Aircraft design process

Topic: Physics

From HandWiki - Reading time: 14 min

From HandWiki - Reading time: 14 min

The aircraft design process is a loosely defined method used to balance many competing and demanding requirements to produce an aircraft that is strong, lightweight, economical and can carry an adequate payload while being sufficiently reliable to safely fly for the design life of the aircraft. Similar to, but more exacting than, the usual engineering design process, the technique is highly iterative, involving high-level configuration tradeoffs, a mixture of analysis and testing and the detailed examination of the adequacy of every part of the structure. For some types of aircraft, the design process is regulated by civil airworthiness authorities.

This article deals with powered aircraft such as airplanes and helicopter designs.

Design constraints

Purpose

The design process starts with the aircraft's intended purpose. Commercial airliners are designed for carrying a passenger or cargo payload, long range and greater fuel efficiency where as fighter jets are designed to perform high speed maneuvers and provide close support to ground troops. Some aircraft have specific missions, for instance, amphibious airplanes have a unique design that allows them to operate from both land and water, some fighters, like the Harrier jump jet, have VTOL (vertical take-off and landing) ability, helicopters have the ability to hover over an area for a period of time.[1]

The purpose may be to fit a specific requirement, e.g. as in the historical case of a British Air Ministry specification, or fill a perceived "gap in the market"; that is, a class or design of aircraft which does not yet exist, but for which there would be significant demand.

Aircraft regulations

Another important factor that influences the design are the requirements for obtaining a type certificate for a new design of aircraft. These requirements are published by major national airworthiness authorities including the US Federal Aviation Administration and the European Aviation Safety Agency.[2][3]

Airports may also impose limits on aircraft, for instance, the maximum wingspan allowed for a conventional aircraft is 80 metres (260 ft) to prevent collisions between aircraft while taxiing.[4]

Financial factors and market

Budget limitations, market requirements and competition set constraints on the design process and comprise the non-technical influences on aircraft design along with environmental factors. Competition leads to companies striving for better efficiency in the design without compromising performance and incorporating new techniques and technology.[5]

In the 1950s and '60s, unattainable project goals were regularly set, but then abandoned, whereas today troubled programs like the Boeing 787 and the Lockheed Martin F-35 have proven far more costly and complex to develop than expected. More advanced and integrated design tools have been developed. Model-based systems engineering predicts potentially problematic interactions, while computational analysis and optimization allows designers to explore more options early in the process. Increasing automation in engineering and manufacturing allows faster and cheaper development. Technology advances from materials to manufacturing enable more complex design variations like multifunction parts. Once impossible to design or construct, these can now be 3D printed, but they have yet to prove their utility in applications like the Northrop Grumman B-21 or the re-engined A320neo and 737 MAX. Airbus and Boeing also recognize the economic limits, that the next airliner generation cannot cost more than the previous ones did.[6]

Environmental factors

An increase in the number of aircraft also means greater carbon emissions. Environmental scientists have voiced concern over the main kinds of pollution associated with aircraft, mainly noise and emissions. Aircraft engines have been historically notorious for creating noise pollution and the expansion of airways over already congested and polluted cities have drawn heavy criticism, making it necessary to have environmental policies for aircraft noise.[7][8] Noise also arises from the airframe, where the airflow directions are changed.[9] Improved noise regulations have forced designers to create quieter engines and airframes.[10] Emissions from aircraft include particulates, carbon dioxide (CO2), sulfur dioxide (SO2), carbon monoxide (CO), various oxides of nitrates and unburnt hydrocarbons.[11] To combat the pollution, ICAO set recommendations in 1981 to control aircraft emissions.[12] Newer, environmentally friendly fuels have been developed[13] and the use of recyclable materials in manufacturing[14] have helped reduce the ecological impact due to aircraft. Environmental limitations also affect airfield compatibility. Airports around the world have been built to suit the topography of the particular region. Space limitations, pavement design, runway end safety areas and the unique location of airport are some of the airport factors that influence aircraft design. However changes in aircraft design also influence airfield design as well, for instance, the recent introduction of new large aircraft (NLAs) such as the superjumbo Airbus A380, have led to airports worldwide redesigning their facilities to accommodate its large size and service requirements.[15][16]

