Jute

From Britannica 11th Edition (1911)

From Britannica 11th Edition (1911) Jute, a vegetable fibre now occupying a position in the manufacturing scale inferior only to cotton and flax. The term jute appears to have been first used in 1746, when the captain of the “Wake” noted in his log that he had sent on shore “60 bales of gunney with all the jute rope” (New Eng. Dict. s.v.). In 1795 W. Roxburgh sent to the directors of the East India Company a bale of the fibre which he described as “the jute of the natives.” Importations of the substance had been made at earlier times under the name of pāt, an East Indian native term by which the fibre continued to be spoken of in England till the early years of the 19th century, when it was supplanted by the name it now bears. This modern name appears to be derived from jhot or jhout (Sansk. jhat), the vernacular name by which the substance is known in the Cuttack district, where the East India Company had extensive roperies when Roxburgh first used the term.

|

| Fig. 1.—Capsules of Jute Plants. a, Corchorus capsularis; b, C. olitorius. |

The fibre is obtained from two species of Corchorus (nat. ord. Tiliaceae), C. capsularis and C. olitorius, the products of both being so essentially alike that neither in commerce nor agriculture is any distinction made between them. These and various other species of Corchorus are natives of Bengal, where they have been cultivated from very remote times for economic purposes, although there is reason to believe that the cultivation did not originate in the northern parts of India. The two species cultivated for jute fibre are in all respects very similar to each other, except in their fructification and the relatively greater size attained by C. capsularis. They are annual plants from 5 to 10 ft. high, with a cylindrical stalk as thick as a man’s finger, and hardly branching except near the top. The light-green leaves are from 4 to 5 in. long by 1½ in. broad above the base, and taper upward into a fine point; the edges are serrated; the two lower teeth are drawn out into bristle-like points. The small whitish-yellow flowers are produced in clusters of two or three opposite the leaves.

The capsules or seed-pods in the case of C. capsularis are globular, rough and wrinkled, while in C. olitorius they are slender, quill-like cylinders (about 2 in. long), a very marked distinction, as may be noted from fig. 1, in which a and b show the capsules of C. capsularis and C. olitorius respectively. Fig. 2 represents a flowering top of C. olitorius.

Both species are cultivated in India, not only on account of their fibre, but also for the sake of their leaves, which are there extensively used as a pot-herb. The use of C. olitorius for the latter purpose dates from very ancient times, if it may be identified, as some suppose, with the mallows (מלוח) mentioned in Job xxx. 4; hence the name Jew’s mallow. It is certain that the Greeks used this plant as a pot-herb; and by many other nations around the shores of the Mediterranean this use of it was, and is still, common. Throughout Bengal the name by which the plants when used as edible vegetables are recognized is nalitā; when on the other hand they are spoken of as fibre-producers it is generally under the name pāt. The cultivation of C. capsularis is most prevalent in central and eastern Bengal, while in the neighbourhood of Calcutta, where, however, the area under cultivation is limited, C. olitorius is principally grown. The fibre known as China jute or Tien-tsin jute is the product of another plant, Abutilon Avicennae, a member of the Mallow family.

Cultivation and Cropping.—Attempts have been made to grow the jute plant in America, Egypt, Africa and other places, but up to the present the fibre has proved much inferior to that obtained from plants grown in India. Here the cultivation of the plant extends from the Hugli through eastern and northern Bengal. The successful cultivation of the plant demands a hot, moist climate, with a fair amount of rain. Too much rain at the beginning of the season is detrimental to the growth, while a very dry season is disastrous. The climate of eastern and northern Bengal appears to be ideal for the growth of the plant.

The quality of the fibre and the produce per acre depend in a measure on the preparation of the soil. The ground should be ploughed about four times and all weeds removed. The seed is then sown broadcast as in the case of flax. It is only within quite recent years that any attention has been paid to the selection of the seed. The following extract from Capital (Jan. 17, 1907) indicates the new interest taken in it.

“Jute seed experiments are being continued and the report for 1906 has been issued. The object of these experiments is, of course, to obtain a better class of jute seed by growing plants, especially for no other purpose than to obtain their seed. The agricultural department has about 300 maunds (25,000 ℔) of selected seed for distribution this year. The selling price is to be Rs. 10 per maund. The agricultural department of the government of Bengal are now fully alive to the importance of fostering the jute industry by showing conclusively that attention to scientific agriculture will make two maunds of jute grow where only one maund grew before. Let them go on (as they will) till all the ryots are thoroughly indoctrinated into the new system.”

The time of sowing extends from the middle of March to the middle of June, while the reaping, which depends upon the time of sowing and upon the weather, is performed from the end of June to the middle of October. The crop is said to be ready for gathering when the flowers appear; if gathered before, the fibre is weak, while if left until the seed is ripe, the fibre is stronger, but is coarser and lacks the characteristic lustre.

