Heinkel

From Wikipedia - Reading time: 14 min

From Wikipedia - Reading time: 14 min

| |

| Industry | Aerospace |

|---|---|

| Founded | 1922 |

| Founder | Ernst Heinkel |

| Defunct | 1965 |

| Fate | Acquired |

| Successor | Vereinigte Flugtechnische Werke (VFW) |

| Headquarters | , |

Key people | Robert Lusser |

| Services | Aircraft engines |

Heinkel Flugzeugwerke (German pronunciation: [ˈhaɪŋkəl ˈfluːktsɔʏçˌvɛɐkə]) was a German aircraft manufacturing company founded by and named after Ernst Heinkel. It is noted for producing bomber aircraft for the Luftwaffe in World War II and for important contributions to high-speed flight, with the pioneering examples of a successful liquid-fueled rocket and a turbojet-powered aircraft in aviation history, with both Heinkel designs' first flights occurring shortly before the outbreak of World War II in Europe.

History

[edit]Following the successful career of Ernst Heinkel as the chief designer for the Hansa-Brandenburg aviation firm in World War I, Heinkel's own firm was established at Warnemünde in 1922, after the restrictions on German aviation imposed by the Treaty of Versailles were relaxed. By 1929, the firm's compressed air-powered catapults were in use on the German Norddeutscher Lloyd ocean-liners SS Bremen and Europa to launch short-range mail planes from the liners' decks.[1]

The company's first post-World War I aircraft design success was the design of the all-metal, single-engined Heinkel He 70 Blitz high-speed mail plane and airliner for Deutsche Luft Hansa in 1932, which broke a number of air speed records for its class. It was followed by the two-engine Heinkel He 111 Doppel-Blitz, which became a mainstay of the Luftwaffe during World War II as a bomber. Heinkel's most important designers at this point were the twin Günter brothers, Siegfried and Walter, and Heinrich Hertel.

The firm's headquarters was in Rostock later known as Heinkel-Nord (Heinkel-North), located in what used to be named the Rostock-Marienehe neighborhood (today's Rostock-Schmarl community, along the west bank of the Unterwarnow estuary), where the firm additionally possessed a factory airfield along the coastline in the Rostock/Schmarl neighborhood roughly three kilometers (1.9 miles) north-northwest of the main offices, with a second Heinkel-Süd engineering and manufacturing facility in Schwechat, Austria, after the Anschluss in 1938.

World War II

[edit]

The Heinkel company is most closely associated with aircraft used by the Luftwaffe during World War II. This began with the adaptation of the He 70 and, in particular, the He 111, to be used as bombers. Heinkel also provided the Luftwaffe's only operational heavy bomber, the Heinkel He 177, although this was never deployed in significant numbers. The German Luftwaffe equipped both of these bombers with the Z-Gerät, Y-Gerät, and Knickebein, developed by Johannes Plendl, and thus they were among the first aircraft to feature advanced night navigation devices, common in all commercial airplanes today.

Heinkel was less successful in selling fighter designs. Before the war, the Heinkel He 112 had been rejected in favour of the Messerschmitt Bf 109, and Heinkel's attempt to top Messerschmitt's design with the Heinkel He 100 failed due to political interference within the Reichsluftfahrtministerium (RLM — Reich Aviation Ministry). The company also provided the Luftwaffe with an outstanding night fighter, the Heinkel He 219, which also suffered from politics and was produced only in limited numbers, but was the first Luftwaffe front-line aircraft to use retractable tricycle gear for its undercarriage design, and the world's first front-line military aircraft to use ejection seats. By contrast, the only heavy bomber to enter service with the Luftwaffe during the war years – the Heinkel He 177 Greif – turned out to be one of the most troublesome German wartime aircraft designs, plagued with numerous engine fires from both its inadequate engine nacelle design and its general airframe design being mis-tasked. The 30-meter (100 ft) class wingspan design was to be built to be able to perform moderate-angle dive bombing attacks from the moment of its approval by the RLM in early November 1937, until this was rescinded in September 1942.[2]

From 1941 until the end of the war, the company was merged with engine manufacturer Hirth to form Heinkel-Hirth, giving the company the capability of manufacturing its own powerplants, including its Heinkel Strahltriebwerke turbojet engine manufacturing firm.

