Stall (fluid mechanics)

Topic: Physics

From HandWiki - Reading time: 24 min

From HandWiki - Reading time: 24 min

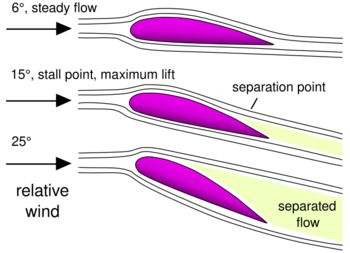

In fluid dynamics, a stall is a reduction in the lift coefficient generated by a foil as angle of attack increases.[1] This occurs when the critical angle of attack of the foil is exceeded. The critical angle of attack is typically about 15 degrees, but it may vary significantly depending on the fluid, foil, and Reynolds number.

Stalls in fixed-wing flight are often experienced as a sudden reduction in lift as the pilot increases the wing's angle of attack and exceeds its critical angle of attack (which may be due to slowing down below stall speed in level flight). A stall does not mean that the engine(s) have stopped working, or that the aircraft has stopped moving—the effect is the same even in an unpowered glider aircraft. Vectored thrust in manned and unmanned aircraft is used to surpass the stall limit, thereby giving rise to post-stall technology.[2][3]

Because stalls are most commonly discussed in connection with aviation, this article discusses stalls as they relate mainly to aircraft, in particular fixed-wing aircraft. The principles of stall discussed here translate to foils in other fluids as well.

Formal definition

A stall is a condition in aerodynamics and aviation wherein the angle of attack increases beyond a certain point such that lift begins to decrease. The angle at which this occurs is called the critical angle of attack. This critical angle is dependent upon the airfoil section or profile of the wing, its planform, its aspect ratio, and other factors, but is typically in the range of 8 to 20 degrees relative to the incoming wind ("relative wind") for most subsonic airfoils. The critical angle of attack is the angle of attack on the lift coefficient versus angle-of-attack curve at which the maximum lift coefficient occurs.[4]

Flow separation begins to occur at small angles of attack while attached flow over the wing is still dominant. As angle of attack increases, the separated regions on the top of the wing increase in size and hinder the wing's ability to create lift. At the critical angle of attack, separated flow is so dominant that additional increases in angle of attack produce less lift and more drag.[citation needed]

A fixed-wing aircraft during a stall may experience buffeting or a change in attitude. Most aircraft are designed to have a gradual stall with characteristics that will warn the pilot and give him or her time to react. For example, an aircraft that does not buffet before the stall may have an audible alarm or a stick shaker installed to simulate the feel of a buffet by vibrating the stick fore and aft. The critical angle of attack in steady straight and level flight can be attained only at low airspeed. Attempts to increase the angle of attack at higher airspeeds can cause a high-speed stall or may merely cause the aircraft to climb.[citation needed]

Any yaw of the aircraft as it enters the stall regime can result in autorotation, which is also sometimes referred to as a "spin". As air no longer flows smoothly over the wings during a stall, aileron control of roll becomes less effective, whilst simultaneously the tendency for the ailerons to generate adverse yaw increases. This characteristic increases the lift from the advancing wing and increases the likelihood of the aircraft entering into a spin.[citation needed]

Graph

The graph shows that the greatest amount of lift is produced as the critical angle of attack is reached (which in early-20th century aviation was called the "burble point"). This angle is 17.5 degrees in this case, but it varies from airfoil to airfoil. In particular, for aerodynamically thick airfoils (thickness to chord ratios of around 10%), the critical angle is higher than with a thin airfoil of the same camber. Symmetric airfoils have lower critical angles (but also work efficiently in inverted flight). The graph shows that, as the angle of attack exceeds the critical angle, the lift produced by the airfoil decreases.

The information in a graph of this kind is gathered using a model of the airfoil in a wind tunnel. Because aircraft models are normally used, rather than full-size machines, special care is needed to make sure that data is taken in the same Reynolds number regime (or scale speed) as in free flight. The separation of flow from the upper wing surface at high angles of attack is quite different at low Reynolds number from that at the high Reynolds numbers of real aircraft. High-pressure wind tunnels are one solution to this problem. In general, steady operation of an aircraft at an angle of attack above the critical angle is not possible because, after exceeding the critical angle, the loss of lift from the wing causes the nose of the aircraft to fall, reducing the angle of attack again. This nose drop, independent of control inputs, indicates the pilot has actually stalled the aircraft.[5][6]

This graph shows the stall angle, yet in practice most pilot operating handbooks (POH) or generic flight manuals describe stalling in terms of airspeed. This is because all aircraft are equipped with an airspeed indicator, but fewer aircraft have an angle of attack indicator. An aircraft's stalling speed is published by the manufacturer (and is required for certification by flight testing) for a range of weights and flap positions, but the stalling angle of attack is not published.

As speed reduces, angle of attack has to increase to keep lift constant until the critical angle is reached. The airspeed at which this angle is reached is the (1g, unaccelerated) stalling speed of the aircraft in that particular configuration. Deploying flaps/slats decreases the stall speed to allow the aircraft to take off and land at a lower speed.

