Lighting

From Britannica 11th Edition (1911)

From Britannica 11th Edition (1911) Lighting. Artificial light is generally produced by raising some body to a high temperature. If the temperature of a solid body be greater than that of surrounding bodies it parts with some of its energy in the form of radiation. Whilst the temperature is low these radiations are not of a kind to which the eye is sensitive; they are exclusively radiations less refrangible and of greater wave-length than red light, and may be called infra-red. As the temperature is increased the infra-red radiations increase, but presently there are added radiations which the eye perceives as red light. As the temperature is further increased, the red light increases, and yellow, green and blue rays are successively thrown off. On raising the temperature to a still higher point, radiations of a wave-length shorter even than violet light are produced, to which the eye is insensitive, but which act strongly on certain chemical substances; these may be called ultra-violet rays. Thus a very hot body in general throws out rays of various wave-length; the hotter the body the more of every kind of radiation will it throw out, but the proportion of short waves to long waves becomes vastly greater as the temperature is increased. Our eyes are only sensitive to certain of these waves, viz. those not very long and not very short. The problem of the artificial production of light with economy of energy is the same as that of raising some body to such a temperature that it shall give as large a proportion as possible of those rays which the eye is capable of feeling. For practical purposes this temperature is the highest temperature we can produce. As an illustration of the luminous effect of the high temperature produced by converting other forms of energy into heat within a small space, consider the following statements. If burned in ordinary gas burners, 120 cub. ft. of 15 candle gas will give a light of 360 standard candles for one hour. The heat produced by the combustion is equivalent to about 60 million foot-pounds. If this gas be burned in a modern gas-engine, about 8 million foot-pounds of useful work will be done outside the engine, or about 4 horse-power for one hour. If this be used to drive a dynamo for one hour, even if the machine has an efficiency of only 80%, the energy of the current will be about 6,400,000 foot-pounds per hour, about half of which, or only 3,200,000 foot-pounds, is converted into radiant energy in the electric arc. But this electric arc will radiate a light of 2000 candles when viewed horizontally, and two or three times as much when viewed from below. Hence 3 million foot-pounds changed to heat in the electric arc may be said roughly to affect our eyes six times as much as 60 million foot-pounds changed to heat in an ordinary gas burner.

Owing to the high temperature at which it remains solid, and to its great emissive power, the radiant body used for artificial illumination is usually some form of carbon. In an oil or ordinary coal-gas flame this carbon is present in minute particles derived from the organic substances with which the flame is supplied and heated to incandescence by the heat liberated in their decomposition, while in the electric light the incandescence is the effect of the heat developed by the electric current passed through a resisting rod or filament of carbon. In some cases, however, other substances replace carbon as the radiating body; in the incandescent gas light certain earthy oxides are utilized, and in metallic filament electric lamps such metals as tungsten or tantalum.

1. Oil Lighting

From the earliest times the burning of oil has been a source of light, but until the middle of the 19th century only oils of vegetable and animal origin were employed in indoor lamps for this purpose. Although many kinds were Vegetable and animal oils. used locally, only colza and sperm oils had any very extended use, and they have been practically supplanted by mineral oil, which was introduced as an illuminant in 1853. Up to the latter half of the 18th century the lamps were shallow vessels into which a short length of wick dipped; the flame was smoky and discharged acrid vapours, giving the minimum of light with the maximum of smell. The first notable improvement was made by Ami Argand in 1784. His burner consisted of two concentric tubes between which the tubular wick was placed; the open inner tube led a current of air to play upon the inner surface of the circular flame, whilst the combustion was materially improved by placing around the flame a chimney which rested on a perforated gallery a short distance below the burner. Argand’s original burner is the parent form of innumerable modifications, all more or less complex, such as the Carcel and the moderator.

