Maglev

Topic: Physics

From HandWiki - Reading time: 56 min

From HandWiki - Reading time: 56 min

The neutrality of this article is disputed. (May 2023) (Learn how and when to remove this template message) |

File:Transrapid Shanghai maglev train ride.webm

Maglev (derived from magnetic levitation) is a system of train transportation that is levitated along a guideway through the use of magnetic forces. By levitating, maglev trains remove the rail-to-wheel contact present in conventional railways, eliminating rolling resistance.[1][2]

Compared to conventional railways, maglev trains can have several advantages, including higher top speeds, superior acceleration and deceleration, lower maintenance costs, improved gradient handling, and lower noise at equivalent speeds. However, maglev systems are more expensive to build, cannot make use of existing infrastructure, and have higher energy usage at high speeds.[3]

Maglev trains have set several speed records. The train speed record of 603 km/h (375 mph) was set by the experimental Japanese L0 Series maglev in 2015.[4] From 2002 until 2021, the record for the highest operational speed of a passenger train of 431 kilometres per hour (268 mph) was held by the Shanghai maglev train, which uses German Transrapid technology.[5] The service connects Shanghai Pudong International Airport and the outskirts of central Pudong, Shanghai. At its historical top speed, it covered the distance of 30.5 kilometres (19 mi) in just over 8 minutes.

Different maglev systems achieve levitation in different ways, which broadly fall into two categories: electromagnetic suspension (EMS) and electrodynamic suspension (EDS). Propulsion is typically provided by a linear motor.[6] The power needed for levitation is typically not a large percentage of the overall energy consumption of a high-speed maglev system.[7] Instead, overcoming drag takes the most energy. Vactrain technology has been proposed as a means to overcome this limitation.

Despite over a century of research and development, there are only six operational maglev trains today — three in China, two in South Korea, and one in Japan.[8][9]

Development

In the late 1940s, the British electrical engineer Eric Laithwaite, a professor at Imperial College London, developed the first full-size working model of the linear induction motor. He became professor of heavy electrical engineering at Imperial College in 1964, where he continued his successful development of the linear motor.[10] Since linear motors do not require physical contact between the vehicle and guideway, they became a common fixture on advanced transportation systems in the 1960s and 1970s. Laithwaite joined one such project, the Tracked Hovercraft RTV-31, based near Cambridge, UK, although the project was cancelled in 1973.[11]

The linear motor was naturally suited to use with maglev systems as well. In the early 1970s, Laithwaite discovered a new arrangement of magnets, the magnetic river, that allowed a single linear motor to produce both lift and forward thrust, allowing a maglev system to be built with a single set of magnets. Working at the British Rail Research Division in Derby, along with teams at several civil engineering firms, the "transverse-flux" system was developed into a working system.

The first commercial maglev people mover was simply called "MAGLEV" and officially opened in 1984 near Birmingham, England. It operated on an elevated 600 metres (2,000 ft) section of monorail track between Birmingham Airport and Birmingham International railway station, running at speeds up to 42 kilometres per hour (26 mph). The system was closed in 1995 due to reliability problems.[12]

History

First maglev patent

High-speed transportation patents were granted to various inventors throughout the world.[13] The first relevant patent, U.S. Patent 714,851 (2 December 1902), issued to Albert C. Albertson, used magnetic levitation to take part of the weight off of the wheels while using conventional propulsion.

Early United States patents for a linear motor propelled train were awarded to German inventor Alfred Zehden. The inventor was awarded U.S. Patent 782,312 (14 February 1905) and U.S. Patent RE12,700 (21 August 1907).[note 1] In 1907, another early electromagnetic transportation system was developed by F. S. Smith.[14] In 1908, Cleveland mayor Tom L. Johnson filed a patent for a wheel-less "high-speed railway" levitated by an induced magnetic field.[15] Jokingly known as "Greased Lightning," the suspended car operated on a 90-foot test track in Johnson's basement "absolutely noiseless[ly] and without the least vibration."[16] A series of German patents for magnetic levitation trains propelled by linear motors were awarded to Hermann Kemper between 1937 and 1941.[note 2] An early maglev train was described in U.S. Patent 3,158,765, "Magnetic system of transportation", by G. R. Polgreen on 25 August 1959. The first use of "maglev" in a United States patent was in "Magnetic levitation guidance system"[17] by Canadian Patents and Development Limited.

New York, United States, 1912

In 1912 French-American inventor Émile Bachelet demonstrated a model train with electromagnetic levitation and propulsion in Mount Vernon, New York.[18] Bachelet's first related patent, U.S. Patent 1,020,942 was granted in 1912. The electromagnetic propulsion was by attraction of iron in the train by direct current solenoids spaced along the track. The electromagnetic levitation was due to repulsion of the aluminum base plate of the train by the pulsating current electromagnets under the track. The pulses were generated by Bachelet's own Synchronizing-interrupter U.S. Patent 986,039 supplied with 220 VAC. As the train moved it switched power to the section of track that it was on. Bachelet went on to demonstrate his model in London, England in 1914, which resulted in the registration of Bachelet Levitated Railway Syndicate Limited July 9 in London, just weeks before the start of WWI.[19]

Bachelet's second related patent, U.S. Patent 1,020,943 granted the same day as the first, had the levitation electromagnets in the train and the track was aluminum plate. In the patent he stated that this was a much cheaper construction, but he did not demonstrate it.

New York, United States, 1968

In 1959, while delayed in traffic on the Throgs Neck Bridge, James Powell, a researcher at Brookhaven National Laboratory (BNL), thought of using magnetically levitated transportation.[20] Powell and BNL colleague Gordon Danby worked out a maglev concept using static magnets mounted on a moving vehicle to induce electrodynamic lifting and stabilizing forces in specially shaped loops, such as figure-of-8 coils on a guideway.[21] These were patented in 1968–1969.[22]

Japan, 1969

Japan operates two independently developed maglev trains. One is HSST (and its descendant, the Linimo line) by Japan Airlines and the other, which is more well known, is SCMaglev by the Central Japan Railway Company.

The development of the latter started in 1969. The first successful SCMaglev run was made on a short track at the Japanese National Railways' (JNR's) Railway Technical Research Institute in 1972.[23] Maglev trains on the Miyazaki test track (a later, 7 km long test track) regularly hit 517 kilometres per hour (321 mph) by 1979. After an accident destroyed the train, a new design was selected. In Okazaki, Japan (1987), the SCMaglev was used for test rides at the Okazaki exhibition. Tests in Miyazaki continued throughout the 1980s, before transferring to a far longer test track, 20 kilometres (12 mi) long, in Yamanashi in 1997. The track has since been extended to almost 43 kilometres (27 mi). The 603 kilometres per hour (375 mph) world speed record for crewed trains was set there in 2015.

Development of HSST started in 1974. In Tsukuba, Japan (1985), the HSST-03 (Linimo) became popular at the Tsukuba World Exposition, in spite of its low 30 kilometres per hour (19 mph) top speed. In Saitama, Japan (1988), the HSST-04-1 was revealed at the Saitama exhibition in Kumagaya. Its fastest recorded speed was 300 kilometres per hour (190 mph).[24]

Construction of a new high-speed maglev line, the Chuo Shinkansen, started in 2014. It is being built by extending the SCMaglev test track in Yamanashi in both directions. The completion date is unknown, with the estimate of 2027 no longer possible following a local governmental rejection of a construction permit.[25]

Hamburg, Germany, 1979

Transrapid 05 was the first maglev train with longstator propulsion licensed for passenger transportation. In 1979, a 908 metres (2,979 ft) track was opened in Hamburg for the first International Transportation Exhibition (IVA 79). Interest was sufficient that operations were extended three months after the exhibition finished, having carried more than 50,000 passengers. It was reassembled in Kassel in 1980.

Ramenskoye, Moscow, USSR, 1979

In 1979 the USSR town of Ramenskoye (Moscow oblast) built an experimental test site for running experiments with cars on magnetic suspension. The test site consisted of a 60-metre ramp which was later extended to 980 metres.[26] From the late 1970s to the 1980s five prototypes of cars were built that received designations from TP-01 (ТП-01) to TP-05 (ТП-05).[27] The early cars were supposed to reach the speed up to 100 kilometres per hour (62 mph).

The construction of a maglev track using the technology from Ramenskoye started in Armenian SSR in 1987[28] and was planned to be completed in 1991. The track was supposed to connect the cities of Yerevan and Sevan via the city of Abovyan.[29] The original design speed was 250 kilometres per hour (160 mph) which was later lowered to 180 kilometres per hour (110 mph).[30] However, the Spitak earthquake in 1988 and the First Nagorno-Karabakh War caused the project to freeze. In the end the overpass was only partially constructed.[31]

In the early 1990s, the maglev theme was continued by the Engineering Research Center "TEMP" (ИНЦ "ТЭМП")[32] this time by the order from the Moscow government. The project was named V250 (В250). The idea was to build a high-speed maglev train to connect Moscow to the Sheremetyevo airport. The train would consist of 64-seater cars and run at speeds up to 250 kilometres per hour (160 mph).[27] In 1993, due to the financial crisis, the project was abandoned. However, from 1999 the "TEMP" research center had been participating as a co-developer in the creation of the linear motors for the Moscow Monorail system.

