Furnace

From Britannica 11th Edition (1911)

From Britannica 11th Edition (1911) Furnace, a contrivance for the production and utilization of heat by the combustion of fuel. The word is common to all the Romance tongues, appearing in more or less modified forms of the Latin fornax. But in all those languages the word has a more extended meaning than in English, as it covers every variety of heating apparatus; while here, in addition to furnaces proper, we distinguish other varieties as ovens, stoves and kilns. The first of these, in the form Ofen, is used in German as a general term like the French four; but in English it has been restricted to those apparatus in which only a moderate temperature, usually below a red heat, is produced in a close chamber. Our bakers’ ovens, hot-air ovens or stoves, annealing ovens for glass or metal, &c., would all be called fours in French and Öfen in German, in common with furnaces of all kinds. Stove, an equivalent of oven, is from the German Stube, i.e. a heated room, and is commonly so understood; but is also applied to open fire-places, which appears to be somewhat of a departure from the original signification.

Furnaces are constructed according to many different patterns with varying degrees of complexity in arrangement; but all may be considered as combining three essential parts, namely, the fire-place in which the fuel is consumed, the heated chamber, laboratory, hearth or working bed, as it is variously called, where the heat is applied to the special work for which the furnace is designed, and the apparatus for producing rapid combustion by the supply of air under pressure to the fire. In the simplest cases the functions of two or more of these parts may be combined into one, as in the smith’s forge, where the fire-place and heating chamber are united, the iron being placed among the coals, only the air for burning being supplied under pressure from a blowing engine by a second special contrivance, the tuyere, tuiron, twyer or blast-pipe; but in the more refined modern furnaces, where great economy of fuel is an object, the different functions are distributed over separate and distinct apparatus, the fuel being converted into gas in one, dried in another, and heated in a third, before arriving at the point of combustion in the working chamber of the furnace proper.

Furnaces may be classified according as the products of combustion are employed (1) only for heating purposes, or (2) both for heating and bringing about some chemical change. The furnaces employed for steam-raising or for heating buildings are invariably of the first type (see Boiler and Heating), while those employed in metallurgy are generally of the second. The essential difference in construction is that in the first class the substances heated do not come into contact with either the fuel or the furnace gases, whereas in the second they do. Metallurgical furnaces of the first class are termed crucible, muffle or retort furnaces, and of the second shaft and reverberatory furnaces. The following is a detailed subdivision:—

(1) Fuel and substance in contact.

(a) Height of furnace greater than diameter = shaft furnaces.

(α) No blast = kilns.

(β) With blast = blast furnaces.

(b) Height not much greater than diameter = hearth furnaces.

(2) Substance heated by products of combustion = reverberatory furnaces.

(a) Charge not melted = roasting or calcining furnaces.

(b) Charge melted = melting furnaces.

(3) Substance is not directly heated by the fuel or by the products of combustion.

(a) Heating chamber fixed and forming part of furnace = muffle furnaces.

(b) Crucible furnaces.

(c) Retort furnaces.

Another classification may be based upon the nature of the heating agent, according as it is coal (or some similar combustible) oil, gas or electricity. In this article the general principles of metallurgical furnaces will be treated; the subject of gas- and oil-heated furnaces is treated in the article Fuel, and of the electric furnace in the article Electrometallurgy. For special furnaces reference should be made to the articles on the industry concerned, e.g. Glass, Gas, § Manufacture, &c.