The fibre is separated from the stalks by a process of retting similar to that for flax and hemp. In certain districts of Bengal it is the practice to stack the crop for a few days previous to retting in order to allow the leaves to dry and to drop off the stalks. It is stated that the colour of the fibre is darkened if the leaves are allowed to remain on during the process of retting. It is also thought that the drying of the plants before retting facilitates the separation of the fibre. Any simple operation which improves the colour of the fibre or shortens the operation of retting is worthy of consideration. The benefits to be derived from the above process, however, cannot be great, for the bundles are usually taken direct to the pools and streams. The period necessary for the completion of the retting process varies according to the temperature and to the properties of the water, and may occupy from two days to a month. After the first few days of immersion the stalks are examined daily to test the progress of the retting. When the fibres are easily separated from the stalk, the operation is complete and the bundles should be withdrawn. The following description of the retting of jute is taken from Royle’s Fibrous Plants of India:—

“The proper point being attained, the native operator, standing up to his middle in water, takes as many of the sticks in his hands as he can grasp, and removing a small portion of the bark from the ends next the roots, and grasping them together, he strips off the whole with a little management from end to end, without breaking either stem or fibre. Having prepared a certain quantity into this half state, he next proceeds to wash off: this is done by taking a large handful; swinging it round his head he dashes it repeatedly against the surface of the water, drawing it through towards him, so as to wash off the impurities; then, with a dexterous throw he fans it out on the surface of the water and carefully picks off all remaining black spots. It is now wrung out so as to remove as much water as possible, and then hung up on lines prepared on the spot, to dry in the sun.”

The separated fibre is then made up into bundles ready for sending to one of the jute presses. The jute is carefully sorted into different qualities, and then each lot is subjected to an enormous hydraulic pressure from which it emerges in the shape of the well-known bales, each weighing 400 ℔.

The crop naturally depends upon the quality of the soil, and upon the attention which the fibre has received in its various stages; the yield per acre varies in different districts. Three bales per acre, or 1200 ℔ is termed a 100% crop, but the usual quantity obtained is about 2.6 bales per acre. Sometimes the crop is stated in lakhs of 100,000 bales each. The crop in 1906 reached nearly 9,000,000 bales, and in 1907 nearly 10,000,000 was reached. The following particulars were issued on the 19th of September 1906 by Messrs. W. F. Souter & Co., Dundee:—

| Year. | Actual acreage. |

Estimated yield (100% equal 3 bales per acre). |

Estimated total crop. Bales. |

Shipment to Europe. | Shipment to America. | Supplies to Indian mills and local consumption. |

Out-turn total crop. Bales. | ||

| Jute. Bales. |

Cuttings. Bales. |

Jute. Bales. |

Cuttings. Bales. | ||||||

| 1901—1st | 2,216,500 | 94% = | 6,250,000 | ||||||

| Final | 2,249,000 | 96% = | 6,500,000 | 3,528,691 | 54,427 | 295,921 | 426,331 | 3,100,000 = | 7,405,370 |

| 1902—1st | 2,200,000 | 80% = | 5,280.000 | ||||||

| Final | 2,200,000 | 80% = | 5,280,000 | 2,773,621 | 39,019 | 230,415 | 207,999 | 2,600,000 = | 5,851,054 |

| 1903—1st | 2,100,000 | 85% = | 5,400,000 | ||||||

| Final | 2,250,000 | 93¾% = | 6,500,000 | 3,161,791 | 59,562 | 329,048 | 236,959 | 3,650,000 = | 7,437,360 |

| 1904—1st | 2,700,000 | 87½% = | 7,100,000 | ||||||

| Final | 2,850,000 | 85% = | 7,400,000 | 2,939,940 | 44,002 | 253,882 | 290,854 | 3,475,782 = | 7,004,460 |

| 1905—1st | 3,163,500 | 87% = | 8,250,000 | ||||||

| Final | 3,145,000 | 87% = | 8,200,000 | 3,483,315 | 63,118 | 347,974 | 245,044 | 4,018,523 = | 8,233,358 |

| Outlying | 200,000 | ||||||||

| Madras | 75,384 | ||||||||

| 1906—1st | 3,271,400 | 87% = | 8,713,000 | ||||||

| Outlying | 67,000 | Madras | 100,000 | ||||||

| Final | 3,336,400 | 8,736,220 | |||||||

| (Outlying Districts and Madras, say 250,000 bales additional) | |||||||||

Estimated consumption of jute 1906-1907.

| In Europe | Bales per annum. | ||

| Scotland | 1,250,000 | ||

| England | 20,000 | ||

| Ireland | 25,000 | ||

| France | 475,000 | ||

| Belgium | 120,000 | ||

| Germany | 750,000 | ||

| Austria and Bohemia | 262,000 | ||

| Norway and Sweden | 62,500 | ||

| Russia | 180,000 | ||

| Holland | 25,000 | ||

| Spain | 90,000 | ||

| Italy | 160,000 | ||

| ——— | 3,419,500 | bales | |

| In America | 600,000 | ||

| ——— | 600,000 | ” | |

| In India— | |||

| Mills | 3,900,000 | ||

| Local | 500,000 | ||

| ———— | 4,400,000 | ” | |

| ——————— | |||

| 8,419,500 | bales | ||

Statistics of consumption of jute, rejections and cuttings.