Safety

The high speeds, fuel tanks, atmospheric conditions at cruise altitudes, natural hazards (thunderstorms, hail and bird strikes) and human error are some of the many hazards that pose a threat to air travel.[17][18][19]

Airworthiness is the standard by which aircraft are determined fit to fly.[20] The responsibility for airworthiness lies with the national civil aviation regulatory bodies, manufacturers, as well as owners and operators.[citation needed]

The International Civil Aviation Organization sets international standards and recommended practices on which national authorities should base their regulations.[21][22] The national regulatory authorities set standards for airworthiness, issue certificates to manufacturers and operators and the standards of personnel training.[23] Every country has its own regulatory body such as the Federal Aviation Administration in USA, DGCA (Directorate General of Civil Aviation) in India, etc.

The aircraft manufacturer makes sure that the aircraft meets existing design standards, defines the operating limitations and maintenance schedules and provides support and maintenance throughout the operational life of the aircraft. The aviation operators include the passenger and cargo airliners, air forces and owners of private aircraft. They agree to comply with the regulations set by the regulatory bodies, understand the limitations of the aircraft as specified by the manufacturer, report defects and assist the manufacturers in keeping up the airworthiness standards.[citation needed]

Most of the design criticisms these days are built on crashworthiness. Even with the greatest attention to airworthiness, accidents still occur. Crashworthiness is the qualitative evaluation of how aircraft survive an accident. The main objective is to protect the passengers or valuable cargo from the damage caused by an accident. In the case of airliners the stressed skin of the pressurized fuselage provides this feature, but in the event of a nose or tail impact, large bending moments build all the way through the fuselage, causing fractures in the shell, causing the fuselage to break up into smaller sections.[24] So the passenger aircraft are designed in such a way that seating arrangements are away from areas likely to be intruded in an accident, such as near a propeller, engine nacelle undercarriage etc.[25] The interior of the cabin is also fitted with safety features such as oxygen masks that drop down in the event of loss of cabin pressure, lockable luggage compartments, safety belts, lifejackets, emergency doors and luminous floor strips. Aircraft are sometimes designed with emergency water landing in mind, for instance the Airbus A330 has a 'ditching' switch that closes valves and openings beneath the aircraft slowing the ingress of water.[26]

Design optimization

Aircraft designers normally rough-out the initial design with consideration of all the constraints on their design. Historically design teams used to be small, usually headed by a Chief Designer who knows all the design requirements and objectives and coordinated the team accordingly. As time progressed, the complexity of military and airline aircraft also grew. Modern military and airline design projects are of such a large scale that every design aspect is tackled by different teams and then brought together. In general aviation a large number of light aircraft are designed and built by amateur hobbyists and enthusiasts.[27]

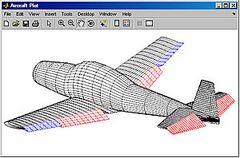

Computer-aided design of aircraft

In the early years of aircraft design, designers generally used analytical theory to do the various engineering calculations that go into the design process along with a lot of experimentation. These calculations were labour-intensive and time-consuming. In the 1940s, several engineers started looking for ways to automate and simplify the calculation process and many relations and semi-empirical formulas were developed. Even after simplification, the calculations continued to be extensive. With the invention of the computer, engineers realized that a majority of the calculations could be automated, but the lack of design visualization and the huge amount of experimentation involved kept the field of aircraft design stagnant. With the rise of programming languages, engineers could now write programs that were tailored to design an aircraft. Originally this was done with mainframe computers and used low-level programming languages that required the user to be fluent in the language and know the architecture of the computer. With the introduction of personal computers, design programs began employing a more user-friendly approach.[28][failed verification]

Design aspects

The main aspects of aircraft design are:

- Aerodynamics

- Propulsion

- Controls

- Mass

- Structure

All aircraft designs involve compromises of these factors to achieve the design mission.[29]

Wing design

The wing of a fixed-wing aircraft provides the lift necessary for flight. Wing geometry affects every aspect of an aircraft's flight. The wing area will usually be dictated by the desired stalling speed but the overall shape of the planform and other detail aspects may be influenced by wing layout factors.[30] The wing can be mounted to the fuselage in high, low and middle positions. The wing design depends on many parameters such as selection of aspect ratio, taper ratio, sweepback angle, thickness ratio, section profile, washout and dihedral.[31] The cross-sectional shape of the wing is its airfoil.[32] The construction of the wing starts with the rib which defines the airfoil shape. Ribs can be made of wood, metal, plastic or even composites.[33]

The wing must be designed and tested to ensure it can withstand the maximum loads imposed by maneuvering, and by atmospheric gusts.