Shaft, Blast and Hearth Furnaces.—The blast furnace in its simplest form is among the oldest, if not the oldest, of metallurgical contrivances. In the old copper-smelting district of Arabia Petraea, clay blast-pipes dating back to the earlier dynasties of ancient Egypt have been found buried in slag heaps; and in India the native smiths and iron-workers continue to use furnaces of similar types. These, when reduced to their most simple expression, are mere basin-shaped hollows in the ground, containing ignited charcoal and the substances to be heated, the fire being urged by a blast of air blown in through one or more nozzles from a bellows at or near the top. They are essentially the same as the smith’s forge. This class of furnace is usually known as an open fire or hearth, and is represented in a more advanced stage of development by the Catalan, German and Walloon forges formerly used in the production of malleable iron.

|

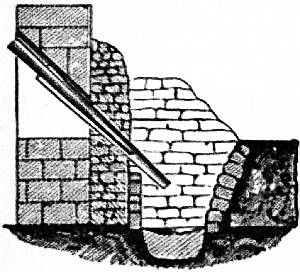

| Fig. 1.—Elevation of Catalan Forge. |

Fig. 1 represents a Catalan forge. The cavity in the ground is represented by a pit of square or rectangular section lined with brick or stone of a kind not readily acted on by heat, about 1½ or 2 ft. deep, usually somewhat larger above than below, with a tuyere or blast-pipe of copper penetrating one of the walls near the top, with a considerable downward inclination, so that the air meets the fuel some way down. In iron-smelting the ore is laid in a heap upon the fuel (charcoal) filling up the hearth, and is gradually brought to the metallic state by the reducing action of the carbon monoxide formed at the tuyere. The metal sinks through the ignited fuel, forming, in the hearth, a spongy mass or ball, which is lifted out by the smelters at the end of each operation, and carried to the forge hammer. The earthy matters form a fusible glass or slag melt, and collect at the lowest point of the hearth, whence they are removed by opening a hole pierced through the front wall at the bottom. The active portion of such a furnace is essentially that above the blast-pipe, the function of the lower part being merely the collection of the reduced metal; the fire may therefore be regarded as burning in an unconfined space, with the waste of a large amount of its heating power. By continuing the walls of the hearth above the tuyere, into a shaft or stack either of the same or some other section, we obtain a furnace of increased capacity, but with no greater power of consuming fuel, in which the material to be treated can be heated up gradually by loading it into the stack, alternately with layers of fuel, the charge descending regularly to the point of combustion, and absorbing a proportion of the heat of the flame that went to waste in the open fire. This principle is capable of very wide extension, the blast furnace being mainly limited in height by the strength the column of materials or “burden” has to resist crushing, under the weight due to the head adopted, and the power of the blowing engine to supply blast of sufficient density to overcome the resistance of the closely packed materials to the free passage of the spent gases. The consuming power of the furnace or the rate at which it can burn the fuel supplied is measured by the number of tuyeres and their section.

The development of blast furnaces is practically the development of iron-smelting. The profile has been very much varied at different times. The earliest examples were square or rectangular in horizontal section, but the general tendency of modern practice is to substitute round sections, their construction being facilitated by the use of specially moulded bricks which have entirely superseded the sandstone blocks formerly used. The vertical section, on the other hand, is subject to considerable variation according to the work to which the furnace is applied. Where the operation is simply one of fusion, as in the iron-founder’s cupola, in which there is no very great change in volume in the materials on their descent to the tuyeres, the stack is nearly or quite straight-sided; but when, as is the case with the smelting of iron ores with limestone flux, a large proportion of volatile matter has to be removed in the process, a wall of varying inclination is used, so that the body of the furnace is formed of two dissimilar truncated cones, joined by their bases, the lower one passing downwards into a short, nearly cylindrical, position. For further consideration of this subject see Iron and Steel.

Hearth furnaces are employed in certain metallurgical operations, e.g. in the air-reduction process for smelting lead ores. The principle is essentially that of the Catalan forge. Such furnaces are very wasteful, and have little to recommend them (see Schnabel, Metallurgy, 1905, vol. 1. p. 409).

Reverberatory Furnaces.—Blast furnaces are, from the intimate contact between the burden to be smelted and the fuel, the least wasteful of heat; but their use supposes the possibility of obtaining fuel of good quality and free from sulphur or other substances likely to deteriorate the metal produced. In all cases, therefore, where it is desired to do the work out of contact with the solid fuel, the operation of burning or heat-producing must be performed in a special fire-place or combustion chamber, the body of flame and heated gas being afterwards made to act upon the surface of the material exposed in a broad thin layer in the working bed or laboratory of the furnace by reverberation from the low vaulted roof covering the bed. Such furnaces are known by the general name of reverberatory or reverbatory furnaces, also as air or wind furnaces, to distinguish them from those worked with compressed air or blast.