| Consumption. | 1894. Bales. | 1904. Bales. | 1906. Bales. |

| United Kingdom | 1,200,000 | 1,200,000 | 1,295,000 |

| Continent | 1,100,000 | 1,800,000 | 2,124,500 |

| America | 500,000 | 500,000 | 600,000 |

| Indian mills | 1,500,000 | 2,900,000 | 3,900,000 |

| Local Indian consumption | 500,000 | 500,000 | 500,000 |

| Total jute crop consumption | 4,800,000 | 6,900,000 | 8,419,500 |

A number of experiments in jute cultivation were made during 1906, and the report showed that very encouraging results were obtained from land manured with cow-dung. If more scientific attention be given to the cultivation it is quite possible that what is now considered as 100% yield may be exceeded.

Characteristics.—The characters by which qualities of jute are judged are colour, lustre, softness, strength, length, firmness, uniformity and absence of roots. The best qualities are of a clear whitish-yellow colour, with a fine silky lustre, soft and smooth to the touch, and fine, long and uniform in fibre. When the fibre is intended for goods in the natural colour it is essential that it should be of a light shade and uniform, but if intended for yarns which are to be dyed a dark shade, the colour is not so important. The cultivated plant yields a fibre with a length of from 6 to 10 ft., but in exceptional cases it has been known to reach 14 or 15 ft. in length. The fibre is decidedly inferior to flax and hemp in strength and tenacity; and, owing to a peculiarity in its microscopic structure, by which the walls of the separate cells composing the fibre vary much in thickness at different points, the single strands of fibre are of unequal strength. Recently prepared fibre is always stronger, more lustrous, softer and whiter than such as has been stored for some time—age and exposure rendering it brown in colour and harsh and brittle in quality. Jute, indeed, is much more woody in texture than either flax or hemp, a circumstance which may be easily demonstrated by its behaviour under appropriate reagents; and to that fact is due the change in colour and character it undergoes on exposure to the air. The fibre bleaches with facility, up to a certain point, sufficient to enable it to take brilliant and delicate shades of dye colour, but it is with great difficulty brought to a pure white by bleaching. A very striking and remarkable fact, which has much practical interest, is its highly hygroscopic nature. While in a dry position and atmosphere it may not possess more than 6% of moisture, under damp conditions it will absorb as much as 23%.

Sir G. Watt, in his Dictionary of the Economic Products of India, mentions the following eleven varieties of jute fibre: Serajganji, Narainganji, Desi, Deora, Uttariya, Deswāl, Bākrabadi, Bhatial, Karimginji, Mirganji and Jungipuri. There are several other varieties of minor importance. The first four form the four classes into which the commercial fibre is divided, and they are commonly known as Serajgunge, Naraingunge, Daisee and Dowrah. Serajgunge is a soft fibre, but it is superior in colour, which ranges from white to grey. Naraingunge is a strong fibre, possesses good spinning qualities, and is very suitable for good warp yarns. Its colour, which is not so high as Serajgunge, begins with a cream shade and approaches red at the roots. All the better class yarns are spun from these two kinds. Daisee is similar to Serajgunge in softness, is of good quality and of great length; its drawback is the low colour, and hence it is not so suitable for using in natural colour. It is, however, a valuable fibre for carpet yarns, especially for dark yarns. Dowrah is a strong, harsh and low quality fibre, and is used principally for heavy wefts. Each class is subdivided according to the quality and colour of the material, and each class receives a distinctive mark called a baler’s mark. Thus, the finest fibres may be divided as follows:—

| Superfine | first marks. | |||

| Extra fine | first marks | 1st, 2nd | and 3rd | numbers. |

| Superior | first marks | ” | ” | ” |

| Standard | ” | ” | ” | ” |

| Good | ” | ” | ” | ” |

| Ordinary | ” | ” | ” | ” |

| Good | second marks | ” | ” | ” |

| Ordinary | ” | ” | ” | ” |

The lower qualities are, naturally, divided into fewer varieties.

|

| Fig. 2.—Corchorus olitorius. |

Each baler has his own marks, the fibres of which are guaranteed equal in equality to some standard mark. It would be impossible to give a list of the different marks, for there are hundreds, and new marks are constantly being added. A list of all the principal marks is issued in book form by the Calcutta Jute Baler’s association.