Birmingham, United Kingdom, 1984–1995

The world's first commercial maglev system was a low-speed maglev shuttle that ran between the airport terminal of Birmingham International Airport and the nearby Birmingham International railway station between 1984 and 1995.[33] Its track length was 600 metres (2,000 ft), and trains levitated at an altitude of 15 millimetres [0.59 in], levitated by electromagnets, and propelled with linear induction motors.[34] It operated for 11 years and was initially very popular with passengers,[35] but obsolescence problems with the electronic systems made it progressively unreliable[36] as years passed, leading to its closure in 1995. One of the original cars is now on display at Railworld in Peterborough, together with the RTV31 hover train vehicle. Another is on display at the National Railway Museum in York.

Several favourable conditions existed when the link was built:[citation needed]

- The British Rail Research vehicle was 3 tonnes and extension to the 8-tonne vehicle was easy.

- Electrical power was available.

- The airport and rail buildings were suitable for terminal platforms.

- Only one crossing over a public road was required and no steep gradients were involved.

- Land was owned by the railway or airport.

- Local industries and councils were supportive.

- Some government finance was provided and because of sharing work, the cost per organization was low.

After the system closed in 1995, the original guideway lay dormant[37] until 2003, when a replacement cable-hauled system, the AirRail Link Cable Liner people mover, was opened.[38][39]

Emsland, Germany, 1984–2012

Transrapid, a German maglev company, had a test track in Emsland with a total length of 31.5 kilometres (19.6 mi). The single-track line ran between Dörpen and Lathen with turning loops at each end. The trains regularly ran at up to 420 kilometres per hour (260 mph). Paying passengers were carried as part of the testing process. The construction of the test facility began in 1980 and finished in 1984.

In 2006, a maglev train accident occurred in Lathen, killing 23 people. It was found to have been caused by human error in implementing safety checks. From 2006 no passengers were carried. At the end of 2011 the operation licence expired and was not renewed, and in early 2012 demolition permission was given for its facilities, including the track and factory.[40]

In March 2021 it was reported the CRRC was investigating reviving the Emsland test track.[41] In May 2019 CRRC had unveiled its 'CRRC 600' prototype which is designed to reach 600 kilometres per hour (370 mph).

Vancouver, Canada and Hamburg, Germany, 1986–88

In Vancouver, Canada, the HSST-03 by HSST Development Corporation (Japan Airlines and Sumitomo Corporation) was exhibited at Expo 86,[42] and ran on a 400-metre (0.25 mi) test track that provided guests with a ride in a single car along a short section of track at the fairgrounds.[43] It was removed after the fair. It was shown at the Aoi Expo in 1987 and is now on static display at Okazaki Minami Park.

Berlin, Germany, 1984–1992

In West Berlin, the M-Bahn was built in 1984. It was a driverless maglev system with a 1.6 kilometres (1.0 mi) track connecting three stations. Testing with passenger traffic started in August 1989, and regular operation started in July 1991. Although the line largely followed a new elevated alignment, it terminated at Gleisdreieck U-Bahn station, where it took over an unused platform for a line that formerly ran to East Berlin. After the fall of the Berlin Wall, plans were set in motion to reconnect this line (today's U2). Deconstruction of the M-Bahn line began only two months after regular service began and was completed during February 1992.

South Korea, 1993 - 2023

In 1993, South Korea completed the development of its own maglev train, shown off at the Taejŏn Expo '93, which was developed further into a full-fledged maglev capable of travelling up to 110 kilometres per hour (68 mph) in 2006. This final model was incorporated in the Incheon Airport Maglev which opened on 3 February 2016, making South Korea the world's fourth country to operate its own self-developed maglev after the United Kingdom's Birmingham International Airport,[45] Germany's Berlin M-Bahn,[46] and Japan 's Linimo.[47] It links Incheon International Airport to the Yongyu Station and Leisure Complex on Yeongjong island.[48] It offers a transfer to the Seoul Metropolitan Subway at AREX's Incheon International Airport Station and is offered free of charge to anyone to ride, operating between 9 am and 6 pm with 15-minute intervals.[49]

The maglev system was co-developed by the South Korea Institute of Machinery and Materials (KIMM) and Hyundai Rotem.[50][51][52] It is 6.1 kilometres (3.8 mi) long, with six stations and a 110 kilometres per hour (68 mph) operating speed.[53]

Two more stages are planned of 9.7 kilometres (6 mi) and 37.4 kilometres (23.2 mi). Once completed it will become a circular line.

It was shut down in September 2023.

Germany/China, 2010–present

Transport System Bögl (TSB) is a driverless maglev system developed by the German construction company Max Bögl since 2010. Its primary intended use is for short to medium distances (up to 30 km) and speeds up to 150 km/h for uses such as airport shuttles. The company has been doing test runs on an 820-meter-long test track at their headquarters in Sengenthal, Upper Palatinate, Germany , since 2012 clocking over 100,000 tests covering a distance of over 65,000 km as of 2018.

In 2018 Max Bögl signed a joint venture with the Chinese company Chengdu Xinzhu Road & Bridge Machinery Co. with the Chinese partner given exclusive rights of production and marketing for the system in China. The joint venture constructed a 3.5 km (2.2 mi) demonstration line near Chengdu, China, and two vehicles were airlifted there in June, 2020.[54] In February 2021 a vehicle on the Chinese test track hit a top speed of 169 km/h (105 mph).[55]

China, since 2000

According to the International Maglev Board there are at least four maglev research programmes underway in China at: Southwest Jiaotong University (Chengdu), Tongji University (Shanghai), CRRC Tangshan-Changchun Railway Vehicle Co. and Chengdu Aircraft Industry Group.[56] The latest high-speed prototype, unveiled in July 2021, was manufactured by CRRC Qingdao Sifang.[57]

Low-to-medium speed

Development of the low-to-medium speed systems, that is, 100–200 km/h (62–124 mph),[58] by the CRRC has led to openingj lines such as the Changsha Maglev Express in 2016 and the Line S1 in Beijing in 2017. In April 2020 a new model capable of 160 km/h (99 mph) and compatible with the Changsha line completed testing. The vehicle, under development since 2018, has a 30 percent increase in traction efficiency and a 60 percent increase in speed over the stock in use on the line since.[59] The vehicles entered service in July 2021 with a top speed of 140 km/h (87 mph).[60] CRRC Zhuzhou Locomotive said in April 2020 it is developing a model capable of 200 km/h (120 mph).[59]

High speed

There are two competing efforts for high-speed maglev systems, i.e., 300–620 km/h (190–390 mph).

- The first is based on the Transrapid technology used in the Shanghai maglev train and is developed by the CRRC under license from Thyssen-Krupp.[61]

- In 2006 the 500 km/h (310 mph) CM1 Dolphin prototype was unveiled[62] and began testing on a new 1.5-kilometre (0.93 mi) test track at Tongji University, northwest of Shanghai.

- A prototype vehicle of the 600 km/h (370 mph) CRRC 600 was developed in 2019 and tested from June 2020.[63]

- In March 2021 a 300 km/h (190 mph) model began trials.[64]

- In July 2021, the CRRC 600 maglev, planned to travel at up to 600 km/h (370 mph), was unveiled in Qingdao.[65] It was reported to be the world's fastest ground vehicle.[66]

- A high-speed test track is under development in China and also, in April 2021, there was consideration given to re-opening the Emsland test facility in Germany.[61]

- A second, incompatible high-speed prototype was unveiled in January 2021. Developed at Southwest Jiaotong University in Chengdu, the design uses high-temperature superconducting magnets, is designed for 620 km/h (390 mph) and was demonstrated on a 165-metre (180 yd) test track.[67]

Technology

In the public imagination, "maglev" often evokes the concept of an elevated monorail track with a linear motor. Maglev systems may be monorail or dual rail—the SCMaglev MLX01 for instance uses a trench-like track—and not all monorail trains are maglevs. Some railway transport systems incorporate linear motors but use electromagnetism only for propulsion, without levitating the vehicle. Such trains have wheels and are not maglevs.[note 3] Maglev tracks, monorail or not, can also be constructed at grade or underground in tunnels. Conversely, non-maglev tracks, monorail or not, can be elevated or underground too. Some maglev trains do incorporate wheels and function like linear motor-propelled wheeled vehicles at slower speeds but levitate at higher speeds. This is typically the case with electrodynamic suspension maglev trains. Aerodynamic factors may also play a role in the levitation of such trains.

