Scissors

From Wikipedia - Reading time: 25 min

From Wikipedia - Reading time: 25 min

This article needs additional citations for verification. (January 2020) |

Scissors are hand-operated shearing tools. A pair of scissors consists of a pair of blades pivoted so that the sharpened edges slide against each other when the handles (bows) opposite to the pivot are closed. Scissors are used for cutting various thin materials, such as paper, cardboard, metal foil, cloth, rope, and wire. A large variety of scissors and shears all exist for specialized purposes. Hair-cutting shears and kitchen shears are functionally equivalent to scissors, but the larger implements tend to be called shears. Hair-cutting shears have specific blade angles ideal for cutting hair. Using the incorrect type of scissors to cut hair will result in increased damage or split ends, or both, by breaking the hair. Kitchen shears, also known as kitchen scissors, are intended for cutting and trimming foods such as meats.

Inexpensive, mass-produced modern scissors are often designed ergonomically with composite thermoplastic and rubber handles.

Terminology

[edit]The noun scissors is treated as a plural noun, and therefore takes a plural verb (e.g., these scissors are).[1] Alternatively, the tool is referred to by the singular phrase a pair of scissors.[2] The word shears is used to describe similar instruments that are larger in size and for heavier cutting.[3]

History

[edit]

The earliest known scissors appeared in Mesopotamia 3,000 to 4,000 years ago. These were of the 'spring scissor' type comprising two bronze blades connected at the handles by a thin, flexible strip of curved bronze which served to hold the blades in alignment, to allow them to be squeezed together, and to pull them apart when released.[5]

Spring scissors continued to be used in Europe until the 16th century. However, pivoted scissors of bronze or iron, in which the blades were pivoted at a point between the tips and the handles, the direct ancestor of modern scissors, were invented by the Romans around 100 AD.[6] They entered common use in not only ancient Rome, but also China, Japan, and Korea, and the idea is still used in almost all modern scissors.

Early manufacture

[edit]During the Middle Ages and Renaissance, spring scissors were made by heating a bar of iron or steel, then flattening and shaping its ends into blades on an anvil. The center of the bar was heated, bent to form the spring, then cooled and reheated to make it flexible.

The Hangzhou Zhang Xiaoquan Company in Hangzhou, China, has been manufacturing scissors since 1663.[7]

William Whiteley & Sons (Sheffield) Ltd. was producing scissors by 1760, although it is believed the business began trading even earlier. The first trade-mark, 332, was granted in 1791.[8] The company is still manufacturing scissors today, and is the oldest company in the West to do so.

Pivoted scissors were not manufactured in large numbers until 1761, when Robert Hinchliffe of Sheffield produced the first pair of modern-day scissors made of hardened and polished cast steel. His major challenge was to form the bows; first, he made them solid, then drilled a hole, and then filed away metal to make this large enough to admit the user's fingers. This process was laborious, and apparently Hinchliffe improved upon it in order to increase production. Hinchliffe lived in Cheney Square (now the site of Sheffield Town Hall), and set up a sign identifying himself as a "fine scissor manufacturer". He achieved strong sales in London and elsewhere.[9]

During the 19th century, scissors were hand-forged with elaborately decorated handles. They were made by hammering steel on indented surfaces known as 'bosses' to form the blades. The rings in the handles, known as bows, were made by punching a hole in the steel and enlarging it with the pointed end of an anvil.

In 1649, in Swedish-ruled Finland, an ironworks was founded in the village of Fiskars between Helsinki and Turku. In 1830, a new owner started the first cutlery works in Finland, making, among other items, scissors with the Fiskars trademark.

Modern manufacturing regions

[edit]China

[edit]The vast majority of global scissor manufacturing takes place in China. As of 2019, China was responsible for 64.3% of worldwide scissors exports. When combined with Chinese Taipei exports, this rises to 68.3%.[10] The primary scissors producing region in China is in Guandong Province.