Aerodynamic description

Fixed-wing aircraft

A fixed-wing aircraft can be made to stall in any pitch attitude or bank angle or at any airspeed but deliberate stalling is commonly practiced by reducing the speed to the unaccelerated stall speed, at a safe altitude. Unaccelerated (1g) stall speed varies on different fixed-wing aircraft and is represented by colour codes on the airspeed indicator. As the plane flies at this speed, the angle of attack must be increased to prevent any loss of altitude or gain in airspeed (which corresponds to the stall angle described above). The pilot will notice the flight controls have become less responsive and may also notice some buffeting, a result of the turbulent air separated from the wing hitting the tail of the aircraft.

In most light aircraft, as the stall is reached, the aircraft will start to descend (because the wing is no longer producing enough lift to support the aircraft's weight) and the nose will pitch down. Recovery from the stall involves lowering the aircraft nose, to decrease the angle of attack and increase the air speed, until smooth air-flow over the wing is restored. Normal flight can be resumed once recovery is complete.[7] The maneuver is normally quite safe, and, if correctly handled, leads to only a small loss in altitude (20–30 m/50–100 ft). It is taught and practised in order for pilots to recognize, avoid, and recover from stalling the aircraft.[8] A pilot is required to demonstrate competency in controlling an aircraft during and after a stall for certification in the United States,[9] and it is a routine maneuver for pilots when getting to know the handling of an unfamiliar aircraft type. The only dangerous aspect of a stall is a lack of altitude for recovery.

A special form of asymmetric stall in which the aircraft also rotates about its yaw axis is called a spin. A spin can occur if an aircraft is stalled and there is an asymmetric yawing moment applied to it.[10] This yawing moment can be aerodynamic (sideslip angle, rudder, adverse yaw from the ailerons), thrust related (p-factor, one engine inoperative on a multi-engine non-centreline thrust aircraft), or from less likely sources such as severe turbulence. The net effect is that one wing is stalled before the other and the aircraft descends rapidly while rotating, and some aircraft cannot recover from this condition without correct pilot control inputs (which must stop yaw) and loading.[11] A new solution to the problem of difficult (or impossible) stall-spin recovery is provided by the ballistic parachute recovery system.

The most common stall-spin scenarios occur on takeoff (departure stall) and during landing (base to final turn) because of insufficient airspeed during these maneuvers. Stalls also occur during a go-around manoeuvre if the pilot does not properly respond to the out-of-trim situation resulting from the transition from low power setting to high power setting at low speed.[12] Stall speed is increased when the wing surfaces are contaminated with ice or frost creating a rougher surface, and heavier airframe due to ice accumulation.

Stalls occur not only at slow airspeed, but at any speed when the wings exceed their critical angle of attack. Attempting to increase the angle of attack at 1g by moving the control column back normally causes the aircraft to climb. However, aircraft often experience higher g-forces, such as when turning steeply or pulling out of a dive. In these cases, the wings are already operating at a higher angle of attack to create the necessary force (derived from lift) to accelerate in the desired direction. Increasing the g-loading still further, by pulling back on the controls, can cause the stalling angle to be exceeded, even though the aircraft is flying at a high speed.[13] These "high-speed stalls" produce the same buffeting characteristics as 1g stalls and can also initiate a spin if there is also any yawing.

Symptoms of onset

One symptom of an approaching stall is slow and sloppy controls. As the speed of the aircraft decreases approaching the stall, there is less air moving over the wing, and, therefore, less air will be deflected by the control surfaces (ailerons, elevator, and rudder) at this lower speed. Some buffeting may also be felt from the turbulent flow above the wings as the stall is reached. The stall warning will sound, if fitted, in most aircraft 5 to 10 knots above the stall speed.[14]

Characteristics

Different aircraft types have different stalling characteristics. A benign stall is one where the nose drops gently and the wings remain level throughout. Slightly more demanding is a stall in which one wing stalls slightly before the other, causing that wing to drop sharply, with the possibility of entering a spin. A dangerous stall is one in which the nose rises, pushing the wing deeper into the stalled state and potentially leading to an unrecoverable deep stall. This can occur in some T-tailed aircraft wherein the turbulent airflow from the stalled wing can blanket the control surfaces at the tail.[citation needed]

Speed

Left edge is the stall speed curve.

Stalls depend only on angle of attack, not airspeed.[15] However, the more slowly an airplane goes, the greater the angle of attack it needs to produce lift equal to the aircraft's weight.[16] As the speed decreases further, at some point this angle will be equal to the critical (stall) angle of attack. This speed is called the "stall speed". An aircraft flying at its stall speed cannot climb, and an aircraft flying below its stall speed cannot stop descending. Any attempt to do so by increasing angle of attack, without first increasing airspeed, will result in a stall.

The actual stall speed will vary depending on the airplane's weight, altitude, configuration, and vertical and lateral acceleration. Guidelines for the case of zero acceleration are provided by the following V speeds:

- VS: The computed stalling speed with flaps retracted at design speed. Often has the same value as VS1.

