Iron

From RationalWiki - Reading time: 16 min

From RationalWiki - Reading time: 16 min

| It matters Chemistry |

| Action and reaction |

| Elementary! |

| Spooky scary chemicals |

| Er, who's got the pox? |

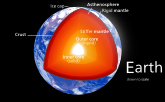

Iron (atomic symbol Fe, from the Latin ferrum) is an iron-y, supremely useful element both by itself and in compounds and alloys. Neutral, it has 26 electrons and is the sixth transition metal in period four of the periodic table (the first to contain transition metals). It is the most common element on Earth by mass (although the bulk of it is found in the Earth's core). Because all that anyone can reach within the Earth is in the crust (thus Jules Verne's colorful Journey to the Center of the Earth is impossible), people must get it from there, where it is still the fourth-most-common element. There's plenty of iron in the Earth's crust, so we are unlikely to ever run out of it, and even if we somehow do there's still plenty of iron in asteroids and meteoroids. Iron rarely appears uncombined in nature on Earth because the element typically oxidizes upon exposure to the atmosphere (forming rust), although it appears heavily in meteorites as a metal and in alloys with other elements (like manganese, cobalt, and nickel). Mined iron ore comes almost entirely from banded-iron formations (BIFs) that came into existence at ages in some instances more than 250,000-600,000 times the piddling 6000 or so years ago associated with young-earth creationism.[1]

Sources[edit]

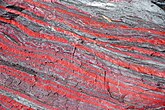

Almost all iron ore comes from banded iron formations in the upper crust of the Earth. These are almost exclusively Precambrian in age, with most deposits dating to the late Archean (2800-2500 Mya) with a secondary peak of deposition in the Orosirian period of the Paleoproterozoic (1850 Ma). Minor amounts were deposited in the early Archean and in the Neoproterozoic (750 Ma).[2][3] The youngest-known banded iron formation is an Early Cambrian formation in western China.[4] Because the processes by which BIFs are formed appear to be restricted to early geologic time and may reflect unique conditions of the Precambrian world, they have been intensively studied by geologists.

Banded iron formations are found worldwide, in every continental shield of every continent. The oldest BIFs are associated with greenstone belts and include the BIFs of the Isua Greenstone Belt, the oldest known, which have an estimated age of 3700 to 3800 Ma.[5] The Temagami[6] banded iron deposits formed over a 50-million-year period, from 2736 to 2687 Ma, and reached a thickness of 60 meters (200 feet).[7] Other examples of early Archean BIFs are found in the Abitibi greenstone belts, the greenstone belts of the Yilgarn and Pilbara cratons (Australia), the Baltic shield, and the cratons of the Amazon, north China, and south and west Africa.

Iron forms a strange material, iron pyrite, often confused with gold (hence it is known as "fool's gold") due to its metallic appearance and a color much like gold. This substance, FeS2 is little like gold, although gold appears in some pyrites (go figure!). It is not a normal sulfide, as the sulfur atoms are partly attached to each other. It gives sparks when it is rubbed hard or struck. Although common, it is almost never mined for its iron content. Pyrite oxidizes under some conditions to form sulfuric acid, which often escapes a mine through a waterway. Acid mine drainage is one of the most horrible forms of water pollution because sulfuric acid destroys most organic matter, including plants and animals, and the sulfur causes the affected areas to smell nasty as well. For a long time, pyrite was heavily used in firearms as a source of ignition for firing a gun.[8]

Scarcity (hint: it's not)[edit]

