Container ship

From Wikipedia - Reading time: 33 min

From Wikipedia - Reading time: 33 min

This article may require cleanup to meet Wikipedia's quality standards. The specific problem is: The "Sources" section needs to match existing short citations under "References", or be moved to a "Further reading" section. See discussion. (June 2024) |

Two Maersk Line container ships

| |

| Class overview | |

|---|---|

| Name | Container ship |

| Subclasses |

|

| Built | 1956–present |

| In service | 9,535 ships as of 2010[1] |

| General characteristics | |

| Propulsion | Typically diesel since 1990[2] |

| Speed | Typically 16–25 knots (30–46 km/h) (19-29 mph)[2] |

| Capacity | Up to 24,000 TEU |

| Notes | Reduced superstructure, containers stacked on deck, bulbous bow |

A container ship (also called boxship or spelled containership) is a cargo ship that carries all of its load in truck-size intermodal containers, in a technique called containerization. Container ships are a common means of commercial intermodal freight transport and now carry most seagoing non-bulk cargo.

Container ship capacity is measured in twenty-foot equivalent units (TEU). Typical loads are a mix of 20-foot (1-TEU) and 40-foot (2-TEU) ISO-standard containers, with the latter predominant.

Today, about 90% of non-bulk cargo worldwide is transported by container ships, the largest of which, from 2023 onward, can carry over 24,000 TEU.

History

[edit]

There are two main types of dry cargo: bulk cargo and break bulk cargo. Bulk cargoes, like grain or coal, are transported unpackaged in the hull of the ship, generally in large volume.[3] Break-bulk cargoes, in contrast, are transported in packages, and are generally manufactured goods.[4]

Before the advent of containerization in the 1950s, break-bulk items required manual loading, lashing, unlashing and unloading from the ship one piece at a time. This stevedoring process became more efficient by grouping cargo into containers, 1,000 to 3,000 cubic feet (28 to 85 m3) of cargo, or up to about 64,000 pounds (29,000 kg), is moved at once and each container is secured to the ship once in a standardized way.[5] Containerization has increased the efficiency of moving traditional break-bulk cargoes significantly, reducing shipping time by 84% and costs by 35%.[6] In 2001, more than 90% of world trade in non-bulk goods was transported in ISO containers.[7] In 2009, almost one quarter of the world's dry cargo was shipped by container, an estimated 125 million TEU or 1.19 billion tonnes worth of cargo.[8]

The first ships designed to carry standardized load units were used in the late 18th century in England. In 1766 James Brindley designed the box boat "Starvationer" with 10 wooden containers, to transport coal from Worsley Delph to Manchester via the Bridgewater Canal.[9] Before the Second World War, the first container ships were used to carry the baggage of the luxury passenger train from London to Paris (Southern Railway's Golden Arrow / La Flèche d'Or). These containers were loaded in London or Paris, and carried to ports of Dover or Calais on flat cars.[10] In February 1931, the first container ship in the world was launched; the Autocarrier, owned by the Southern Railway. It had 21 slots for containers of Southern Railway.[9][11]

The earliest container ships after the Second World War were converted oil tankers, built up from surplus T2 tankers after World War II. In 1951, the first purpose-built container vessels began operating in Denmark, and between Seattle and Alaska. The first commercially successful container ship was Ideal X,[12] a T2 tanker, owned by Malcom McLean, which carried 58 metal containers between Newark, New Jersey and Houston, Texas, on its first voyage.[13] In 1955, McLean built his company, McLean Trucking into one of the United States' biggest freighter fleets. In 1955, he purchased the small Pan Atlantic Steamship Company from Waterman Steamship and adapted its ships to carry cargo in large uniform metal containers.[14] On April 26, 1956, the first of these rebuilt container vessels, Ideal X, left the Port Newark in New Jersey and a new revolution in modern shipping resulted.[15][16]

In the 1950s, a new standardized steel Intermodal container based on specifications from the United States Department of Defense began to revolutionize freight transportation.

The White Pass & Yukon Route railway acquired the world's first purpose built container ship, the Clifford J. Rogers, built in 1955, and introduced containers to its railway in 1956.[17]

MV Kooringa was the world's first fully cellular, purpose-built container ship.[18] and was built by Australian company Associated Steamships, a partnership formed by the 1964 merger of the Adelaide Steamship Company with McIlwraith, McEacharn & Co, then commissioned in May 1964.[19]

Container ships were designed to accommodate intermodal transport of goods,[20] and eliminated requirements for the individual hatches, holds and other dividers of traditional cargo ships. The hull of a typical container ship is similar to an airport hangar, or a huge warehouse, which is divided into individual holding cells, using vertical guide rails. The ship's cells are designed to hold cargo containers, which are typically constructed of steel, though sometimes of aluminum, fiberglass or plywood, and designed for intermodal transfers between ship and train, truck or semi-trailer. Shipping containers are categorized by type, size and function.[21]

Today, about 90% of non-bulk cargo worldwide is transported by container by about 50,000 container ships.[22] Modern container ships can carry over 24,000 TEU. The largest container ships measure about 400 metres (1,300 ft) in length, and carry loads equal to the cargo-carrying capacity of sixteen to seventeen pre-World War II freighter ships.[23]

Architecture

[edit]There are several key points in the design of modern container ships. The hull, similar to that of bulk carriers and general cargo ships, is built around a strong keel.[24] Into this frame is set one or more below-deck cargo holds, numerous tanks, and the engine room. The holds are topped by hatch covers, onto which more containers can be stacked. Many container ships have cargo cranes installed on them, and some have specialized systems for securing containers on board.

The hull of a modern cargo ship is a complex arrangement of steel plates and strengthening beams. Resembling ribs, and fastened at right angles to the keel, are the ship's frames.[24] The ship's main deck, the metal platework that covers the top of the hull framework, is supported by beams that are attached to the tops of the frames and run the full breadth of the ship.[24] The beams not only support the deck, but along with the deck, frames, and transverse bulkheads, strengthen and reinforce the shell.[24] Another feature of recent hulls is a set of double-bottom tanks, which provide a second watertight shell that runs most of the length of a ship.[25] The double-bottoms generally hold liquids such as fuel oil, ballast water or fresh water.[25]

A ship's engine room houses its main engines and auxiliary machinery such as the fresh water and sewage systems, electrical generators, fire pumps, and air conditioners.[25] In most new ships, the engine room is located in the aft portion.[25]

Size categories

[edit]

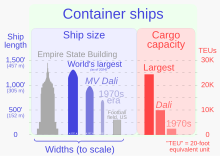

Container ships are distinguished into 7 major size categories: small feeder, feeder, feedermax, Panamax, Post-Panamax, Neopanamax and ultra-large.[27] As of December 2012, there were 161 container ships in the VLCS class (Very Large Container Ships, more than 10,000 TEU), and 51 ports in the world can accommodate them.[28]