Fuselage

The fuselage is the part of the aircraft that contains the cockpit, passenger cabin or cargo hold.[34]

Empennage

Propulsion

Aircraft propulsion may be achieved by specially designed aircraft engines, adapted auto, motorcycle or snowmobile engines, electric engines or even human muscle power. The main parameters of engine design are:[35]

- Maximum engine thrust available

- Fuel consumption

- Engine mass

- Engine geometry

The thrust provided by the engine must balance the drag at cruise speed and be greater than the drag to allow acceleration. The engine requirement varies with the type of aircraft. For instance, commercial airliners spend more time in cruise speed and need more engine efficiency. High-performance fighter jets need very high acceleration and therefore have very high thrust requirements.[36]

Landing gear

Weight

The weight of the aircraft is the common factor that links all aspects of aircraft design such as aerodynamics, structure, and propulsion, all together. An aircraft's weight is derived from various factors such as empty weight, payload, useful load, etc. The various weights are used to then calculate the center of mass of the entire aircraft.[37] The center of mass must fit within the established limits set by the manufacturer.

Structure

The aircraft structure focuses not only on strength, aeroelasticity, durability, damage tolerance, stability, but also on fail-safety, corrosion resistance, maintainability and ease of manufacturing. The structure must be able to withstand the stresses caused by cabin pressurization, if fitted, turbulence and engine or rotor vibrations.[38]

Design process and simulation

The design of any aircraft starts out in three phases[39]

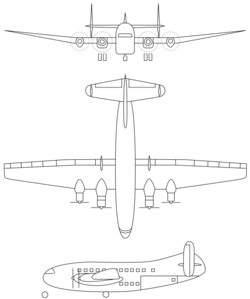

Conceptual design

Aircraft conceptual design involves sketching a variety of possible configurations that meet the required design specifications. By drawing a set of configurations, designers seek to reach the design configuration that satisfactorily meets all requirements as well as go hand in hand with factors such as aerodynamics, propulsion, flight performance, structural and control systems.[40] This is called design optimization. Fundamental aspects such as fuselage shape, wing configuration and location, engine size and type are all determined at this stage. Constraints to design like those mentioned above are all taken into account at this stage as well. The final product is a conceptual layout of the aircraft configuration on paper or computer screen, to be reviewed by engineers and other designers.

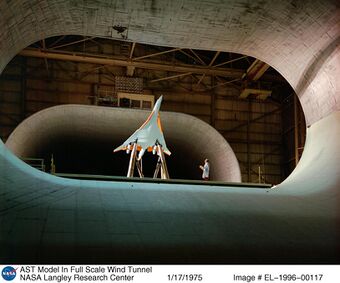

Preliminary design phase

The design configuration arrived at in the conceptual design phase is then tweaked and remodeled to fit into the design parameters. In this phase, wind tunnel testing and computational fluid dynamic calculations of the flow field around the aircraft are done. Major structural and control analysis is also carried out in this phase. Aerodynamic flaws and structural instabilities if any are corrected and the final design is drawn and finalized. Then after the finalization of the design lies the key decision with the manufacturer or individual designing it whether to actually go ahead with the production of the aircraft.[41] At this point several designs, though perfectly capable of flight and performance, might have been opted out of production due to their being economically nonviable.

Detail design phase

This phase simply deals with the fabrication aspect of the aircraft to be manufactured. It determines the number, design and location of ribs, spars, sections and other structural elements.[42] All aerodynamic, structural, propulsion, control and performance aspects have already been covered in the preliminary design phase and only the manufacturing remains. Flight simulators for aircraft are also developed at this stage.