- VS0: The stall speed in landing configuration (full flaps, landing gear down, spoilers retracted).

- VS1: The stall speed in a "clean" configuration (flaps, landing gear and spoilers all retracted as far as possible).

- VSR: Reference stall speed.[17]

- VSR0: Reference stall speed in the landing configuration.

- VSR1: Reference stall speed in the clean configuration.

- VSW: Speed at which onset of natural or artificial stall warning occurs.

On an airspeed indicator, the bottom of the white arc indicates VS0 at maximum weight, while the bottom of the green arc indicates VS1 at maximum weight. While an aircraft's VS speed is computed by design, its VS0 and VS1 speeds must be demonstrated empirically by flight testing.[18]

In accelerated and turning flight

The normal stall speed, specified by the VS values above, always refers to straight and level flight, where the load factor is equal to 1g. However, if the aircraft is turning or pulling up from a dive, additional lift is required to provide the vertical or lateral acceleration, and so the stall speed is higher. An accelerated stall is a stall that occurs under such conditions.[19]

Considering, for example, a banked turn, the lift required is equal to the weight of the aircraft plus extra lift to provide the centripetal force necessary to perform the turn; that is:[20][21]

where:

- = lift

- = load factor (greater than 1 in a turn)

- = weight of the aircraft

To achieve the extra lift, the lift coefficient, and so the angle of attack, will have to be higher than it would be in straight and level flight at the same speed. Therefore, given that the stall always occurs at the same critical angle of attack,[22] by increasing the load factor (e.g., by tightening the turn) such critical angle – and the stall – will be reached with the airspeed remaining well above the normal stall speed,[20] that is:[23][24][25]

where:

- = stall speed

- = stall speed of the aircraft in straight, level flight

- = load factor

The table that follows gives some examples of the relation between the angle of bank and the square root of the load factor. It derives from the trigonometric relation (secant) between and .

Bank angle 30° 1.07 45° 1.19 60° 1.41

For example, in a turn with bank angle of 45°, Vst is 19% higher than Vs.

It should be noted that, according to Federal Aviation Administration (FAA) terminology, the above example illustrates a so-called turning flight stall, while the term accelerated is used to indicate an accelerated turning stall only, that is, a turning flight stall where the airspeed decreases at a given rate.[26]

A notable example of air accident involving a low-altitude turning flight stall is the 1994 Fairchild Air Force Base B-52 crash.

Types

Dynamic stall

Dynamic stall is a non-linear unsteady aerodynamic effect that occurs when airfoils rapidly change the angle of attack. The rapid change can cause a strong vortex to be shed from the leading edge of the aerofoil, and travel backwards above the wing.[27] The vortex, containing high-velocity airflows, briefly increases the lift produced by the wing. As soon as it passes behind the trailing edge, however, the lift reduces dramatically, and the wing is in normal stall.[28]

Dynamic stall is an effect most associated with helicopters and flapping wings, though also occurs in wind turbines[29], and due to gusting airflow. During forward flight, some regions of a helicopter blade may incur flow that reverses (compared to the direction of blade movement), and thus includes rapidly changing angles of attack. Oscillating (flapping) wings, such as those of insects—including the most famous one, the bumblebee—may rely almost entirely on dynamic stall for lift production, provided the oscillations are fast compared to the speed of flight, and the angle of the wing changes rapidly compared to airflow direction.[28]

Stall delay can occur on airfoils subject to a high angle of attack and a three-dimensional flow. When the angle of attack on an airfoil is increasing rapidly, the flow will remain substantially attached to the airfoil to a significantly higher angle of attack than can be achieved in steady-state conditions. As a result, the stall is delayed momentarily and a lift coefficient significantly higher than the steady-state maximum is achieved. The effect was first noticed on propellers.[30]

Deep stall

A deep stall (or super-stall) is a dangerous type of stall that affects certain aircraft designs,[31] notably jet aircraft with a T-tail configuration and rear-mounted engines. In these designs, the turbulent wake of a stalled main wing, nacelle-pylon wakes and the wake from the fuselage[32] "blanket" the horizontal stabilizer, rendering the elevators ineffective and preventing the aircraft from recovering from the stall. Taylor[33] states T-tail propeller aircraft, unlike jet aircraft, do not usually require a stall recovery system during stall flight testing due to increased airflow over the wing root from the prop wash. Nor do they have rear mounted nacelles which can contribute substantially to the problem.[34] The A400M was fitted with a vertical tail booster for some flight tests in case of deep stall.[35]

Trubshaw[36] gives a broad definition of deep stall as penetrating to such angles of attack that pitch control effectiveness is reduced by the wing and nacelle wakes. He also gives a definition that relates deep stall to a locked-in condition where recovery is impossible. This is a single value of , for a given aircraft configuration, where there is no pitching moment, i.e. a trim point.

Typical values both for the range of deep stall, as defined above, and the locked-in trim point are given for the Douglas DC-9 Series 10 by Schaufele.[37] These values are from wind tunnel tests for an early design. The final design had no locked in trim point so recovery from the deep stall region was possible, as required to meet certification rules. Normal stall beginning at the 'g' break (sudden decrease of the vertical load factor[35]) was at 18 degrees , deep stall started at about 30 degrees and the locked-in unrecoverable trim point was at 47 degrees.