The two main types of maglev technology are:

- Electromagnetic suspension (EMS), electronically controlled electromagnets in the train attract it to a magnetically conductive (usually steel) track.

- Electrodynamic suspension (EDS) uses superconducting electromagnets or strong permanent magnets that create a magnetic field, which induces currents in nearby metallic conductors when there is relative movement, which pushes and pulls the train towards the designed levitation position on the guide way.

Electromagnetic suspension (EMS)

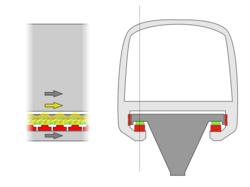

In electromagnetic suspension (EMS) systems, the train levitates by attraction to a ferromagnetic (usually steel) rail while electromagnets, attached to the train, are oriented toward the rail from below. The system is typically arranged on a series of C-shaped arms, with the upper portion of the arm attached to the vehicle, and the lower inside edge containing the magnets. The rail is situated inside the C, between the upper and lower edges.

Magnetic attraction varies inversely with the square of distance, so minor changes in distance between the magnets and the rail produce greatly varying forces. These changes in force are dynamically unstable—a slight divergence from the optimum position tends to grow, requiring sophisticated feedback systems to maintain a constant distance from the track, (approximately 15 millimetres [0.59 in]).[70][71]

The major advantage to suspended maglev systems is that they work at all speeds, unlike electrodynamic systems, which only work at a minimum speed of about 30 kilometres per hour (19 mph). This eliminates the need for a separate low-speed suspension system, and can simplify track layout. On the downside, the dynamic instability demands fine track tolerances, which can offset this advantage. Eric Laithwaite was concerned that to meet required tolerances, the gap between magnets and rail would have to be increased to the point where the magnets would be unreasonably large.[72] In practice, this problem was addressed through improved feedback systems, which support the required tolerances. Air gap and energy efficiency can be improved by using the socalled "Hybrid Electromagnetic Suspension (H-EMS)", where the main levitation force is generated by permanent magnets, while the electromagnet controls the air gap,[73] what is called electropermanent magnets. Ideally it would take negligible power to stabilize the suspension and in practice the power requirement is less than it would be if the entire suspension force were provided by electromagnets alone.[74]

Electrodynamic suspension (EDS)

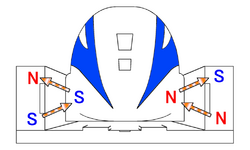

In electrodynamic suspension (EDS), both the guideway and the train exert a magnetic field, and the train is levitated by the repulsive and attractive force between these magnetic fields.[75] In some configurations, the train can be levitated only by repulsive force. In the early stages of maglev development at the Miyazaki test track, a purely repulsive system was used instead of the later repulsive and attractive EDS system.[76] The magnetic field is produced either by superconducting magnets (as in JR–Maglev) or by an array of permanent magnets (as in Inductrack). The repulsive and attractive force in the track is created by an induced magnetic field in wires or other conducting strips in the track.

A major advantage of EDS maglev systems is that they are dynamically stable—changes in distance between the track and the magnets creates strong forces to return the system to its original position.[72] In addition, the attractive force varies in the opposite manner, providing the same adjustment effects. No active feedback control is needed.

However, at slow speeds, the current induced in these coils and the resultant magnetic flux is not large enough to levitate the train. For this reason, the train must have wheels or some other form of landing gear to support the train until it reaches take-off speed. Since a train may stop at any location, due to equipment problems for instance, the entire track must be able to support both low- and high-speed operation.

Another downside is that the EDS system naturally creates a field in the track in front and to the rear of the lift magnets, which acts against the magnets and creates magnetic drag. This is generally only a concern at low speeds, and is one of the reasons why JR abandoned a purely repulsive system and adopted the sidewall levitation system.[76] At higher speeds other modes of drag dominate.[72]

The drag force can be used to the electrodynamic system's advantage, however, as it creates a varying force in the rails that can be used as a reactionary system to drive the train, without the need for a separate reaction plate, as in most linear motor systems. Laithwaite led development of such "traverse-flux" systems at his Imperial College laboratory.[72] Alternatively, propulsion coils on the guideway are used to exert a force on the magnets in the train and make the train move forward. The propulsion coils that exert a force on the train are effectively a linear motor: an alternating current through the coils generates a continuously varying magnetic field that moves forward along the track. The frequency of the alternating current is synchronized to match the speed of the train. The offset between the field exerted by magnets on the train and the applied field creates a force moving the train forward.

Tracks

The term "maglev" refers not only to the vehicles, but to the railway system as well, specifically designed for magnetic levitation and propulsion. All operational implementations of maglev technology make minimal use of wheeled train technology and are not compatible with conventional rail tracks. Because they cannot share existing infrastructure, maglev systems must be designed as standalone systems. The SPM maglev system is inter-operable with steel rail tracks and would permit maglev vehicles and conventional trains to operate on the same tracks.[72] MAN in Germany also designed a maglev system that worked with conventional rails, but it was never fully developed.[citation needed]

Evaluation

Each implementation of the magnetic levitation principle for train-type travel involves advantages and disadvantages.

| Technology | Pros | Cons |

|---|---|---|

| EMS[77][78] (electromagnetic suspension) | Magnetic fields inside and outside the vehicle are less than EDS; proven, commercially available technology; high speeds (500 kilometres per hour or 310 miles per hour); no wheels or secondary propulsion system needed. | The separation between the vehicle and the guideway must be constantly monitored and corrected due to the unstable nature of electromagnetic attraction; the system's inherent instability and the required constant corrections by outside systems may induce vibration. |

| EDS[79][80] (electrodynamic suspension) |

Onboard magnets and large margin between rail and train enable highest-recorded speeds (603 kilometres per hour or 375 miles per hour) and heavy load capacity; demonstrated successful operations using high-temperature superconductors in its onboard magnets, cooled with inexpensive liquid nitrogen.[citation needed] | Strong magnetic fields on the train would make the train unsafe for passengers with pacemakers or magnetic data storage media such as hard drives and credit cards, necessitating the use of magnetic shielding; limitations on guideway inductivity limit maximum speed;[citation needed] vehicle must be wheeled for travel at low speeds. |

| Inductrack system[81][82] (permanent magnet passive suspension) | Failsafe suspension—no power required to activate magnets; Magnetic field is localized below the car; can generate enough force at low speeds (around 5 kilometres per hour or 3.1 miles per hour) for levitation; given power failure cars stop safely; Halbach arrays of permanent magnets may prove more cost-effective than electromagnets. | Requires either wheels or track segments that move for when the vehicle is stopped. Under development as of 2008[update]; no commercial version or full-scale prototype. |

Neither Inductrack nor the Superconducting EDS are able to levitate vehicles at a standstill, although Inductrack provides levitation at much lower speed; wheels are required for these systems. EMS systems are wheel-free.

The German Transrapid, Japanese HSST (Linimo), and Korean Rotem EMS maglevs levitate at a standstill, with electricity extracted from guideway using power rails for the latter two, and wirelessly for Transrapid. If guideway power is lost on the move, the Transrapid is still able to generate levitation down to 10 kilometres per hour (6.2 mph) speed,[citation needed] using the power from onboard batteries. This is not the case with the HSST and Rotem systems.

Propulsion

EMS systems such as HSST/Linimo can provide both levitation and propulsion using an onboard linear motor. But EDS systems and some EMS systems such as Transrapid levitate but do not propel. Such systems need some other technology for propulsion. A linear motor (propulsion coils) mounted in the track is one solution. Over long distances coil costs could be prohibitive.

Stability

Earnshaw's theorem shows that no combination of static magnets can be in a stable equilibrium.[83] Therefore a dynamic (time varying) magnetic field is required to achieve stabilization. EMS systems rely on active electronic stabilization that constantly measures the bearing distance and adjusts the electromagnet current accordingly. EDS systems rely on changing magnetic fields to create currents, which can give passive stability.

Because maglev vehicles essentially fly, stabilisation of pitch, roll and yaw is required. In addition to rotation, surge (forward and backward motions), sway (sideways motion) or heave (up and down motions) can be problematic.

Superconducting magnets on a train above a track made out of a permanent magnet lock the train into its lateral position. It can move linearly along the track, but not off the track. This is due to the Meissner effect and flux pinning.

Guidance system

Some systems use Null Current systems (also sometimes called Null Flux systems).[75][84] These use a coil that is wound so that it enters two opposing, alternating fields, so that the average flux in the loop is zero. When the vehicle is in the straight ahead position, no current flows, but any moves off-line create flux that generates a field that naturally pushes/pulls it back into line.