Iron is common in the Earth because it is common in the Universe and is heavy enough to collect within a planet's solid part (unlike hydrogen or helium). Iron is the end of the line for nucleosynthesis in giant stars. Stars produce energy by fusing lighter elements from hydrogen to helium and so on (to the extent that such is possible due to the mass of the star) up to nickel-56. Nickel-56 is unstable, grabbing a pair of electrons that transform a pair of protons into neutrons, with nickel-56 becoming iron-56. The heaviest elements tend to collect in the core, whose heaviest element in quantity is iron. At that point, no further energy can come from nucleosynthesis in the heavy, iron-rich core.[9] The core contracts, creating a partial vacuum, and the hot plasma collapses upon the core, causing the star to explode in a supernova![]() that expels the gases and plasma of the outer layers of the star into space. It's then curtains for the star — well, technically, a supernova remnant even if it might resemble curtains in a way. Although much of the iron in a star going supernova may become a neutron star (in which case the iron becomes something else) or a black hole (in which case whatever it becomes becomes irrelevant beyond the black hole), a significant part of the iron goes into outer space to collect elsewhere, as in future planets. But even without the star exploding in a supernova, a star can give off material through mass ejections.[10]

that expels the gases and plasma of the outer layers of the star into space. It's then curtains for the star — well, technically, a supernova remnant even if it might resemble curtains in a way. Although much of the iron in a star going supernova may become a neutron star (in which case the iron becomes something else) or a black hole (in which case whatever it becomes becomes irrelevant beyond the black hole), a significant part of the iron goes into outer space to collect elsewhere, as in future planets. But even without the star exploding in a supernova, a star can give off material through mass ejections.[10]

Heavy elements such as iron and elements with high melting points such as carbon and silicon from nucleosynthesis tend to congeal as they get cold in space and combine as rocks that themselves form planets. The large number of iron meteorites demonstrates the commonness of iron in the universe in a form that rarely appears on the Earth's surface. In the early Earth, the collection of rocks and metals melted, with metallic iron (the heaviest common element) mostly tending toward the middle of the Earth in its core. Part of the core of the Earth is the hot, dense, solid inner core mostly of iron and nickel. Above that is an outer core that under lesser pressure but still great heat is a molten mass mostly of iron. This molten iron on the Earth creates a powerful magnet that creates a strong magnetic field that fends off dangerous-to-life charged particles from the Sun and other stars. Without that magnetic field, life as we know it would be irradiated into dead matter.

Uses[edit]

Pure iron has all of the traits commonly associated with metal, including high melting and boiling points, a metallic luster, and high conductivity of heat and electricity. It is soft and malleable enough when hot to be worked into useful and desirable items (literally wrought iron). It is common enough to be readily available, although it rarely appears uncombined in nature. Iron is stronger than the metals discovered before it (copper,![]() silver,

silver,![]() gold, mercury, tin,

gold, mercury, tin,![]() and lead), so it proved to be better suited to tools and weapons in early antiquity. Indeed, the Iron Age

and lead), so it proved to be better suited to tools and weapons in early antiquity. Indeed, the Iron Age![]() was a significant break from the Bronze Age

was a significant break from the Bronze Age![]() for technology that allows stronger tools and weapons but requires heating an ore in a chemical process to extract the metal, and processing hot iron through pounding and cutting while it is still hot or casting it into molds. This created the long-lasting career of the blacksmith, who formed essential metal objects from antiquity (including nails and horseshoes, the swords of the warrior and plowshares of the farmer, as well as hammer-heads and anvils as tools of the blacksmith) to modern times. The successor of the blacksmith is the steel mill that does the blacksmith's old work on a larger scale. As a bonus, iron is easy to magnetize, which makes it useful in certain machinery. The Iron Age continued at least into the 20th century, including the industrial era that depended heavily upon iron machinery for manufacturing and upon the processing of iron and steel as products, ending only when materials with potential uses for which iron and steel were unsuited, such as aluminum and plastics, were introduced.

for technology that allows stronger tools and weapons but requires heating an ore in a chemical process to extract the metal, and processing hot iron through pounding and cutting while it is still hot or casting it into molds. This created the long-lasting career of the blacksmith, who formed essential metal objects from antiquity (including nails and horseshoes, the swords of the warrior and plowshares of the farmer, as well as hammer-heads and anvils as tools of the blacksmith) to modern times. The successor of the blacksmith is the steel mill that does the blacksmith's old work on a larger scale. As a bonus, iron is easy to magnetize, which makes it useful in certain machinery. The Iron Age continued at least into the 20th century, including the industrial era that depended heavily upon iron machinery for manufacturing and upon the processing of iron and steel as products, ending only when materials with potential uses for which iron and steel were unsuited, such as aluminum and plastics, were introduced.