The Hangzhou Zhang Xiaoquan Company, founded in 1663, is one of the oldest continuously operating scissor manufacturers in the world. The company was nationalized in 1958 and now employs 1500 people who annually mass-produce an estimated seven million pairs of inexpensive scissors that retail for an average of US$4 each.[7]

France

[edit]In the late 14th century, the English word "scissors" came into usage. It was derived from the Old French word cisoires, which referred to shears.[11]

There are several historically important scissor-producing regions in France: Haute-Marne in Nogent-en Bassigny, Châtellereault, Thiers and Rouen.[12] These towns, like many other scissor-producing communities, began with sabre, sword and bayonet production, which transitioned to scissors and other blades in the late 18th and early 19th centuries.[13]

Thiers, in the Puy-de-Dôme department of Auvergne, remains an important centre of scissor and cutlery production. It is home to both the Musée de la Coutellerie, which showcases the town's 800-year history of blade-making,[14] as well as Coutellia, an industry tradeshow that advertises itself as one of the largest annual gatherings of artisanal blade-makers in the world.

Germany

[edit]Germany was responsible for manufacturing just under 7% of global scissors exports in 2019.[15] Often called "The City of Blades", Solingen, in North Rhine-Westphalia, has been a center for the manufacturing of scissors since medieval times. At the end of the 18th century it's estimated that there were over 300 scissorsmiths in Solingen.[16]

In 1995 the City of Solingen passed The Solingen Ordinance, an update to a 1930s law that decreed "Made in Solingen" stamps could only be applied to products almost entirely manufactured in the old industrial area of Solingen. In 2019 this applied to approximately 150 companies making high-quality blades of all kinds, including scissors.[17]

Friedrich Herder, founded in Solingen in 1727, is one of the oldest scissors manufacturers still operating in Germany.[18]

Italy

[edit]

Premana, in Lecco Province, has its origins in ironworks and knife manufacturing beginning in the 16th century. In 1900 there were ten scissor manufacturing workshops, 20 in 1952 and 48 by 1960.[19] Today, Consorzio Premax, an industrial partnership, organizes over 60 local companies involved in the manufacture of scissors for global markets.[20] In 2019 Italy exported 3.5% of scissors manufactured globally.[21]

One of the oldest Premanese scissor manufacturing firms still in operation is Sanelli Ambrogio, which was founded in 1869.[22]

Japan

[edit]Scissormaking in Japan evolved from sword making in the 14th century.[23] Seki, in Gifu Prefecture, was a renowned center of swordmaking beginning in the 1200s. After citizens were no longer permitted to carry swords, the city's blacksmiths turned to making scissors and knives.[24] There are many specialized types of Japanese scissors, but sewing scissors were introduced by American Commodore Matthew Perry from the United States in 1854.[25]

The Sasuke workshop in Sakai City south of Osaka is run by Yasuhiro Hirakawa, a 5th generation scissorsmith. The company has been in operation since 1867.[26] Yasuhiro Hirakawa is the last traditional scissormaker in Japan, making scissors in the traditional style where the blades are believed to be thinner, lighter and sharper than European scissors.[27] In 2018 he was profiled in a documentary that featured a pair of his bonsai snips which retailed for US$35,000.[28]

Spain

[edit]In Solsona, Spain, scissor manufacturing began in the 16th century. At the industry's peak in the 18th century there were 24 workshops, organized as the Guild of Saint Eligius, the patron saint of knife makers.[29] By the mid-1980s there were only two, and by 2021, Pallarès Solsona, founded in 1917 by Lluìs and Carles Pallarès Canal, and still family-operated, was the town's sole remaining artisanal scissor manufacturer.[30]

United Kingdom

[edit]Sheffield was home to the first mass production of scissors beginning in 1761. By the 19th century there were an estimated 60 steel scissor companies in Sheffield. However, since the 1980s, industry globalization and a shift towards cheaper, mass-produced scissors created price deflation that many artisanal manufacturers could not compete with. The Sheffield scissor industry consisted of just two local companies in 2021.[31]