The relative prices of the different classes depend upon the crop, upon the demand and upon the quality of the fibre; in 1905 the prices of Daisee jute and First Marks were practically the same, although the former is always considered inferior to the latter. It does not follow that a large crop of jute will result in low prices, for the year 1906-1907 was not only a record one for crops, but also for prices. R. F. C. grade has been as high as £40 per ton, while its lowest recorded price is £12. Similarly the price for First Marks reached £29, 15s. in 1906 as compared with £9, 5s. per ton in 1897. The following table shows a few well-known grades with the average prices during December for the years 1903, 1904, 1905 and 1906.

| Class. | Dec. 1903. | Dec. 1904. | Dec. 1905. | Dec. 1906. | ||||||||

| £ | s. | d. | £ | s. | d. | £ | s. | d. | £ | s. | d. | |

| First marks | 12 | 15 | 0 | 16 | 0 | 0 | 19 | 15 | 0 | 27 | 15 | 0 |

| Blacks S C C | 11 | 2 | 6 | 14 | 5 | 0 | 17 | 15 | 0 | 20 | 15 | 0 |

| Red S C C | 12 | 0 | 0 | 14 | 17 | 6 | 18 | 15 | 0 | 23 | 15 | 0 |

| Native rejections | 8 | 2 | 6 | — | 14 | 10 | 0 | 15 | 17 | 6 | ||

| S 4 group | — | — | 25 | 10 | 0 | 38 | 0 | 0 | ||||

| R F block D group | — | — | — | 36 | 0 | 0 | ||||||

| R F circle D group | 14 | 10 | 0 | 16 | 15 | 0 | 21 | 10 | 0 | — | ||

| R F D group | 11 | 15 | 0 | 14 | 2 | 6 | 17 | 12 | 6 | 22 | 0 | 0 |

| N B green D | 14 | 5 | 0 | — | 21 | 0 | 0 | 32 | 0 | 0 | ||

| Heart T 4 | 14 | 12 | 6 | 17 | 10 | 0 | 22 | 10 | 0 | 34 | 0 | 0 |

| Heart T 5 | 14 | 12 | 6 | 17 | 10 | 0 | 21 | 0 | 0 | 31 | 0 | 0 |

| Daisee 2 | 12 | 17 | 6 | — | 18 | 15 | 0 | 25 | 10 | 0 | ||

| Daisee assortment | 12 | 10 | 0 | 14 | 17 | 6 | 18 | 5 | 0 | — | ||

| Mixed cuttings | 4 | 5 | 0 | — | 10 | 0 | 0 | 10 | 0 | 0 | ||

Jute Manufacture.—Long before jute came to occupy a prominent place amongst the textile fibres of Europe, it formed the raw material of a large and important industry throughout the regions of Eastern Bengal. The Hindu population made the material up into cordage, paper and cloth, the chief use of the latter being in the manufacture of gunny bags. Indeed, up to 1830-1840 there was little or no competition with hand labour for this class of material. The process of weaving gunnies for bags and other coarse articles by these hand-loom weavers has been described as follows:—

“Seven sticks or chattee weaving-posts, called tanā parā or warp, are fixed upon the ground, occupying the length equal to the measure of the piece to be woven, and a sufficient number of twine or thread is wound on them as warp called tanā. The warp is taken up and removed to the weaving machine. Two pieces of wood are placed at two ends, which are tied to the ohari and okher or roller; they are made fast to the khoti. The belut or treadle is put into the warp; next to that is the sarsul; a thin piece of wood is laid upon the warp, called chupari or regulator. There is no sley used in this, nor is a shuttle necessary; in the room of the latter a stick covered with thread called singa is thrown into the warp as woof, which is beaten in by a piece of plank called beyno, and as the cloth is woven it is wound up to the roller. Next to this is a piece of wood called khetone, which is used for smoothing and regulating the woof; a stick is fastened to the warp to keep the woof straight.”

Gunny cloth is woven of numerous qualities, according to the purpose to which it is devoted. Some kinds are made close and dense in texture, for carrying such seed as poppy or rape and sugar; others less close are used for rice, pulses, and seeds of like size, and coarser and opener kinds again are woven for the outer cover of packages and for the sails of country boats. There is a thin close-woven cloth made and used as garments among the females of the aboriginal tribes near the foot of the Himalayas, and in various localities a cloth of pure jute or of jute mixed with cotton is used as a sheet to sleep on, as well as for wearing purposes. To indicate the variety of uses to which jute is applied, the following quotation may be cited from the official report of Hem Chunder Kerr as applying to Midnapur.

“The articles manufactured from jute are principally (1) gunny bags; (2) string, rope and cord; (3) kampa, a net-like bag for carrying wood or hay on bullocks; (4) chat, a strip of stuff for tying bales of cotton or cloth; (5) dola, a swing on which infants are rocked to sleep; (6) shika, a kind of hanging shelf for little earthen pots, &c.; (7) dulina, a floor-cloth; (8) beera, a small circular stand for wooden plates used particularly in poojahs; (9) painter’s brush and brush for white-washing; (10) ghunsi, a waist-band worn next to the skin; (11) gochh-dari, a hair-band worn by women; (12) mukbar, a net bag used as muzzle for cattle; (13) parchula, false hair worn by players; (14) rakhi-bandhan, a slender arm-band worn at the Rakhi-poornima festival; and (15) dhup, small incense sticks burned at poojahs.”

