Glasmine 43

From Wikipedia - Reading time: 6 min

From Wikipedia - Reading time: 6 min

| Glasmine 43 | |

|---|---|

Glasmine 43 | |

| Type | Minimum metal anti-personnel mine |

| Place of origin | Germany |

| Service history | |

| In service | 1944–1945 |

| Used by | Germany, |

| Wars | World War II |

| Production history | |

| Produced | 1944–1945 |

| No. built | 11 million |

| Variants |

|

| Specifications | |

| Height | 6 inches (150 mm) |

| Diameter | 4.5 inches (110 mm) |

| Filling | TNT |

| Filling weight | 200 grams (7.1 oz) |

Detonation mechanism | Pressure – weight of around 40 pounds (18 kg)[1] |

The Glasmine 43 was an anti-personnel mine with a glass body used by Nazi Germany during World War II.

This mine was an early form of minimum metal mine, designed so to reduce the likelihood of detection by the Polish mine detector then in use by Allied forces. The reduced use of metal was also beneficial because it saved this valuable war resource for other uses.

Description

[edit]

The mine consists of a glass bowl, six inches (15 cm) in diameter containing an explosive charge and a detonator. The top of the mine was covered by a sheet-glass disk 0.25 inches (6.4 mm) thick, under a thick, moulded glass pressure plate. Each mine was supplied with a small quantity of cement putty to seal gaps between the main body and the glass disk cover and make the mine waterproof.[2]

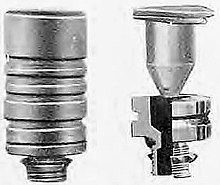

When stepped on, the pressure plate shattered the glass disk and activated the detonator, detonating the mine's main explosive charge. This was a Sprengkörper 28 – a standard demolition charge with 200 grams (7.1 oz) of explosive.[1][2] Two types of detonators were used. Early versions of the mine used a mechanical detonator, known as a Hebelzünder 44 which used a percussion cap.[3] Later versions fired the main charge using a device known as a Buck igniter.

The Buck igniter was a small can of thin, corrugated aluminium. This contained a glass ampoule of sulfuric acid, surrounded by flash powder that included powdered naphthalene. The can crushed when subjected to a force equivalent to around five pounds (2.3 kg), shattering the ampoule and causing the acid to mix with the powder. The resulting chemical reaction produced a flash that ignited the detonator of the main explosive charge.[5][6]

In 1944 and 1945, 11 million mines were produced; at the end of World War II, 9.7 million were still in stock.[7] Along with other companies, the Glashütte Gifhorn participated in the production.

Effect and legacy

[edit]Glass shrapnel was not easily detectable via X-rays, which rendered medical assistance to victims much harder than conventional mines. Glass made life-threatening injuries more difficult to assess.[citation needed]

Mines of this type are still buried in the Eifel National Park on the grounds of the Vogelsang Military Training Area, a former "Nazi leadership" training center.[8]

Demining areas with this type of mine is resource intensive, as the fields must be swept either by hand or with mine flails like the Keiler, not forgetting that the latter has a certain margin of error since it was developed with military-tactical deployments in mind (creating pathways through minefields).

In 2004, the Colombian Government claimed that "home-made" glass mines were employed by guerrillas in Colombia.[9]

References

[edit]- ^ a b c Office of the Chief of Ordnance (1945). Catalog Of Enemy Ordnance Materiel. OCLC 464601649.

- ^ a b United States War Office (1953). German Explosive Ordnance. Department of the Army Technical Manual TM 9-1985-2. Washington: United States Government Printing Office (published March 1953). p. 275. OCLC 713755660.

- ^ Functioning, Assembly and Pictures of Glasminen (english) Archived 2009-01-22 at the Wayback Machine(Retrieved on 11 June 2012)

- ^ Catalog Of Enemy Ordnance Material. Office of the Chief of Ordnance. 1 August 1945. p. 283.

- ^ Norman Youngblood (2006). The Development of Mine Warfare: A Most Murderous and Barbarous Conduct. Greenwood Publishing Group. pp. 115–. ISBN 978-0-275-98419-9.

- ^ German Explosive Ordnance. Department of the Army Technical Manual TM 9-1985-2. Washington: US Government Printing Office (published March 1953). 1953. p. 308.

- ^ TM-E 30-451 Handbook on German Military Forces (english) (Retrieved on 11 Juni 2012)

- ^ Dieter Wulf: Am Rande des Nationalparks Eifel, 5. April 2009 in Deutschlandfunk, Retrieved on 8 September 2013

- ^ Personenminen Retrieved 21 November 2012

External links

[edit]- Description and images on LEXPEV

- Catalog of Enemy Ordnance, U.S. Office of Chief of Ordnance, 1945 Archived 2019-11-06 at the Wayback Machine

- Another short description on Castle Argghhh!!!

KSF

KSF