The very high for a deep stall locked-in condition occurs well beyond the normal stall but can be attained very rapidly as the aircraft is unstable beyond the normal stall and requires immediate action to arrest it. The loss of lift causes high sink rates which, together with the low forward speed at the normal stall, give a high with little or no rotation of the aircraft.[38] BAC 1-11 G-ASHG, during stall flight tests before the type was modified to prevent a locked-in deep stall condition, descended at over 10,000 feet per minute (50 m/s) and struck the ground in a flat attitude moving only 70 feet (20 m) forward after initial impact.[38] Sketches which show how the wing wake blankets the tail may be misleading if they imply that deep stall requires a high body angle. Taylor and Ray[39] show how the aircraft attitude in the deep stall is relatively flat, even less than during the normal stall, with very high negative flight path angles.

Effects similar to deep stall had been known to occur on some aircraft designs before the term was coined. A prototype Gloster Javelin (serial WD808) was lost in a crash on 11 June 1953, to a "locked in" stall[40] However, Waterton[41] states that the trimming tailplane was found to be the wrong way for recovery. Low speed handling tests were being done to assess a new wing.[41] Handley Page Victor XL159 was lost to a "stable stall" on 23 March 1962.[42] It had been clearing the fixed droop leading edge with the test being stall approach, landing configuration, C of G aft. The brake parachute had not been streamed as it may have hindered rear crew escape.[43]

The name "deep stall" first came into widespread use after the crash of the prototype BAC 1-11 G-ASHG on 22 October 1963, which killed its crew.[44] This led to changes to the aircraft, including the installation of a stick shaker (see below) to clearly warn the pilot of an impending stall. Stick shakers are now a standard part of commercial airliners. Nevertheless, the problem continues to cause accidents; on 3 June 1966, a Hawker Siddeley Trident (G-ARPY), was lost to deep stall;[45] deep stall is suspected to be cause of another Trident (the British European Airways Flight 548 G-ARPI) crash – known as the "Staines Disaster" – on 18 June 1972 when the crew failed to notice the conditions and had disabled the stall recovery system.[46] On 3 April 1980, a prototype of the Canadair Challenger business jet crashed after initially entering a deep stall from 17,000 ft and having both engines flame-out. It recovered from the deep stall after deploying the anti-spin parachute but crashed after being unable to jettison the chute or relight the engines. One of the test pilots was unable to escape from the aircraft in time and was killed.[47] On the 26 July 1993, a Canadair CRJ-100 was lost in flight testing due to a deep stall.[48] It has been reported that a Boeing 727 entered a deep stall in a flight test, but the pilot was able to rock the airplane to increasingly higher bank angles until the nose finally fell through and normal control response was recovered.[49] A 727 accident on 1 December 1974, has also been attributed to a deep stall.[50] The crash of West Caribbean Airways Flight 708 in 2005 was also attributed to a deep stall.

Reports on the crash of Air France Flight 447 have stated that the accident involved a deep stall entered at 38,000 ft (11,582 m) and continued for more than three minutes until impact,[51] but this was a steady state conventional stall[52][53] because the aircraft (an Airbus A330) did not have a T-tail.[54]

Canard-configured aircraft are also at risk of getting into a deep stall. Two Velocity aircraft crashed due to locked-in deep stalls.[55] Testing revealed that the addition of leading edge cuffs to the outboard wing prevented the aircraft from getting into a deep stall. The Piper Advanced Technologies PAT-1, N15PT, another canard-configured aircraft, also crashed in an accident attributed to a deep stall.[56] Wind tunnel testing of the design at the NASA Langley Research Center showed that it was vulnerable to a deep stall.[57]

In the early 1980s, a Schweizer SGS 1-36 sailplane was modified for NASA's controlled deep-stall flight program.[58]

Tip stall

Aircraft with a swept wing suffer from a particular form of stalling behaviour at low speed. At high speed the airflow over the wing tends to progress directly along the chord, but as the speed is reduced a sideways component due to the angle of the leading edge has time to build up. Airflow at the root is affected only by the angle of the wing, but at a point further along the span, the airflow is affected both by the angle as well as any sideways component of the airflow from the air closer to the root. This results in a pattern of airflow that is progressively "sideways" as one moves toward the wingtip.

As it is only the airflow along the chord that contributes to lift, this means that the wing begins to develop less lift at the tip than the root. in extreme cases, this can lead to the wingtip entering stall long before the wing as a whole. In this case the average lift of the wing as a whole moves forward; the inboard sections are continuing to generate lift and are generally in front of the center of gravity (C of G), while the tips are no longer contributing and are behind the C of G. This produces a strong nose-up pitch in the aircraft, which can lead to more of the wing stalling, the lift moving further forward, and so forth. This chain reaction is considered very dangerous and was known as the pitch-up.