Originally the term cupola was used for the reverberatory furnace, but in the course of time it has changed its meaning, and is now given to a small blast furnace such as that used by iron-founders—reverberatory smelting furnaces in the same trade being called air furnaces.

|

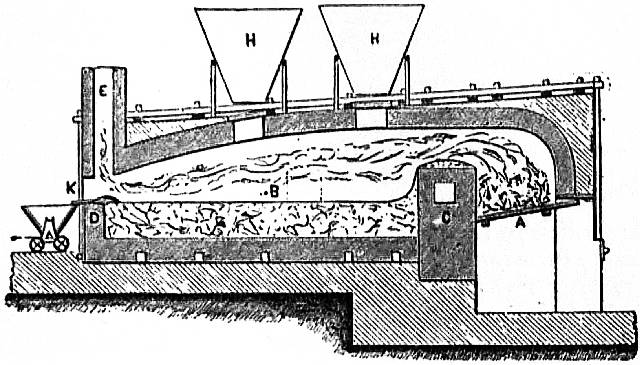

| Fig. 2.—Longitudinal section of Reverberatory Furnace. |

|

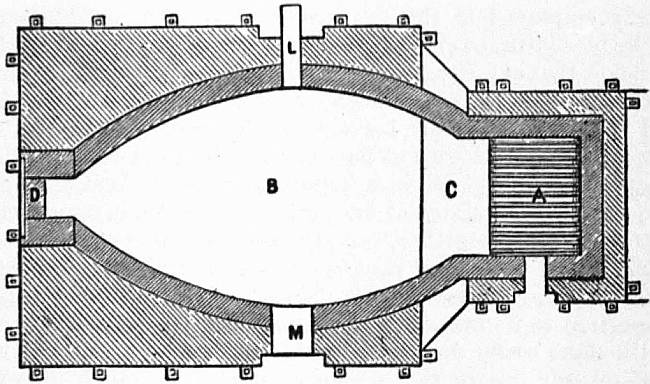

| Fig. 3.—Reverberatory Furnace (horizontal section). |

|

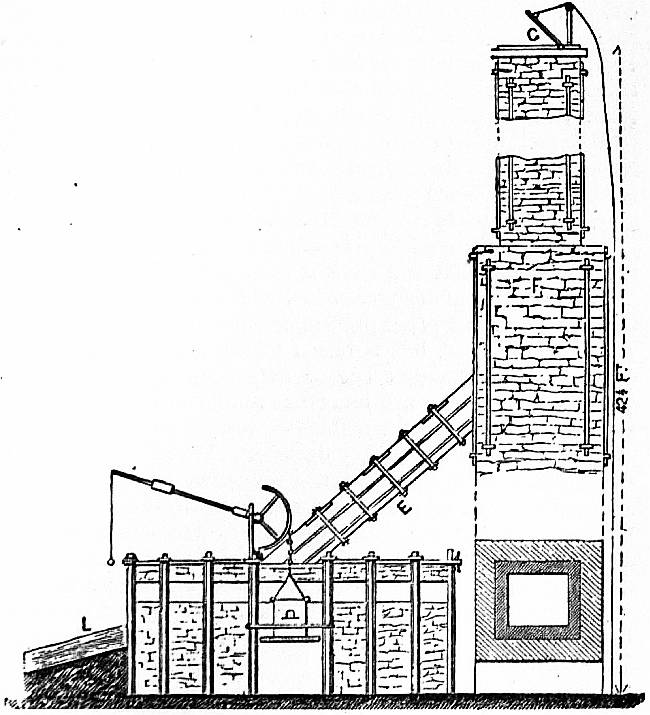

| Fig. 4.—Reverberatory Furnace (elevation at flue end). |

Figs. 2, 3 and 4 represent a reverberatory furnace such as is used for the fusion of copper ores for regulus, and may be taken as generally representing its class. The fire-place A is divided from the working bed B by a low wall C known as the fire bridge, and at the opposite end there is sometimes, though not invariably, a second bridge of less height called the flue bridge D. A short diagonal flue or up-take E conveys the current of spent flame to the chimney F, which is of square section, diminishing by steps at two or three different heights, and provided at the top with a covering plate or damper G, which may be raised or lowered by a chain reaching to the ground, and serves for regulating the speed of the exhaust gases, and thereby the draught of air through the fire. Where several furnaces are connected with the same chimney stack, the damper takes the form of a sliding plate in the mouth of the connecting flue, so that the draught in one may be modified without affecting the others. The fire bridge is partially protected against the intense heat of the body of flame issuing through the fire arch by a passage to which the air has free access. The material to be melted is introduced into the furnace from the hoppers HH through the charging holes in the roof. When melted the products separate on the bed (which is made of closely packed sand or other infusible substances), according to their density; the lighter earthy matters forming an upper layer of slag are drawn out by the slag hole K at the flue end into an iron wagon or bogie, while the metal subsides to the bottom of the bed, and at the termination of the operation is run out by the tap hole L into moulds or granulated into water. The opposite opening M is the working door, through which the tool for stirring the charge is introduced. It is covered by a plate suspended to a lever, similar to that seen in the end elevation (fig. 4) in front of the slag hole.