The Heinkel name was also behind pioneering work in jet engine and rocket development, and also the German aviation firm that attempted to popularize the use of retractable tricycle landing gear, a relative rarity in early WW II German airframe design. In 1939, flown by Erich Warsitz,[3] the Heinkel He 176 and Heinkel He 178 became the first aircraft designs to fly under liquid-fuel rocket and turbojet power respectively.

Heinkel was the first to develop a jet fighter to prototype stage, the Heinkel He 280, the first Heinkel design to use and fly with retractable tricycle gear. In early 1942, the photographic interpretation unit at RAF Medmenham first saw evidence of the existence of the 280 in aerial reconnaissance photographs taken after a bombing raid on the Rostock factory. Thereafter, the Allies began intensive aerial reconnaissance intended to learn more about the German jet aircraft programme.[4]

The He 219 night fighter design was the first German frontline combat aircraft to have retracting tricycle gear, and the first operational military aircraft anywhere to use ejection seats. Heinkel's He 280, the firm's only twin-jet aircraft design to fly never reached production, however, since the RLM wanted Heinkel to concentrate on bomber production and instead promoted the development of the rival Messerschmitt Me 262. Very late in the war, a Heinkel single-jet powered fighter finally took to the air as the Heinkel He 162A Spatz (sparrow) as the first military jet to use retractable tricycle landing gear, use a turbojet engine from its maiden flight forward, and use an ejection seat from the start, but it had barely entered service at the time of Germany's surrender.

Slave labour during World War II

[edit]Heinkel was a major user of Sachsenhausen concentration camp labour, using between 6,000 and 8,000 prisoners on the He 177 bomber.[5]

Post-war

[edit]

Following the war, Heinkel was prohibited from manufacturing aircraft and instead built bicycles, motor scooters (see below), and the Heinkel microcar. The company eventually returned to aircraft in the mid-1950s, licence building Lockheed Martin F-104 Starfighters for the West German Luftwaffe. In 1965, the company was absorbed by Vereinigte Flugtechnische Werke (VFW), which was in turn absorbed by Messerschmitt-Bölkow-Blohm in 1980 and later became part of Airbus.

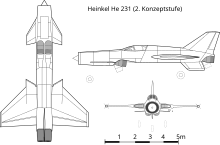

Entwicklungsring Süd, a research and development conglomeration in a joint venture with Bölkow and Messerschmitt, designed the EWR VJ 101A/He 231, a VSTOL prototype, intended to protect West Germany's airfields against Soviet attack.[6]

Products

[edit]Aircraft

[edit]- HD - Heinkel Doppeldecker

- Heinkel HD 14

- Heinkel HD 15

- Heinkel HD 16

- Heinkel HD 17

- Heinkel HD 19

- Heinkel HD 20

- Heinkel HD 21

- Heinkel HD 22

- Heinkel HD 23

- Heinkel HD 24 seaplane trainer (1926)

- Heinkel HD 25

- Heinkel HD 26

- Heinkel HD 27

- Heinkel HD 28

- Heinkel HD 29

- Heinkel HD 30

- Heinkel HD 32

- Heinkel HD 33

- Heinkel HD 34

- Heinkel HD 35

- Heinkel HD 36

- Heinkel HD 37 fighter (biplane)

- Heinkel HD 38 fighter (biplane)

- Heinkel HD 39

- Heinkel HD 40

- Heinkel HD 41

- Heinkel HD 42 seaplane trainer

- Heinkel HD 43 fighter (biplane)

- Heinkel HD 44

- Heinkel HD 45

- Heinkel HD 46

- Heinkel HD 49

- Heinkel HD 50

- Heinkel HD 55 reconnaissance flying boat

- Heinkel HD 56

- Heinkel HD 59

- Heinkel HD 60

- Heinkel HD 61

- Heinkel HD 62

- Heinkel HD 63

- Heinkel HD 66

- HE - Heinkel Eindecker

- Heinkel HE 1 low-wing floatplane (monoplane)

- Heinkel HE 2 improvement on the HE 1

- Heinkel HE 3

- Heinkel HE 4 reconnaissance (monoplane)