Delays

Some commercial aircraft have experienced significant schedule delays and cost overruns in the development phase. Examples of this include the Boeing 787 Dreamliner with a delay of 4 years with massive cost overruns, the Boeing 747-8 with a two-year delay, the Airbus A380 with a two-year delay and US$6.1 billion in cost overruns, the Airbus A350 with delays and cost overruns, the Bombardier C Series, Global 7000 and 8000, the Comac C919 with a four-year delay and the Mitsubishi Regional Jet, which was delayed by four years and ended up with empty weight issues.[43]

Program development

An existing aircraft program can be developed for performance and economy gains by stretching the fuselage, increasing the MTOW, enhancing the aerodynamics, installing new engines, new wings or new avionics. For a 9,100 nmi long range at Mach 0.8/FL360, a 10% lower TSFC saves 13% of fuel, a 10% L/D increase saves 12%, a 10% lower OEW saves 6% and all combined saves 28%.[44]

Re-engine

| Base | Previous engines | First flight | Re-engined | New engines | First flight |

|---|---|---|---|---|---|

| DC-8 Super 60 | JT3D | May 30, 1958 | DC-8 Super 70 | CFM56 | 1982 |

| Boeing 737 Original | JT8D | Apr 9, 1967 | Boeing 737 Classic | CFM56 | Feb 24, 1984 |

| Fokker F28 | Rolls-Royce Spey | May 9, 1967 | Fokker 100/70 | Rolls-Royce Tay | Nov 30, 1986 |

| Boeing 747 | JT9D/CF6-50/RB211-524 | Feb 9, 1969 | Boeing 747-400 | PW4000/CF6-80/RB211-524G/H | Apr 29, 1988 |

| Douglas DC-10 | JT9D/CF6-50 | Aug 29, 1970 | MD-11 | PW4000/CF6-80 | Jan 10, 1990 |

| Douglas DC-9/MD-80 | JT8D | Feb 25, 1965 | MD-90 | V2500 | Feb 22, 1993 |

| Boeing 737 Classic | CFM56-3 | Feb 24, 1984 | Boeing 737 NG | CFM56-7 | Feb 9, 1997 |

| Boeing 747-400 | PW4000/CF6/RB211 | Apr 29, 1988 | Boeing 747-8 | GEnx-2b | Feb 8, 2010 |

| Airbus A320 | CFM56/V2500 | Feb 22, 1987 | Airbus A320neo | CFM LEAP/PW1100G | Sep 25, 2014 |

| Boeing 737 NG | CFM56 | Feb 9, 1997 | Boeing 737 MAX | CFM LEAP | Jan 29, 2016 |

| Embraer E-Jet | CF34 | Feb 19, 2002 | Embraer E-Jet E2 | PW1000G | May 23, 2016 |

| Airbus A330 | CF6/PW4000/Trent 700 | Nov 2, 1992 | Airbus A330neo | Trent 7000 | Oct 19, 2017 |

| Boeing 777 | GE90/PW4000/Trent 800 | Jun 12, 1994 | Boeing 777X | GE9X | Jan 25, 2020 |

Fuselage stretch

| Base | Base length | First flight | Stretched | Stretched length | First flight |

|---|---|---|---|---|---|

| Boeing 737-100 | 28.65 m (94.00 ft) | Apr 9, 1967 | 737-200 | 30.5 m (100.2 ft) | Aug 8, 1967 |

| 737-500/600 | 31.00–31.24 m (101.71–102.49 ft) | ||||

| 737-300/700 | 33.4–33.63 m (109.6–110.3 ft) | ||||

| 737 MAX 7 | 35.56 m (116.7 ft) | ||||

| 737-400 | 36.40 m (119.4 ft) | ||||

| 737-800/MAX 8 | 39.47 m (129.5 ft) | ||||

| 737-900/MAX 9 | 42.11 m (138.2 ft) | ||||

| 737 MAX 10 | 43.80 m (143.7 ft) | plan. 2020 | |||

| Boeing 747-100/200/300/400 | 70.66 m (231.8 ft) | Feb 9, 1969 | Boeing 747SP | 56.3 m (185 ft) | Jul 4, 1975 |

| Boeing 747-8 | 76.25 m (250.2 ft) | Feb 8, 2010 | |||

| Boeing 757 | 47.3 m (155 ft) | Feb 19, 1982 | Boeing 757-300 | 54.4 m (178 ft) | |

| Boeing 767-200/ER | 48.51 m (159.2 ft) | Sep 26, 1981 | Boeing 767-300/ER | 54.94 m (180.2 ft) | |