According to the purposes to which they are applied, reverberatory furnaces may be classed into two groups, namely, fusion or melting furnaces, and calcining or wasting furnaces, also called calciners. The former have a very extended application in many branches of industry, being used by both founders and smelters in the fusion of metals; in the concentration of poor metallic compounds by fusion into regulus; in the reduction of lead and tin ores; for refining copper and silver; and for making malleable iron by the puddling processes and welding. Calcining furnaces have a less extended application, being chiefly employed in the conversion of metallic sulphides into oxides by continued exposure to the action of air at a temperature far below that of fusion, or into chlorides by roasting with common salt. As some of these substances (for example, lead sulphide and copper pyrites) are readily fusible when first heated, but become more refractory as part of the sulphur is dissipated and oxygen takes its place, it is important that the heat should be very carefully regulated at first, otherwise the mass may become clotted or fritted together, and the oxidizing effect of the air soon ceases unless the fritted masses be broken small again. This is generally done by making the bed of the furnace very long in proportion to its breadth and to the fire-grate area, which may be the more easily done as a not inconsiderable amount of heat is given out during the oxidation of the ore—such increased length being often obtained by placing two or even three working beds one above the other, and allowing the flame to pass over them in order from below upwards. Such calciners are used especially in roasting zinc blende into zinc oxide, and in the conversion of copper sulphides into chlorides in the wet extraction process. In some processes of lead-smelting, where the minerals treated contain sand, the long calciner is provided with a melting bottom close to the fire-place, so that the desulphurized ore leaves the furnace as a glassy slag or silicate, which is subsequently reduced to the metallic state by fusion with fluxes in blast furnaces. Reverberatory furnaces play an important part in the manufacture of sodium carbonate; descriptions and illustrations are given in the article Alkali Manufacture.

Muffle, Crucible and Retort Furnaces.—A third class of furnaces is so arranged that the work is done by indirect heating; that is, the material under treatment, whether subjected to calcination, fusion or any other process, is not brought in contact either with fuel or flame, but is raised to the proper temperature by exposure in a chamber heated externally by the products of combustion. These are known as muffle or chamber furnaces; and by supposing the crucibles or retorts to represent similar chambers of only temporary duration, the ordinary pot melting air furnaces, and those for the reduction of zinc ores or the manufacture of coal gas, may be included in the same category. These are almost invariably air furnaces, though sometimes air under pressure is used, as, for example, in the combustion of small anthracitic coal, where a current of air from a fan-blower is sometimes blown under the grate to promote combustion. Types of muffle furnaces are figured in the article Annealing, Hardening and Tempering.