The fibre began to receive attention in Great Britain towards the close of the 18th century, and early in the 19th century it was spun into yarn and woven into cloth in the town of Abingdon. It is claimed that this was the first British town to manufacture the material. For years small quantities of jute were imported into Great Britain and other European countries and into America, but it was not until the year 1832 that the fibre may be said to have made any great impression in Great Britain. The first really practical experiments with the fibre were made in this year in Chapelshade Works, Dundee, and these experiments proved to be the foundation of an enormous industry. It is interesting to note that the site of Chapelshade Works was in 1907 cleared for the erection of a large new technical college.

In common with practically all new industries progress was slow for a time, but once the value of the fibre and the cloth produced from it had become known the development was more rapid. The pioneers of the work were confronted with many difficulties; most people condemned the fibre and the cloth, many warps were discarded as unfit for weaving, and any attempt to mix the fibre with flax, tow or hemp was considered a form of deception. The real cause of most of these objections was the fact that suitable machinery and methods of treatment had not been developed for preparing yarns from this useful fibre. Warden in his Linen Trade says:—

“For years after its introduction the principal spinners refused to have anything to do with jute, and cloth made of it long retained a tainted reputation. Indeed, it was not until Mr. Rowan got the Dutch government, about 1838, to substitute jute yarns for those made from flax in the manufacture of the coffee bagging for their East Indian possessions, that the jute trade in Dundee got a proper start. That fortunate circumstance gave an impulse to the spinning of the fibre which it never lost, and since that period its progress has been truly astonishing.”

The demand for this class of bagging, which is made from fine hessian yarns, is still great. These fine Rio hessian yarns form an important branch of the Dundee trade, and in some weeks during 1906 as many as 1000 bales were despatched to Brazil, besides numerous quantities to other parts of the world.

For many years Great Britain was the only European country engaged in the manufacture of jute, the great seat being Dundee. Gradually, however, the trade began to extend, and now almost every European country is partly engaged in the trade.

The success of the mechanical method of spinning and weaving of jute in Dundee and district led to the introduction of textile machinery into and around Calcutta. The first mill to be run there by power was started in 1854, while by 1872 three others had been established. In the next ten years no fewer than sixteen new mills were erected and equipped with modern machinery from Great Britain, while in 1907 there were thirty-nine mills engaged in the industry. The expansion of the Indian power trade may be gathered from the following particulars of the number of looms and spindles from 1892 to 1906. In one or two cases the number of spindles is obtained approximately by reckoning twenty spindles per loom, which is about the average for the Indian mills.

| Year. | Looms. | Spindles. |

| 1892-3 | 8,479 | 177,732 |

| 1893-4 | 9,082 | 189,144 |

| 1894-5 | 9,504 | 197,673 |

| 1895-6 | 10,071 | 212,595 |

| 1896-7 | 12,276 | 254,610 |

| 1897-8 | 12,737 | 271,363 |

| 1898-9 | 13,323 | 277,398 |

| 1899-1900 | 14,021 | 293,218 |

| 1900-01 | 15,242 | 315,264 |

| 1901-02 | 16,059 | 329,300 |

| 1902-03 | 17,091 | 350,120 |

| 1904* | 19,901 | 398,020** |

| 1905* | 21,318 | 426,360** |

| 1906* | 26,799 | 520,980** |

* End of calendar year, the remainder being taken to the 31st of March, the end of financial year.

** Approximate number of spindles.

The Calcutta looms are engaged for the most part with a few varieties of the commoner classes of jute fabrics, but the success in this direction has been really remarkable. Dundee, on the other hand, turns out not only the commoner classes of fabrics, but a very large variety of other fabrics. Amongst these may be mentioned the following: Hessian, bagging, tarpaulin, sacking, scrims, Brussels carpets, Wilton carpets, imitation Brussels, and several other types of carpets, rugs and matting, in addition to a large variety of fabrics of which jute forms a part. Calcutta has certainly taken a large part of the trade which Dundee held in its former days, but the continually increasing demands for jute fabrics for new purposes have enabled Dundee to enter new markets and so to take part in the prosperity of the trade.

The development of the trade with countries outside India from 1828 to 1906 may be seen by the following figures of exports:—

| Average | per year | from | 1828 | to | 1832-33 | 11,800 | cwt. |

| ” | ” | ” | 1833-34 | ” | 1837-38 | 67,483 | ” |

| ” | ” | ” | 1838-39 | ” | 1842-43 | 117,047 | ” |

| ” | ” | ” | 1843-44 | ” | 1847-48 | 234,055 | ” |

| ” | ” | ” | 1848-49 | ” | 1852-53 | 439,850 | ” |

| ” | ” | ” | 1853-54 | ” | 1857-58 | 710,826 | ” |

| ” | ” | ” | 1858-59 | ” | 1862-63 | 969,724 | ” |

| ” | ” | ” | 1863-64 | ” | 1867-68 | 2,628,110 | ” |

| ” | ” | ” | 1868-69 | ” | 1872-73 | 4,858,162 | ” |

| ” | ” | ” | 1873-74 | ” | 1877-78 | 5,362,267 | ” |

| ” | ” | ” | 1878-79 | ” | 1882-83 | 7,274,000 | ” |

| ” | ” | ” | 1883-84 | ” | 1887-88 | 8,223,859 | ” |

| ” | ” | ” | 1888-89 | ” | 1892-93 | 10,372,991 | ” |

| ” | ” | ” | 1893-94 | ” | 1897-98 | 12,084,292 | ” |

| ” | ” | ” | 1898-99 | ” | 1902-03 | 11,959,189 | ” |

| ” | ” | ” | 1903-04 | ” | 1905-06 | 13,693,090 | ” |

The subjoined table shows the extent of the trade from an agricultural, as well as from a manufacturing, point of view. The difference between the production and the exports represents the native consumption, for very little jute is sent overland. The figures are taken to the 31st of March, the end of the Indian financial year.

