Trylinka

Topic: Engineering

From HandWiki - Reading time: 4 min

From HandWiki - Reading time: 4 min

Trylinka (Polish: [trɨˈliŋka] (![]() listen); pl. trylinkiTemplate:--), also known as shashka Trylins'koho (Ukrainian: шашка Трилінського),[1] is a concrete block in the shape of a regular hexagon or occasionally a tetragon, with stone fragments embedded in its upper layer. Different stone varieties, which include basalt and porphyry, are used for the embedments depending on the local availability of the stones. Inexpensive, durable and relatively simple to build, trylinki were mass-produced and used on a large scale in the construction of roads in interwar Poland, covering an estimated 1 million square metres (11×106 sq ft) of surface area between 1933 and 1938.[2][3] Some of those roads are in present-day Belarus and Ukraine.

listen); pl. trylinkiTemplate:--), also known as shashka Trylins'koho (Ukrainian: шашка Трилінського),[1] is a concrete block in the shape of a regular hexagon or occasionally a tetragon, with stone fragments embedded in its upper layer. Different stone varieties, which include basalt and porphyry, are used for the embedments depending on the local availability of the stones. Inexpensive, durable and relatively simple to build, trylinki were mass-produced and used on a large scale in the construction of roads in interwar Poland, covering an estimated 1 million square metres (11×106 sq ft) of surface area between 1933 and 1938.[2][3] Some of those roads are in present-day Belarus and Ukraine.

Trylinka was named after its inventor, Władysław Tryliński, a transportation engineer recognised for the engineering design of the Maurzyce Bridge, a credit he shared with construction engineer Stefan Bryła.[4] Whilst Tryliński was overseeing construction aggregate and paving slab productions at the Miękini porphyry quarry (pl), he noticed that the production processes left large amounts of fragmented stone wastes, leading to the idea of recycling the fragments as embedments in trylinki.[5]

Descriptions

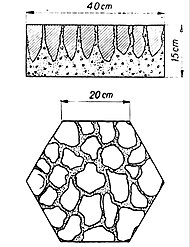

Władysław Tryliński filed a patent application for "driveways and sidewalks made of hexagonal concrete slabs (Polish: jezdnię drogową i chodniki z płyt betonowych sześciokątnych)" in 1932 and obtained the patent from the Polish Patent Office in 1933.[2] Trylinka was designed to be 15 to 20 centimetres (6 to 8 in) thick[6] and each of the hexagon's six sides 20 centimetres (8 in) long.[3] Sometimes reinforced with iron wire, a trylinka typically weighs 35 to 37 kilograms (77 to 82 lb).[3] The six sides of each hexagonal blocks were to be coated with resin and the blocks were laid tightly together on a sand-and-gravel bed in the hexagonal tiling—the gaps between the blocks being filled with asphalt.[7]

The main idea in the patent was to make a mixture of concrete mortar and stone fragments, formed into tetragonal or hexagonal paving blocks; the hexagonal shape was preferable, according to him, because the weakest part of the roadway was long straight joints between the paving blocks, which were absent if hexagonal ones were used.[3]

Uses

Trylinka was extensively used in the construction of roads in interwar Poland during the 1930s, due to its low cost, durability, and ease of manufacturing—as a variety of stones could be used depending on their local availability, its production was inexpensive and relatively simple. Unskilled labourers could be hired for the process because the manufacture and laying of the blocks did not require complicated tools or heavy equipments.[7] So long as the work was organised properly, it was possible to pave 1 kilometre (0.62 mi) of road in six days.[7] Another advantage was that trylinki pavements could be built without taking the road out of service; the pavement was laid on one side of the road, leaving the other open for traffic.[7] Between 1933 and 1938, approximately 10 million pieces of trylinka were produced, and an estimated 1 million square metres (11×106 sq ft) of surface area was covered with them.[3]

In Volhynia, black basalt fragments from Janowa Dolina (present-day Bazaltove, Ukraine) and Berestovets (uk) were used.[3] In Pinsk, a city in present-day Belarus, trylinka covered the central town square in 1938.[8] Janowa Dolina's black basalt was used to make trylinka in the city. In Kraków, the second-largest city in Poland, purple porphyry from Krzeszowice, a town in the Lesser Poland Voivodeship, was used to produce trylinka; the pavement of the Nowy Kleparz (pl) market square at the exit of Długa Street (pl) is one of the extant examples.[3]

References

- ↑ Торбіч, Антоніна (2017). "Від гаїв донецьких до лісів волинських". ЗнеДОленІ? неЗДОланнІ! історії переселенців. Pylyp Orlyk Institute for Democracy (uk). p. 25. ISBN 978-617-581-306-5. https://idpo.org.ua/wp-content/uploads/2017/book-2.pdf. Retrieved 2023-09-21. "Це трилінка, або шашка Трилінського, така бруківка на бетонній основі – частина історії луцька."

- ↑ 2.0 2.1 "Белорусские имена в мировой науке и технике: Трилинский Владислав". Republican Scientific and Technical Library (ru) (RSTL). http://rntbcat.org.by/belnames/F_HTM/Trilinskij.HTML.

- ↑ 3.0 3.1 3.2 3.3 3.4 3.5 3.6 Rajchel, Jacek (2010). "Trylinka: Zabytek techniki drogowej". Nowy Kamieniarz [New Stonemason] 49 (6). ISSN 1899-3419. http://www.rynekkamienia.pl/Archiwum_pdf/NK_49_Trylinka.pdf. Retrieved 2023-05-21.

- ↑ Orłowski, Bolesław. "Tryliński Władysław". Institute of National Remembrance. https://gigancinauki.pl/gn/biogramy/83957,Trylinski-Wladyslaw.html.

- ↑ Bałda, Waldemar (13 April 2014). "Wynalazek inżyniera z kamieniołomu w Miękini. Tam powstała trylinka". https://historia.interia.pl/ii-rzeczpospolita/news-wynalazek-inzyniera-z-kamieniolomu-w-miekini-tam-powstala-tr,nId,1409103.

- ↑ Sarychev, Vasily (2006). "ПЛИТКА-ТРИЛИНКА". in Vecherniy Brest Editorial Board. В поисках утрачаннико вреияние. ISBN 985-6814-04-9. http://www.vb.by/sarychev/content/10/main.php. Retrieved 2023-06-07.

- ↑ 7.0 7.1 7.2 7.3 "Trylinkę zawdzięczamy inż. Władysławowi Trylińskiemu". General Directorate for National Roads and Highways. 2021-06-21. https://www.archiwum.gddkia.gov.pl/pl/a/41564/Trylinke-zawdzieczamy-inz-Wladyslawowi-Trylinskiemu.

- ↑ "ЭТО СТОИТ УВИДЕТЬ". Pinsk City Executive Committee (be-tarask). http://pinsk.gov.by/content/dostoprimechatelnosti-pinska/IT_S_WORTH_SEEING.php.

External links

|

KSF

KSF