Furnace Materials.—The materials used in the construction of furnaces are divisible into two classes, namely, ordinary and refractory or fire-resisting. The former are used principally as casing, walls, pillars or other supporting parts of the structure, and includes ordinary red or yellow bricks, clay-slate, granite and most building stones; the latter are reserved for the parts immediately in contact with the fuel and flame, such as the lining of the fire-place, the arches, roof and flues, the lower part if not the whole of the chimney lining in reverberatory furnaces, and the whole of the internal walls of blast furnaces. Among such substances are fireclay and firebricks, certain sandstones, silica in the form of ganister, and Dinas stone and bricks, ferric oxide and alumina, carbon (as coke and graphite), magnesia, lime and chromium oxide—their relative importance being indicated by their order, the last two or three indeed being only of limited use.

The most essential point in good fireclays, or in the bricks or other objects made from them, is the power of resisting fusion at the highest heat to which they may be exposed. This supposes them to be free from metallic oxides forming easily fusible compounds with silica, such as lime or iron, the presence of the former even in comparatively small proportion being very detrimental. As clays they must be sufficiently plastic to be readily moulded, but at the same time possess sufficient stiffness not to contract too strongly in drying, whereby the objects produced would be liable to be warped or cracked before firing. In most cases, however, the latter tendency is guarded against, in making up the paste for moulding, by adding to the fresh clay a certain proportion of burnt material of the same kind, such as old bricks or potsherds, ground to a coarse powder. Coke dust or graphite is used for the same purpose in crucible making (see Firebrick).

The most highly valued fireclays are derived from the Coal Measures. Among the chief localities are the neighbourhood of Stourbridge in Worcestershire and Stannington near Sheffield, which supply most of the materials for crucibles used in steel and brass melting, and the pots for glass houses; Newcastle-on-Tyne and Glenboig near Glasgow, where heavy blast furnace and other firebricks, gas retorts, &c., are made in large quantities. Coarse-grained but very strong firebricks are also made of the waste of china clay works.

In Belgium the clay raised at Andenne is very largely used for making retorts for zinc furnaces. The principal French fireclays are derived from the Tertiary strata in the south, and more nearly resemble porcelain clays than those of the Coal Measures. They give wares of remarkably fine texture and surface, combined with high refractory character.

In Germany, Ips and Passau on the Danube, and Gross Almerode in Hesse, are the best known localities producing fireclay goods, the crucibles from the last-mentioned place, known as Hessian crucibles, going all over the world. These, though not showing a great resistance to extreme heat, are very slightly affected by sudden alternations in heating, as they may be plunged cold into a strongly heated furnace without cracking, a treatment to which French and Stourbridge pots cannot be subjected with safety.

Plumbago or graphite is largely used in the production of crucibles, not in the pure state but in admixture with fireclay; the proportion of the former varies with the quality from 25 to nearly 50%. These are the most enduring of all crucibles, the best lasting out 70 or 80 meltings in brass foundries, about 50 with bronze, and 8 to 10 in steel-melting.

Silica is used in furnace-building in the forms of sand, ganister, a finely ground sandstone from the Coal Measures of Yorkshire, and the analogous substance known as Dinas clay, which is really nearly pure silica, containing at most about 2½% of bases. Dinas clay is found at various places in the Vale of Neath in South Wales, in the form of a loose disintegrated sandstone, which is crushed between rollers, mixed with about 1% of lime, and moulded into bricks that are fired in kilns at a very high temperature. These bricks are specially used for the roof, fire arches, and other parts subjected to intense heat in reverberatory steel-melting furnaces, and, although infusible under ordinary conditions, are often fairly melted by the heat without fluxing or corrosion after a certain amount of exposure. Ganister, a slightly plastic siliceous sand, is similarly used for the lining of Bessemer steel converters; it is found in the neighbourhood of Sheffield.