The most obvious fault of iron is that it corrodes easily, especially in salt water and in acids. Rust readily flakes off iron, with "fresh" bare iron being exposed for further, destructive rusting until the metal is gone. Surrounding structures can also be damaged, as rust is more voluminous than iron. Most often it is found as hematite, magnetite (two oxides) and siderite (a carbonate), but iron can be released from such rocks by burning it with carbon from coal or charcoal. Iron pyrites contain much iron, too, but this sulfide is difficult to break down without releasing dangerous compounds of sulfur,![]() and if sulfur remains in the melt it tends to make the iron or steel softer and more brittle, so it is not used as an iron ore.[note 1] Most commonly, iron is combined with carbon to form steel, which is more rigid. In modern times, steel is heavily used in machines, vehicles, ships, containers, and materials used in construction. Steel production correlates closely to economic activity, especially in construction. Steel is a basic material in building skyscrapers and bridges. Much of it is reinforcing bars in concrete, as in highways. Paradoxically, iron is a good container for fluorine and hydrogen fluoride, both of which can cause even glass (normally an excellent container, so long as it does not break, for most acids) to disintegrate, because fluorine forms a rigid coating of ferric fluoride that does not abrade as does iron oxide rust.[11] Also significant: unlike many other metals, iron does not form an amalgam

and if sulfur remains in the melt it tends to make the iron or steel softer and more brittle, so it is not used as an iron ore.[note 1] Most commonly, iron is combined with carbon to form steel, which is more rigid. In modern times, steel is heavily used in machines, vehicles, ships, containers, and materials used in construction. Steel production correlates closely to economic activity, especially in construction. Steel is a basic material in building skyscrapers and bridges. Much of it is reinforcing bars in concrete, as in highways. Paradoxically, iron is a good container for fluorine and hydrogen fluoride, both of which can cause even glass (normally an excellent container, so long as it does not break, for most acids) to disintegrate, because fluorine forms a rigid coating of ferric fluoride that does not abrade as does iron oxide rust.[11] Also significant: unlike many other metals, iron does not form an amalgam![]() with highly-toxic mercury. Much less brittle than glass, iron is a much-favored material for transporting that dangerous liquid.

with highly-toxic mercury. Much less brittle than glass, iron is a much-favored material for transporting that dangerous liquid.

In order to protect iron from rust it is often galvanized, which involves dipping iron or steel into molten zinc. Zinc corrodes more easily than iron, but its oxide better protects iron than rust does. Another is chrome plating, which can have the bonuses of shininess and resistance to wear.

A second fault is that iron is at best a mediocre conductor of electricity. It has roughly six times as much resistivity to electricity (and one sixth the conductivity) of copper, so it is the worst of both worlds as a conductor of electricity in wires but still capable of delivering dangerous levels of charge (as from lightning). Iron surfaces are to be avoided in thunderstorms. A fully-enclosed iron or steel frame as in aircraft, motor vehicles, or buildings may provide some protection, but any high-profile iron object (such as a golf club) is a potential lightning rod carrying dangerous current to someone near it. [12]

Iron and steel are easy to recycle by melting. The iron that once was in a scrapped tugboat may have ended up in rail cars, rails for trains, automobiles, appliances, aircraft, shipping containers, construction rebars, and again a tugboat. In scrapyards, the means of separating iron objects is an electromagnet made of… you guessed it, iron… that when charged holds the scrap iron and drops it once the electricity is turned off to the electromagnet.