- Heinkel HE 5 reconnaissance (monoplane)

- Heinkel HE 8 reconnaissance (monoplane)

- Heinkel HE 9

- Heinkel HE 12

- Heinkel HE 18

- He - Heinkel (RLM designator)

- Heinkel He 45 bomber + trainer

- Heinkel He 46 reconnaissance

- Heinkel He 49 fighter (biplane)

- Heinkel He 50 reconnaissance + dive bomber (biplane)

- Heinkel He 51 fighter + close-support (biplane)

- Heinkel He 57 Heron

- Heinkel He 58

- Heinkel He 59 reconnaissance (biplane seaplane)

- Heinkel He 60 ship-borne reconnaissance (biplane seaplane)

- Heinkel He 62 reconnaissance seaplane

- Heinkel He 63 trainer biplane

- Heinkel He 64 sports plane

- Heinkel He 70 "Blitz" (Lightning), single-engine transport + mailplane, 1932

- Heinkel He 71 single-seat monoplane

- Heinkel He 72 Kadett (Cadet), trainer

- Heinkel He 74 fighter + advanced trainer (prototype)

- Heinkel He 100 fighter

- Heinkel He 111 bomber

- Heinkel He 112 fighter

- Heinkel He 113 (fictitious alternative designation for He 100D-1)

- Heinkel He 114 reconnaissance seaplane

- Heinkel He 115 general-purpose seaplane

- Heinkel He 116 transport + reconnaissance

- Heinkel He 118

- Heinkel He 119 single-engine high-speed bomber (prototypes), reconnaissance aircraft, 1937

- Heinkel He 120 four-engine long-range passenger flying-boat (project), 1938

- Heinkel He 162 Spatz (sparrow), Volksjäger (People's Fighter) design competition choice, fighter (jet-engined)

- Heinkel He 170

- Heinkel He 172 trainer (prototype)

- Heinkel He 176 pioneering liquid-fueled rocket-powered experimental aircraft (prototype)

- Heinkel He 177 Greif (Griffon), the Third Reich's only long-range heavy bomber

- Heinkel He 178 world's first jet-engined aircraft

- Heinkel He 219 Uhu (Eagle-Owl), night-fighter

- Heinkel He 220 four-engine long-range passenger flying-boat (project), 1939

- Heinkel He 270

- Heinkel He 274 high-altitude bomber, He 177 development, two prototypes completed post-war in France

- Heinkel He 275 four-engine bomber; project only

- Heinkel He 277 heavy bomber, paper-only Amerika Bomber He 177 development (by February 1943) with four BMW 801E radial engines, never built

- Heinkel He 278 four-engine turboprop bomber; project only

- Heinkel He 280 fighter (jet-engined)

- Heinkel He 343 four-engined bomber (jet-engined project), 1944

- Heinkel He 519, high-speed bomber (He 119 derivative; project only), 1944

- Heinkel Type 98 Medium Bomber - He 111 for service with the IJNAS

- Heinkel A7He He 112 development for the IJAAS

- Heinkel Navy Type He Interceptor Fighter He 100 development for the IJNAS

P - Projekt

- Heinkel P.1054

- Heinkel P.1062

- Heinkel P.1063

- Heinkel P.1064

- Heinkel P.1065

- Heinkel P.1066

- Heinkel P.1069

- Heinkel P.1070

- Heinkel P.1071

- Heinkel P.1072

- Heinkel P.1074

- Heinkel P.1075

- Heinkel He P.1076, A nearly conventional 1944 design, with slightly forward swept wings and contra-rotating propellers at the front.