Proposed technology enhancements

Evacuated tubes

Some systems (notably the Swissmetro system and the Hyperloop) propose the use of vactrains—maglev train technology used in evacuated (airless) tubes, which removes air drag. This has the potential to increase speed and efficiency greatly, as most of the energy for conventional maglev trains is lost to aerodynamic drag.[85]

One potential risk for passengers of trains operating in evacuated tubes is that they could be exposed to the risk of cabin depressurization unless tunnel safety monitoring systems can repressurize the tube in the event of a train malfunction or accident though since trains are likely to operate at or near the Earth's surface, emergency restoration of ambient pressure should be straightforward. The RAND Corporation has depicted a vacuum tube train that could, in theory, cross the Atlantic or the USA in around 21 minutes.[86]

Rail-maglev hybrid

The Polish startup Nevomo (previously Hyper Poland) is developing a system for modifying existing railway tracks into a maglev system, on which conventional wheel-rail trains, as well maglev vehicles can travel.[87] Vehicles on this so-called 'magrail' system will be able to reach speeds of up to 300 kilometres per hour (190 mph) at significantly lower infrastructure costs than stand-alone maglev lines. In 2023 Nevomo conducted the first MagRail tests on Europe's longest test track for passive magnetic levitation, which the company had previously built in Poland.[88]

Energy use

Energy for maglev trains is used to accelerate the train. Energy may be regained when the train slows down via regenerative braking. It also levitates and stabilises the train's movement. Most of the energy is needed to overcome air drag. Some energy is used for air conditioning, heating, lighting and other miscellany.

At low speeds the percentage of power used for levitation can be significant, consuming up to 15% more power than a subway or light rail service.[89] For short distances the energy used for acceleration might be considerable.

The force used to overcome air drag increases with the square of the velocity and hence dominates at high speed. The energy needed per unit distance increases by the square of the velocity and the time decreases linearly. However power increases by the cube of the velocity. For example, 2.37 times as much power is needed to travel at 400 kilometres per hour (250 mph) than 300 kilometres per hour (190 mph), while drag increases by 1.77 times the original force.[90]

Aircraft take advantage of lower air pressure and lower temperatures by cruising at altitude to reduce energy consumption but unlike trains need to carry fuel on board. This has led to the suggestion of conveying maglev vehicles through partially evacuated tubes.

High-speed maglev comparison with conventional high-speed trains

Maglev transport is non-contact and electric powered. It relies less or not at all on the wheels, bearings and axles common to wheeled rail systems.[91]

- Speed: Maglev allows higher top speeds than conventional rail. While experimental wheel-based high-speed trains have demonstrated similar speeds, conventional trains will suffer from friction between wheels and track and thus elevating the maintenance cost if operating at such speed, unlike levitated maglev trains.

- Maintenance: Maglev trains currently in operation have demonstrated the need for minimal guideway maintenance. Vehicle maintenance is also minimal (based on hours of operation, rather than on speed or distance traveled). Traditional rail is subject to mechanical wear and tear that increases rapidly with speed, also increasing maintenance.[91] For example: the wearing down of brakes and overhead wire wear have caused problems for the Fastech 360 rail Shinkansen. Maglev would eliminate these issues.

- Weather: In theory, maglev trains should be unaffected by snow, ice, severe cold, rain or high winds. However, as of yet no maglev system has been installed in a location with such a harsh climate.

- Acceleration: Maglev vehicles accelerate and decelerate faster than mechanical systems regardless of the slickness of the guideway or the slope of the grade, because they are non-contact systems.[91]

- Track: Maglev trains are not compatible with conventional track, and therefore require custom infrastructure for their entire route. By contrast conventional high-speed trains such as the TGV are able to run, albeit at reduced speeds, on existing rail infrastructure, thus reducing expenditure where new infrastructure would be particularly expensive (such as the final approaches to city terminals), or on extensions where traffic does not justify new infrastructure. John Harding, former chief maglev scientist at the Federal Railroad Administration, claimed that separate maglev infrastructure more than pays for itself with higher levels of all-weather operational availability and nominal maintenance costs. These claims have yet to be proven in an intense operational setting and they do not consider the increased maglev construction costs. However, in countries like China, there are discussion of building some key conventional high-speed rail tunnels/bridges to a standard that would allow them upgrading to maglev.

- Efficiency: Conventional rail is probably[citation needed] more efficient at lower speeds. But due to the lack of physical contact between the track and the vehicle, maglev trains experience no rolling resistance, leaving only air resistance and electromagnetic drag, potentially improving power efficiency.[92] Some systems, however, such as the Central Japan Railway Company SCMaglev use rubber tires at low speeds, reducing efficiency gains.[citation needed]

- Weight: The electromagnets in many EMS and EDS designs require between 1 and 2 kilowatts per ton.[93] The use of superconductor magnets can reduce the electromagnets' energy consumption. A 50-ton Transrapid maglev vehicle can lift an additional 20 tons, for a total of 70 tons, which consumes 70–140 kilowatts (94–188 hp).[citation needed] Most energy use for the TRI is for propulsion and overcoming air resistance at speeds over 100 miles per hour (160 km/h).[citation needed]

- Weight loading: High-speed rail requires more support and construction for its concentrated wheel loading. Maglev cars are lighter and distribute weight more evenly.[94]

- Noise: Because the major source of noise of a maglev train comes from displaced air rather than from wheels touching rails, maglev trains produce less noise than a conventional train at equivalent speeds. However, the psychoacoustic profile of the maglev may reduce this benefit: a study concluded that maglev noise should be rated like road traffic, while conventional trains experience a 5–10 dB "bonus", as they are found less annoying at the same loudness level.[95][96][97]

- Magnet reliability: Superconducting magnets are generally used to generate the powerful magnetic fields to levitate and propel the trains. These magnets must be kept below their critical temperatures (this ranges from 4.2 K to 77 K, depending on the material). New alloys and manufacturing techniques in superconductors and cooling systems have helped address this issue.

- Control systems: No signalling systems are needed for high-speed maglev, because such systems are computer controlled.[citation needed] Human operators cannot react fast enough to manage high-speed trains. High-speed systems require dedicated rights of way and are usually elevated. Two maglev system microwave towers are in constant contact with trains. There is no need for train whistles or horns, either.

- Terrain: Maglevs are able to ascend higher grades, offering more routing flexibility and reduced tunneling.[98]

High-speed maglev comparison with aircraft

Differences between airplane and maglev travel:

- Efficiency: For maglev systems the lift-to-drag ratio can exceed that of aircraft (for example Inductrack can approach 200:1 at high speed, far higher than any aircraft). This can make maglevs more efficient per kilometer. However, at high cruising speeds, aerodynamic drag is much larger than lift-induced drag. Jet-powered aircraft take advantage of low air density at high altitudes to significantly reduce air drag. Hence despite their lift-to-drag ratio disadvantage, they can travel more efficiently at high speeds than maglev trains that operate at sea level.[citation needed]

- Routing: Maglevs offer competitive journey times for distances of 800 kilometres (500 mi) or less. Additionally, maglevs can easily serve intermediate destinations. Air routes don't require infrastructure between the origin and destination airport and therefore provide greater flexibility to modify service endpoints as needed.

- Availability: Maglevs are little affected by weather.[citation needed]

- Travel time: Maglevs do not face the extended security protocols faced by air travelers nor is time consumed for taxiing, or for queuing for take-off and landing.[citation needed]

Economics

As more maglev systems are deployed, experts expect construction costs to drop by employing new construction methods and from economies of scale.[99]

High-speed systems

The Shanghai maglev demonstration line cost US$1.2 billion to build in 2004.[100] This total includes capital costs such as right-of-way clearing, extensive pile driving, on-site guideway manufacturing, in-situ pier construction at 25 metres (82 ft) intervals, a maintenance facility and vehicle yard, several switches, two stations, operations and control systems, power feed system, cables and inverters, and operational training. Ridership is not a primary focus of this demonstration line, since the Longyang Road station is on the eastern outskirts of Shanghai. Once the line is extended to South Shanghai Train station and Hongqiao Airport station, which may not happen because of economic reasons, ridership was expected to cover operation and maintenance costs and generate significant net revenue.[according to whom?]

The South Shanghai extension was expected to cost approximately US$18 million per kilometre. In 2006, the German government invested $125 million in guideway cost reduction development that produced an all-concrete modular design that is faster to build and is 30% less costly. Other new construction techniques were also developed that put maglev at or below price parity with new high-speed rail construction.[101]

The United States Federal Railroad Administration, in a 2005 report to Congress, estimated cost per mile of between US$50 million and US$100 million.[102] The Maryland Transit Administration (MTA) Environmental Impact Statement estimated a pricetag at US$4.9 billion for construction, and $53 million a year for operations of its project.[103]

The proposed Chuo Shinkansen maglev in Japan was estimated to cost approximately US$82 billion to build, with a route requiring long tunnels. A Tokaido maglev route replacing the Shinkansen be 1/10 the cost, as no new tunnel would be needed, but noise pollution concerns made it infeasible.[citation needed][neutrality is disputed]

Low-speed systems

The Japanese Linimo HSST, cost approximately US$100 million/km to build.[104] Besides offering improved operation and maintenance costs over other transit systems, these low-speed maglevs provide ultra-high levels of operational reliability and introduce little noise and generate zero air pollution into dense urban settings.