Iron and economics[edit]

In the pre-industrial era, iron and steel could be produced in adequate quantities, if expensively, in blacksmith shops for tools, plows, weapons, and nails. Economies of scale required much larger iron-mining operations and steel mills to produce the iron necessary in the marvelous inventions such as reapers, rail cars, iron tracks (railroads are literally "iron roads" or chemins de fer in French and "iron paths" Eisenbahnen in German), and trains (which were often described in the English-speaking world as "iron horses"). Iron was also put to use in barbed wire and containers for canned fruits, vegetables, and meats. Wrought iron, a strong and durable item of decoration, became a commonplace detail in architecture. In the 19th century, iron-hulled ships largely supplanted the wooden ships of the pre-industrial era. The "tin can" is usually iron plated with tin and not tin itself because tin is comparatively expensive. Manufacturing equipment, motor vehicles, and appliances became heavy users of iron. Iron went from being a relatively expensive material to one of the cheapest.

The iron and steel industry became a mass employer in industrialized countries from the United States to western Europe to Imperial Russia as giant steel mills formed to meet the economic need for iron. Such steel mills were also dangerous places to work. Tycoons who owned these mills tended toward monopoly and treated their employees badly. Such workers often formed labor unions to protect their rights by strikes to get shorter hours for more pay, taking advantage of the prosperity that iron and steel production created. The tycoons usually won the contest. The iron and steel industry also created a huge demand for miners to wrest coal and limestone from the Earth for use in the production of iron and steel. Miners and steel workers became a large contingent of what Karl Marx would call a potentially-revolutionary proletariat.

The giant US Steel was a holding company for several American steel producers that could as one corporation control the market and break strikes. The man who put together this monopoly, Elbert Henry Gary, was an attorney who knew how to get tycoons together in a common interest. US Steel established a great steel mill in Gary, Indiana, the city named after the founder of US Steel. An apocryphal claim by some workers says, "Eldridge Gary never learned what the inside of a steel mill was like until he died" (in a reference to Hell, which in some depictions resembles a steel mill).

At least in America, workers had a meaningful vote and used it, pushing politicians to draft legislation sympathetic to the interests of workers. Much the same was so in such countries as Canada, the United Kingdom, France, Italy, Belgium, Luxembourg, and the Netherlands, where not only steel workers, but also miners and assembly-line workers who built the machines, could vote and strike for better conditions and wages.

In the Russian Empire, which had a large steel industry that was quickly put together largely to produce machinery and provide large numbers of military weapons, the workers' plight was even worse, and workers became the target audience for radical extremists who eventually congealed as the Bolsheviks who promised to rid Russia of the exploitative industrialists and financiers in the supposed service of the proletariat. Russia had no semblance of liberal democracy before the Bolshevik Revolution and no mitigation of the degrading poverty and authoritarian management of Russian manufacturing of all kinds.

The German Empire and Austro-Hungarian Empire were in between the democracies and Russia in terms of oppression of workers of all kinds. Tycoons such as Krupp and Thyssen had far more power in the legislative systems of those countries, and they used it to keep industrial pay low and labor discipline hard. One of the peak times for iron and steel production was the First World War, when huge quantities of iron and steel would go into the creation of naval ships (including submarines), tanks, and artillery weapons that would reap a harvest of mass death not yet known at that time. The war would end with a great destabilization of the world, with revolutionary uprisings in the Russian, German and Austro-Hungarian empires. The one in Russia succeeded and scared plutocrats everywhere of being dispossessed, exiled, or murdered. In the shaky democracies that formed after the First World War, the tycoons often bankrolled fascist movements, including Mussolini's Fascisti, Hitler's Nazi Party, and the Romanian Iron Guard in attempts to weaken or destroy labor unions. Fascism led to oppressive, militaristic regimes that would offer great profits to tycoons, many of them owners of iron and steel mills, for producing the steel for the weaponry of an even deadlier war than the First World War. There would be naval vessels, tanks, bomber and fighter aircraft, and of course firearms to devour the iron and steel.