The size of a Panamax vessel is limited by the original Panama canal's lock chambers, which can accommodate ships with a beam of up to 32.31 m, a length overall of up to 294.13 m, and a draft of up to 12.04 m.[29] The Post-Panamax category has historically been used to describe ships with a moulded breadth over 32.31 m,[30] however the Panama Canal expansion project has caused some changes in terminology. The Neopanamax category is based on the maximum vessel size that is able to transit a new third set of locks, which opened in June 2016.[31][32] The third set of locks were built to accommodate a container ship with a length overall of 366 metres (1,201 ft), a maximum beam (width) of 49 metres (161 ft), and tropical fresh-water draft of 15.2 metres (50 ft).[32][33] Such a vessel, called Neopanamax class, is wide enough to carry 19 columns of containers, can have a total capacity of approximately 12,000 TEU and is comparable in size to a capesize bulk carrier or a Suezmax tanker.[33]

Container ships under 3,000 TEU are generally called feeder ships or feeders. They are small ships that typically operate between smaller container ports. Some feeders collect their cargo from small ports, drop it off at large ports for transshipment on larger ships, and distribute containers from the large port to smaller regional ports.[2] This size of vessel is the most likely to carry cargo cranes on board.[34]

| Name | Capacity (TEU)[27] |

Length | Beam | Draft | Example | |

|---|---|---|---|---|---|---|

| Ultra Large Container Vessel (ULCV) | 14,501 and higher | 1,200 ft (366 m) and longer | 160.7 ft (49 m) and wider | 49.9 ft (15.2 m) and deeper | With a length of 400 m, a beam of 59 m, draft of 14.5 m, and a capacity of 18,270 TEU, ships of the Maersk Triple E class are able to transit the Suez canal.[35] Photo: MV Mærsk Mc-Kinney Møller |

|

| New Panamax (or Neopanamax) | 10,000–14,500 | 1,200 ft (366 m) | 160.7 ft (49 m) | 49.9 ft (15.2 m) | With a beam of 43 m, ships of the COSCO Guangzhou class are much too big to fit through the Panama Canal's old locks, but could easily fit through the new expansion. Photo: The 9,500 TEU MV COSCO Guangzhou pierside in Hamburg |

|

| Post-Panamax | 5,101–10,000 | |||||

| Panamax | 3,001–5,100 | 965 ft (294.13 m) |

106 ft (32.31 m) | 39.5 ft (12.04 m) | Ships of the Bay class are at the upper limit of the Panamax class, with an overall length of 292.15 m, beam of 32.2m, and maximum depth of 13.3 m.[36] Photo: The 4,224 TEU MV Providence Bay passing through the Panama Canal |

|

| Feedermax | 2,001–3,000 | Container ships under 3,000 TEU are typically called feeders. In some areas of the world, they might be outfitted with cargo cranes. Photo: The 384 TEU MV TransAtlantic at anchor[37] |

| |||

| Feeder | 1,001–2,000 | |||||

| Small feeder | Up to 1,000 | |||||

Cargo cranes

[edit]

A major characteristic of a container ship is whether it has cranes installed for handling its cargo. Those that have cargo cranes are called geared and those that do not are called ungeared or gearless. The earliest purpose-built container ships in the 1970s were all gearless.[34] Since then, the percentage of geared newbuilds has fluctuated widely, but has been decreasing overall, with only 7.5% of the container ship capacity in 2009 being equipped with cranes.[34]

While geared container ships are more flexible in that they can visit ports that are not equipped with pierside container cranes, they suffer from several drawbacks.[34] To begin with, geared ships will cost more to purchase than a gearless ship.[34] Geared ships also incur greater recurring expenses, such as maintenance and fuel costs.[34] The United Nations Council on Trade and Development characterizes geared ships as a "niche market only appropriate for those ports where low cargo volumes do not justify investment in port cranes or where the public sector does not have the financial resources for such investment".[34]

Instead of the rotary cranes, some geared ships have gantry cranes installed.[38] These cranes, specialized for container work, are able to roll forward and aft on rails.[38] In addition to the additional capital expense and maintenance costs, these cranes generally load and discharge containers much more slowly than their shoreside counterparts.[38]

The introduction and improvement of shoreside container cranes have been a key to the success of the container ship.[38] The first crane that was specifically designed for container work was built in California's Port of Alameda in 1959.[38] By the 1980s, shoreside gantry cranes were capable of moving containers on a 3-minute-cycle, or up to 400 tons per hour.[38] In March 2010, at Port Klang in Malaysia, a new world record was set when 734 container moves were made in a single hour.[39] The record was achieved using 9 cranes to simultaneously load and unload MV CSCL Pusan, a ship with a capacity of 9,600 TEU.[39]

Vessels in the 1,500–2,499 TEU range are the most likely size class to have cranes, with more than 60% of this category being geared ships.[34] Slightly less than a third of the very smallest ships (from 100–499 TEU) are geared, and almost no ships with a capacity of over 4,000 TEU are geared.[34]

Cargo holds

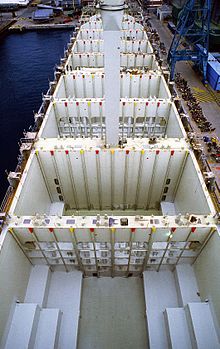

[edit]Efficiency has always been key in the design of container ships.[40] While containers may be carried on conventional break-bulk ships, cargo holds for dedicated container ships are specially constructed to speed loading and unloading, and to efficiently keep containers secure while at sea.[40] A key aspect of container ship specialization is the design of the hatches, the openings from the main deck to the cargo holds.[41] The hatch openings stretch the entire breadth of the cargo holds, and are surrounded by a raised steel structure known as the hatch coaming.[40][41] On top of the hatch coamings are the hatch covers. Until the 1950s, hatches were typically secured with wooden boards and tarpaulins held down with battens.[42] Today, some hatch covers can be solid metal plates that are lifted on and off the ship by cranes, while others are articulated mechanisms that are opened and closed using powerful hydraulic rams.

Another key component of dedicated container-ship design is the use of cell guides.[40] Cell guides are strong vertical structures constructed of metal installed into a ship's cargo holds.[40] These structures guide containers into well-defined rows during loading and provide some support for containers against the ship's rolling at sea.[40] So fundamental to container ship design are cell guides that organizations such as the United Nations Conference on Trade and Development use their presence to distinguish dedicated container ships from general break-bulk cargo ships.[30]

A system of three dimensions is used in cargo plans to describe the position of a container aboard the ship.[43] The first coordinate is the bay, which starts at the front of the ship and increases aft.[43] The second coordinate is the row.[43] Rows on the starboard side are given odd numbers and those on the port side are given even numbers.[43] The rows nearest the centerline are given low numbers, and the numbers increase for slots further from the centerline.[43] The third coordinate is the tier, with the first tier at the bottom of the cargo holds, the second tier on top of that, and so forth.[43]

Container ships typically take 20 foot and 40 foot containers. Some ships can take 45 footers above deck. A few ships (APL since 2007,[44] Carrier53 since 2022 [45]) can carry 53 foot containers. 40 foot containers are the primary container size, making up about 90% of all container shipping and since container shipping moves 90% of the world's freight, over 80% of the world's freight moves via 40 foot containers.