The two remaining Sheffield scissor manufacturers are William Whiteley, founded in 1760,[32] and Ernest Wright, which was established in 1902. Both now focus on high-end/niche crafting of "products for life" rather than mass production.[33] Between these two firms it is estimated that there are no more than ten "putter-togetherers" or "putters" who are the master-trained craftspeople responsible for high quality Sheffield scissor assembly.[34] In 2020, Ernest Wright was recognized with the Award for Endangered Crafts by the British Heritage Crafts Association.[35]

Description and operation

[edit]A pair of scissors consists of two pivoted blades. In lower-quality scissors, the cutting edges are not particularly sharp; it is primarily the shearing action between the two blades that cuts the material. In high-quality scissors, the blades can be both extremely sharp, and tension sprung – to increase the cutting and shearing tension only at the exact point where the blades meet. The hand movement (pushing with the thumb, pulling with the fingers) can add to this tension. An ideal example is in high-quality tailor's scissors or shears, which need to be able to perfectly cut (and not simply tear apart) delicate cloths such as chiffon and silk.

Children's scissors are usually not particularly sharp, and the tips of the blades are often blunted or 'rounded' for safety.

Mechanically, scissors are a first-class double-lever with the pivot acting as the fulcrum. For cutting thick or heavy material, the mechanical advantage of a lever can be exploited by placing the material to be cut as close to the fulcrum as possible. For example, if the applied force (at the handles) is twice as far away from the fulcrum as the cutting location (i.e., the point of contact between the blades), the force at the cutting location is twice that of the applied force at the handles. Scissors cut material by applying at the cutting location a local shear stress which exceeds the material's shear strength.

Some scissors have an appendage, called a finger brace or finger tang, below the index finger hole for the middle finger to rest on to provide for better control and more power in precision cutting. A finger tang can be found on many quality scissors (including inexpensive ones) and especially on scissors for cutting hair (see hair scissors pictured below). In hair cutting, some claim the ring finger is inserted where some place their index finger, and the little finger rests on the finger tang.

For people who do not have the use of their hands, there are specially designed foot-operated scissors. Some quadriplegics can use a motorized mouth-operated style of scissor.

Right-handed and left-handed scissors

[edit]

Most scissors are best suited for use with the right hand, but left-handed scissors are designed for use with the left hand. Because scissors have overlapping blades, they are not symmetric. This asymmetry is true regardless of the orientation and shape of the handles and blades: the blade that is on top always forms the same diagonal regardless of orientation. Human hands are asymmetric, and when closing the scissors the thumb and fingers do not close vertically, but have a lateral component to the motion. Specifically, the thumb pushes out from the palm and the fingers pull inwards. For right-handed scissors held in the right hand, the thumb blade is closer to the user's body, so that the natural tendency of the right hand is to push the cutting blades together. Conversely, if right-handed scissors are held in the left hand, the natural tendency of the left hand would be to push the cutting blades apart. Furthermore, with right-handed scissors held by the right hand, the shearing edge is visible, but when they are used with the left hand, the cutting edge of the scissors is behind the top blade, and the cutter cannot see what is being cut.

There are two varieties of left-handed scissors. Many common left-handed scissors (often called "semi"-left-handed scissors) simply have reversed finger grips. The blades open and close as with right-handed scissors, so that users tend to pull the blades apart as they are cutting. This can be challenging for craftspeople as the blades still obscure the cut. "True" left-handed scissors have both reversed finger grips and reversed blade layout, like mirror images of right-handed scissors.[36] A left-handed person accustomed to using semi-left handed scissors may find using true left-handed scissors difficult at first, as they may have learned to rely heavily on the strength of their thumb to pull the blades apart vs. pushing the blades together in order to cut.[37]

Some scissors are marketed as ambidextrous. These have symmetric handles so there is no distinction between the thumb and finger handles, and have very strong pivots so that the blades rotate without any lateral give. However, most "ambidextrous" scissors are in fact still right-handed in that the upper blade is on the right, and hence is on the outside when held in the right hand. Even if they cut successfully, the blade orientation will block the view of the cutting line for a left-handed person. True ambidextrous scissors are possible if the blades are double-edged and one handle is swung all the way around (to almost 360 degrees) so that what were the backs of the blades become the new cutting edges. U.S. patent 3,978,584 was awarded for true ambidextrous scissors.

