Chittaranjan Locomotive Works

From Wikipedia - Reading time: 12 min

From Wikipedia - Reading time: 12 min

This article needs additional citations for verification. (January 2021) |

| |

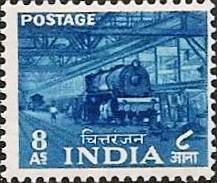

Commemorative Postal Stamp, 1955 | |

| Formerly | Loco Building Works |

|---|---|

| Company type | Electric locomotive production unit |

| Industry | Electric locomotive |

| Founded | 26 January 1950 |

| Headquarters | Chittaranjan, Asansol, West Bengal, India |

| Products | WAP-5 WAP-7 WAG-9 |

| Owner | Indian Railways |

| Website | clw |

Chittaranjan Locomotive Works (CLW) is an electric locomotive manufacturer based in India. The works are located at Chittaranjan in the Asansol Sadar subdivision of West Bengal, with an ancillary unit in Dankuni. The main unit is 32 km from Asansol’s City Bus Terminus and 237 km from Kolkata. CLW has stores and offices in Kolkata, as well as inspection cells in New Delhi, Mumbai, Kolkata, and Bangalore. It is the largest locomotive manufacturer unit in the world.[1] In FY 2024–25, it produced 700 locomotives surpassing the United States and Europe.[2]

History

[edit]Chittaranjan Locomotive Works (CLW) has been named after the great freedom fighter, leader and statesmen Deshbandhu Chittaranjan Das. A new survey led to the present site at Chittaranjan being established, which was approved by the railway board in 1947.[3] A survey of the proposed area began on 9 January 1948; the rocky soil was an advantage in erecting structural foundations, and the undulating terrain solved the problem of drainage for the township. The Damodar Valley Corporation envisioned hydro-electric and thermal power stations in the area, assuring adequate power availability for the project.[4]

The project was launched as Loco Building Works in 1950 to produce 120 average-sized steam locomotives. It also had the capacity to manufacture 50 spare boilers. Production of steam locomotives commenced on 26 January 1950. The first President of India, Rajendra Prasad, dedicated the first steam locomotive to the nation on 1 November 1950, and on the same day, the Loco Building Works was renamed as Chittaranjan Locomotive Works after Deshbandhu Chittaranjan Das. The nearby Mihijam Station was also renamed as Chittaranjan.

Steel Foundry at Chittaranjan

[edit]The technical collaborators in the U.K. for setting up of a Steel Foundry at Chittaranjan to produce steel castings for railway track. The final Draft agreement has been drawn up and sent to Messrs. F. H. Lloyd & Co.. U.K., for acceptance. The production is expected to commence after the completion of construction and installation work which is estimated to take a period of about three years from the date of the signing of the Agreement. The estimated cost of this foundry is Rs. 2.8 crores, approximately.

The terms of the agreement are that we shall pay a sum of £1 lakh to the company with which we are collaborating, they will be responsible for supplying all the designs, supervision, advice in procurement of machinery etc.; if it is purchased in England, they will be responsible for the inspection of the machinery; also generally, they are to help us in putting up the foundry and also to train up the necessary personnel. In the first instance, the installed capacity is going to be 6,000 tons for steel castings for locomotives, and about 1,000 tons for track, from for points and crossings, from austenitic steel castings, which are made of a very hard type of steel. It will be mainly producing heavy and medium size castings im our steam locomotives.[5]

In 1962–63, a steel foundry was set up to manufacture cast steel locomotive parts. Production of diesel-hydraulic locomotives began in 1968. After manufacturing 2351 steam locomotives of 5 types and 842 diesel-hydraulic locomotives of 7 types, production of both of these classes was discontinued from 1950 to 1972 and 1968 to 1993, respectively.[4][6] [why?] Electric locomotive production commenced in 1961. The first Prime Minister of India, Pandit Jawaharlal Nehru, commissioned the first 1500 V DC Locomotive named Lokmanya on 14 October 1961. The production of 25 kV AC DC locomotives commenced on 16 November 1963, with the WAG-1 series, a broad-gauge 25 kV A.C. freight locomotive with 2840 hp and a maximum speed of 80 km/h. The first WAG-1 locomotive was named Bidhan.

CLW gradually began upgrading their locomotives to produce 6000 hp and achieve 160 km/h, and also started building the 25 kV AC/1500 V DC, AC/DC WCAM-1 series for hauling mail/express trains on the Western Railway. Additionally, production of DC traction motors and control equipment commenced in April 1967. CLW became the first manufacturer in India (as well as the second in Asia and fifth in the world) to manufacture a 3-phase GTO Thyristor-controlled electric locomotive[clarification needed]. The first WAG-9 series locomotive—the first indigenous 6000 hp freight electric locomotive—was rolled out on 14 November 1988, and christened Navyug.10 May 2000 Navodit, the first passenger version of the WAP-5 series with a service speed of 160 km/h and the potential to reach 200 km/h, was manufactured; the project's highest-priority items are the development of material sourcing, indigenization, and cost reduction.

CLW has in-house facilities for machining and assembly of wheelsets, fabrication, bogies, etc.[citation needed] The facilities include modern CNC machines, plasma cutting machines, and inert gas welding sets. The factory obtains its iron and steel from Steel Authority of India, RINL[clarification needed] and MDN,[clarification needed] and sometimes from private steel plants like TATA, Jamshespur, and Jindal Steel. Hydroelectric power comes from Power Grid Corporation of India and the Damodar Valley Corporation's Maithon dam.

CLW's environment conservation efforts have been recognized by the World Environment Foundation, and was awarded the Golden Peacock Award for Environment Management 2006.[citation needed] CLW has fully complied with the provisions of the Industrial Safety Act, 1948 and was awarded the Safety Innovation Award in 2006 and 2009 by India's Institute of Engineers.[citation needed]

See also

[edit]- Banaras Locomotive Works, Varanasi

- Patiala Locomotive Works, Patiala

- Diesel Locomotive Factory, Marhowrah

- Electric Locomotive Factory, Madhepura

- Integral Coach Factory, Chennai

- Modern Coach Factory, Raebareli

- Rail Coach Factory, Kapurthala

- Rail Wheel Factory, Yelahanka

- Rail Wheel Plant, Bela

- Titagarh Wagons, Titagarh

- List of locomotive builders by countries

References

[edit]- ^ "Chittaranjan Locomotive Works is now world's biggest locomotive producer". The Statesman. 2 April 2019. Retrieved 12 September 2019.

- ^ "New Milestone in Locomotive Production: India Surpasses the US and Europe by Producing 1,681 Locomotives for the Financial Year 2024-25". New Delhi. 2 April 2025. Retrieved 8 April 2025.

- ^ "About Chittaranjan Locomotive Works". Chittaranjan Locomotive Works.

- ^ a b "Estimates Committee Report" (PDF). eparlib.nic.in. 1955. Retrieved 17 December 2020.

- ^ https://eparlib.nic.in/bitstream/123456789/1916/1/lsd_02_08_10-09-1959.pdf page 9

- ^ "Estimates Committee Report" (PDF). eparlib.nic.in. 1955. Retrieved 17 December 2020.

External links

[edit]- Chittaranjan Locomotive Works (CLW) Company website

KSF

KSF