The two industrial powers that could churn out the most military pieces, the United States and the Soviet Union, would be the two superpowers when the war ended and would remain as such for several decades. In the aftermath of the Second World War, countries that had lost much of their iron and steel capacity would need to rebuild their industry with newer and more efficient equipment. However, due to several factors, such as the OPEC petroleum embargo, neoliberal trade deals, an increase in automation, and just plain incompetent financial decisions on the part of steel manufacturers, the steel industry has been on a steady decline in the U.S., with it producing one third of the steel and employing one fifth of the people that it did in its peak.[13] The decline is especially pronounced in the so-called "rust belt" states such as Michigan, Ohio, and Pennsylvania, named for the industrial decline which resulted in negative economic and demographic effects on these areas. Today, China is the world's biggest steel producer, producing 57% of the global supply.[14] Currently, much of the world's steel is recycled from things such as cars, ships, and steel cans rather than mined. This still leads to dangerous, low paying jobs to this day, with the "ship graveyard" of Chittagong in Bangladesh being a particularly notorious example, where hundreds of workers who break apart ships for their steel have died.[15]

Dyes and medicines[edit]

Iron also appears in numerous useful and necessary compounds. One of the most common inks is a substance known as Prussian blue, a complex cyanide of iron. (Unlike most other cyanides that are extremely toxic substances, this one is harmless and can even be used as a medicine as a means of fighting, of all things, poisons.) Prussian blue is the most common of all dyes used in inks, and painters love to use this inexpensive dye. It serves well in the art of tattooing.

Iron is an essential component of heme groups in biology. Heme groups are essential to the function of several important classes of proteins, including cytochromes and hemoglobin, which carries oxygen within red blood cells in the bloodstream of most animals, including humans. A deficiency of iron is big trouble for any human, causing anemia. An excess of iron is toxic, and one of the most common forms of poisoning comes from taking an excess of iron as in vitamins. (The dose makes the poison.) Thus, iron-containing vitamins must be kept out of reach of children.

Medical woo[edit]

For several decades a product named 'Geritol' was heavily marketed to elderly people with the claim that its proprietary brand of ferric ammonium citrate could cure "iron-poor tired blood". whatever that is. An iron deficiency can contribute to anemia, but a low level of iron is easily detected in a blood test and is easily treated with non-proprietary iron compounds, prescription or otherwise. Advertising claims on behalf of this product were discredited in court findings as "conduct amounted to gross negligence and bordered on recklessness", ruled as a false and misleading claim, and heavily penalized with fines totaling $812,000, the largest FTC fine up to that date (1973).[16][17] Although subsequent trials and appeals from 1965 to 1973 concluded that some of the FTC demands exceeded its authority, this irresponsibly-marketed product was already well known and its maker was the largest U.S. company selling iron and B-vitamin supplements through 1979.

Since then, supplemental iron products have been contraindicated because of concerns over hemochromatosis,[18][19] and serious questions raised in studies for men, postmenopausal women, and nonanemic patients with liver disease, heart disease, type 2 diabetes, or cancer.[20][21][22]

Semiconductors[edit]

Iron pyrite's original uses are now obsolete: It sparks when struck, and it has been used for starting fires before matches were available and in firearms of the musket era. Other sources of iron for metallurgy are easier to process for the metal, and pyrite is more likely to be used for its sulfur than for iron.

Pyrite is however is a semiconductor[23][24] with potential use for photovoltaic solar panels.[25] As a semiconductor, it was formerly used in early crystal radios as a detector of radio waves before vacuum tubes became the norm.[26][27]

Holocaust denial and iron[edit]

Concrete that contains iron compounds is discolored blue in the presence of cyanide such as the Zyklon-B that the Nazis used in gas chambers in extermination camps and elsewhere. Holocaust deniers often make a point that the concrete in the "gas chambers" in Auschwitz is not discolored blue, so the Nazis could have never have used those in mass murder. Technically this is true, in that the Nazis destroyed the original gas chambers when retreating before the Soviet armed forces at Auschwitz. The gas chambers at Auschwitz are not those; they are reconstructions built by the post-war Polish government as a memorial to those murdered there. Cyanide has never been used in those memorials. The Nazis failed to destroy the active gas chambers at Majdanek,![]() and the gas chambers there show the evidence of the homicidal use of Zyklon-B within them.

and the gas chambers there show the evidence of the homicidal use of Zyklon-B within them.