Lashing systems

[edit]

Numerous systems are used to secure containers aboard ships, depending on factors such as the type of ship, the type of container, and the location of the container.[46][47] Stowage inside the holds of fully cellular (FC) ships is simplest, typically using simple metal forms called container guides, locating cones, and anti-rack spacers to lock the containers together.[48] Above-decks, without the extra support of the cell guides, more complicated equipment is used.[46] Three types of systems are currently in wide use: lashing systems, locking systems, and buttress systems.[46] Lashing systems secure containers to the ship using devices made from wire rope, rigid rods, or chains and devices to tension the lashings, such as turnbuckles.[46] The effectiveness of lashings is increased by securing containers to each other, either by simple metal forms (such as stacking cones) or more complicated devices such as twist-lock stackers.[46] A typical twist-lock is inserted into the casting hole of one container and rotated to hold it in place, then another container is lowered on top of it.[49] The two containers are locked together by twisting the device's handle.[49] A typical twist-lock is constructed of forged steel and ductile iron and has a shear strength of 48 tonnes.[50]

The buttress system, used on some large container ships, uses a system of large towers attached to the ship at both ends of each cargo hold.[51] As the ship is loaded, a rigid, removable stacking frame is added, structurally securing each tier of containers together.[51]

Bridge

[edit]Container ships have typically had a single bridge and accommodation unit towards the rear, but to reconcile demand for larger container capacity with SOLAS visibility requirements, several new designs have been developed. As of 2015[update], some large container ships are being developed with the bridge further forward, separate from the exhaust stack. Some smaller container ships working in European ports and rivers have liftable wheelhouses, which can be lowered to pass under low bridges.

Fleet characteristics

[edit]

|

As of 2010[update], container ships made up 13.3% of the world's fleet in terms of deadweight tonnage.[56] The world's total of container ship deadweight tonnage has increased from 11 million DWT in 1980 to 169.0 million DWT in 2010.[57] The combined deadweight tonnage of container ships and general cargo ships, which also often carry containers, represents 21.8% of the world's fleet.[58]

As of 2009[update], the average age of container ships worldwide was 10.6 years, making them the youngest general vessel type, followed by bulk carriers at 16.6 years, oil tankers at 17 years, general cargo ships at 24.6 years, and others at 25.3 years.[59]

Most of the world's carrying capacity in fully cellular container ships is in the liner service, where ships trade on scheduled routes.[34][60] As of January 2010, the top 20 liner companies controlled 67.5% of the world's fully cellular container capacity, with 2,673 vessels of an average capacity of 3,774 TEU.[1] The remaining 6,862 fully cellular ships have an average capacity of 709 TEU each.[1]

The vast majority of the capacity of fully cellular container ships used in the liner trade is owned by German shipowners, with approximately 75% owned by Hamburg brokers.[60] It is a common practice for the large container lines to supplement their own ships with chartered-in ships, for example in 2009, 48.9% of the tonnage of the top 20 liner companies was chartered-in in this manner.[60]

Flag states

[edit]International law requires that every merchant ship be registered in a country, called its flag state.[61] A ship's flag state exercises regulatory control over the vessel and is required to inspect it regularly, certify the ship's equipment and crew, and issue safety and pollution prevention documents. As of 2006[update], the United States Bureau of Transportation Statistics count 2,837 container ships of 10,000 long tons deadweight (DWT) or greater worldwide.[62] Panama was the world's largest flag state for container ships, with 541 of the vessels in its registry.[62] Seven other flag states had more than 100 registered container ships: Liberia (415), Germany (248), Singapore (177), Cyprus (139), the Marshall Islands (118) and the United Kingdom (104).[62] The Panamanian, Liberian, and Marshallese flags are open registries and considered by the International Transport Workers' Federation to be flags of convenience.[63] By way of comparison, traditional maritime nations such as the United States and Japan only had 75 and 11 registered container ships, respectively.[62]

Vessel purchases

[edit]This section needs to be updated. (January 2018) |

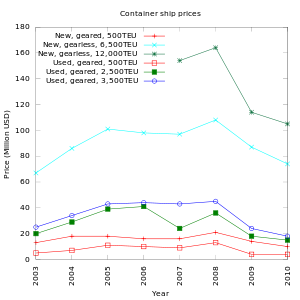

In recent years, oversupply of container ship capacity has caused prices for new and used ships to fall. From 2008 to 2009, new container ship prices dropped by 19–33%, while prices for 10-year-old container ships dropped by 47–69%.[64] In March 2010, the average price for a geared 500-TEU container ship was $10 million, while gearless ships of 6,500 and 12,000 TEU averaged prices of $74 million and $105 million respectively.[65] At the same time, secondhand prices for 10-year-old geared container ships of 500-, 2,500-, and 3,500-TEU capacity averaged prices of $4 million, $15 million, and $18 million respectively.[66]

In 2009, 11,669,000 gross tons of newly built container ships were delivered.[67] Over 85% of this new capacity was built in the Republic of Korea, China, and Japan, with Korea accounting for over 57% of the world's total alone.[67] New container ships accounted for 15% of the total new tonnage that year, behind bulk carriers at 28.9% and oil tankers at 22.6%.[67]

Scrapping

[edit]Most ships are removed from the fleet through a process known as scrapping.[68] Scrapping is rare for ships under 18 years old and common for those over 40 years in age.[69] Ship-owners and buyers negotiate scrap prices based on factors such as the ship's empty weight (called light ton displacement or LTD) and prices in the scrap metal market.[70] Scrapping rates are volatile, the price per light ton displacement has swung from a high of $650 per LTD in mid-2008 to $200 per LTD in early 2009, before building to $400 per LTD in March 2010.[71] As of 2009[update], over 96% of the world's scrapping activity takes place in China, India, Bangladesh, and Pakistan.[72]

The global economic downturn of 2008–2009 resulted in more ships than usual being sold for scrap.[71] In 2009, 364,300 TEU worth of container ship capacity was scrapped, up from 99,900 TEU in 2008.[71] Container ships accounted for 22.6% of the total gross tonnage of ships scrapped that year.[73] Despite the surge, the capacity removed from the fleet only accounted for 3% of the world's container ship capacity.[71] The average age of container ships scrapped in 2009 was 27.0 years.[73]

Largest ships

[edit]| Built | Name | Class size |

Maximum TEU | Sources |

|---|---|---|---|---|

| 2023 | MSC Irina | 6 | 24,346 | [74] |

| 2023 | OOCL Spain | 8 | 24,188 | [75] |

| 2023 | ONE Innovation | 6 | 24,136 | [76] |

| 2023 | MSC Tessa | 8 | 24,116 | [77] |

| 2021 | Ever Ace | 6 | 23,992 | [78] |

| 2020 | HMM Algeciras | 7 | 23,964 | [78] |

| 2020 | HMM Oslo | 5 | 23,792 | [79] |

| 2019 | MSC Gülsün | 6 | 23,756 | [78] |

| 2019 | MSC Mina | 10 | 23,656 | [80] |

| 2020 | CMA CGM Jacques Saadé | 9 | 23,112 | [81] |

| 2017 | OOCL Hong Kong | 6 | 21,413 | [82] |

| 2018 | COSCO Shipping Universe | 6 | 21,237 | [83] |

| 2018 | CMA CGM Antoine de Saint Exupery | 3 | 20,954 | [84] |

| 2017 | Madrid Mærsk | 11 | 20,568 | [85] |

| 2017 | MOL Truth | 2 | 20,182 | [86] |

| 2017 | MOL Triumph | 4 | 20,170 | [87] |

| 2019 | Ever Glory | 4 | 20,160 | [88] |

| 2018 | Ever Goods | 7 | 20,124 | [89] |

| 2018 | COSCO Shipping Taurus | 5 | 20,119 | [89] |

This section needs additional citations for verification. (April 2024) |

Economies of scale have dictated an upward trend in the size of container ships in order to reduce expenses. However, there are certain limitations to the size of container ships. Primarily, these are the availability of sufficiently large main engines and the availability of a sufficient number of ports and terminals prepared and equipped to handle ultra-large container ships. Furthermore, the permissible maximum ship dimensions in some of the world's main waterways could present an upper limit in terms of vessel growth. This primarily concerns the Suez Canal and the Singapore Strait.

