Cong-Rpt-may01.pdf.

- Vinoya, Carlo L.; Ubando, Aristotle T.; Culaba, Alvin B.; Chen, Wei-Hsin (2023-04-03). "State-of-the-Art Review of Small Modular Reactors". Energies 16 (7): 3224. doi:10.3390/en16073224. ISSN 1996-1073.

- Lyman, Edwin (September 2013). "Small Isn't Always Beautiful. Safety, Security, and Cost Concerns about Small Modular Reactors". ucsusa.org. https://www.ucsusa.org/sites/default/files/2019-10/small-isnt-always-beautiful.pdf.

External links

- "Advanced Reactor Information System (ARIS) IAEA database". 2016-05-17. https://aris.iaea.org/.

- "Small Nuclear Power Reactors". 2018-02-07. https://www.world-nuclear.org/information-library/nuclear-fuel-cycle/nuclear-power-reactors/small-nuclear-power-reactors.aspx.

- "Small Modular Reactors: Challenges and Opportunities". 2023-07-03. https://www.oecd-nea.org/jcms/pl_57979/small-modular-reactors-challenges-and-opportunities.

- "Small Modular Reactors (SMR)". https://www.base.bund.de/EN/ns/ni-germany/smr/small-modular-reactors_node.html.

- DOE Office of Nuclear Energy

- American Nuclear Regulatory Commission

- World Nuclear Association

- American Nuclear Society

- International Atomic Energy Agency

- Overview and Status of SMRs Being Developed in the United States [|permanent dead link|dead link}}]

|

KSF

KSF