Specialized scissors and shears

[edit]Specialized scissors and shears include:

Gardening, agriculture and animal husbandry

[edit]| Type | Image | Description/purpose |

|---|---|---|

| Hedge trimmers |

|

for trimming hedges |

| Grass shears |

|

for trimming grass |

| Averruncators |

|

for trimming high branches |

| Pruning shears or secateurs |

|

for trimming small branches |

| Loppers |

|

for cutting through large branches |

| Blade shears |

|

for cutting an animal's fleece to harvest wool |

Food and drug

[edit]| Type | Image | Description/purpose |

|---|---|---|

| Kitchen scissors or kitchen shears |

|

For food preparation and other purposes. Usually made from stainless steel for hygiene and rust-resistance. May have additional kitchen functionality in the handles, such as bottle-cap remover, fish scaler, nutcracker. |

| Poultry shears |

|

to cut poultry |

| Cigar cutter |

|

specialized scissors with concave blade edges to cut cigars |

Grooming

[edit]| Type | Image | Description/purpose |

|---|---|---|

| Hair-cutting shears |

|

for trimming hair |

| Thinning shears |

|

for thinning thick hair to avoid a bushy look |

| Hair clippers |

|

Used by barbers, hairdressers, and pet groomers for cutting hair |

| Nail scissors |

|

for cutting finger- and toenails |

| Moustache scissors | for trimming moustaches | |

| Nose scissors |

|

small scissors for nostril and ear hair, blunt-ended to protect the sensitive interior of the nose and ears |

Metalwork

[edit]| Type | Image | Description/purpose |

|---|---|---|

| Snips |

|

for cutting through sheet metal |

| Tin, or tinner, snips |

|

|

| Compound action snips |

|

|

| Pipe and duct snips | ||

| Hydraulic cutters |

|

for cutting heavy sheet metal, often in traffic collisions. Sometimes referred to by the genericized trademark "Jaws of Life". |

| Throatless shears |

|

for cutting complex shapes in sheet metal |

Medical

[edit]| Type | Image | Description/purpose |

|---|---|---|

| Trauma shears, or "tuff cuts" |

|

for use in emergency medical response and rescue to cut off clothing. The rounded tips are designed to slide across skin without causing injury. |

| Dissection scissors | for cutting flesh in dissection | |

| Surgical scissors |

|

for cutting flesh in surgery |

| Suture scissors |

|

for cutting sutures, the hook lifts the suture |

| Iris scissors | for ophthalmic surgery | |

| Metzenbaum scissors |

|

for delicate surgery |

| Tenotomy scissors |

|

for delicate surgery |

| Mayo scissors |

|

often for cutting fascia |

| Bandage scissors |

|

for cutting bandages |

Ceremonial

[edit]| Type | Image | Description/purpose |

|---|---|---|

| Ceremonial scissors |

|

giant scissors used for ceremonial ribbon-cutting events |

Sewing and clothes-making

[edit]| Type | Image | Description/purpose |

|---|---|---|

| All purpose, or Crafting scissors |

|

With long blades and pointed tips, designed to cut long, straight, smooth cuts in a variety of materials, and to get into small areas with the tips. In sewing applications they are primarily used for non-fabric cutting applications, such as cutting out paper patterns. |

| Applique scissors | An offset handle and paddle-shaped blade pushes away the bottom layer of fabric, for controlled cuts close the stitching. Designed to cut/trim close to the fabric while protecting it from damage, and used for appliqué work and rug-making. | |

| Button hole scissors |

|

Adjustable, short-bladed, heavy-duty scissors for opening button holes. |

| Dress-maker's shears |

|

Dressmaker's shears have a long blade, typically 7–10 in (18–25 cm), for cutting out fabric. Blades are tapered, with one pointed and one rounded tip; the blunt tip prevents fabric from snagging on seams and threads. Blades have a "knife edge": the top blade is set at an acute angle which allows the scissors to cut through fabric easily. Heavier-duty than general scissors, the bottom blade sits flush on the table, making it easier to cut accurately through fabric. This photo is of a left-handed pair of shears. |

