Squeeze bore

Topic: Engineering

From HandWiki - Reading time: 4 min

From HandWiki - Reading time: 4 min

Left: Armor-piercing composite non-rigid (APCNR)

Right: Armor-piercing (AP)

A squeeze bore, alternatively taper-bore, cone barrel or conical barrel, is a weapon where the internal barrel diameter progressively decreases towards the muzzle resulting in a reduced final internal diameter. These weapons are used in conjunction with special sub-caliber ammunition where the projectile is fitted with soft-metal flanges which fills out the caliber.[1] As the projectile travels through the squeeze bore the flanges fold inwards, resulting in a reduced caliber round with an increased velocity compared to a traditional full-caliber round.[1]

Mechanism

A squeeze bore utilizes the energy of the propellant to squeeze the diameter of the bullet or shell down, increasing penetration and velocity significantly. This process also meant high chamber pressure and low barrel service life.[2] For example, the service life of a squeeze bore 7.5 cm Pak 41 could be as low as 1000 rounds compared to 5000-7000 rounds for the 7.5 cm Pak 39 (L/48).[3] The diameter of a fired shell could decrease as much as 40% from .50 caliber to .30 caliber (achieved in a version of the M2 machine gun). Rather than squeezing solid shot, this is accomplished through a hardened penetrator core (tungsten for example) and a softer outer jacket (aluminium alloy) forming flanges or wings. This outer jacket was crushed as the projectile left the barrel.[4][5]

The squeeze bore concept typically was used in anti-tank guns before the widespread use of shaped charges.[4] Later, the perfection of discarding sabot ammo, which is based on the same concept of using a larger caliber barrel to fire a smaller caliber projectile at high-speed, negated the need for the squeeze bore concept.[2]

History and usage

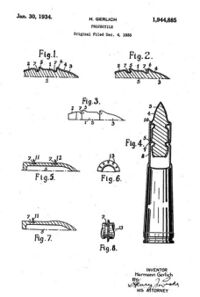

The squeeze bore concept was first patented by German Karl Puff in 1903, even though the general principle was known already in 19th century and used in Armstrong guns. Later, Hermann Gerlich in the 1920s and 1930s experimented with the concept resulting in an experimental 7cm anti-tank rifle with a 1,800 m/s (5,900 ft/s). This led to the squeeze bore concept sometimes being called the "Gerlich principle".

Between 1939-40, Mauser-Werk AG produced the 2.8 cm sPzB 41 and Krupp (in 1941) produced the 7.5 cm Pak 41. These were eventually discontinued due to the lack of tungsten and manufacturing complexity for the ammunition.[2][7][8]

Other uses of the squeeze bore include the British Littlejohn adaptor, a QF 6-pounder adapter and a version of the M2 machine gun produced during WW2.[5] Squeezing down from 40mm to 30mm, 57mm to 42.6mm, and .50 caliber to .30 caliber respectively. The Littlejohn adapter was used to extend the service life of the QF 2 pounder and was designed by František Janeček whose anglicized name gave the Littlejohn its designation. The QF 6 pounder adapter was never adopted.

Gallery

-

2.8 cm sPzB 41 squeeze-bore anti-tank gun captured by British forces in Sicily 1943.

-

4.2 cm Pak 41 light squeeze-bore anti-tank gun in Italy 1943.

-

A German 10 cm schwere Kanone 18 with an 8,8 cm squeeze-bore adapter attached to the muzzle.[1]

-

A Mk VII Tetrarch Mk I with a squeeze-bore Littlejohn adaptor.

See also

Squeeze bore artillery

- 2.8 cm sPzB 41

- 4.2 cm Pak 41

- 7.5 cm Pak 41

References

- ↑ 1.0 1.1 1.2 Rollof, Yngve. "Artillerimaterielens utvecklingstendenser under senaste decenniet". Tidskrift i Sjöväsendet Number 7 1953.

- ↑ 2.0 2.1 2.2 McCollum, Ian (18 February 2017). "Q&A #9: Gas Impingement, Reading List, Squeeze-Bores, and More!". Youtube. https://www.youtube.com/watch?v=y-udMSKJL74. Retrieved 8 July 2018.

- ↑ Ankerstjerne, Christian. "Anti-tank Ammunition Types" (in en). https://panzerworld.com/anti-tank-ammunition#armor-piercing-composite-non-rigid.

- ↑ 4.0 4.1 McCollum, Ian (24 April 2018). "Q&A #17: Bullpups, Stocked Pistols, Delayed Blowback, and More!". Youtube. https://www.youtube.com/watch?v=08XhdWX_AN4. Retrieved 6 July 2018.

- ↑ 5.0 5.1 "Exotic Barrels Part 1: Squeeze Bores | WeaponsMan". WeaponsMan. http://weaponsman.com/?p=21443. Retrieved 6 July 2018.

- ↑ Gerlich, Hermann. "Projectile" (in en). Free Patents Online. http://www.freepatentsonline.com/1944885.pdf. Retrieved 18 July 2018.

- ↑ "Squeeze Bore". 12 January 2011. http://shootingwithhobie.blogspot.com/2011/01/squeeze-bore.html. Retrieved 8 July 2018.

- ↑ S, Rusty (20 May 2016). "Mauser's high-tech antitank gun: the 2.8cm sPzB 41 - The Firearm Blog". https://www.thefirearmblog.com/blog/2016/05/20/mausers-high-tech-antitank-gun-2-8cm-spzb-41/. Retrieved 8 July 2018.

|

KSF

KSF

![A German 10 cm schwere Kanone 18 with an 8,8 cm squeeze-bore adapter attached to the muzzle.[1]](https://handwiki.org/wiki/images/thumb/0/0c/German_10%2C5_cm_squeeze_bore.png/120px-German_10%2C5_cm_squeeze_bore.png)