Tip stall can be prevented in a number of ways, at least one of which is found on almost all modern aircraft. An early solution was the addition of wing fences to re-direct sideways moving air back towards the rear of the wing. A similar solution is the dog-tooth notch seen on some aircraft, like the Avro Arrow. A more common modern solution is to use some degree of washout.

Warning and safety devices

Fixed-wing aircraft can be equipped with devices to prevent or postpone a stall or to make it less (or in some cases more) severe, or to make recovery easier.

- An aerodynamic twist can be introduced to the wing with the leading edge near the wing tip twisted downward. This is called washout and causes the wing root to stall before the wing tip. This makes the stall gentle and progressive. Since the stall is delayed at the wing tips, where the ailerons are, roll control is maintained when the stall begins.

- A stall strip is a small sharp-edged device that, when attached to the leading edge of a wing, encourages the stall to start there in preference to any other location on the wing. If attached close to the wing root, it makes the stall gentle and progressive; if attached near the wing tip, it encourages the aircraft to drop a wing when stalling.

- A stall fence is a flat plate in the direction of the chord to stop separated flow progressing out along the wing[59]

- Vortex generators, tiny strips of metal or plastic placed on top of the wing near the leading edge that protrude past the boundary layer into the free stream. As the name implies, they energize the boundary layer by mixing free stream airflow with boundary layer flow thereby creating vortices, this increases the momentum in the boundary layer. By increasing the momentum of the boundary layer, airflow separation and the resulting stall may be delayed.

- An anti-stall strake is a leading edge extension that generates a vortex on the wing upper surface to postpone the stall.

- A stick pusher is a mechanical device that prevents the pilot from stalling an aircraft. It pushes the elevator control forward as the stall is approached, causing a reduction in the angle of attack. In generic terms, a stick pusher is known as a stall identification device or stall identification system.[60]

- A stick shaker is a mechanical device that shakes the pilot's controls to warn of the onset of stall.

- A stall warning is an electronic or mechanical device that sounds an audible warning as the stall speed is approached. The majority of aircraft contain some form of this device that warns the pilot of an impending stall. The simplest such device is a stall warning horn, which consists of either a pressure sensor or a movable metal tab that actuates a switch, and produces an audible warning in response.

- An angle-of-attack indicator for light aircraft, the "AlphaSystemsAOA" and a nearly identical "Lift Reserve Indicator", are both pressure differential instruments that display margin above stall and/or angle of attack on an instantaneous, continuous readout. The General Technics CYA-100 displays true angle of attack via a magnetically coupled vane. An AOA indicator provides a visual display of the amount of available lift throughout its slow speed envelope regardless of the many variables that act upon an aircraft. This indicator is immediately responsive to changes in speed, angle of attack, and wind conditions, and automatically compensates for aircraft weight, altitude, and temperature.

- An angle of attack limiter or an "alpha" limiter is a flight computer that automatically prevents pilot input from causing the plane to rise over the stall angle. Some alpha limiters can be disabled by the pilot.

Stall warning systems often involve inputs from a broad range of sensors and systems to include a dedicated angle of attack sensor.

Blockage, damage, or inoperation of stall and angle of attack (AOA) probes can lead to unreliability of the stall warning, and cause the stick pusher, overspeed warning, autopilot, and yaw damper to malfunction.[61]

If a forward canard is used for pitch control, rather than an aft tail, the canard is designed to meet the airflow at a slightly greater angle of attack than the wing. Therefore, when the aircraft pitch increases abnormally, the canard will usually stall first, causing the nose to drop and so preventing the wing from reaching its critical AOA. Thus, the risk of main wing stalling is greatly reduced. However, if the main wing stalls, recovery becomes difficult, as the canard is more deeply stalled and angle of attack increases rapidly.[62]

If an aft tail is used, the wing is designed to stall before the tail. In this case, the wing can be flown at higher lift coefficient (closer to stall) to produce more overall lift.

Most military combat aircraft have an angle of attack indicator among the pilot's instruments, which lets the pilot know precisely how close to the stall point the aircraft is. Modern airliner instrumentation may also measure angle of attack, although this information may not be directly displayed on the pilot's display, instead driving a stall warning indicator or giving performance information to the flight computer (for fly by wire systems).

Flight beyond the stall

As a wing stalls, aileron effectiveness is reduced, making the plane hard to control and increasing the risk of a spin starting. Post stall, steady flight beyond the stalling angle (where the coefficient of lift is largest) requires engine thrust to replace lift as well as alternative controls to replace the loss of effectiveness of the ailerons. For high-powered aircraft, the loss of lift (and increase in drag) beyond the stall angle is less of a problem than maintaining control. Some aircraft may be subject to post-stall gyration (e.g. the F-4) or susceptible to entering a flat-spin (e.g. F-14). Control beyond-stall can be provided by reaction control systems (e.g. NF-104A), vectored thrust, as well as a rolling stabilator (or taileron). The enhanced manoeuvering capability by flights at very high angles of attack can provide a tactical advantage for military fighters such as the F-22 Raptor. Short term stalls at 90–120° (e.g. Pugachev's Cobra) are sometimes performed at airshows.[63] The highest angle of attack in sustained flight so far demonstrated was 70 degrees in the X-31 at the Dryden Flight Research Center.[64] Sustained post-stall flight is a type of supermaneuverability.