In 2008 the South Korean shipbuilder STX announced plans to construct a container ship capable of carrying 22,000 TEU,[90] and with a proposed length of 450 m (1,480 ft) and a beam of 60 m (200 ft).[91] If constructed, the container ship would become the largest seagoing vessel in the world.[92]

Since even very large container ships are vessels with relatively low draft compared to large tankers and bulk carriers, there is still considerable room for vessel growth. Compared to today's largest container ships, Maersk Line's 15,200 TEU Emma Mærsk-type series, a 20,000 TEU container ship would only be moderately larger in terms of exterior dimensions. According to a 2011 estimate, an ultra-large container ship of 20,250 TEU would measure 440 m × 59 m (1,444 ft × 194 ft), compared to 397.71 m × 56.40 m (1,304.8 ft × 185.0 ft) for the Emma Mærsk class.[93][94] It would have an estimated deadweight of circa 220,000 tons. While such a vessel might be near the upper limit for a Suez Canal passage, the so-called Malaccamax concept (for Straits of Malacca) does not apply for container ships, since the Malacca and Singapore Straits' draft limit of about 21 metres (69 ft) is still above that of any conceivable container ship design. In 2011, Maersk announced plans to build a new "Triple E" family of container ships with a capacity of 18,000 TEU, with an emphasis on lower fuel consumption.[95]

In the present market situation, main engines will not be as much of a limiting factor for vessel growth either. The steadily rising expense of fuel oil in the early 2010s had prompted most container lines to adapt a slower, more economical voyage speed of about 21 knots, compared to earlier top speeds of 25 or more knots. Subsequently, newly built container ships can be fitted with a smaller main engine. Engine types fitted to today's ships of 14,000 TEU are thus sufficiently large to propel future vessels of 20,000 TEU or more. Maersk Line, the world's largest container shipping line, nevertheless opted for twin engines (two smaller engines working two separate propellers), when ordering a series of ten 18,000 TEU vessels from Daewoo Shipbuilding in February 2011.[96] The ships were delivered between 2013 and 2014. In 2016, some experts believed that the current largest container ships are at the optimum size, and could not economically be larger, as port facilities would be too expensive, port handling too time consuming, the number of suitable ports too low, and insurance cost too high.[97][98]

In March 2017 the first ship with an official capacity over 20,000 TEUs was christened at Samsung Heavy Industries. MOL Triumph has a capacity of 20,150 TEUs. Samsung Heavy Industries was expected to deliver several ships of over 20,000 TEUs in 2017, and has orders for at least ten vessels in that size range for OOCL and MOL.[87]

The world's largest container ship, MSC Irina, was delivered March 9, 2023 by builder Yangzi Xinfu Shipbuilding to the Mediterranean Shipping Company (MSC), with a capacity of 24,346 TEUs. Measuring 399.99 metres in length and 61.3 metres in beam, the ship is one of four ordered from the builder in 2020,[99] and exceeded MSC's 24,116 TEU MSC Tessa, which had been delivered that same day by the China State Shipbuilding Corporation (CSSC).[77] In April, MSC Irina sister ship MSC Loreto, with an equal capacity of 24,346 TEU was received by MSC.[100]

On June 2, 2023 Ocean Network Express took delivery of the ONE Innovation with a capacity of 24,136 TEUs. ONE Innovation is one of six new Megamax vessels ordered by Ocean Network Express in December 2020 to be built by a consortium of Imabari Shipbuilding and Japan Marine United.[76]

Freight market

[edit]The act of hiring a ship to carry cargo is called chartering. Outside special bulk cargo markets, ships are hired by three types of charter agreements: the voyage charter, the time charter, and the bareboat charter.[101] In a voyage charter, the charterer rents the vessel from the loading port to the discharge port.[102] In a time charter, the vessel is hired for a set period of time, to perform voyages as the charterer directs.[102] In a bareboat charter, the charterer acts as the ship's operator and manager, taking on responsibilities such as providing the crew and maintaining the vessel.[103] The completed chartering contract is known as a charter party.[104]

The United Nations Conference on Trade and Development [UNCTAD], tracks in its 2010 Review of Maritime Trade two aspects of container shipping prices:[105] The first one is a chartering price, specifically the price to time-charter a 1 TEU slot for 14 tonnes of cargo on a container ship.[60] The other is the freight rate; or comprehensive daily cost to deliver one-TEU worth of cargo on a given route.[60][106] As a result of the late-2000s recession, both indicators showed sharp drops during 2008–2009, and have shown signs of stabilization since 2010.

UNCTAD uses the Hamburg Shipbrokers' Association (formally the Vereinigung Hamburger Schiffsmakler und Schiffsagenten e. V. or VHSS for short) as its main industry source for container ship freight prices.[60] The VHSS maintains a few indices of container ship charter prices. The oldest, which dates back to 1998, is called the Hamburg Index.[60] This index considers time-charters on fully cellular container ships controlled by Hamburg brokers.[60] It is limited to charters of 3 months or more, and presented as the average daily cost in U.S. dollars for a one-TEU slot with a weight of 14 tonnes.[60] The Hamburg Index data is divided into ten categories based primarily on vessel carrying capacity.[60] Two additional categories exist for small vessels of under 500 TEU that carry their own cargo cranes.[60] In 2007, VHSS started another index, the New ConTex which tracks similar data obtained from an international group of shipbrokers.[60]