Records

The highest-recorded maglev speed is 603 kilometres per hour (375 mph), achieved in Japan by JR Central's L0 superconducting maglev on 21 April 2015,[105] 28 kilometres per hour (17 mph) faster than the conventional TGV wheel-rail speed record. However, the operational and performance differences between these two very different technologies is far greater. The TGV record was achieved accelerating down a 72.4 kilometres (45 mi) slight decline, requiring 13 minutes. It then took another 77.25 kilometres (48 mi) for the TGV to stop, requiring a total distance of 149.65 kilometres (93 mi) for the test.[106] The L0 record, however, was achieved on the 42.8 kilometres (26.6 mi) Yamanashi test track – less than 1/3 the distance.[107] No maglev or wheel-rail commercial operation has actually been attempted at speeds over 500 kilometres per hour (310 mph).

History of maglev speed records

| Year | Country | Train | Speed | Notes |

|---|---|---|---|---|

| 1971 | West Germany | Prinzipfahrzeug | 90 kilometres per hour (56 mph) | |

| 1971 | West Germany | TR-02 (TSST) | 164 kilometres per hour (102 mph) | |

| 1972 | Japan | ML100 | 60 kilometres per hour (37 mph) | crewed |

| 1973 | West Germany | TR04 | 250 kilometres per hour (160 mph) | crewed |

| 1974 | West Germany | EET-01 | 230 kilometres per hour (140 mph) | uncrewed |

| 1975 | West Germany | Komet | 401 kilometres per hour (249 mph) | by steam rocket propulsion, uncrewed |

| 1978 | Japan | HSST-01 | 308 kilometres per hour (191 mph) | by supporting rockets propulsion, made in Nissan, uncrewed |

| 1978 | Japan | HSST-02 | 110 kilometres per hour (68 mph) | crewed |

| 1979-12-12 | Japan | ML-500R | 504 kilometres per hour (313 mph) | (uncrewed) It succeeds in operation over 500 kilometres per hour (310 mph) for the first time in the world. |

| 1979-12-21 | Japan | ML-500R | 517 kilometres per hour (321 mph) | (uncrewed) |

| 1987 | West Germany | TR-06 | 406 kilometres per hour (252 mph) | (crewed) |

| 1987 | Japan | MLU001 | 401 kilometres per hour (249 mph) | (crewed) |

| 1988 | West Germany | TR-06 | 413 kilometres per hour (257 mph) | (crewed) |

| 1989 | West Germany | TR-07 | 436 kilometres per hour (271 mph) | (crewed) |

| 1993 | Germany | TR-07 | 450 kilometres per hour (280 mph) | (crewed) |

| 1994 | Japan | MLU002N | 431 kilometres per hour (268 mph) | (uncrewed) |

| 1997 | Japan | MLX01 | 531 kilometres per hour (330 mph) | (crewed) |

| 1997 | Japan | MLX01 | 550 kilometres per hour (340 mph) | (uncrewed) |

| 1999 | Japan | MLX01 | 552 kilometres per hour (343 mph) | (crewed/five-car formation) Guinness authorization. |

| 2003 | Japan | MLX01 | 581 kilometres per hour (361 mph) | (crewed/three formation) Guinness authorization.[108] |

| 2015 | Japan | L0 | 590 kilometres per hour (370 mph) | (crewed/seven-car formation)[109] |

| 2015 | Japan | L0 | 603 kilometres per hour (375 mph) | (crewed/seven-car formation)[105] |

Systems

Operational systems

High speed

Shanghai Maglev (2003)

The Shanghai Maglev Train, an implementation of the German Transrapid system, has a top speed of 300 kilometres per hour (190 mph).[5] The line is the fastest and first commercially operational high speed maglev. It connects Shanghai Pudong International Airport and the outskirts of central Pudong, Shanghai. The service covers a distance of 30.5 kilometres (19.0 mi) in just 8 minutes.[110]

In January 2001, the Chinese signed an agreement with Transrapid to build an EMS high-speed maglev line to link Pudong International Airport with Longyang Road Metro station on the southeastern edge of Shanghai. This Shanghai Maglev Train demonstration line, or Initial Operating Segment (IOS), has been in commercial operations since April 2004[111] and now operates 115 daily trips (up from 110 in 2010) that traverse the 30 kilometres (19 mi) between the two stations in 8 minutes, achieving a top speed of 300 kilometres per hour (190 mph) and averaging 224 kilometres per hour (139 mph). Prior to May 2021 services operated at up to 431 kilometres per hour (268 mph), taking only 7 minutes to complete the trip.[112] On a 12 November 2003 system commissioning test run, it achieved 501 kilometres per hour (311 mph), its designed top cruising speed. The Shanghai maglev is faster than Birmingham technology and comes with on-time—to the second—reliability greater than 99.97%.[113]

Plans to extend the line to Shanghai South Railway Station and Hongqiao Airport on the northwestern edge of Shanghai are on hold. After the Shanghai–Hangzhou Passenger Railway became operational in late 2010, the maglev extension became somewhat redundant and may be cancelled.

Low speed

Linimo (Tobu Kyuryo Line, Japan) (2005)

The commercial automated "Urban Maglev" system commenced operation in March 2005 in Aichi, Japan. The Tobu Kyuryo Line, otherwise known as the Linimo line, covers 9 kilometres (5.6 mi). It has a minimum operating radius of 75 metres (246 ft) and a maximum gradient of 6%. The linear-motor magnetically levitated train has a top speed of 100 kilometres per hour (62 mph). More than 10 million passengers used this "urban maglev" line in its first three months of operation. At 100 kilometres per hour (62 mph), it is sufficiently fast for frequent stops, has little or no noise impact on surrounding communities, can navigate short radius rights of way, and operates during inclement weather. The trains were designed by the Chubu HSST Development Corporation, which also operates a test track in Nagoya.[114]

Daejeon Expo Maglev (2008)

The first maglev test trials using electromagnetic suspension opened to public was HML-03, made by Hyundai Heavy Industries for the Daejeon Expo in 1993, after five years of research and manufacturing two prototypes, HML-01 and HML-02.[115][116][117] Government research on urban maglev using electromagnetic suspension began in 1994.[117] The first operating urban maglev was UTM-02 in Daejeon beginning on 21 April 2008 after 14 years of development and one prototype; UTM-01. The train runs on a 1 kilometre (0.6 mi) track between Expo Park and National Science Museum[118][119] which has been shortened with the redevelopment of Expo Park. The track currently ends at the street parallel to the science museum. Meanwhile, UTM-02 conducted the world's first-ever maglev simulation.[120][121] However, UTM-02 is still the second prototype of a final model. The final UTM model of Rotem's urban maglev, UTM-03, was used for a new line that opened in 2016 on Incheon's Yeongjong island connecting Incheon International Airport (see below).[122]

Incheon Airport Maglev (2016)

The Incheon Airport Maglev began commercial operation on 3 February 2016.[44] It was developed and built domestically. Compared to Linimo, it has a more futuristic design thanks to it being lighter with construction costs cut to half.[123] It connects Incheon International Airport with Yongyu Station, cutting journey time.[124] It covers a distance of 6.1 km.

Changsha Maglev (2016)

The Hunan provincial government launched the construction of a maglev line between Changsha Huanghua International Airport and Changsha South Railway Station, covering a distance of 18.55 km. Construction started in May 2014 and was completed by the end of 2015.[125][126] Trial runs began on 26 December 2015 and trial operations started on 6 May 2016.[127] As of 13 June 2018 the Changsha maglev had covered a distance of 1.7 million km and carried nearly 6 million passengers. A second generation of these vehicles has been produced which have a top speed of 160 km/h (99 mph).[128] In July 2021 the new model entered service operating at a top speed of 140 km/h (87 mph), which reduced the travel time by 3 minutes.[129]

Beijing Line S1 (2017)

Beijing has built China's second low-speed maglev line, Line S1, Beijing Subway, using technology developed by National University of Defense Technology. The line was opened on 30 December 2017. The line operates at speeds up to 100 kilometres per hour (62 mph).[130]

Fenghuang Maglev (2022)

Fenghuang Maglev (凤凰磁浮) is a medium- to low-speed maglev line in Fenghuang County, Xiangxi, Hunan province, China. The line operates at speeds up to 100 kilometres per hour (62 mph). The first phase is 9.12 kilometres (5.67 mi) with 4 stations (and 2 more future infill stations). The first phase opened on 30 July 2022[131] and connects the Fenghuanggucheng railway station on the Zhangjiajie–Jishou–Huaihua high-speed railway with the Fenghuang Folklore Garden.[132]