Spoilers

Except for flight training, airplane testing, and aerobatics, a stall is usually an undesirable event. Spoilers (sometimes called lift dumpers), however, are devices that are intentionally deployed to create a carefully controlled flow separation over part of an aircraft's wing to reduce the lift it generates, increase the drag, and allow the aircraft to descend more rapidly without gaining speed.[65] Spoilers are also deployed asymmetrically (one wing only) to enhance roll control. Spoilers can also be used on aborted take-offs and after main wheel contact on landing to increase the aircraft's weight on its wheels for better braking action.

Unlike powered airplanes, which can control descent by increasing or decreasing thrust, gliders have to increase drag to increase the rate of descent. In high-performance gliders, spoiler deployment is extensively used to control the approach to landing.

Spoilers can also be thought of as "lift reducers" because they reduce the lift of the wing in which the spoiler resides. For example, an uncommanded roll to the left could be reversed by raising the right wing spoiler (or only a few of the spoilers present in large airliner wings). This has the advantage of avoiding the need to increase lift in the wing that is dropping (which may bring that wing closer to stalling).

History

Otto Lilienthal died while flying in 1896 as the result of a stall. Wilbur Wright encountered stalls for the first time in 1901, while flying his second glider. Awareness of Lilienthal's accident and Wilbur's experience, motivated the Wright Brothers to design their plane in "canard" configuration. This made recoveries from stalls easier and more gentle. The design saved the brothers' lives more than once.[66]

The aircraft engineer Juan de la Cierva worked on his "Autogiro" project to develop a rotary wing aircraft which, he hoped, would be unable to stall and which therefore would be safer than aeroplanes. In developing the resulting "autogyro" aircraft, he solved many engineering problems which made the helicopter possible.

See also

- Articles

- Aviation safety

- Coffin corner (aerodynamics)

- Compressor stall

- Lift coefficient

- Spin (flight)

- Spoiler (aeronautics)

- Wing twist

- Notable accidents

- 1966 Felthorpe Trident crash

- British European Airways Flight 548

- Air France Flight 447

- Colgan Air Flight 3407

- Turkish Airlines Flight 1951

- Indonesia AirAsia Flight 8501[67]

Notes

- ↑ Crane, Dale: Dictionary of Aeronautical Terms, third edition, p. 486. Aviation Supplies & Academics, 1997. ISBN 1-56027-287-2

- ↑ Benjamin Gal-Or, Vectored Propulsion, Supermaneuverability, and Robot Aircraft, Springer Verlag, 1990, ISBN 0-387-97161-0, ISBN 3-540-97161-0

- ↑ USAF & NATO Report RTO-TR-015 AC/323/(HFM-015)/TP-1 (2001)

- ↑ Clancy, L.J., Aerodynamics, Section 5.7

- ↑ Clancy, L.J., Aerodynamics, Sections 5.28 and 16.48

- ↑ Anderson, J.D., A History of Aerodynamics, pp. 296–311

- ↑ FAA Airplane flying handbook ISBN 978-1-60239-003-4 Chapter 4, p. 7

- ↑ 14 CFR part 61

- ↑ Federal Aviation Regulations Part25 section 201

- ↑ FAA Airplane flying handbook ISBN 978-1-60239-003-4 Chapter 4, pp. 12–16

- ↑ 14 CFR part 23

- ↑ FAA Airplane flying handbook ISBN 978-1-60239-003-4 Chapter 4, pp. 11–12

- ↑ FAA Airplane flying handbook ISBN 978-1-60239-003-4 Chapter 4, p. 9

- ↑ Federal Aviation Regulations part 25 section 207

- ↑ Langewiesche, Wolfgang (1972). Stick and Rudder. McGraw Hill. pp. 18–21.

- ↑ "Pilot's Handbook of Aeronautical Knowledge – Chapter 4". Federal Aviation Administration. http://www.faa.gov/regulations_policies/handbooks_manuals/aircraft/airplane_handbook/media/faa-h-8083-3a-3of7.pdf. Retrieved 2014-03-13.

- ↑ "Electronic Code of Federal Regulations – Chapter 14.1". Federal Aviation Administration. http://www.ecfr.gov/cgi-bin/text-idx?c=ecfr&SID=f553dbb9c06409a040f3d6865e435c70&rgn=div8&view=text&node=14:1.0.1.1.1.0.1.2&idno=14;cc=ecfr. Retrieved 2008-05-07.

- ↑ Flight testing of fixed wing aircraft. Ralph D. Kimberlin ISBN 978-1-56347-564-1

- ↑ Brandon, John. "Airspeed and the properties of air". Recreational Aviation Australia Inc. Archived from the original on 2008-07-31. https://web.archive.org/web/20080731103646/http://www.auf.asn.au/groundschool/umodule2.html#accel_stall. Retrieved 2008-08-09.