The Hamburg Index shows some clear trends in recent chartering markets. First, rates were generally increasing from 2000 to 2005. From 2005 to 2008, rates slowly decreased, and in mid-2008 began a "dramatic decline" of approximately 75%, which lasted until rates stabilized in April 2009.[60] Rates have ranged from $2.70 to $35.40 in this period, with prices generally lower on larger ships. The most resilient sized vessel in this time period were those from 200 to 300 TEU, a fact that the United Nations Council on Trade and Development attributes to lack of competition in this sector.[60] Overall, in 2010, these rates rebounded somewhat, but remained at approximately half of their 2008 values.[60] As of 2011, the index shows signs of recovery for container shipping, and combined with increases in global capacity, indicates a positive outlook for the sector in the near future.[60]

| From | To | 2008 | 2009 | ||||||

|---|---|---|---|---|---|---|---|---|---|

| Q1 | Q2 | Q3 | Q4 | Q1 | Q2 | Q3 | Q4 | ||

| Asia | U.S. | 1.8 | 1.8 | 1.9 | 1.9 | 1.7 | 1.4 | 1.2 | 1.3 |

| U.S. | Asia | 0.8 | 1.0 | 1.2 | 1.2 | 0.9 | 0.8 | 0.8 | 0.9 |

| Europe | Asia | 1.0 | 1.1 | 1.1 | 1.1 | 0.9 | 0.7 | 0.8 | 0.9 |

| Asia | Europe | 2.0 | 1.9 | 1.8 | 1.6 | 1.0 | 0.9 | 1.0 | 1.4 |

| U.S. | Europe | 1.3 | 1.4 | 1.6 | 1.7 | 1.5 | 1.4 | 1.4 | 1.5 |

| Europe | U.S. | 1.6 | 1.6 | 1.6 | 1.6 | 1.3 | 1.2 | 1.1 | 1.3 |

UNCTAD also tracks container freight rates. Freight rates are expressed as the total price in U.S. dollars for a shipper to transport one TEU worth of cargo along a given route.[60] Data is given for the three main container liner routes: U.S.-Asia, U.S.-Europe, and Europe-Asia.[60] Prices are typically different between the two legs of a voyage, for example the Asia-U.S. rates have been significantly higher than the return U.S.-Asia rates in recent years.[60] Generally, from the fourth quarter of 2008 through the third quarter of 2009, both the volume of container cargo and freight rates have dropped sharply.[60] In 2009, the freight rates on the U.S.–Europe route were sturdiest, while the Asia-U.S. route fell the most.[60]

| $ per TEU from Shanghai to | 2009 | 2010 | 2011 | 2012 | 2013 | 2014 |

|---|---|---|---|---|---|---|

| United States West Coast | 1372 | 2308 | 1667 | 2287 | 2033 | 1970 |

| United States East Coast | 2367 | 3499 | 3008 | 3416 | 3290 | 3720 |

| Northern Europe | 1395 | 1789 | 881 | 1353 | 1084 | 1161 |

| Mediterranean | 1397 | 1739 | 973 | 1336 | 1151 | 1253 |

| South America (Santos) | 2429 | 2236 | 1483 | 1771 | 1380 | 1103 |

| South Africa (Durban) | 1495 | 1481 | 991 | 1047 | 805 | 760 |

| Singapore | 318 | 210 | 256 | 231 | 233 | |

| East Japan | 316 | 337 | 345 | 346 | 273 |

Liner companies responded to their overcapacity in several ways. For example, in early 2009, some container lines dropped their freight rates to zero on the Asia-Europe route, charging shippers only a surcharge to cover operating costs.[60] They decreased their overcapacity by lowering the ships' speed (a strategy called "slow steaming") and by laying up ships.[60] Slow steaming increased the length of the Europe-Asia routes to a record high of over 40 days.[60] Another strategy used by some companies was to manipulate the market by publishing notices of rate increases in the press, and when "a notice had been issued by one carrier, other carriers followed suit".[109]

The Trans-Siberian Railroad (TSR) has recently become a more viable alternative to container ships on the Asia-Europe route.[109] This railroad can typically deliver containers in 1/3 to 1/2 of the time of a sea voyage, and in late 2009 announced a 20% reduction in its container shipping rates.[109] With its 2009 rate schedule, the TSR will transport a forty-foot container to Poland from Yokohama for $2,820, or from Pusan for $2,154.[109]

Shipping industry alliances

[edit]| Alliance | Partners | Ships | Weekly services | Ports | Port pairs |

|---|---|---|---|---|---|

| Ocean Alliance | CMA CGM, COSCO Shipping Lines, Evergreen | 323 | 40 | 95 | 1,571 |

| THE Alliance | Hapag-Lloyd, HMM Co Ltd., Ocean Network Express, Yang Ming | 241 | 32 | 78 | 1,327 |

| 2M Alliance | Maersk Line, Mediterranean Shipping Company | 223 | 25 | 76 | 1,152 |

In an effort to control costs and maximize capacity utilization on ever-larger ships, vessel sharing agreements, co-operative agreements, and slot-exchanges have become a growing feature of the maritime container shipping industry. As of March 2015, 16 of the world's largest container shipping lines had consolidated their routes and services accounting for 95 percent of container cargo volumes moving in the dominant east-west trade routes.[111] Carriers remain operationally independent, as they are forbidden by antitrust regulators in multiple jurisdictions from colluding on freight rates or capacity. Similarities can be drawn [according to whom?] with airline alliances.

In July 2016 the European Commission reported that it had raised concerns with 14 container shipping carriers regarding their practice of announcing General Rate Increases (GRIs) in a coordinated manner, which potentially conflicted with the EU and EEA rules on concerted practices which could distort competition (Article 101 of the Treaty on the Functioning of the European Union). The shipping companies announced a series of commitments aiming to address the Commission's concerns, which for its part the Commission accepted as "legally binding" for the period from 2016 to 2019.[112] General Rate Increases continue to be published in the industry either annually or sixth-monthly.[113]

Container ports

[edit]

Container traffic through a port is often tracked in terms of twenty foot equivalent units or TEU of throughput.[114] As of 2019[update], the Port of Shanghai was the world's busiest container port, with 43,303,000 TEU handled.[115]

That year, seven of the busiest ten container ports were in the People's Republic of China, with Shanghai in 1st place, Ningbo 3rd, Shenzhen 4th, Guangzhou 5th, Qingdao 7th, Hong Kong 8th and Tianjin 9th.[115]

Rounding out the top ten ports were Singapore at 2nd, Busan in South Korea at 6th and Rotterdam in the Netherlands in the 10th position.[115]

In total, the busiest twenty container ports handled 220,905,805 TEU in 2009, almost half of the world's total estimated container traffic that year of 465,597,537 TEU.[114]

Losses and safety problems

[edit]It has been estimated that container ships lose between 2,000[116] and 10,000 containers at sea each year,[117] costing $370 million.[118] A survey for the six years 2008 through 2013 estimates average losses of individual containers overboard at 546 per year, and average total losses including catastrophic events such as vessel sinkings or groundings at 1,679 per year[119] More recently, a survey conducted by the WSC from 2008–2019, saw an average of 1,382 shipping containers lost at sea. However, in the 3-year period from 2017–2019, that number was nearly halved, down to an average of 779 containers lost annually. Most go overboard on the open sea during storms but there are some examples of whole ships being lost with their cargo.[120] One major shipping accident occurred in 2013 when the MOL Comfort sank with 4,293 containers onboard in the Indian Ocean.[121] When containers are dropped, they immediately become an environmental threat – termed "marine debris".[122] Once in the ocean, they fill with water and sink if the contents cannot hold air. Rough waters smash the container, sinking it quickly.[116]

As container ships get larger and stacking becomes higher, the threat of containers toppling into the sea during a storm increases. This results from a phenomenon called "parametric rolling," by which a ship can roll 30-40 degrees during rough seas creating a powerful torque on a 10-high stack of containers which can easily snap lashings and locks of the stack, resulting in losses into the sea.[123]

See also

[edit]- BBC Box

- Container on barge

- Environmental impact of shipping

- List of largest container ships

- List of world's longest ships

- Ship resistance and propulsion

References

[edit]- ^ a b c UNCTAD, 2010, p. 33.