Alumina as a refractory material is chiefly used in the form of bauxite, but its applications are somewhat special. It has been found to stand well for the linings of rotatory puddling furnaces, where, under long-continued heating, it changes into a substance as hard and infusible as natural emery. In the Paris Exhibition of 1878 bricks very hard and dense in character, said to be of pure alumina, were exhibited by Muller & Co. of Paris, as well as bricks of magnesia, the latter being specially remarkable for their great weight. They are intended for use at the extreme temperatures obtainable in steel furnaces, or for the melting of platinum before the oxy-hydrogen blowpipe. For the latter purpose, however, lime is generally used; but as this substance has only small stability, it is usually bedded in a casing of firebrick. Oxide of chromium and chrome iron ore have been proposed as refractory crucible materials. The former may be used as a bed for melting platinum in the same way as lime or magnesia, without affecting the quality of the metal.

Ferric oxide, though not strictly infusible, is largely used as a protecting lining for furnaces in which malleable iron is made, a portion of the ore being reduced and recovered in the process. In an oxidizing atmosphere it is indifferent to silica, and therefore siliceous bricks containing a considerable proportion of ferric oxide, when used in flues of boilers, brewers’ coppers, &c. and similar situations, are perfectly fire-resisting so long as the heated gas contains a large proportion of unconsumed air. The red firebricks known as Windsor bricks, which are practically similar in composition to soft red sandstone, are of this character.

The electric furnace has led to the discovery of several important materials, which have been employed as furnace linings. Carborundum (q.v.) was applied by Engels in 1899, firebricks being washed with carborundum paste and then baked. Siloxicon, a compound of carbon, silicon and oxygen, formed from carbon and silica in the electric furnace, was patented by E.G. Acheson in 1903. It is very refractory, and is applied by mixing with water and some bond, such as sodium silicate or gas-tar. An amorphous, soft silicon carbide, also formed in the electric furnace, was patented by B. Talbot in 1899. For basic linings, magnesia crystallized in the electric furnace is being extensively used, replacing dolomite to some extent (see E. Kilburn Scott, “Refractory Materials for Furnace Linings,” Faraday Soc., 1906, p. 289).

Furnace Construction.—In the construction of furnaces provision has to be made for the unequal expansion of the different parts under the effect of heat. This is especially necessary in the case of reverberatory furnaces, which are essentially weak structures, and therefore require to be bound together by complicated systems of tie rods and uprights or buck staves. The latter are very commonly made of old flat bottom rails, laid with the flat of the flange against the wall. Puddling furnaces are usually entirely cased with iron plates, and blast furnaces with hoops round each course of the stack, or in those of thinner constructions the firebrick work is entirely enclosed in a wrought iron casing or jacket. Such parts as may be subjected to extreme heat and the fretting action of molten material, as the tuyere and slag breasts of blast furnaces, and the fire bridges and bed plates of reverberatory furnaces, are often made in cast iron with double walls, a current of water or air being kept circulating through the intermediate space. In this way the metal, owing to its high conductivity and low specific heat as compared to that of water, is kept at a temperature far below its melting point if the water is renewed quickly enough. It is of course necessary in such cases that the circulation shall be perfectly free, in order to prevent the accumulation of steam under pressure in the interior of the casting. This method has received considerable extension, notably in furnace-smelting of iron ores containing manganese, where the entire hearth is often completely water-cased, and in some lead furnaces where no firebrick lining is used, the lower part of the furnace stack being a mere double iron box cooled by water sufficiently to keep a coating of slag adhering to the inner shell which prevents the metal from being acted upon.