9/11 crankery and iron[edit]

The 9/11 attacks on the Twin Towers, in which the terrorist clique al-Qaeda commandeered commercial jetliners and turned them into literal weapons of mass destruction, have resulted in a large and pitiable literature in which other, more complicated and dubious, explanations come to the fore. Rather than accepting the more conventional story of jet fuel burning at temperatures likely to destroy the tensile strength of iron and steel that formed the reliable structure of the Twin Towers, these "truthers" offer worthless delusion. As a blacksmith shows, cold iron is strong and rigid; heated to red heat, iron becomes soft and weak, unable to hold its shape even if it does not melt.

Although there were explosions, many of those resulted from the rapid boiling of water in enclosed spaces such as soft-drink machines, toilets, water coolers, refrigerator and freezer compartments, and cans and bottles from rapid expansion as liquids vaporize. Such explosions were destructive in their own right, but they could never have weakened the iron structure enough to cause the buildings to pancake as is shown in video.

Knowledge of the essential properties of iron as a material aids in the refutation of nonsense theories.

External links[edit]

- Ontario banded iron formation, American Museum of Natural History

Notes[edit]

- ↑ This is one of the reasons why mine drainage in pyrite-rich areas is a problem, as the eroded iron ions will give creeks an orange color while the eroded sulfur will cause them to smell like rotten eggs.

References[edit]

- ↑ Origin of Life and Energy by Ronald F. Fox (2004) In: Encyclopedia of Energy, edited by Cutler J. Cleveland. ISBN 012176480X.

- ↑ Condie, Kent C. (2015). Earth as an evolving planetary system (3 ed.). Academic Press. ISBN 9780128036891.

- ↑ Trendall, A.F.; Blockley, J.G. (2004). "Precambrian iron-formation". In Eriksson, P.G.; Altermann, W.; Nelson, D.R.; Mueller, W.U.; Catuneanu, O. (eds.). Evolution of the Hydrosphere and Atmosphere. Developments in Precambrian Geology. Developments in Precambrian Geology. 12. pp. 359–511. doi:10.1016/S0166-2635(04)80007-0. ISBN 9780444515063

- ↑ Li, Zhi-Quan; Zhang, Lian-Chang; Xue, Chun-Ji; Zheng, Meng-Tian; Zhu, Ming-Tian; Robbins, Leslie J.; Slack, John F.; Planavsky, Noah J.; Konhauser, Kurt O. (2 July 2018). "Earth's youngest banded iron formation implies ferruginous conditions in the Early Cambrian ocean". Scientific Reports. 8 (1): 9970. Bibcode:2018NatSR...8.9970L. doi:10.1038/s41598-018-28187-2. PMC 6028650. PMID 29967405.

- ↑ Czaja, Andrew D.; Johnson, Clark M.; Beard, Brian L.; Roden, Eric E.; Li, Weiqiang; Moorbath, Stephen (February 2013). "Biological Fe oxidation controlled deposition of banded iron formation in the ca. 3770Ma Isua Supracrustal Belt (West Greenland)". Earth and Planetary Science Letters. 363: 192–203. Bibcode:2013E&PSL.363..192C. doi:10.1016/j.epsl.2012.12.025.

- ↑ Alexander, D.R. (21 November 1977). "Geological and electromagnetic (VLP) surveys on part of Strathy-Cassels Group". Timmins, Ontario: Hollinger Mines Limited: 3, 4, 9. AFRI 31M04SW0091

- ↑ Ontario banded iron formation". American Museum of Natural History. Retrieved 17 June 2020.