- ^ a b c McNicholas, p. 45.

- ^ Joint Chief of Staff (2005-08-31). "Bulk cargo" (PDF). Department of Defense Dictionary of Military and Associated Terms. Washington: Department of Defense. p. 73. Archived from the original (PDF) on June 4, 2011. Retrieved 2011-02-22.

- ^ From the American Heritage dictionary definition available on-line at Houghton Mifflin Company (2003). "Break bulk". The American Heritage Dictionary of the English Language, Fourth Edition. Huntingdon Valley, PA: Farlex Inc. Retrieved 2011-02-22..

- ^ Meurn, 2004, pp. 1–7.

- ^ Bohlman, 2001, p. 13.

- ^ Bohlman, 2001, p. 15.

- ^ UNCTAD, 2010, p. 84.

- ^ a b Lewandowski, Krzysztof (2016). "The containers ships, which really was the first?". Transport Means 2016, Proceedings of the 20th International Scientific Conference, October 5–7, 2016, Juodkrante, Lithuania.: 668–676. ISSN 1822-296X.

- ^ Lewandowski, Krzysztof (2014). "Czechoslovak activity to prepare European norms for containers before the Second World War" (PDF). Acta Logistica. 1 (4): 1–7. doi:10.22306/al.v1i4.25. ISSN 1339-5629.

- ^ | url= http://www.faktaomfartyg.se/autocarrier_1931_b_1.htm

- ^ Levinson, 2006, p. 1.

- ^ Meurn, 2004, pp. 1–3.

- ^ Cudahy, 2004, p. 19.

- ^ Cudahy, 2004, p. 29.

- ^ "History - Port of New York and New Jersey - Port Authority of New York & New Jersey".

- ^ "Intermodal freight transport", Wikipedia, 2024-06-04, retrieved 2024-06-19

- ^ "First purpose-built cellular container ship". Guiness World Records. Retrieved 19 April 2024.

- ^ "Adelaide Steamship Co". TheShipsList.com. The Ships List. Retrieved 19 April 2024.

- ^ "Understanding Design Of Container Ships". Marine Insight. 2019-07-22. Retrieved 19 April 2024.

- ^ ""Cargo Packaging and unitization"" (PDF). ASEAN.org. Association of Southeast Asian Nations (ASEAN). 2014. p. 9. Retrieved 19 April 2024.

- ^ "Shipping Contributes Heavily to Climate Change. Are Green Ships the Solution?". New York Times. 2023-10-30. Retrieved 19 April 2024.

- ^ Olsen, Alexander Arnfinn (2023). Merchant Ship Types (1st ed.). New York, NY: Routledge. p. Table 2.1. ISBN 978-1-032-37876-3. Retrieved 19 April 2024.

- ^ a b c d Hayler & Keever, 2004, p. 15-2.

- ^ a b c d Hayler & Keever, 2004, p. 15-3.

- ^ a b Koeze, Ella (March 28, 2024). "The Dali Is a Big Ship. But Not the Biggest". The New York Times. Archived from the original on March 30, 2024. Source credits: "Sources: "The Geography of Transport Systems," by Jean-Paul Rodrigue; VesselFinder; the Empire State Building; the Eiffel Tower; ShipHub; Maryland Port Administration".

- ^ a b MAN Diesel, 2009, p.6.

- ^ Vesterager, Jacob. "Alphaliner: Verdens havne er ikke klar til gigantskibe" (World ports not ready for giant ships). ShippingWatch, December 2012.

- ^ Autoridad del Canal de Panamá 2005, pp. 11 – 12.

- ^ a b UNCTAD, 2010, p. xiii.

- ^ The Associated Press (2016-06-26). "Panama Canal Opens $5B Locks, Bullish Despite Shipping Woes". The New York Times. Retrieved 2016-06-26.

- ^ a b Autoridad del Canal de Panamá, 2009.

- ^ a b Autoridad del Canal de Panamá, 2006, p. 45.

- ^ a b c d e f g h i j UNCTAD, 2010, p. 32.

- ^ "Mærsk Mc-Kinney Møller (13232687)". ABS Record. American Bureau of Shipping. Retrieved 1 May 2014.

van Ham, Hans; Rijsenbrij, Joan Rijsenbrij (2012). Development of containerization success through vision, drive and technology (Online-Ausg. ed.). Amsterdam: IOS Press. p. 290. ISBN 9781614991472. - ^ Reederei Blue Star GmbH (2011). "Bay Class Overview". Reederei Blue Star Fleet. Hamburg: Reederei Blue Star GmbH. Archived from the original on July 19, 2011. Retrieved 2011-03-05.

- ^ Fearnresearch (2005). "Fearnley's Annual Review, 2004" (PDF). Oslo: Fearnleys AS. p. 90. Retrieved 2011-03-05.

- ^ a b c d e f Conrad, 1989, p. 249.

- ^ a b UNCTAD, 2010, p. 100.

- ^ a b c d e f Meurn & Sauerbier, 2004, pp. 1–16.

- ^ a b Hayler & Keever, 2004, pp. 5–10.

- ^ Hayler & Keever, 2004, pp. 5-9 – 5-10.

- ^ a b c d e f Meurn & Sauerbier, 2004, p. 1-19–1-21.

- ^ "APL to Take Delivery of First 'Ocean-capable' 53-foot Containers". www.marinelink.com. 31 October 2007. Retrieved 26 March 2024.

- ^ "Tailor made dedicated 53FT shipping service". www.carrier53.com. Retrieved 26 March 2024.

- ^ a b c d e Meurn and Sauerbier, 2006, p. 1-35.

- ^ Peck and Hale, 2000, p. 1-4.

- ^ Peck and Hale, 2000, p. 2.

- ^ a b Peck and Hale, 2000, p. 12.

- ^ Peck and Hale, 2000, p. 10.

- ^ a b Meurn and Sauerbier, 2006, p. 1-38–1-40.

- ^ "PublicTop100". alphaliner.axsmarine.com. Retrieved 2021-04-14.

- ^ "PublicTop100". alphaliner.axsmarine.com. Retrieved 2022-04-14.

- ^ "World container-fleet capacity has grown by 50 percent since 2008". Progressive Economy. 12 December 2012. Retrieved 30 June 2015.

- ^ "Global containership fleet - TEUs 2017 | Statistic". Statista. Retrieved 2018-02-23.

- ^ UNCTAD 2010, p. 30.

- ^ UNCTAD 2010, p. 31.

- ^ UNCTAD 2006, p. 19.

- ^ UNCTAD 2010, p. 34.

- ^ a b c d e f g h i j k l m n o p q r s t u v w x UNCTAD, 2010, pp. 85.

- ^ ICFTU et al., 2002, p. 7.

- ^ a b c d Bureau of Transportation Statistics, 2007, p. 80.