Mechanical Furnaces.—The introduction and withdrawal of the charges in fusion furnaces is effected by gravitation, the solid masses of raw ore, fuel and flux being thrown in at the top, and flowing out of the furnace at the taphole or slag run at the bottom. Vertical kilns, such as those used for burning limestone, are worked in a similar manner—the raw stone going in at the top, and the burnt product falling through holes in the bottom when allowed to do so. With reverberatory calciners, however, where the work is done upon a horizontal bed, a considerable amount of hand labour is expended in raking out the charge when finished, and in drawing slags from fusion furnaces; and more particularly in the puddling process of refining iron the amount of manual exertion required is very much greater. To diminish the item of expenditure on this head, various kinds of mechanical furnaces have been adopted, all of which can be classified under three heads of gravitating furnaces, mechanical stirrers and revolving furnaces.

1. In gravitating furnaces the bed is laid at a slope just within the angle of repose of the charge, which is introduced at the upper end, and is pushed down the slope by fresh material, when necessary, in the contrary direction to the flame which enters at the lower end. Gerstenhofer’s pyrites burner is a furnace of this class. It has a tall vertical chamber heated from below, and traversed by numerous narrow horizontal cross bars at different heights. The ore in fine powder is fed in at the top, through a hopper, in a regular thin stream, by a pair of rollers, and in falling lodges on the flats of the bars, forming a talus upon each of the height corresponding to the angle of rest of the material, which is, however, at short intervals removed to lower levels by the arrival of fresh ore from above. In this way a very large surface is exposed to the heat, and the ore, if containing sufficient sulphur to maintain the combustion, is perfectly burned when it arrives at the bottom; if, however, it is imperfectly sized or damp, or if it contains much earthy matter, the result is not very satisfactory. There are many other furnaces in which the same principle is utilized.

2. Mechanical stirrers constitute a second division of mechanical furnaces, in which the labour of rabbling or stirring the charges is performed by combinations of levers and wheel-work taking motion from a rotating shaft, and more or less perfectly imitating the action of hand labour. They are almost entirely confined to puddling furnaces.

3. Revolving furnaces, the third and most important division of mechanical furnaces, are of two kinds. The first of these resemble an ordinary reverberatory furnace by having a flat bed which, however, has the form of a circular disk mounted on a central shaft, and receives a slow movement of rotation from a water-wheel or other motor, so that every part of the surface is brought successively under the action of the fire, the charge being stirred and ultimately removed by passing under a series of fixed scraper arms placed above the surface at various points. Brunton’s calciner, used in the “burning” of the pyritic minerals associated with tin ore, is a familiar example of this type. The hearth may either rotate on an inclined axis, so that the path of its surface is oblique to that of the flame, or the working part may be a hollow cylinder, between the fireplace and flue, with its axis horizontal or nearly so, whose inner surface represents the working bed, mounted upon friction rollers, and receiving motion from a special steam-engine by means of a central belt of spur gearing. Furnaces of the second kind were first used in alkali works for the conversion of sulphate into carbonate of sodium in the process known as black ash fusion, but have since been applied to other processes. As calciners they are used in tin mines and for the chlorination of silver ores. Mechanical furnaces are figured in the article Alkali Manufacture.

Use of Heated Air.—The calorific intensity of fuel is found to be very considerably enhanced, if the combustion be effected with air previously heated to any temperature between that of boiling water and a dull red heat, the same effect being observed both with solid and gaseous fuel. The latter, especially when brought to the burning point at a high temperature, produces a heat that can be resisted by the most refractory substances only, such as silica, alumina and magnesia. This is attained in the regenerative furnace of Siemens, detailed consideration of which belongs more properly to the subject of iron.