- ↑ 20.0 20.1 Clancy, L.J., Aerodynamics, Section 5.22

- ↑ McCormick, Barnes W. (1979), Aerodynamics, Aeronautics and Flight Mechanics, p. 464, John Wiley & Sons, New York ISBN 0-471-03032-5

- ↑ Clancy, L.J., Aerodynamics, Sections 5.8 and 5.22

- ↑ Clancy, L.J., Aerodynamics, Equation 14.11

- ↑ McCormick, Barnes W. (1979), Aerodynamics, Aeronautics and Flight Mechanics, Equation 7.57

- ↑ "Stall speed". http://home.anadolu.edu.tr/~mcavcar/common/Stall.pdf.

- ↑ "Part 23 – Airworthiness Standards: §23.203 Turning flight and accelerated turning stalls". Federal Aviation Administration. February 1996. http://ecfr.gpoaccess.gov/cgi/t/text/text-idx?c=ecfr&sid=3a0a07257d2f5a7f42a2c1920e63f263&rgn=div8&view=text&node=14:1.0.1.3.10.2.65.40&idno=14. Retrieved 2009-02-18.

- ↑ Buchner, A. J.; Soria, J. (2015). "Measurements of the flow due to a rapidly pitching plate using time resolved high resolution PIV". Aerospace Science and Technology (Aerospace Science and Technology) 44: 4. doi:10.1016/j.ast.2014.04.007. http://www.sciencedirect.com/science/article/pii/S1270963814000789. Retrieved 18 October 2015.

- ↑ 28.0 28.1 "Dynamic Stall, Unsteady Aerodynamics". Archived from the original on December 29, 2007. https://web.archive.org/web/20071229110350/http://aerodyn.org/Dstall/dstall.html. Retrieved March 25, 2016.

- ↑ Buchner, A-J.; Soria, J.; Honnery, D.; Smits, A.J. (2018). "Dynamic stall in vertical axis wind turbines: Scaling and topological considerations". Journal of Fluid Mechanics 841: 746-66. doi:10.1017/jfm.2018.112. Bibcode: 2018JFM...841..746B.

- ↑ Burton, Tony; David Sharpe; Nick Jenkins; Ervin Bossanyi (2001) (digitized online by Google books). Wind Energy Handbook. John Wiley and Sons. p. 139. ISBN 0-471-48997-2. https://books.google.com/books?id=4UYm893y-34C&pg=PA139&lpg=PA139&dq=%22stall+delay%22. Retrieved 2009-01-01.

- ↑ "What is the super-stall?". Aviationshop. Archived from the original on 2009-10-13. https://web.archive.org/web/20091013203208/http://www.aviationshop.com.au/avfacts/editorial/tipstall/. Retrieved 2009-09-02.

- ↑ "Aerodynamic Design Features of the DC-9" Shevell and Schaufele, J. Aircraft Vol. 3, No. 6, Nov–Dec 1966, p. 518

- ↑ "Archived copy". http://www.airborne-sys.com/files/pdf/spin_stall_parachute_recovery_systems_ss_17543100.pdf.

- ↑ Taylor, Robert T & Edward J. Ray (15 November 1965). "A Systematic Study of the Factors Contributing to Post-Stall Longitudinal Stability of T-Tail Transport Configurations". NASA Langley Research Center. p. 9. https://ntrs.nasa.gov/archive/nasa/casi.ntrs.nasa.gov/19660017791.pdf.

- ↑ 35.0 35.1 "Archived copy". http://www.sfte2013.com/files/75234188.pdf.

- ↑ "Low Speed Handling with Special Reference to the Super Stall" Trubshaw, Appendix III in "Trubshaw Test Pilot" Trubshaw and Edmondson, Sutton Publishing 1998, ISBN 0 7509 1838 1, p. 166

- ↑ "Applied Aerodynamics at the Douglas Aircraft Company-A Historical Perspective" Roger D. Schaufele, 37th AIAA Aerospace Sciences Meeting and Exhibit, January 11–14, 1999/Reno, NVFig.26 Deep Stall Pitching Moments

- ↑ 38.0 38.1 "Accident Report No. EW/C/039, Appendix IV in "Trubshaw Test Pilot" Trubshaw and Edmondson, Sutton Publishing 1998, ISBN 0 7509 1838 1, p. 182

- ↑ Taylor, Robert T & Edward J. Ray (15 November 1965). "A Systematic Study of the Factors Contributing to Post-Stall Longitudinal Stability of T-Tail Transport Configurations". NASA Langley Research Center. p. 20. https://ntrs.nasa.gov/archive/nasa/casi.ntrs.nasa.gov/19660017791.pdf.

- ↑ ASN Wikibase Occurrence # 20519 Retrieved 4 September 2011.

- ↑ 41.0 41.1 "The Quick and the Dead" W.A.Waterton, Frederick Mueller, London 1956, p. 216

- ↑ A Tale of Two Victors Retrieved 4 September 2011.