- ^ "FOC Countries". International Transport Workers' Federation. 2005-06-06. Archived from the original on 2010-07-18. Retrieved 2010-07-02.

- ^ UNCTAD 2010, p. 53, 57.

- ^ UNCTAD 2010, p. 56.

- ^ UNCTAD 2010, p. 57.

- ^ a b c UNCTAD 2010, p. 50.

- ^ Bailey, Paul J. (2000). "Is there a decent way to break up ships?". Sectoral Activities Programme. International Labour Organization. Retrieved 2007-05-29.

- ^ UNCTAD, 2010, p. 35.

- ^ Maritime Transport Coordination Platform (November 2006). "3: The London Tonnage Convention" (PDF). Tonnage Measurement Study. MTCP Work Package 2.1, Quality and Efficiency. Bremen/Brussels. p. 3.3. Archived from the original (PDF) on 2007-03-30. Retrieved 2007-05-29.

{{cite book}}: CS1 maint: location missing publisher (link) - ^ a b c d UNCTAD 2010, p. 51.

- ^ UNCTAD 2010, p. 53.

- ^ a b UNCTAD 2010, p. 52.

- ^ "MSC vessel "Irina" is the world's largest container ship". ajot.com. American Journal of Transportation. Retrieved 2024-04-18.

- ^ "OOCL Kicks Off New Generation of Ultra-Large Boxships". Maritime Executive. Retrieved 20 April 2024.

- ^ a b "ONE Plans Six World's Largest Containerships". The Maritime Executive. December 24, 2020. Retrieved 2024-01-31.

- ^ a b "World's largest container ship MSC Tessa delivered, made in China". Interesting Engineering. Retrieved 19 April 2024.

- ^ a b c "Do you know these are the largest cargo ships in the world?". news9live.com. News9 Live. 2024-03-27. Retrieved 20 April 2024.

- ^ "Inaugural stopover of the mega container ship HMM OSLO at the Port of Le Havre". ajot.com. American Journal of Transportation. Retrieved 20 April 2024.

- ^ "MSC MINA, one of the world's largest container ships, docks at King Abdullah Port". Hellenic Shipping News. Retrieved 20 April 2024.

- ^ "World's largest gas-powered container ship rolls off Shanghai slipway, a milestone for global shipping and China's shipbuilding". SCMP. Retrieved 20 April 2024.

- ^ "New Largest Containership In The World 'OOCL Hong Kong' Christened haul". Archived from the original on 9 March 2020. Retrieved 28 July 2017.

- ^ "China's largest cargo ship handed over to owners | Hellenic Shipping News Worldwide". www.hellenicshippingnews.com. Archived from the original on 2020-02-26. Retrieved 2018-06-14.

- ^ "CMA CGM ANTOINE DE SAINT EXUPERY". www.cma-cgm.com. Retrieved 2018-02-02.

- ^ "Ships for the long (and short) haul". John Churchill, AP Moller-Maersk (Press release). Archived from the original on 2017-05-05. Retrieved 2017-05-11.

{{cite press release}}: CS1 maint: bot: original URL status unknown (link) - ^ "MOL Truth, Japan's 1st 20,000 TEU Containership, Delivered - Largest Built in Japan, to be Launched on Asia-North Europe Trade -". Mitsui O.S.K. Lines. Retrieved 2018-01-06.

- ^ a b "World's Largest Container Ship Named". The Maritime Executive. Retrieved 2017-03-18.

- ^ "EVER GLOBE (IMO 9786841) - Container Ship". Vessel Tracking. Retrieved 20 April 2024.

- ^ a b "Top 22 World's Largest Container Ships in 2024". Marine Insight. 11 April 2024. Retrieved 20 April 2024.

- ^ "STX reveals design for world's largest container ship". SeaTrade Asia. May 2008. Archived from the original on 2008-12-24. Retrieved 2008-09-10.

- ^ "STX ponders 20,000 TEU boxship". Turkish Maritime. May 2008. Retrieved 2008-09-10.

- ^ "New designs on the world's biggest container ships". Shipping Times. Shipping Times UK. 2008-05-28. Archived from the original on 2020-03-01. Retrieved 2008-09-10.

- ^ "Emma Maersk (06151181)". ABS Record. American Bureau of Shipping. Retrieved 2011-03-13.

- ^ "Alphaliner" (PDF). Archived from the original (PDF) on 2011-07-07. Retrieved 2018-12-28.

- ^ "NORDIC ROUNDUP: Maersk Orders 10 Container Carriers - Source - WSJ.com". The Wall Street Journal. 2011-02-22. Retrieved 2011-02-22.[permanent dead link]

- ^ "Maersk Line shipping containers worldwide". www.maerskline.com. Archived from the original on July 14, 2011.

- ^ "Hafen muss Mega-Containerschiffen angepasst werden". Archived from the original on 2020-02-29. Retrieved 2016-03-14.

- ^ "Obergrenzen helfen Reedern und Häfen" (PDF). Archived from the original (PDF) on 2020-03-15. Retrieved 2016-03-14.

- ^ "MSC Shatters Records With Delivery Of 24,346TEU MSC Irina". Ships Monthly. Kelsey Media. Retrieved 19 April 2024.

- ^ "Europe sets its gaze on the world's largest ship: A closer look at MSC Loreto". Offshore Energy. 26 May 2023. Retrieved 20 April 2024.

- ^ Aragon & Messer, 2001, p. 233.

- ^ a b Huber 2001, p. 212.

- ^ Huber 2001, pp. 212–213.

- ^ Huber 2001, p. 213.

- ^ UNCTAD, 2010, pp. 85–89.

- ^ Huber 2001, p. 225.

- ^ UNCTAD, 2010, p. 88.

- ^ "Table 3.1. Container freight markets and rates" (PDF). Review of Maritime Transport. United Nations conference on trade and development. 14 October 2015. p. 58.

- ^ a b c d UNCTAD, 2010, p. 89.

- ^ "Ready to go". Drewry Shipping Consultants Limited. 12 Mar 2017.

- ^ Leach, Peter (7 January 2015). "Shippers, regulators will be watching closely as alliances launch services". JOC.com. Retrieved 23 March 2015.

- ^ European Commission, Antitrust: Commission accepts commitments by container liner shipping companies on price transparency, published 7 July 2016, accessed 9 May 2023

- ^ Freightos Ltd., GRI Shipping Increases 2023, Freight Term Glossary, accessed 9 May 2023

- ^ a b UNCTAD, 2010, p.97.

- ^ a b c "Lloyd's List One Hundred Ports 2020". Archived from the original on 2020-08-31.

- ^ a b Containers Overboard![dead link] TT Club Archived March 4, 2011, at the Wayback Machine (Maritime insurers). Accessed: 26 February 2011.

- ^ Janice Podsada (19 June 2001). "Lost Sea Cargo: Beach Bounty or Junk?". National Geographic News. Archived from the original on July 3, 2001. Retrieved 2008-04-08.

- ^ Hauke Kite‐Powell. Benefits to maritime commerce from ocean surface vector wind observations and forecasts Archived 2021-03-20 at the Wayback Machine NOAA, December 2008. Accessed: 26 February 2011.