Economy of Waste Heat.—In every system of artificial heating, the amount of heat usefully applied is but a small proportion of that developed by combustion. Even under the most advantageous application, that of evaporation of water in a steam boiler where the gases of the fire have to travel through a great length of flues bounded by thin iron surfaces of great heat-absorbing capacity, the temperature of the current at the chimney is generally much above that required to maintain an active draught in the fireplace; and other tubes containing water, often in considerable numbers, forming the so-called fuel economizers, may often be interposed between the boiler and the chimney with marked advantage as regards saving of fuel. In reverberatory and air furnaces used in the different operations of iron manufacture, where an extremely high temperature has to be maintained in spaces of comparatively small extent, such as the beds of puddling, welding and steel-melting furnaces, the temperature of the exhaust gases is exceedingly high, and if allowed to pass directly into the chimney they appear as a great body of flame at the top. It is now general to save a portion of this heat by passing the flame through flues of steam boilers, air-heating apparatus, or both—so that the steam required for the necessary operations of the forge and heated blast for the furnace itself may be obtained without further expenditure of fuel. The most perfect method of utilizing the waste heat hitherto applied is that of the Siemens regenerator, in which the spent gases are made to travel through chambers, known as regenerators or recuperators of heat, containing a quantity of thin firebricks piled into a cellular mass so as to offer a very large heat-absorbing surface, whereby their temperature is very considerably reduced, and they arrive at the chimney at a heat not exceeding 300 or 400 degrees. As soon as the bricks have become red hot, the current is diverted to an adjacent chamber or pair of chambers, and the acquired heat is removed by a current of cool gas or air passing towards the furnace, where it arrives at a temperature sufficiently high to ensure the greatest possible heating effect in combustion.

In iron-smelting blast furnaces the waste gases are of considerable fuel value, and may render important services if properly applied. Owing to the conditions of the work, which require the maintenance of a sensibly reducing atmosphere, they contain a very notable proportion of carbonic oxide, and are drawn off by large wrought iron tubes near the top of the furnace and conveyed by branch pipes to the different boilers and air-heating apparatus, which are now entirely heated by the combustion of such gases, or mixed with air and exploded in gas engines. Formerly they were allowed to burn to waste at the mouth of a short chimney place above the furnace top, forming a huge body of flame, which was one of the most striking features of the Black Country landscape at night.

Laboratory and Portable Furnaces.—Small air-furnaces with hot plates or sand bath flues were formerly much employed in chemical laboratories, as well as small blast furnaces for crucibles heated with charcoal or coke. The use of such furnaces has very considerably diminished, owing to the general introduction of coal-gas for heating purposes in laboratories, which has been rendered possible by the invention of the Bunsen burner, in which the mixture of air and gas giving the least luminous but most powerfully heating flame is effected automatically by the effluent gas. These burners, or modifications of them, have also been applied to muffle furnaces, which are convenient when only a few assays have to be made—the furnace being a mere clay shell and soon brought to a working temperature; but the fuel is too expensive to allow of their being used habitually or on a large scale. Petroleum, or rather the heavy oils obtained in tar refineries, having an equal or superior heating power to coal-gas, may also be used in laboratories for producing high temperatures. The oil is introduced in a thin stream upon a series of inclined and channelled bars, where it is almost immediately volatilized and burnt by air flowing in through parallel orifices. Furnaces of this kind may be used for melting cast iron or bronze in small quantities, and were employed by H. Sainte Claire Deville in experiments in the metallurgy of the platinum group of metals.

Sefstrom’s blast furnace, used in Sweden for the assay of iron ores, is a convenient form of portable furnace applied to melting in crucibles. It consists of a sheet-iron cylinder about 8 or 9 in. in diameter, within which is fixed one of smaller size lined with fireclay. The space between the two cylinders serves as a heater and distributor for the blast, which is introduced through the nozzle at the bottom, and enters the furnace through a series of several small tuyeres arranged round the inner lining. Charcoal is the fuel used, and the crucibles stand upon the bottom of the clay lining. When a large body of fuel is required, the cylinder can be lengthened by an iron hoop which fits over the top ring. Deville’s portable blast furnace is very similar in principle to the above, but the body of the furnace is formed of a single cast iron cylinder lined with fireclay, closed below by a cast iron plate perforated by a ring of small holes—a hemispherical basin below forming the air-heating chamber.

↧ Download as ZWI file | Last modified: 11/17/2022 15:24:15 | 26 views

☰ Source: https://oldpedia.org/article/britannica11/Furnace | License: Public domain in the USA. Project Gutenberg License

ZWI signed:

ZWI signed: KSF

KSF