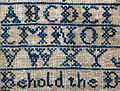

| Embroidery scissors |

|

Small scissors which have fine sharp pointed tips, designed to get close to the fabric to effectively snip threads without damaging the material. Embroidery scissors may be elaborately decorated. |

| Pinking shears |

|

for cutting cloth leaving a sawtooth edge, so that the fabric does not fray. |

| Sewing chatelaine scissors | Chatelaine is a French term meaning 'mistress of a castle, chateau or stately home' that dates back to the Middle Ages. It became used in English to refer to an ornamental clasp or hook from which chains were hung from the waist, holding perhaps, a purse, watch, keys, scissors or thimble case. The sewing chatelaine became a popular ornamental appendage worn by Victorian ladies at their waist, but disappeared when fashion changed and skirts were no longer full and long. Sewing chatelaines are now produced and worn as pendants around the neck. | |

| Tailor's scissors |

|

Designed to cut through heavy-duty materials such as leather, or multiple layers of fabric. Typically with thick blades about 5 in (13 cm) long, with precision-ground knife-edges which cut all the way to the tip. |

In popular culture

[edit]Due to their ubiquity across cultures and classes, scissors have numerous representations across world culture.

Art

[edit]Numerous art forms worldwide enlist scissors as a tool/material with which to accomplish the art. For cases where scissors appear in or are represented by the final art product, see Commons:Category:Scissors in art.

Film

[edit]- Dead Again is a 1991 film starring Kenneth Branagh and Emma Thompson in a thriller revolving around repressed memories of scissors.

- Edward Scissorhands is a 1990 film starring Johnny Depp as a young man who has hands made of multiple pairs of scissors.

- Running with Scissors is a 2006 film based on the memoir of the same title.

- Us is a 2019 psychological horror film directed by Jordan Peele about a family confronted by their scissor-wielding doppelgängers.

Games

[edit]- The game Rock paper scissors involves two or more players making shapes with their hands to determine the outcome of the game. One of the three shapes, 'scissors', is made by extending the index and middle fingers to mimic the shape of most scissors.

- In the horror video game franchise, Clock Tower, there is a character called Scissorman. Although the identity is usually taken by multiple individuals throughout the series, Scissorman is usually portrayed as a demonic serial killer with a giant pair of scissors, and kills anyone without showing any signs of mercy or remorse.

- An anthropomorphic pair of scissors appears as a boss in Paper Mario: The Origami King. Various additions of scissor related activity appear as well, such as a variation of Rock paper scissors.[38]

Literature

[edit]Heinrich Hoffmann's 1845 children's book Struwwelpeter includes Die Geschichte vom Daumenlutscher ("The Story of the Thumb-Sucker") in which a child continues to suck his thumbs despite his mother's warnings about The Great Tall Scissorman.

Augusten Burroughs' 2002 memoir Running with Scissors spent eight weeks on the New York Times best seller list. The book was later adapted into a film.

Music

[edit]- Running with Scissors is the title of a 1999 album by "Weird Al" Yankovic.

- The song "The Tailor Shop on Enbizaka (円尾坂の仕立屋 Enbizaka no Shitateya)" from Vocaloid producer Akuno-P tells a story about a tailor that kills a man and his family, whom she mistakes for her unfaithful lover and his three mistresses, using her sewing scissors.

- The XTC song "Scissor Man", later covered by Primus.

- "Save Your Scissors" – song by City and Colour.

- The song "Scissors" by American Rock Band "Slipknot"

Proverbs

[edit]Proverbs about scissors are found in many language communities.