- Heinkel P.1077 Julia rocket-propulsion point-defense interceptor

- Heinkel P.1078

- Heinkel He P.1078A, fighter (jet-engined) (project)

- Heinkel He P.1078B, tailless fighter (jet-engined) (project)

- Heinkel He P.1078C, tailless fighter (jet-engined) (project), 1944

- Heinkel He P.1079A, two-engine night-fighter (jet-engined) (project)

- Heinkel He P.1079B/I, all-weather heavy fighter (flying wing design) (jet-engined)

- Heinkel He P.1079B/II, all-weather heavy fighter (flying wing design) (jet-engined), 1945

- Heinkel Lerche

- Heinkel Wespe

Microcar

[edit]

Heinkel introduced the "Kabine" bubble car in 1956. It competed with the BMW Isetta and the Messerschmitt KR200. It had a unit body and a four-stroke single-cylinder engine.[7]

Heinkel stopped manufacturing the Kabine in 1958 but production continued under licence, first by Dundalk Engineering Company in Ireland and then by Trojan Cars Ltd., which ceased production in 1966.[7][8]

Scooters

[edit]

Heinkel introduced the "Tourist" motor scooter in the 1950s which was known for its reliability. A large and relatively heavy touring machine, it provided good weather protection with a full fairing and the front wheel turning under a fixed nose extension. The "Tourist" had effective streamlining, perhaps unsurprising in view of its aircraft ancestry, and although it had only a 174 cc (10.6 cu in), 9.5 bhp 4-stroke engine, it was capable of sustaining speeds of up to 70 miles per hour (110 km/h) (official figures 58 miles per hour (93 km/h)), given time to get there.

Heinkel also made a lighter 150 cc (9.2 cu in) scooter called the Heinkel 150.[9]

Mopeds

[edit]

Heinkel built the Perle moped from 1954 to 1957.[10] The Perle was a sophisticated cycle with a cast alloy unit frame, rear suspension, a fully enclosed chain with part of the chain enclosure integral with the swingarm, and interchangeable wheels. This high level of sophistication came at a high cost.[11][12] As with most mopeds, it had a two-stroke engine with a displacement of 50cc that operated on a mixture of gasoline and lubrication oil.[13] Approximately twenty-seven thousand Perles were sold.[10]

See also

[edit]- List of RLM aircraft designations

- Maicoletta

- Zündapp Bella

- Jägerstab (Fighter Staff)

- Rüstungsstab (Armament Staff)

References

[edit]- ^ "The Heinkel Catapult on the S.S. BREMEN". histaviation.com. August 3, 1929. Retrieved July 13, 2017.

THE HEINKEL K2 catapult installed upon the North German Lloyd liner "Bremen," which figured prominently in the establishment of the recent trans-Atlantic mail record, is the result of two years of experimentation and development by Dr. Ernst Heinkel, its designer.

- ^ Griehl, Manfred; Dressel, Joachim (1998). Heinkel He 177 – 277 – 274. Shrewsbury, UK: Airlife Publishing. p. 54. ISBN 1-85310-364-0.

- ^ Warsitz, Lutz: THE FIRST JET PILOT - The Story of German Test Pilot Erich Warsitz, Pen and Sword Books Ltd., England, 2009 Archived 2013-12-02 at the Wayback Machine

- ^ Constance Babington-Smith,"Air Spy," Ballantine Books, NY, 1957, p. 175

- ^ "Use of Prisoners in the aircraft industry (translated)". Nazi Conspiracy and Aggression Volume IV. The Avalon Project at Yale Law School. 1996–2007. Retrieved 2008-02-25.

- ^ Mike Hirschberg V/STOL Fighter Programs in Germany: 1956-1975, 2000 International Powered Lift Conference, 1 November 2000 via www.robertcmason.com, accessed 17 March 2021

- ^ a b Bruce Weiner Microcar Museum: 1956 Heinkel Kabine www.microcarmuseum.com, accessed 17 March 2021

- ^ Bruce Weiner Microcar Museum: 1963 Trojan 200 Archived 2008-10-25 at the Wayback Machine

- ^ Heinkel 150 Faraway Montevideo Heinkel 150 site, www.faraway.htmlplanet.com, accessed 17 March 2021

- ^ a b Biker Szene Interview with Ernst Heinkel's Son[permanent dead link]

- ^ Wilson, H. "The Encyclopedia of the Motorcycle" p. 77 Dorling-Kindersley Limited, 1995 ISBN 0-7513-0206-6

- ^ CycleMaster PAGE 10. 1955 Earls Court Show: Debut of the ‘Mo-ped’ - "HEINKEL - Stand 96"

- ^ Die Heinkel-Perle von Dieter Lammersdorf www.heinkel-club.de, accessed 17 March 2021

KSF

KSF