Maglevs under construction

Chūō Shinkansen (Japan)

The Chuo Shinkansen is a high-speed maglev line in Japan. Construction began in 2014, commercial operations was expected to start by 2027.[133] The 2027 target was given up in July 2020.[134] The Linear Chuo Shinkansen Project aims to connect Tokyo and Osaka by way of Nagoya, the capital city of Aichi, in approximately one hour, less than half the travel time of the fastest existing bullet trains connecting the three metropolises.[135] The full track between Tokyo and Osaka was originally expected to be completed in 2045, but the operator is now aiming for 2037.[136][137][138]

The L0 Series train type is undergoing testing by the Central Japan Railway Company (JR Central) for eventual use on the Chūō Shinkansen line. It set a crewed world speed record of 603 kilometres per hour (375 mph) on 21 April 2015.[105] The trains are planned to run at a maximum speed of 505 kilometres per hour (314 mph),[139] offering journey times of 40 minutes between Tokyo (Shinagawa Station) and Nagoya, and 1 hour 7 minutes between Tokyo and Osaka (Shin-Ōsaka Station).[140]

Qingyuan Maglev (China)

Qingyuan Maglev (清远磁浮旅游专线) is a medium- to low-speed maglev line in Qingyuan, Guangdong province, China. The line will operate at speeds up to 100 kilometres per hour (62 mph).[141] The first phase is 8.1 km with 3 stations (and 1 more future infill station).[141] The first phase was originally scheduled to open in October 2020[142] and will connect the Yinzhan railway station on the Guangzhou–Qingyuan intercity railway with the Qingyuan Chimelong Theme Park.[143] In the long term the line will be 38.5 km.[144]

Test tracks

AMT test track – Powder Springs, Georgia, USA

A second prototype system in Powder Springs, Georgia, USA, was built by American Maglev Technology, Inc. The test track is 610 metres (2,000 ft) long with a 168.6 metres (553 ft) curve. Vehicles are operated up to 60 kilometres per hour (37 mph), below the proposed operational maximum of 97 kilometres per hour (60 mph). A June 2013 review of the technology called for an extensive testing program to be carried out to ensure the system complies with various regulatory requirements including the American Society of Civil Engineers (ASCE) People Mover Standard. The review noted that the test track is too short to assess the vehicles' dynamics at the maximum proposed speeds.[145]

FTA's UMTD program, USA

In the US, the Federal Transit Administration (FTA) Urban Maglev Technology Demonstration program funded the design of several low-speed urban maglev demonstration projects. It assessed HSST for the Maryland Department of Transportation and maglev technology for the Colorado Department of Transportation. The FTA also funded work by General Atomics at California University of Pennsylvania to evaluate the MagneMotion M3 and of the Maglev2000 of Florida superconducting EDS system. Other US urban maglev demonstration projects of note are the LEVX in Washington State and the Massachusetts-based Magplane.

San Diego, California USA

General Atomics has a 120-metre (390 ft) test facility in San Diego, that is used to test Union Pacific's 8 kilometres (5 mi) freight shuttle in Los Angeles. The technology is "passive" (or "permanent"), using permanent magnets in a Halbach array for lift and requiring no electromagnets for either levitation or propulsion. General Atomics received US$90 million in research funding from the federal government. They are also considering their technology for high-speed passenger services.[146]

SCMaglev, Yamanashi Japan

Japan has a demonstration line in Yamanashi prefecture where test train SCMaglev L0 Series Shinkansen reached 603 kilometres per hour (375 mph), faster than any wheeled trains.[105] The demonstration line will become part of the Chūō Shinkansen linking Tokyo and Nagoya which, is currently under construction.

These trains use superconducting magnets, which allow for a larger gap, and repulsive/attractive-type electrodynamic suspension (EDS).[75][147] In comparison, Transrapid uses conventional electromagnets and attractive-type electromagnetic suspension (EMS).[148][149]

On 15 November 2014, The Central Japan Railway Company ran eight days of testing for the experimental maglev Shinkansen train on its test track in Yamanashi Prefecture. One hundred passengers covered a 42.8-kilometre (26.6 mi) route between the cities of Uenohara and Fuefuki, reaching speeds of up to 500 kilometres per hour (310 mph).[150]

Sengenthal, Germany and Chengdu, China

Transport System Bögl, a division of German construction company Max Bögl, has built a test track in Sengenthal, Bavaria, Germany. In appearance, it's more like the German M-Bahn than the Transrapid system.[151] The vehicle tested on the track is patented in the US by Max Bögl.[152] The company is also in a joint venture with a Chinese firm. A 3.5 km (2.2 mi) demonstration line has been built near Chengdu, China and two vehicles were airlifted there in June, 2000.[54] In April 2021 a vehicle on the Chinese test track hit a top speed of 169 km/h (105 mph).[153]

Southwest Jiaotong University, China

On 31 December 2000, the first crewed high-temperature superconducting maglev was tested successfully at Southwest Jiaotong University, Chengdu, China. This system is based on the principle that bulk high-temperature superconductors can be levitated stably above or below a permanent magnet. The load was over 530 kilograms (1,170 lb) and the levitation gap over 20 millimetres (0.79 in). The system uses liquid nitrogen to cool the superconductor.[154][155][156]

Jiading Campus of Tongji University, China

A 1.5 km (0.93 mi) maglev test track has been operating since 2006 at the Jiading Campus of Tongji University, northwest of Shanghai. The track uses the same design as the operating Shanghai Maglev. Top speed is restricted to 120 km/h (75 mph) due to the length of track and its topology.

MagRail test track, Poland

In the first quarter of 2022, Polish technology startup Nevomo completed the construction of Europe's longest test track for passive magnetic levitation. The 700 meter-long railway track in Subcarpathian Voivodeship in Poland allows vehicles utilizing the company's MagRail system to travel at speeds of up to 160 kph.[157] The installation of all necessary wayside equipment was completed in December 2022 and tests began in spring 2023.[158]

Proposed maglev systems

Many maglev systems have been proposed in North America, Asia and Europe.[159] Many are in the early planning stages or were explicitly rejected.

Australia

- Sydney-Illawarra

A maglev route was proposed between Sydney and Wollongong.[160] The proposal came to prominence in the mid-1990s. The Sydney–Wollongong commuter corridor is the largest in Australia, with upwards of 20,000 people commuting each day. Existing trains use the Illawarra line, between the cliff face of the Illawarra escarpment and the Pacific Ocean, with travel times about 2 hours. The proposal would cut travel times to 20 minutes.

- Melbourne

In late 2008, a proposal was put forward to the Government of Victoria to build a privately funded and operated maglev line to service the Greater Melbourne metropolitan area in response to the Eddington Transport Report that did not investigate above-ground transport options.[161][162] The maglev would service a population of over 4 million[citation needed] and the proposal was costed at A$8 billion.

However, despite road congestion and Australia's highest roadspace per capita,[citation needed] the government dismissed the proposal in favour of road expansion including an A$8.5 billion road tunnel, $6 billion extension of the Eastlink to the Western Ring Road and a $700 million Frankston Bypass.

Canada

Toronto Zoo: Edmonton-based Magnovate proposed a new ride and transportation system at the Toronto Zoo reviving the Toronto Zoo Domain Ride system, which was closed following two severe accidents in 1994. The Zoo's board unanimously approved the proposal on 29 November 2018.

The company plans to construct and operate the $25 million system on the former route of the Domain Ride (known locally as the Monorail, despite not being considered one) at zero cost to the Zoo and operate it for 15 years, splitting the profits with the Zoo. The ride will serve a single-directional loop around Zoo grounds, serving five stations and likely replacing the current Zoomobile tour tram service. Planned to be operational by 2022 at the earliest, this would be the first commercial maglev system in North America should it be approved.[163]

China

Beijing – Guangzhou line

A maglev test line linking Xianning in Hubei Province and Changsha in Hunan Province will start construction in 2020. The test line is about 200 kilometres (120 mi) in length and might be part of Beijing – Guangzhou maglev in long-term planning.[164][165] In 2021, the Guangdong government proposed a Maglev line between Hong Kong and Guangzhou via Shenzhen and beyond to Beijing.[166][167]

Other proposed lines

- Shanghai – Hangzhou

China planned to extend the existing Shanghai Maglev Train,[168] initially by around 35 kilometres (22 mi) to Shanghai Hongqiao Airport and then 200 kilometres (120 mi) to the city of Hangzhou (Shanghai-Hangzhou Maglev Train). If built, this would be the first inter-city maglev rail line in commercial service.