- "Dull scissors don't cut straight." English[39]

- "An old bachelor is only half a pair of scissors." English[40]

- "A man without a woman like half a scissors, that would not cut but scratch." Romanian[41]

- "Scissors do not cut out the scissors' nail." Hungarian[42]

- "A face shaped like petals of the lotus, a voice as cool as sandal, a heart like a pair of scissors, and excessive humility, these are the signs of a rogue." Sanskrit[43]

- "Those who have scissors are many but those who sew are none." Pagu[44]

- "Spoon, fork, scissors, and lamp are not for little children." Volga German[45]

Sport

[edit]The term 'scissor kick' may be found in several sports, including:

- Scissor kick (strike), a generic martial arts term for any of a number of moves that may resemble the appearance or action of a pair of scissors.

- Bicycle kicks in football are sometimes known as 'scissor kicks'.

- Swimming strokes including the sidestroke incorporate a leg movement often known as a 'scissor kick'.

Superstition

[edit]Scissors have a widespread place in cultural superstitions. In many cases, the details of the superstition may be specific to a given country, region, tribe, religion or even situation.

- Africa

- In parts of North Africa, it was held that scissors could be used to curse a bridegroom. When the bridegroom was on horseback, the person enacting the curse would stand behind him with the scissors open and call his name. If the bridegroom answered to his name being called, the scissors would then be snapped shut and the bridegroom would be unable to consummate his marriage with his bride.[46]

- Asia

- In Pakistan, some believe that scissors should never be idly opened and closed without purpose; this is believed to cause bad luck.[citation needed]

- Western Europe

- As iron was believed to ward off fairies, British parents traditionally hung a pair of iron scissors over cradles to keep fairies away. Sometimes the scissors were kept open to make the shape of a cross for extra protection.[47]

- North America

- United States

- In New Orleans, some believed that putting an open pair of scissors underneath your pillow at night was a sound method for sleeping well, even if one is cursed.[48]

- United States

- Eastern Europe

- In some Eastern European countries, it is believed that leaving scissors open causes fights and disagreements within a household.[citation needed]

- China

- In China, it is believed that to give scissors to a friend or loved one is to be cutting ties with them.[citation needed]

Science

[edit]Scissors have been used in the sciences for various purposes, including descriptions of animals or natural features.

Nature

[edit]Animals named after scissors include:

- Birds

- The scissor-tailed flycatcher of North and Central America.

- The scissor-tailed hummingbird

- The scissor-tailed kite, a bird that is widespread throughout Africa.

- The scissor-tailed nightjar of South America.

- Fish

- The scissor-tail rasbora, several species of fish that are commonly used for freshwater aquariums.[49][50]

Gallery

[edit]-

Chinese scissors, early to mid-Tang dynasty

-

A pair of iron scissors dating from the Han dynasty

-

Fiskars scissors from 1967

-

Embroidery scissors in the form of a crane

-

A pair of shears

-

Scissors for cutting carpet pile

-

These scissors are used in Japan to cut threads in sewing.

-

Scissors, pre-1850s iron from Norway, used to cut cloth

-

Chinese-style scissors seen in a Hangzhou museum

See also

[edit]- Hemostat resembles a pair of scissors, but is used as a clamp in surgery and does not cut at all.

- Nippers cut (break) small pieces out of tile.

- Pliers used for holding and crimping metal or wire.

- Tijeras Canyon a geological feature in New Mexico, US and Tijeras a village in the same canyon, after "scissors" in Spanish.

References

[edit]- ^ "Definition of SCISSORS". Merriam-Webster. Retrieved 2023-04-27.

- ^ "Definition of SHEAR". Merriam-Webster. Retrieved 2023-04-27.

- ^ "pair of scissors". Collins Dictionary. Retrieved April 27, 2023.

- ^ "Shears: Roman Period". Metropolitan Museum. n.d. Archived from the original on 2018-07-18. Retrieved 2018-07-18.

- ^ "History 101: Scissors". Daily Kos. Archived from the original on 2022-04-09. Retrieved 2022-02-28.

- ^ Zoom Inventors and Inventions Archived 2017-09-10 at the Wayback Machine. Enchanted Learning. Retrieved 2010-11-05.