- ↑ "The Handley Page Victor Volume 2" Roger R. Brooks, Pen & Sword Aviation 2007, ISBN 978 1 84415 570 5, p. 250

- ↑ ""Report on the Accident to B.A.C. One-Eleven G-ASHG at Cratt Hill, near Chicklade, Wiltshire on 22nd October 1963, Ministry of Aviation C.A.P. 219, 1965

- ↑ "ASN Aircraft accident Hawker Siddeley HS-121 Trident 1C G-ARPY Felthorpe". Aviation-safety.net. 1966-06-03. http://aviation-safety.net/database/record.php?id=19660603-1. Retrieved 2013-04-02.

- ↑ AIB Report 4/73, p. 54

- ↑ "Winging It The Making Of The Canadair Challenger" Stuart Logie, Macmillan Canada 1992, ISBN 0-7715-9145-4, p. 169

- ↑ "ASN Aircraft accident Canadair CL-600-2B19 Regional Jet CRJ-100 C-FCRJ Byers, KS". Aviation-safety.net. 1993-07-26. http://aviation-safety.net/database/record.php?id=19930726-2. Retrieved 2013-04-02.

- ↑ Robert Bogash. "Deep Stalls". http://www.rbogash.com/Safety/deep_stall.html. Retrieved 4 September 2011.

- ↑ Accident description Retrieved 4 September 2011.

- ↑ Pew, Glenn (May 2011). "Air France 447 — How Did This Happen?". AvWeb. http://www.avweb.com/avwebflash/news/air_france_447_investigators_stall_crash_204730-1.html. Retrieved 30 May 2011.

- ↑ "Flight AF 447 on 1st June 2009, A330-203, registered F-GZCP, 27 May 2011 briefing". BEA. Archived from the original on 8 December 2015. https://web.archive.org/web/20151208144900/http://www.bea.aero/en/enquetes/flight.af.447/info27may2011.en.php.

- ↑ Bethany Whitfield (May 27, 2011). "Air France 447 Stalled at High Altitude, Official BEA Report Confirms". Flying. http://www.flyingmag.com/news/air-france-447-stalled-high-altitude-official-bea-report-confirms.

- ↑ Peter Garrison (Jun 1, 2011). "Air France 447: Was it a Deep Stall?". Flying. http://www.flyingmag.com/news/air-france-447-was-it-deep-stall.

- ↑ Cox, Jack, Velocity... Solving a Deep Stall Riddle, EAA Sport Aviation, July 1991, pp. 53–59.

- ↑ ASN Wikibase Occurrence # 10732 Retrieved 4 September 2011.

- ↑ Williams, L.J.; Johnson, J.L. Jr. and Yip, L.P., Some Aerodynamic Considerations For Advanced Aircraft Configurations, AIAA paper 84-0562, January 1984.

- ↑ Schweizer-1-36 index: Schweizer SGS 1-36 Photo Gallery Contact Sheet

- ↑ "Stall fences and vortex generators". http://www.centennialofflight.gov/essay/Theories_of_Flight/Transonic_Wings/TH20G6.htm.

- ↑ US Federal Aviation Administration, Advisory Circular 25-7A Flight Test Guide for Certification of Transport Category Airplanes, paragraph 228

- ↑ "Harco Probes Still Causing Eclipse Airspeed Problems". http://www.ainonline.com/news/single-news-page/article/harco-probes-still-causing-eclipse-airspeed-problems/.

- ↑ Airplane stability and control By Malcolm J. Abzug, E. Eugene Larrabee Chapter 17 ISBN 0-521-80992-4

- ↑ Pugachev's Cobra Maneuver

- ↑ X-31 EC94-42478-3: X-31 at High Angle of Attack

- ↑ "Spoilers". NASA, Glenn Research Center. http://www.grc.nasa.gov/WWW/K-12/airplane/spoil.html.

- ↑ Designing the 1900 Wright Glider

- ↑ "AirAsia flight QZ8501 'climbed too fast'". BBC. 20 January 2015. https://www.bbc.com/news/world-asia-30902237. Retrieved 21 January 2015.

References

- USAF & NATO Report RTO-TR-015 AC/323/(HFM-015)/TP-1 (2001

- Anderson, J.D., A History of Aerodynamics (1997). Cambridge University Press. ISBN 0-521-66955-3

- Chapter 4, "Slow Flight, Stalls, and Spins," in the Airplane Flying Handbook. (FAA H-8083-3A)

- L. J. Clancy (1975), Aerodynamics, Pitman Publishing Limited, London. ISBN 0-273-01120-0

- Stengel, R. (2004), Flight Dynamics, Princeton University Press, ISBN 0-691-11407-2

- Alpha Systems AOA Website for information on AOA and Lift Reserve Indicators [1]

- 4239-01 Angle of Attack (AoA) Sensor Specifications [2]

- Airplane flying Handbook. Federal Aviation Administration ISBN 1-60239-003-7 Pub. Skyhorse Publishing Inc.

- Federal Aviation Administration (25 September 2000), Stall and Spin Awareness Training, AC No: 61-67C

- Prof. Dr Mustafa Cavcar, "Stall Speed" [3]

KSF

KSF