The project was controversial and repeatedly delayed. In May 2007 the project was suspended by officials, reportedly due to public concerns about radiation from the system.[169] In January and February 2008 hundreds of residents demonstrated in downtown Shanghai that the line route came too close to their homes, citing concerns about sickness due to exposure to the strong magnetic field, noise, pollution and devaluation of property near to the lines.[170][171] Final approval to build the line was granted on 18 August 2008. Originally scheduled to be ready by Expo 2010,[172] plans called for completion by 2014. The Shanghai municipal government considered multiple options, including building the line underground to allay public fears. This same report stated that the final decision had to be approved by the National Development and Reform Commission.[173]

In 2007 the Shanghai municipal government was considering building a factory in Nanhui district to produce low-speed maglev trains for urban use.[174]

- Shanghai – Beijing

A proposed line would have connected Shanghai to Beijing, over a distance of 1,300 kilometres (800 mi), at an estimated cost of £15.5 billion.[175] No projects had been revealed as of 2014.[176]

Germany

On 25 September 2007, Bavaria announced a high-speed maglev-rail service from Munich to its airport. The Bavarian government signed contracts with Deutsche Bahn and Transrapid with Siemens and ThyssenKrupp for the €1.85 billion project.[177]

On 27 March 2008, the German Transport minister announced the project had been cancelled due to rising costs associated with constructing the track. A new estimate put the project between €3.2–3.4 billion.[178]

Hong Kong

In March 2021 a government official said Hong Kong would be included in a planned maglev network across China, planned to operate at 600 km/h (370 mph) and begin opening by 2030.[179]

Hong Kong is already connected to the Chinese high-speed rail network by the Guangzhou–Shenzhen–Hong Kong Express Rail Link, which opened on Sunday 23 September 2018.

India

Mumbai – Delhi: A project was presented to then Indian railway minister (Mamata Banerjee) by an American company to connect Mumbai and Delhi. Then Prime Minister Manmohan Singh said that if the line project was successful the Indian government would build lines between other cities and also between Mumbai Central and Chhatrapati Shivaji International Airport.[180]

Mumbai – Nagpur: The State of Maharashtra approved a feasibility study for a maglev train between Mumbai and Nagpur, some 1,000 kilometres (620 mi) apart.[181]

Chennai – Bangalore – Mysore: A detailed report was to be prepared and submitted by December 2012 for a line to connect Chennai to Mysore via Bangalore at a cost $26 million per kilometre, reaching speeds of 350 kilometres per hour (220 mph).[182]

Iran

In May 2009, Iran and a German company signed an agreement to use maglev to link Tehran and Mashhad. The agreement was signed at the Mashhad International Fair site between Iranian Ministry of Roads and Transportation and the German company. The 900 kilometres (560 mi) line possibly could reduce travel time between Tehran and Mashhad to about 2.5 hours.[citation needed] Munich-based Schlegel Consulting Engineers said they had signed the contract with the Iranian ministry of transport and the governor of Mashad. "We have been mandated to lead a German consortium in this project," a spokesman said. "We are in a preparatory phase." The project could be worth between €10 billion and €12 billion, the Schlegel spokesman said.[183]

Italy

A first proposal was formalized in April 2008, in Brescia, by journalist Andrew Spannaus who recommended a high-speed connection between Malpensa airport to the cities of Milan, Bergamo and Brescia.[184]

In March 2011, Nicola Oliva proposed a maglev connection between Pisa airport and the cities of Prato and Florence (Santa Maria Novella train station and Florence Airport).[185][186] The travelling time would be reduced from the typical 1 hour 15 minutes to around 20 minutes.[187] The second part of the line would be a connection to Livorno, to integrate maritime, aerial and terrestrial transport systems.[188][189]

Malaysia/Singapore

A Consortium led by UEM Group Bhd and ARA Group, proposed maglev technology to link Malaysian cities to Singapore. The idea was first mooted by YTL Group. Its technology partner then was said to be Siemens. High costs sank the proposal. The concept of a high-speed rail link from Kuala Lumpur to Singapore resurfaced. It was cited as a proposed "high impact" project in the Economic Transformation Programme (ETP) that was unveiled in 2010.[190] Approval has been given for the Kuala Lumpur–Singapore high-speed rail project, but not using maglev technology.[citation needed]

Philippines

Philtram Consortium's Cebu Monorail project will be initially built as a monorail system. In the future, it will be upgraded to a patented maglev technology named Spin-Induced Lenz's Law Magnetic Levitation Train.[191]

Switzerland

SwissRapide: The SwissRapide AG together with the SwissRapide Consortium was planning and developing the first maglev monorail system for intercity traffic between the country's major cities. SwissRapide was to be financed by private investors. In the long-term, the SwissRapide Express was to connect the major cities north of the Alps between Geneva and St. Gallen, including Lucerne and Basel. The first projects were Bern – Zurich, Lausanne – Geneva as well as Zurich – Winterthur. The first line (Lausanne – Geneva or Zurich – Winterthur) could go into service as early as 2020.[192][193]

Swissmetro: An earlier project, Swissmetro AG envisioned a partially evacuated underground maglev (a vactrain). As with SwissRapide, Swissmetro envisioned connecting the major cities in Switzerland with one another. In 2011, Swissmetro AG was dissolved and the IPRs from the organisation were passed onto the EPFL in Lausanne.[194]

United Kingdom

London – Glasgow: A line[195] was proposed in the United Kingdom from London to Glasgow with several route options through the Midlands, Northwest and Northeast of England. It was reported to be under favourable consideration by the government.[196] The approach was rejected in the Government White Paper Delivering a Sustainable Railway published on 24 July 2007.[197] Another high-speed link was planned between Glasgow and Edinburgh but the technology remained unsettled.[198][199][200]

United States

Washington, D.C. to New York City: Using Superconducting Maglev (SCMAGLEV) technology developed by the Central Japan Railway Company, the Northeast Maglev would ultimately connect major Northeast metropolitan hubs and airports traveling more than 480 kilometers per hour (300 miles per hour),[201] with a goal of one-hour service between Washington, D.C. and New York City .[202] As of 2019[update] the Federal Railroad Administration and Maryland Department of Transportation were preparing an Environmental Impact Statement (EIS) to evaluate the potential impacts of constructing and operating the system's first leg between Washington, DC and Baltimore, Maryland with an intermediate stop at BWI Airport.[203]

Union Pacific freight conveyor: Plans are under way by American railroad Union Pacific to build a 7.9 kilometres (4.9 mi) container shuttle between the Ports of Los Angeles and Long Beach, with UP's intermodal container transfer facility. The system would be based on "passive" technology, especially well-suited to freight transfer as no power is needed on board. The vehicle is a chassis that glides to its destination. The system is being designed by General Atomics.[146]

California-Nevada Interstate Maglev: High-speed maglev lines between major cities of southern California and Las Vegas are under study via the California-Nevada Interstate Maglev Project.[204] This plan was originally proposed as part of an I-5 or I-15 expansion plan, but the federal government ruled that it must be separated from interstate public work projects.

After the decision, private groups from Nevada proposed a line running from Las Vegas to Los Angeles with stops in Primm, Nevada; Baker, California; and other points throughout San Bernardino County into Los Angeles. Politicians expressed concern that a high-speed rail line out of state would carry spending out of state along with travelers.

The Pennsylvania Project: The Pennsylvania High-Speed Maglev Project corridor extends from the Pittsburgh International Airport to Greensburg, with intermediate stops in Downtown Pittsburgh and Monroeville. This initial project was claimed to serve approximately 2.4 million people in the Pittsburgh metropolitan area. The Baltimore proposal competed with the Pittsburgh proposal for a US$90 million federal grant.[205]

San Diego-Imperial County airport: In 2006, San Diego commissioned a study for a maglev line to a proposed airport located in Imperial County. SANDAG claimed that the concept would be an "airports [sic] without terminals", allowing passengers to check in at a terminal in San Diego ("satellite terminals"), take the train to the airport and directly board the airplane. In addition, the train would have the potential to carry freight. Further studies were requested although no funding was agreed.[206]

Orlando International Airport to Orange County Convention Center: In December 2012, the Florida Department of Transportation gave conditional approval to a proposal by American Maglev to build a privately run 14.9 miles (24 km), 5-station line from Orlando International Airport to Orange County Convention Center. The Department requested a technical assessment and said there would be a request for proposals issued to reveal any competing plans. The route requires the use of a public right of way.[207] If the first phase succeeded American Maglev would propose two further phases (of 4.9 and 19.4 miles [7.9 and 31.2 km]) to carry the line to Walt Disney World.[208]

San Juan – Caguas: A 16.7-mile (26.9 km) maglev project was proposed linking Tren Urbano's Cupey Station in San Juan with two proposed stations in the city of Caguas, south of San Juan. The maglev line would run along Highway PR-52, connecting both cities. According to American Maglev project cost would be approximately US$380 million.[209][210][211]

Incidents

Two incidents involved fires. A Japanese test train in Miyazaki, MLU002, was completely consumed by a fire in 1991.[212]

On 11 August 2006, a fire broke out on the commercial Shanghai Transrapid shortly after arriving at the Longyang terminal. People were evacuated without incident before the vehicle was moved about 1 kilometre to keep smoke from filling the station. NAMTI officials toured the SMT maintenance facility in November 2010 and learned that the cause of the fire was "thermal runaway" in a battery tray. As a result, SMT secured a new battery vendor, installed new temperature sensors and insulators and redesigned the trays.[citation needed]

On 22 September 2006, a Transrapid train collided with a maintenance vehicle on a test/publicity run in Lathen (Lower Saxony / north-western Germany).[213][214] Twenty-three people were killed and ten were injured; these were the first maglev crash fatalities. The accident was caused by human error. Charges were brought against three Transrapid employees after a year-long investigation.[215]

Safety is a greater concern with high-speed public transport due to the potential for high impact force and large number of casualties. In the case of maglev trains as well as conventional high-speed rails, an incident could result from human error, including loss of power, or factors outside human control, such as ground movement caused by an earthquake.