| Year. | Acres under cultivation. | Production in cwt. | Exports by sea in cwt. |

| 1893 | 2,181,334 | 20,419,000 | 10,537,512 |

| 1894 | 2,230,570 | 17,863,000 | 8,690,133 |

| 1895 | 2,275,335 | 21,944,400 | 12,976,791 |

| 1896 | 2,248,593 | 19,825,000 | 12,266,781 |

| 1897 | 2,215,105 | 20,418,000 | 11,464,356 |

| 1898 | 2,159,908 | 24,425,000 | 15,023,325 |

| 1899 | 1,690,739 | 19,050,000 | 9,864,545 |

| 1900 | 2,070,668 | 19,329,000 | 9,725,245 |

| 1901 | 2,102,236 | 23,307,000 | 12,414,552 |

| 1902 | 2,278,205 | 26,564,000 | 14,755,115 |

| 1903 | 2,142,700 | 23,489,000 | 13,036,486 |

| 1904 | 2,275,050 | 25,861,000 | 13,721,447 |

| 1905 | 2,899,700 | 26,429,000 | 12,875,312 |

| 1906 | 3,181,600 | 29,945,000 | 14,581,307 |

Manufacture.—In their general features the spinning and weaving of jute fabrics do not differ essentially as to machinery and processes from those employed in the manufacture of hemp and heavy flax goods. Owing, however, to the woody and brittle nature of the fibre, it has to undergo a preliminary treatment peculiar to itself. The pioneers of the jute industry, who did not understand this necessity, or rather who did not know how the woody and brittle character of the fibre could be remedied, were greatly perplexed by the difficulties they had to encounter, the fibre spinning badly into a hard, rough and hairy yarn owing to the splitting and breaking of the fibre. This peculiarity of jute, coupled also with the fact that the machinery on which it was first spun, although quite suitable for the stronger and more elastic fibres for which it was designed, required certain modifications to suit it to the weaker jute, was the cause of many annoyances and failures in the early days of the trade.

|

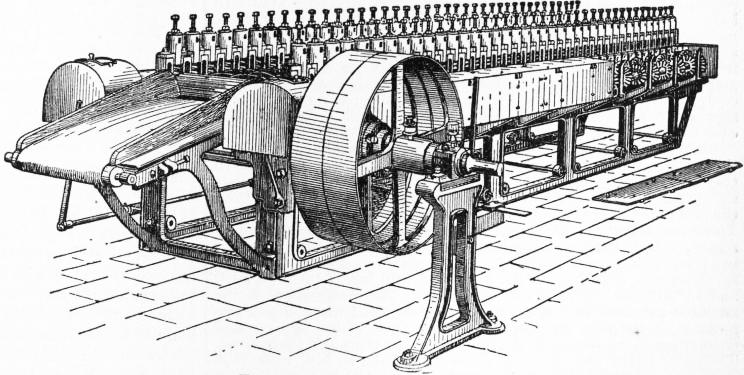

| Fig. 3.—Jute Opener. (The three machines shown in this article are made by Urquhart, Lindsay & Co., Ltd., Dundee.) |