| Boeing 767-400ER | 61.37 m (201.3 ft) | ||||

| Boeing 777-200/ER/LR | 63.73 m (209.1 ft) | Jun 12, 1994 | Boeing 777X-8 | 69.8 m (229 ft) | |

| Boeing 777-300/ER | 73.86 m (242.3 ft) | Oct 16, 1997 | |||

| Boeing 777X-9 | 76.7 m (252 ft) | Jan 25, 2020 | |||

| Boeing 787-8 | 56.72 m (186.08 ft) | Dec 15, 2009 | Boeing 787-9 | 62.81 m (206.08 ft) | Sep 17, 2013 |

| Boeing 787-10 | 68.28 m (224 ft) | Mar 31, 2017 | |||

| Airbus A300 | 53.61–54.08 m (175.9–177.4 ft) | Oct 28, 1972 | Airbus A310 | 46.66 m (153.1 ft) | Apr 3, 1982 |

| Airbus A320 (neo) | 37.57 m (123.3 ft) | Feb 22, 1987 | Airbus A318 | 31.44 m (103.1 ft) | Jan 15, 2002 |

| Airbus A319 (neo) | 33.84 m (111.0 ft) | Aug 25, 1995 | |||

| Airbus A321 (neo) | 44.51 m (146.0 ft) | Mar 11, 1993 | |||

| Airbus A330-300/900 | 63.67 m (208.9 ft) | Nov 2, 1992 | Airbus A330-200/800 | 58.82 m (193.0 ft) | Aug 13, 1997 |

| Airbus A340-300 | 63.69 m (209.0 ft) | Oct 25, 1991 | Airbus A340-200 | 59.40 m (194.9 ft) | Apr 1, 1992 |

| Airbus A340-500 | 67.93 m (222.9 ft) | Feb 11, 2002 | |||

| Airbus A340-600 | 75.36 m (247.2 ft) | Apr 23, 2001 | |||

| Airbus A350-900 | 66.61 m (218.5 ft) | Jun 14, 2013 | A350-1000 | 73.59 m (241.4 ft) | Nov 24, 2016 |

See also

- Index of aviation articles

- Aerospace engineering

- Aircraft manufacturer

- Iron bird (aviation)

References

- ↑ "Hovering". Flight maneuvers. www.dynamicflight.com. http://www.dynamicflight.com/flight_maneuvers/hovering/.

- ↑ "Airworthiness - Transport Canada". Airworthiness Directives. Transport Canada. http://www.tc.gc.ca/eng/civilaviation/publications/tp14371-lra-2-0-2566.htm#2-7.

- ↑ "Airworthiness - CASA". Airworthiness Directives. CASA - Australian Government. http://www.casa.gov.au/scripts/nc.dll?WCMS:STANDARD::pc=PC_90822.

- ↑ "ICAO Aerodrome Standards". ICAO Regulations. ICAO. http://www.icao.int/fsix/_Library%5CManual%20Aerodrome%20Stds.pdf.

- ↑ Lloyd R. Jenkinson; Paul Simpkin; Darren Rhodes (1999). "Aircraft Market". Civil Jet Aircraft Design. Great Britain: Arnold Publishers. p. 10. ISBN 0-340-74152-X.

- ↑ Graham Warwick (May 6, 2016). "Problems Aerospace Still Has To Solve". Aviation Week & Space Technology. http://aviationweek.com/technology-milestones/problems-aerospace-still-has-solve.

- ↑ "Travel(Air) - Aircraft Noise". Mobility and Transport. European Commission. 2010-10-30. http://ec.europa.eu/transport/air/environment/aircraft_noise_en.htm.

- ↑ "Annex 16 - Environmental Protection". Convention on International Civil Aviation. ICAO. p. 29. http://www.icao.int/icaonet/anx/info/annexes_booklet_en.pdf.

- ↑ William Wilshire. "Airframe Noise Reduction". NASA Aeronautics. NASA. http://www.aeronautics.nasa.gov/docs/chicago/airframe.htm.

- ↑ Neal Nijhawan. "Environment: Aircraft Noise Reduction". NASA Aeronautics. NASA. http://www.aeronautics.nasa.gov/docs/chicago/noise.htm.