- ^ a b Sudworth, John (2013-04-22). "The scissor-maker that has cut through Chinese history". BBC News. Archived from the original on 2018-05-05. Retrieved 2018-07-21.

- ^ "History". William Whiteley & Sons. Archived from the original on 2014-12-08. Retrieved 2015-01-20.

- ^ Leader, Robert Eadon (1901). [Reminiscences of] Sheffield in the Eighteenth Century. Sheffield: The Sheffield Independent Press Limited. pp. 69–70.

- ^ The Observatory of Economy Complexity, trade data for scissors as of 2019 Archived 2022-01-06 at the Wayback Machine. Retrieved 11/29/21.

- ^ (2014-11-03) "History 101: Scissors" Archived 2022-01-06 at the Wayback Machine, Daily KOS. Retrieved 12-04-21

- ^ "Re-editions of Vintage Scissors" Archived 2022-01-06 at the Wayback Machine, Sajou Blog. Retrieved 01-06-22

- ^ Official Website for Tourism in Champagne-Ardenne Archived 2022-01-06 at the Wayback Machine. Retrieved 01-06-22

- ^ Alastair (2020-01-12) "Thiers: Cutlery Capital of France" Archived 2022-01-06 at the Wayback Machine. Mechtravller. Retrieved 01-06-22

- ^ The Observatory of Economy Complexity, trade data for scissors as of 2019. Archived 2022-01-06 at the Wayback Machine Retrieved 12/04/21.

- ^ Zautor, Capital (2019-04-13) "How the Knife Makers from Solingen Survived" Archived 2022-01-06 at the Wayback Machine. Retrieved 12/04/21

- ^ Zautor, Capital (2019-04-13) "How the Knife Makers from Solingen Survived" Archived 2022-01-06 at the Wayback Machine. Retrieved 12/04/21

- ^ Friedrich Herder: Company History. Archived 2022-01-06 at the Wayback Machine Retrieved 12/04/21

- ^ Municipality of Premana: Economy. Archived 2022-01-07 at the Wayback Machine Retrieved 11/27/21.

- ^ Ecco Lecco Tourist Guide to Lecco Province: Premana. Archived 2022-01-07 at the Wayback Machine Retrieved 11/27/21.

- ^ The Observatory of Economy Complexity, trade data for scissors as of 2019. Archived 2022-01-06 at the Wayback Machine Retrieved 12/04/21.

- ^ Ambrogio Sanelli: Company History. Archived 2021-05-10 at the Wayback Machine Retrieved 11/27/21.

- ^ Sibert, Jake (2018-09-19) "See Why This Pair of Scissors Costs $35,000 USD" Archived 2022-01-06 at the Wayback Machine, HypeBeast Great Big Story. Retrieved 12-04-21.

- ^ Visit Seki Official Guide, Gifu Prefecture. Archived 2022-01-06 at the Wayback Machine Retrieved 12/04/21

- ^ Kitajima Y., Kito K., Migaki M., Matsumuro K., Murata Y., Hamada H. (2015) Process Analysis of Manufacturing of Sewing Scissors by All Forging Process and Understanding of Its Sharpness. In: Duffy V. (eds) Digital Human Modeling. Applications in Health, Safety, Ergonomics and Risk Management: Human Modeling. Archived 2022-04-09 at the Wayback Machine DHM 2015. Lecture Notes in Computer Science, vol 9184. Springer, Cham.

- ^ Ken (2019-12-27), "Sasuke: Witness the Art of Japanese Blacksmithing in Osaka" Archived 2022-01-06 at the Wayback Machine, Matcha Japan. Retrieved 12/04/21.

- ^ Kazue (2021-04-19) "Discovering Quality Japanese Scissors and Knives" Archived 2022-01-06 at the Wayback Machine. Retrieved 12-04-21

- ^ Sibert, Jake (2018-09-19) "See Why This Pair of Scissors Costs $35,000 USD" Archived 2022-01-06 at the Wayback Machine, HypeBeast Great Big Story. Retrieved 12-04-21

- ^ Pallarès Solsona: Company History. Archived 2022-01-06 at the Wayback Machine Retrieved 11/27/21.