- ^ Survey Results for Containers Lost At Sea – 2014 Update Archived 2020-11-08 at the Wayback Machine, June 2014. Accessed: 16 August 2019.

- ^ "Freak waves spotted from space". BBC News. 22 July 2004. Retrieved 6 October 2009.

- ^ Stoltz, Ryan (February 27, 2022). "How Many Shipping Containers are Lost at Sea Annually?". Container Addict. Retrieved April 15, 2022.

- ^ Sources of Marine Debris NOAA. Retrieved: 25 November 2010.

- ^ "Shipping firms experience a sharp rise in containers lost at sea," Feb. 25, 2021, Lockton Companies

Sources

[edit]Shipboard operations

[edit]- Conrad, Edward E. (1989). "12. Containership Operations". In Hayler, William (ed.). Merchant Marine Officers' Handbook: based on the original edition by Edward A. Turpin and William A. MacEwen (5th ed.). Cambridge, Md: Cornell Maritime Press. ISBN 978-0-87033-379-8.

- Huber, Mark (2001). Tanker operations: a handbook for the person-in-charge (PIC). Cambridge, MD: Cornell Maritime Press. ISBN 978-0-87033-528-0.

- Cudahy, Brian J. (2006). Box boats: how container ships changed the world. New York: Fordham University Press. ISBN 978-0-8232-2568-2.

- Hayler, William B.; Keever, John M. (2003). American Merchant Seaman's Manual. Cornell Maritime Pr. ISBN 978-0-87033-549-5.

- Peck and Hale (2000). "Container Stowage and Securing Systems" (PDF). West Sayville, NY: Peck & Hale. Archived from the original (PDF) on 2011-07-15. Retrieved 2011-03-01.

- Sauerbier, Charles L.; Meurn, Robert J. (2004). Marine Cargo Operations: a guide to stowage. Cambridge, Md: Cornell Maritime Press. ISBN 978-0-87033-550-1.

Vessel categories

[edit]- Autoridad del Canal de Panamá (2005). MR Notice to Shipping Number N-1-2005 (PDF). Notices to Shipping. Balboa-Ancon: Autoridad del Canal de Panamá. pp. 11–12. Archived from the original (PDF) on 2011-06-11. Retrieved 2008-04-01.

- Autoridad del Canal de Panamá (2006). Proposal for the Expansion of the Panama Canal: Third Set of Locks Project (PDF). Notices to Shipping. Balboa-Ancon: Autoridad del Canal de Panamá. Archived from the original (PDF) on 2011-07-21. Retrieved 2011-03-06.

- Autoridad del Canal de Panamá (2009). Dimensions for Future Lock Chambers and "New Panamax" Vessels (PDF). Notices to Shipping. Balboa-Ancon: Autoridad del Canal de Panamá. Archived from the original (PDF) on 2009-05-06. Retrieved 2011-03-06.

- MAN Diesel (2009). "Propulsion Trends in Container Vessels" (PDF). Copenhagen: MAN Diesel. Archived from the original (PDF) on 2012-05-07. Retrieved 2011-12-29.

Statistics

[edit]- Bureau of Transportation Statistics 2007 (2008). Maritime Trade & Transportation (PDF). Washington, D.C.: United States Department of Transportation, Research and Innovative Technology Administration. Archived from the original (PDF) on 2009-05-10. Retrieved 2011-03-02.

{{cite book}}: CS1 maint: numeric names: authors list (link) - Central Intelligence Agency (2009). CIA World Factbook 2009. Skyhorse Publishing. ISBN 978-1-60239-080-5. Retrieved 2011-02-21.

- Economic and Social Commission for Asia and the Pacific (2009). Review of Developments in Transport in Asia and the Pacific 2007: Data and Trends (Economic and Social Commission for Asia and the Pacific). New York: United Nations. pp. 144–146. ISBN 978-92-1-120534-3. Retrieved 2011-03-05.[permanent dead link]

- United Nations Conference on Trade and Development (UNCTAD) (2010). Review of Maritime Transport, 2010 (PDF). New York and Geneva: United Nations. ISBN 978-92-1-112810-9.[permanent dead link]

- United Nations Conference on Trade and Development (UNCTAD) (2012). Review of Maritime Transport, 2012 (PDF). New York and Geneva: United Nations. ISBN 978-92-1-112860-4.

History

[edit]- Bohlman, Michael T. (September 2001). "ISO's container standards are nothing but good news" (PDF). ISO Bulletin: 12–15. Archived from the original (PDF) on 2008-04-09.

- The New Scientist (22 May 1958). "News and Comments". New Scientist. 4 (79): 10. Archived from the original on 7 July 2014..

- Cudahy, Brian J. (September–October 2006). "The Containership Revolution: Malcom McLean's 1956 Innovation Goes Global" (PDF). TR News. 246: 5–9. Retrieved 2011-03-01..

- Horizon Lines. "History of Sea-Land, CSX Lines, and Horizon Lines Timeline (1956–Present)". Horizon Lines web site. Archived from the original on 2010-12-27. Retrieved 2011-02-24.

- International Confederation of Free Trade Unions; Trade Union Advisory Committee to the OECD; International Transport Workers' Federation; Greenpeace International (2002). More Troubled Waters: Fishing, Pollution, and FOCs (PDF). Johannesburg: 2002 World Summit on Sustainable Development. Retrieved 2010-06-12.[permanent dead link]

- Jankowski, William M. (2003). Maritime Shipping Container Security and the Defense Transportation System: Problems and Policy in the 21st Century (M.S. thesis). Naval Postgraduate School. Archived from the original on 2011-06-29. Retrieved 2011-02-23.

- Levinson, Marc (2006). The Box: How the Shipping Container Made the World Smaller and the World Economy Bigger. Princeton, N.J: Princeton University Press. ISBN 978-0-691-12324-0.

- Nichols, C. Reid; Williams, Robert G. (November 2008). Encyclopedia of Marine Science. Infobase Publishing. pp. 121–122. ISBN 978-0-8160-5022-2. Retrieved 8 March 2011.

- Roland, Alex; Bolster, W Jeffrey; Keyssar, Alexander (2008). The way of the ship: America's maritime history reenvisioned. Hoboken, New Jersey: John Wiley and Sons. ISBN 978-0-470-13600-3.

- "The container industry: The world in a box". The Economist. 2006-03-16. Retrieved 2011-02-22.

Safety and security

[edit]- Michael McNicholas (2008). Maritime security: an introduction. Boston, MA: Butterworth Heinemann. ISBN 978-0-12-370859-5. Retrieved 2011-03-05.

- Chia-Hsun Chan; Jingjing Xu; Dong-Ping Song (March 2014). "An analysis of safety and security risks in container shipping operations: A case study of Taiwan". Safety Science. 63 (925–7535): 168–178. doi:10.1016/j.ssci.2013.11.008. Retrieved 17 April 2024.

External links

[edit]| External image | |

|---|---|

- Ancient and modern mariners: The romance of the high seas in an age of quantification – article in The Economist about a voyage on a 21st-century container ship

- Rodrigo de Larrucea, Jaime. "Container Ship Safety" (PDF). Retrieved 19 April 2012.

KSF

KSF