- ↑ "Safeguarding our atmosphere". Fact Sheet. NASA - Glenn Research Center. http://www.nasa.gov/centers/glenn/about/fs10grc.html.

- ↑ "ICAO Airport Air Quality Guidance Manual". ICAO Guidelines. ICAO (International Civil Aviation Organisation). 2007-04-15. http://www.icao.int/icaonet/dcs/9889/9889_en.pdf.(see http://www.icao.int/environmental-protection/Documents/Publications/FINAL.Doc%209889.1st%20Edition.alltext.en.pdf for updated manual.

- ↑ "Biofuel Flight Demonstration". Environment. Virgin Atlantic. 2008. http://www.virgin-atlantic.com/en/us/allaboutus/environment/biofuel.jsp.

- ↑ "Aircraft Recycling: Life and times of an aircraft". Pressroom - Airlines International. IATA. http://www.iata.org/pressroom/airlines-international/august-2011/pages/aircraft-recycling.aspx.

- ↑ Alexandre Gomes de Barros; Sumedha Chandana Wirasinghe (1997). "New Aircraft Characteristics Related To Airport Planning". First ATRG Conference, Vancouver, Canada. Air Transport Research Group of the WCTR Society. http://my.fit.edu/~dkirk/3241/Lectures/Atrgpap.pdf.

- ↑ Sandra Arnoult (2005-02-28). "Airports prepare for the A380". Airline Finance/Data. ATW (Air Transport World). http://atwonline.com/airline-financedata/article/airports-prepare-a380-0309.

- ↑ "Bird hazards". Hazards. www.airsafe.com. http://www.airsafe.com/birds.htm.

- ↑ "The human component in air accidents". Air Safety. www.pilotfriend.com. http://www.pilotfriend.com/safe/safety/human_and_accidents.htm.

- ↑ "Aviation Weather Hazards". LAKP Prairies. www.navcanada.ca. http://www.navcanada.ca/ContentDefinitionFiles/publications/lak/CanadianPrairies/2-P32E.PDF.

- ↑ "Airworthiness". Dictionary. The Free online Dictionary. http://www.thefreedictionary.com/airworthiness.

- ↑ "ICAO regulations". ICAO. http://www.icao.int/environmental-protection/Pages/technology-standards.aspx.

- ↑ "Annex 8 - ICAO" (PDF) (Press release). ICAO. Archived from the original (PDF) on 2012-09-05. Retrieved May 5, 2012.

- ↑ L. Jenkinson; P. Simpkin; D. Rhodes (1999). Civil Jet Aircraft Design. Great Britain: Arnold Publishers. p. 55. ISBN 0-340-74152-X.

- ↑ D. L. Greer; J. S. Breeden (1965-11-18). "Crashworthy Design Principles". Technical Report. Defense Technical Information Center (DTIC). http://www.dtic.mil/cgi-bin/GetTRDoc?Location=U2&doc=GetTRDoc.pdf&AD=AD0623575.

- ↑ Dennis F. Shanahan (2004). "Basic Principles of Crashworthiness". CiteSeerX 10.1.1.214.8052.

- ↑ "Airbus A330-A340 Overhead Panel". Data. www.smartcockpit.com. http://www.smartcockpit.com/data/pdfs/plane/airbus/a340/instructor/A330-A340_Overhead_Pushbuttons.pdf.

- ↑ "Amateur Built Aircraft". General Aviation and Recreational Aircraft. FAA. http://www.faa.gov/aircraft/gen_av/ultralights/amateur_built/.

- ↑ "Aircraft Design Software". Computer Technology. NASA. http://www.sti.nasa.gov/tto/spinoff1997/ct11.html.

- ↑ "Techniques for Aircraft Configuration Optimization". Aircraft Design : Synthesis and Analysis. Stanford University. http://adg.stanford.edu/aa241/design/optimization1.html.

- ↑ Jenkinson, Lloyd R.; Rhodes, Darren; Simpkin, Paul (1999). Civil jet aircraft design. p. 105. ISBN 0-340-74152-X.

- ↑ Jenkinson, Lloyd R.; Rhodes, Darren; Simpkin, Paul (1999). Civil Jet Aircraft design. ISBN 0-340-74152-X.