- ↑ Larson, Bruce (2003-01-01). "Firearms". An Interpretation of Firearms in the Archaeological Record in Virginia 1607-1625. Dissertations, Theses, and Masters Projects. 1. pp. 413–418.

- ↑ http://www.physics.rutgers.edu/analyze/wiki/cc_supernovae.html

- ↑ http://www.sci-news.com/astronomy/betelgeuse-size-distance-08957.html

- ↑ J. Aigueperse, P. Mollard, D. Devilliers, M. Chemla, R. Faron, R. Romano, J. P. Cuer, "Fluorine Compounds, Inorganic" in Ullmann's Encyclopedia of Industrial Chemistry, Wiley-VCH, Weinheim, 2005.doi:10.1002/14356007.a11_307

- ↑ https://www.fs.usda.gov/visit/know-before-you-go/lightning

- ↑ Barack Obama wrong about size of U.S. steel production, work force, Louis Jacobson, Politifact 5 July 2016

- ↑ The world's largest crude steel producers in 2020, by production volume, Statistica, 7 June 2021

- ↑ 46 workers killed on the shipbreaking yards of South Asia this year, NGO Shipbreaking Platform 14 December 2020

- ↑ "Geritol's Bitter Pill", Time magazine, February 5, 1973

- ↑ The J. B. WILLIAMS COMPANY, Inc., and Parkson Advertising Agency, Inc., Petitioner, v. FEDERAL TRADE COMMISSION, United States Court of Appeals Sixth Circuit, August 11, 1967

- ↑ "HEMOCHROMATOSIS: A COMMON (YET PREVENTABLE) CHRONIC DISEASE", CD Summary, Vol. 46, No. 16. August 5, 1997.

- ↑ Dietary Supplement Fact Sheet: Iron, Office of Dietary Supplements • National Institutes of Health. August 24, 2007. Retrieved May 26, 2009

- ↑ TF Emery (1991) Iron and Your Health: Facts and Fallacies, CRC. ISBN 0-8493-6763-8

- ↑ RB Lauffer (1992) Iron and Human Disease, CRC. ISBN 0-8493-6779-4

- ↑ Xin Zhang & Mengquin Li (2017-06-19). "Potential resolution to the doping puzzle in iron pyrite: Carrier type determination by Hall effect and thermopower". Physical Review Materials. 1 (1): 015402. Bibcode:2017PhRvM...1a5402Z. doi:10.1103/PhysRevMaterials.1.015402.

- ↑ Ellmer, K. & Tributsch, H. (2000-03-11). "Iron Disulfide (Pyrite) as Photovoltaic Material: Problems and Opportunities". Proceedings of the 12th Workshop on Quantum Solar Energy Conversion – (QUANTSOL 2000). Archived from the original on 2010-01-15.

- ↑ Xin Zhang & Mengquin Li (2017-06-19). "Potential resolution to the doping puzzle in iron pyrite: Carrier type determination by Hall effect and thermopower". Physical Review Materials. 1 (1): 015402. Bibcode:2017PhRvM...1a5402Z. doi:10.1103/PhysRevMaterials.1.015402.

- ↑ Wadia, Cyrus; Alivisatos, A. Paul; Kammen, Daniel M. (2009). "Materials availability expands the opportunity for large-scale photovoltaics deployment". Environmental Science & Technology. 43 (6): 2072–7. Bibcode:2009EnST...43.2072W. doi:10.1021/es8019534. PMID 19368216. S2CID 36725835.

- ↑ The Principles Underlying Radio Communication. U.S. Army Signal Corps. Radio Pamphlet. 40. 1918. section 179, pp 302–305 – via Google Books.

- ↑ Thomas H. Lee (2004). The Design of Radio Frequency Integrated Circuits (2nd ed.). Cambridge, UK: Cambridge University Press. pp. 4–6. ISBN 9780521835398 – via Google Books.

KSF

KSF