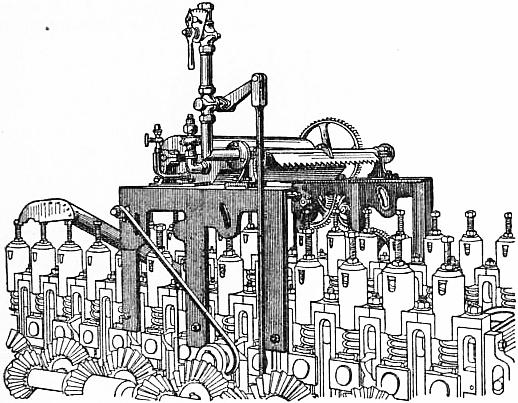

The first process in the manufacture of jute is termed batching. Batch setting is the first part of this operation; it consists of selecting the different kinds or qualities of jute for any predetermined kind of yarn. The number of bales for a batch seldom exceeds twelve, indeed it is generally about six, and of these there may be three, four or even more varieties or marks. The “streaks”1 or “heads” of jute as they come from the bale are in a hard condition in consequence of having been subjected to a high hydraulic pressure during baling; it is therefore necessary to soften them before any further process is entered. The streaks are sometimes partly softened or crushed by means of a steam hammer during the process of opening the bale, then taken to the “strikers-up” where the different varieties are selected and hung on pins, and then taken to the jute softening machine. The more general practice, however, is to employ what is termed a “bale opener,” or “jute crusher.” The essential parts of one type of bale opener are three specially shaped rollers, the peripheries of which contain a number of small knobs. Two of these rollers are supported in the same horizontal plane of the framework, while the third or top roller is kept in close contact by means of weights and springs acting on each end of the arbor. Another type of machine termed the three pair roller jute opener is illustrated in fig. 3. The layers from the different bales are laid upon the feed cloth which carries them up to the rollers, between which the layers are crushed and partly separated. The proximity of the weighted roller or rollers to the fixed ones depends upon the thickness of material passing through the machine. The fibre is delivered by what is called the delivery cloth, and the batcher usually selects small streaks of about 1½ ℔ to 2 ℔ weight each and passes them on to the attendant or feeder of the softening machine. These small streaks are now laid as regularly as possible upon the feed-cloth of the softening machine, a general view of which is shown in fig. 4. The fibre passes between a series of fluted rollers, each pair of which is kept in contact by spiral springs as shown in the figure. The standard number of pairs is sixty-three, but different lengths obtain. There is also a difference in the structure of the flutes, some being straight, and others spiral, and each pair may or may not contain the same number of flutes. The springs allow the top rollers of each pair to rise as the material passes through the machine. Advantage is taken of this slight upward and downward movement of the top rollers to automatically regulate the flow of water and oil upon the material. The apparatus for this function is placed immediately over the 11th and 12th rollers of the softening machine and an idea of its construction may be gathered from fig. 5. In many cases the water and oil are applied by less automatic, but equally effective, means. The main object is to see that the liquids are distributed evenly while the fibre is passing through, and to stop the supply when the machine stops or when no fibre is passing. The uniform moistening of the fibre in this machine facilitates the subsequent operations, indeed the introduction of this preliminary process (originally by hand) constituted the first important step in the practical solution of the difficulties of jute spinning. The relative quantities of oil and water depend upon the quality of the batch. Sometimes both whale and mineral oils are used, but in most cases the whale oil is omitted. About 1 to 1¼ gallons of oil is the usual amount given per bale of 400 ℔ of jute, while the quantity of water per bale varies from 3 to 7 gallons. The delivery attendants remove the streaks, give them a twist to facilitate future handling, and place them on what are termed jute barrows. The streaks are now handed over to the cutters who cut off the roots, and finally the material is allowed to remain for twelve to twenty-four hours to allow the mixture of oil and water to thoroughly spread over the fibre.

|

| Fig. 4.—Jute Softening Machine. |

|

| Fig. 5.—Improved Batching Gear. |

When the moisture has spread sufficiently, the material is taken to the “breaker card,” the first machine in the preparing department. A certain weight of jute, termed a “dollop,” is laid upon the feed cloth for each revolution of the latter. The fibre, which should be arranged on the sheet as evenly as possible, is carried up by the feed cloth and passes between the feed roller and the shell on to the large cylinder. This cylinder, which has a high surface speed, carries part of the fibre towards the workers and strippers; the surface speed of the workers being much slower than that of the cylinder. The pins in the two rollers oppose each other, those of the workers being “back-set,” and this arrangement, combined with the relative angle of the pins, and the difference in the surface speeds of the two rollers, results in part of the fibre being broken and carried round by the worker towards the stripper. This, as its name implies, strips the fibre off the worker, and carries it round to the cylinder. The pins of the stripper and cylinder point in the same direction, but since the surface speed of the cylinder is much greater than the surface speed of the stripper, it follows that the fibre is combed between the two, and that part is carried forward by the cylinder to be reworked. The strippers and workers are in pairs, of which there may be two or more. After passing the last pair of workers and strippers the fibre is carried forward towards the doffing roller, the pins of which are back-set, and the fibre is removed from the cylinder by the doffer, from which it passes between the drawing and pressing rollers into the conductor, and finally between the delivery and pressing rollers into the sliver can. It may be mentioned that more or less breaking takes place between each pair of rollers, the pins of which are opposed, and that combing and drawing out obtains between those rollers with pins pointing in the same direction. The ratio of the surface speeds of the drawing roller and the feed roller is termed the draft:—

| surface speed of drawing roller | = draft. |

| surface speed of feed roller |

In this machine the draft is usually about thirteen.

The sliver from the can of the breaker card may be wound into balls, or it may be taken direct to the finisher card. In the latter method from eight to fifteen cans are placed behind the feed rollers, and all the slivers from these cans are united before they emerge from the machine. The main difference between a breaker card and a finisher card is that the latter is fitted with finer pins, that it contains two doffing rollers, and that it usually possesses a greater number of pairs of workers and strippers—a full circular finisher card having four sets.