See also

- Bombardier Advanced Rapid Transit – transit systems using linear induction motors

- Electromagnetic suspension

- Ground-effect train

- Hyperloop

- Land speed record for rail vehicles

- Launch loop would be a maglev system for launching to orbit or escape velocity.

- Mass driver

- Nagahori Tsurumi-ryokuchi Line

- Oleg Tozoni worked on a published non-linearly stabilised maglev design.

- StarTram – a maglev launch system

- Transfer table

Notes

- ↑ Zehden describes a geometry in which the linear motor is used below a steel beam, giving partial levitation of the vehicle. These patents were later cited by Electromagnetic apparatus generating a gliding magnetic field by Jean Candelas (U.S. Patent 4,131,813), Air cushion supported, omnidirectionally steerable, traveling magnetic field propulsion device by Harry A. Mackie (U.S. Patent 3,357,511) and Two-sided linear induction motor especially for suspended vehicles by Schwarzer et al. (U.S. Patent 3,820,472)

- ↑ These German patents would be GR643316 (1937), GR44302 (1938), GR707032 (1941).

- ↑ This is the case with the Moscow Monorail—currently the only non-maglev linear motor-propelled monorail train in active service.

References

- ↑ "Japanese Maglev Train: World's Fastest Bullet Train - JRailPass". 27 February 2017. https://www.jrailpass.com/blog/maglev-bullet-train.

- ↑ "Magnetic Levitation - an overview | ScienceDirect Topics". https://www.sciencedirect.com/topics/engineering/magnetic-levitation#:~:text=Maglev%20train%20systems%20use%20powerful,and%20propulsion%20along%20a%20track.

- ↑ "Will maglev ever become mainstream?" (in en-GB). 17 January 2018. https://www.railway-technology.com/features/will-maglev-ever-become-mainstream/.

- ↑ "Japan's maglev train breaks world speed record with 600km/h test run". The Guardian. United Kingdom: Guardian News and Media Limited. 21 April 2015. https://www.theguardian.com/world/2015/apr/21/japans-maglev-train-notches-up-new-world-speed-record-in-test-run.

- ↑ 5.0 5.1 "Everything about Shanghai Maglev Train: Speed, Station, Map, Ticket & Price, Facts..." (in en). https://www.chinadiscovery.com/shanghai/shanghai-maglev.html.

- ↑ Yaghoubi, Hamid (2013-03-27). "The Most Important Maglev Applications" (in en). Journal of Engineering 2013: e537986. doi:10.1155/2013/537986. ISSN 2314-4904.

- ↑ Transrapid uses more power for air conditioning

- ↑ "The Six Operational Maglev Lines in 2018". https://www.maglev.net/six-operational-maglev-lines-in-2018.

- ↑ "High-speed rail trains are stalled in the US—and that might not change for a while" (in en-US). 2022-10-05. https://www.popsci.com/technology/high-speed-trains-hyperloop-history/.

- ↑ Radford, Tim (11 October 1999). "Nasa takes up idea pioneered by Briton – Magnetic levitation technology was abandoned by government". The Guardian (London). https://www.theguardian.com/uk/1999/oct/11/timradford.

- ↑ "Obituary for the late Professor Eric Laithwaite" , Daily Telegraph, 6 December 1997.

- ↑ "The magnetic attraction of trains". BBC News. 9 November 1999. http://news.bbc.co.uk/1/hi/sci/tech/488394.stm.

- ↑ U.S. Patent 3,736,880, 21 January 1972. Page 10 Column 1 Line 15 to Page 10 Column 2 Line 25.

- ↑ U.S. Patent 859,018, 2 July 1907.

- ↑ U.S. Patent 1,090,213, 17 March 1914

- ↑ Johnson, Tom L.. My Story. B. W. Huebsch, 1911; reprint Kent State University Press 1993. pg. xlv-xlvi

- ↑ U.S. Patent 3,858,521; 26 March 1973.

- ↑ "Here's an Aerial Vehicle Which Darts Along Poised Above Its Roadway". New-York Tribune 1912 June 2 Images 21 & 23. https://chroniclingamerica.loc.gov/lccn/sn83030214/1912-06-02/ed-1/seq-21/.

- ↑ MacNair, Miles (2008). "Emile Bachelet (1863–1946): The Showman and the Flying Train". Transactions of the Newcomen Society (Transactions of the Newcomen Society Vol 78, 2008 Issue 2) 78 (2): 235–260. doi:10.1179/175035208X317693. https://www.tandfonline.com/doi/abs/10.1179/175035208X317693?journalCode=yhet19. Retrieved 16 July 2023.

- ↑ Muller, Christopher (23 January 1997). "Magnetic Levitation for Transportation". railserve.com. http://www.railserve.com/maglev.html.

- ↑ "Brookhaven Lab Retirees Win Benjamin Franklin Medal For Their Invention of Magnetically Levitated Trains". Brookhaven National Laboratory. 18 April 2000. http://www.bnl.gov/bnlweb/pubaf/pr/2000/bnlpr041800.html.

- ↑ & Gordon T Danby"Electromagnetic inductive suspension and stabilization system for a ground vehicle" US patent 3470828, published 1969-10-07, issued 1969-10-07

- ↑ U.S.-Japan Maglev (2012). "History". USJMAGLEV. http://usjmaglev.com/usjmaglev/History.html.

- ↑ Sanchanta, Mariko (26 January 2010). "High-Speed Rail Approaches Station". WSJ. https://www.wsj.com/articles/SB10001424052748704762904575024611266446690.

- ↑ "JR Central gives up on opening new maglev train service in 2027". Kyodo News. 3 July 2020. https://english.kyodonews.net/news/2020/07/a97dfd2524f6-shizuoka-says-no-to-construction-for-new-maglev-train-service.html.

- ↑ "Дорога на магнитном подвесе: второе дыхание в России?" , РЖД-Партнёр, 2009-10-01

- ↑ 27.0 27.1 "Советский маглев: 25 лет под целлофаном". https://www.popmech.ru/technologies/58629-sovetskiy-maglev-25-let-pod-tsellofanom/.

- ↑ "The unknown russian monorail". http://www.izmerov.narod.ru/monor/monor5.html.

- ↑ "Юные красноярские железнодорожники разработали модель поезда на магнитной подушке". http://newslab.ru/news/626312.

- ↑ "Советский маглев: будущее, которое не случилось". 2 March 2018. https://habr.com/ru/company/mailru/blog/410545/.

- ↑ "Как маглев до Еревана не "доехал". Армения могла стать первой в СССР республикой с магнитным монорельсом". Центр поддержки русско-армянских стратегических и общественных инициатив. 2017-02-19. http://russia-armenia.info/node/35882.

- ↑ "ОАО Инженерно-научный центр "ТЭМП"". http://erc-temp.ru/.

- ↑ "The magnetic attraction of trains". BBC News. 9 November 1999. http://news.bbc.co.uk/1/hi/sci/tech/488394.stm.

- ↑ Maglev, A film for The People Mover Group

- ↑ "The World's First Maglev Lines That No Longer Operate". https://www.maglev.net/worlds-first-maglev-lines-no-longer-operate.

- ↑ Goodall, Roger (2012). "Maglev – an unfulfilled dream?". p. 6. https://repository.lboro.ac.uk/articles/conference_contribution/Maglev_an_unfulfilled_dream_/9552941.

- ↑ "New plan aims to bring the Maglev back". Birmingham Mail. http://www.birminghammail.net/news/solihull-news/tm_objectid=17662730&method=full&siteid=50002&headline=new-plan-aims-to-bring-the-maglev-back-name_page.html.

- ↑ "AirRail Shuttle Birmingham International Airport". DCC Doppelmayr. http://www.dcc.at/doppelmayr/references/en/tmp_1_1762145202/Birmingham,_UK_detail.aspx.