- ↑ John Cutler; Jeremy Liber (2006-02-10). Understanding aircraft structures. ISBN 1-4051-2032-0.

- ↑ Hugh Nelson (1938). Aero Engineering Vol II Part I. George Newnes.

- ↑ "Fuselage Layout". Stanford University. http://adg.stanford.edu/aa241/fuselayout/fusesection.html.

- ↑ Takahashi, Timothy (2016). Aircraft Performance and Sizing, Volume I. Momentum Press Engineering. pp. 77–100. ISBN 978-1-60650-683-7.

- ↑ "Beginner's Guide to Propulsion". Beginner's Guide. NASA. http://www.grc.nasa.gov/WWW/K-12/airplane/bgp.html.

- ↑ "Aircraft weight and balance". Pilot friend - Flight training. www.pilotfriend.com. http://www.pilotfriend.com/training/flight_training/wt_bal.htm.

- ↑ T.H.G Megson (16 February 2010). Aircraft Structures (4th ed.). Elsevier Ltd.. p. 353. ISBN 978-1-85617-932-4.

- ↑ John D. Anderson (1999). Aircraft Performance and design. McGraw-Hill. pp. 382–386. ISBN 0-07-001971-1.

- ↑ D. Raymer (1992). Aircraft Design - A conceptual approach. American institute of Aeronautics and Astronautics. p. 4. ISBN 0-930403-51-7.

- ↑ D. Raymer (1992). Aircraft design - A conceptual approach. American institute of Aeronautics and Astronautics. p. 5. ISBN 0-930403-51-7.

- ↑ John D. Anderson (1999). Aircraft performance and Design. Mc Graw Hill. ISBN 0-07-001971-1.

- ↑ "Program management in aerospace and defense - Still late and over budget". Deloitte. 2016. https://www2.deloitte.com/content/dam/Deloitte/us/Documents/manufacturing/us-manufacturing-program-management-aerospace-defense.pdf.

- ↑ Committee on Analysis of Air Force Engine Efficiency Improvement Options for Large Non-fighter Aircraft (2007). Improving the Efficiency of Engines for Large Nonfighter Aircraft. US National Research Council. p. 15. ISBN 978-0-309-66765-4. https://download.nap.edu/cart/download.cgi?record_id=11837.

External links

- Egbert Torenbeek (1976), Synthesis of Subsonic Airplane Design, Delft University Press, https://www.academia.edu/14985385

- Antonio Filippone (2000), "Data and performances of selected aircraft and rotorcraft", Progress in Aerospace Sciences (Elsevier) 36 (8): 629–654, doi:10.1016/S0376-0421(00)00011-7, Bibcode: 2000PrAeS..36..629F

- "Aircraft Design: Synthesis and Analysis". Desktop Aeronautics, Inc.. 2001. https://www.academia.edu/36508303.

- Dennis F. Shanahan (8 Mar 2005). "Basic principles of Crashworthiness". NATO. https://www.sto.nato.int/publications/STO%20Educational%20Notes/RTO-EN-HFM-113/EN-HFM-113-07.pdf.

- M. Nila; D. Scholz (2010). "From preliminary aircraft cabin design to cabin optimization". https://www.fzt.haw-hamburg.de/pers/Scholz/OPerA/OPerA_PUB_DLRK_10-08-31.pdf.

- "Airman". Nonresident Training Courses. U.S. Navy. December 2012. http://www.courses.netc.navy.mil/downloads.htm?cid=1495.

- Guy Norris (Mar 10, 2014). "Boeing's 'Wonder Wall'". Aviation Week Network. https://aviationweek.com/blog/boeings-wonder-wall.

- Dieter Scholz (9 July 2018). "Aircraft Design - an Open Educational Resource". Hamburg Open Online University. http://www.fzt.haw-hamburg.de/pers/Scholz/HOOU/.

Re-engine

- Thomas C. Hayes (November 27, 1981). "BOEING'S 'RE-ENGINING' WORRY". NY Times. https://www.nytimes.com/1981/11/27/business/boeing-s-re-engining-worry.html.

- Oliver Wyman (December 2010). "To Re-Engine or Not to Re-Engine: That is the Question". Aviation Week Network. http://speednews.com/article/6950.

|

KSF

KSF