- ^ "The Makers: Carving a Place in History" Archived 2022-01-06 at the Wayback Machine, Reste Journal. Retrieved 11/27/21

- ^ Scissor-Making: Red List of Endangered Crafts Archived 2022-01-06 at the Wayback Machine, British Heritage Crafts Association. Retrieved 11/27/21

- ^ William Whiteley: Heritage. Archived 2022-01-06 at the Wayback Machine Retrieved 12/04/21

- ^ Floyd, Charlie (2021-04-04) "Why Ernest Wright Scissors are so expensive" Archived 2022-01-07 at the Wayback Machine. Business Insider. Retrieved 11/27/21

- ^ Scissor-Making: Red List of Endangered Crafts Archived 2022-01-06 at the Wayback Machine, British Heritage Crafts Association. Retrieved 11/27/21

- ^ Carpenter, Daniel (2020-10-08), "Winners of the 2020 Heritage Crafts Awards" Archived 2022-01-06 at the Wayback Machine. Retrieved 11/27/21

- ^ "What's the Difference Between Right- and Left-Handed Scissors?" Kim Griffin, Griffin Occupational Therapy Blog. https://www.griffinot.com/difference-left-handed-scissors/ Archived 2021-11-27 at the Wayback Machine, retrieved 11/27/21

- ^ "Do You Know – Left-Handed Scissors" Olive Branch Educators, https://www.obeducators.com/reflections/do-you-know-left-handed-scissors Archived 2021-11-27 at the Wayback Machine, retrieved 11/27/21

- ^ "Paper Mario: The Origami King Wiki Guide: Bowser's Castle". IGN. 2020-08-20. Archived from the original on 2022-03-10. Retrieved 2022-04-09.

- ^ p. 527. Mieder, Wolfgang, Stewart Kingsbury, Kelsie Harder. 1992. A Dictionary of American Proverbs. Oxford University Press.

- ^ p. 50. Christy, Robert. Proverbs, Maxims and Phrases of All Ages, Volume 1. Putnam. 1889.

- ^ p. 28. Bărbulescu, Elena. "Constructing Gender in Romanian Proverbs." Studia Universitatis Babeş-Bolyai-Historia 57, no. Special (2012): 21-33.

- ^ p. 22, Vargha, Katalin, and Anna T. Litovkina. "Punning in Hungarian anti-proverbs." The European Journal of Humour Research 1, no. 3 (2013): 15-25.

- ^ p. 445. Carr, Mark William.Sanskrit Proverbs. Asian Educational Services, 1999.

- ^ p. 333, Perangin-Angin, Dalan M., and Novita Dewi. "A study of Pagu proverbs: Saving an endangered language of North Halmahera." Indonesian Journal of Applied Linguistics 10, no. 2 (2020): 327-339.

- ^ p. 56, Gabel, Marie. "Proverbs of Volga German settlers in Ellis County." Heritage of Kansas v.9 no.2-3:55-59, (2012).

- ^ Radford, Edwin; Radford, Mona A. (October 2004). Encyclopedia of Superstitions 1949 – Edwin Radford, Mona A. Radford – Google Boeken. Kessinger. ISBN 9781417976553. Archived from the original on 2022-04-09. Retrieved 2012-02-28.

- ^ Fairies and Elves By Shannon Knudsen p.27

- ^ Hearn, Lafcadio (1886). "New Orleans Superstitions". Internet Sacred Text Archive. Archived from the original on 2012-01-27. Retrieved 2012-02-28.

- ^ "Scissortail – Rasbora trilineata". Aquaticcommunity. Archived from the original on 2012-03-18. Retrieved 2012-02-28.

- ^ Mike. "Scissor Tail Rasbora Care (Rasbora trilineata)". FishLore. Archived from the original on 2017-04-28. Retrieved 2012-02-28.

External links

[edit] Media related to Scissors at Wikimedia Commons

Media related to Scissors at Wikimedia Commons

KSF

KSF