After the fibre has been thoroughly carded by the above machines, the cans containing the sliver from the finisher card are taken to the first drawing frame. A very common method is to let four slivers run into one sliver at the first drawing, then two slivers from the first drawing are run into one sliver at the second drawing frame. There are several types of drawing frames, e.g. push-bar or slide, rotary, spiral, ring, open-link or chain, the spiral being generally used for the second drawing. All, however, perform the same function, viz., combing out the fibres and thus laying them parallel, and in addition drawing out the sliver. The designation of the machine indicates the particular method in which the gill pins are moved. These pins are much finer than those of the breaker and finisher cards, consequently the fibres are more thoroughly separated. The draft in the first drawing varies from three to five, while that in the second drawing is usually five to seven. It is easy to see that a certain amount of draft, or drawing out of the sliver, is necessary, otherwise the various doublings would cause the sliver to emerge thicker and thicker from each machine. The doublings play a very important part in the appearance of the ultimate rove and yarn, for the chief reason for doubling threads or slivers is to minimize irregularities of thickness and of colour in the material. In an ordinary case, the total doublings in jute from the breaker card to the end of the second drawing is ninety-six: 12 × 4 × 2 = 96; and if the slivers were made thinner and more of them used the ultimate result would naturally be improved.

The final preparing process is that of roving. In this operation there is no doubling of the slivers, but each sliver passes separately through the machine, from the can to the spindle, is drawn out to about eight times its length, and receives a small amount of twist to strengthen it, in order that it may be successfully wound upon the roving bobbin by the flyer. The chief piece of mechanism in the roving frame is the gearing known as the “differential motion.” It works in conjunction with the disk and scroll, the cones, or the expanding pulley, to impart an intermittingly variable speed to the bobbin (each layer of the bobbin has its own particular speed which is constant for the full traverse, but each change of direction of the builder is accompanied by a quick change of speed to the bobbin). It is essential that the bobbin should have such a motion, because the delivery of the sliver and the speed of the flyer are constant for a given size of rove, whereas the layers of rove on the bobbin increase in length as the bobbin fills. In the jute roving frame the bobbin is termed the “follower,” because its revolutions per minute are fewer than those of the flyer. Each layer of rove increases the diameter of the material on the bobbin shank; hence, at the beginning of each layer, the speed of the bobbin must be increased, and kept at this increased speed for the whole traverse from top to bottom or vice versa.

| Let R = the revolutions per second of the flyer; r = the revolutions per second of the bobbin; d = the diameter of bobbin shaft plus the material; L = the length of sliver delivered per second; then (R − r) d·π = L. |

In the above expression R, π and L are constant, therefore as d increases the term (R − r) must decrease; this can happen only when r is increased, that is, when the bobbin revolves quicker. It is easy to see from the above expression that if the bobbin were the “leader” its speed would have to decrease as it filled.

The builder, which receives its motion from the disk and scroll, from the cones, or from the expanding pulley, has also an intermittingly variable speed. It begins at a maximum speed when the bobbin is empty, is constant for each layer, but decreases as the bobbin fills.

The rove yarn is now ready for the spinning frame, where a further draft of about eight is given. The principles of jute spinning are similar to those of dry spinning for flax. For very heavy jute yarns the spinning frame is not used—the desired amount of twist being given at the roving frame.

The count of jute yarn is based upon the weight in pounds of 14,400 yds., such length receiving the name of “spyndle.” The finest yarns weigh 2¾ ℔ to 3 ℔ per spyndle, but the commonest kinds are 7 ℔, 8 ℔, 9 ℔ and 10 ℔ per spyndle. The sizes rise in pounds up to about 20 ℔, then by 2 ℔ up to about 50 ℔ per spyndle, with much larger jumps above this weight. It is not uncommon to find 200 ℔ to 300 ℔ rove yarn, while the weight occasionally reaches 450 ℔ per spyndle. The different sizes of yarn are extensively used in a large variety of fabrics, sometimes alone, sometimes in conjunction with other fibres, e.g. with worsted in the various kinds of carpets, with cotton in tapestries and household cloths, with line and tow yarns for the same fabrics and for paddings, &c., and with wool for horse clothing. The yarns are capable of being dyed brilliant colours, but, unfortunately, the colours are not very fast to light. The fibre can also be prepared to imitate human hair with remarkable closeness, and advantage of this is largely taken in making stage wigs.

For detailed information regarding jute, the cloths made from it and the machinery used, see the following works: Watts’s Dictionary of the Economic Products of India; Royle’s Fibrous Plants of India; Sharp’s Flax, Tow and Jute Spinning; Leggatt’s Jute Spinning; Woodhouse and Milne’s Jute and Linen Weaving; and Woodhouse and Milne’s Textile Design: Pure and Applied.

1 Also in the forms “streek,” “strick” or “strike,” as in Chaucer, Cant. Tales, Prologue 676, where the Pardoner’s hair is compared with a “strike of flax.” The term is also used of a handful of hemp or other fibre, and is one of the many technical applications of “strike” or “streak,” which etymologically are cognate words.

↧ Download as ZWI file | Last modified: 11/17/2022 15:23:51 | 26 views

☰ Source: https://oldpedia.org/article/britannica11/Jute | License: Public domain in the USA. Project Gutenberg License

ZWI signed:

ZWI signed: KSF

KSF