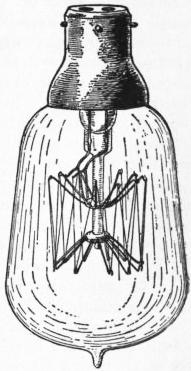

|

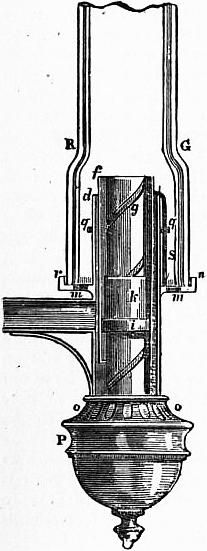

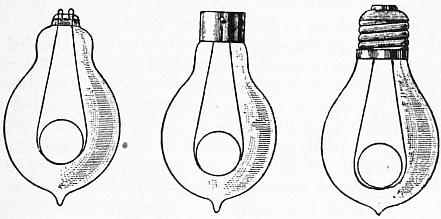

| Fig. 1. |

|

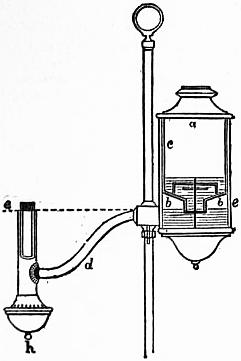

| Fig. 2.—Section of Reading Lamp. |

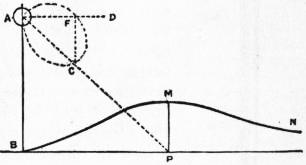

A typical example of the Argand burner and chimney is represented in fig. 1, in which the burner is composed of three tubes, d, f, g. The tube g is soldered to the bottom of the tube d, just above o, and the interval between the outer surface of the tube g and the inner surface of the tube d is an annular cylindrical cavity closed at the bottom, containing the cylindrical cotton wick immersed in oil. The wick is fixed to the wick tube ki, which is capable of being moved spirally; within the annular cavity is also the tube f, which can be moved round, and serves to elevate and depress the wick. P is a cup that screws on the bottom of the tube d, and receives the superfluous oil that drops down from the wick along the inner surface of the tube g. The air enters through the holes o, o, and passes up through the tube g to maintain the combustion in the interior of the circular flame. The air which maintains the combustion on the exterior part of the wick enters through the holes m, with which rn is perforated. When the air in the chimney is rarefied by the heat of the flame, the surrounding heavier air, entering the lower part of the chimney, passes upward with a rapid current, to restore the equilibrium. RG is the cylindrical glass chimney with a shoulder or constriction at R, G. The oil flows from a side reservoir, and occupies the cavity between the tubes g and d. The part ki is a short tube, which receives the circular wick, and slides spirally on the tube g, by means of a pin working in the hollow spiral groove on the exterior surface of g. The wick-tube has also a catch, which works in a perpendicular slit in the tube f; and, by turning the tube f, the wick-tube will be raised or lowered, for which purpose a ring, or gallery, rn, fits on the tube d, and receives the glass chimney RG; a wire S is attached to the tube f, and, bending over, descends along the outside of d. The part rn, that supports the glass chimney, is connected by four other wires with the ring q, which surrounds the tube d, and can be moved round. When rn is turned round, it carries with it the ring q, the wire S, and the tube f, thus raising or depressing the wick.

A device in the form of a small metallic disk or button, known as the Liverpool button from having been first adopted in the so-called Liverpool lamp, effects for the current of air passing up the interior of the Argand burner the same object as the constriction of the chimney RG secures in the case of the external tube. The button fixed on the end of a wire is placed right above the burner tube g, and throws out equally all round against the flame the current of air which passes up through g. The result of these expedients, when properly applied, is the production of an exceedingly solid brilliant white light, absolutely smokeless, this showing that the combustion of the oil is perfectly accomplished.

The means by which a uniformly regulated supply of oil is brought to the burner varies with the position of the oil reservoir. In some lamps, not now in use, by ring-formed reservoirs and other expedients, the whole of the oil was kept as nearly as possible at the level of the burner. In what are termed fountain reading, or study lamps, the principal reservoir is above the burner level, and various means are adopted for maintaining a supply from them at the level of the burner. But the most convenient position for the oil reservoir in lamps for general use is directly under the burner, and in this case the stand of the lamp itself is utilized as the oil vessel. In the case of fixed oils, as the oils of animal and vegetable origin used to be called, it is necessary with such lamps to introduce some appliance for forcing a supply of oil to the burner, and many methods of effecting this were devised, most of which were ultimately superseded by the moderator lamp. The Carcel or pump lamp, invented by B. G. Carcel in 1800, is still to some extent used in France. It consists of a double piston or pump, forcing the oil through a tube to the burner, worked by clockwork.

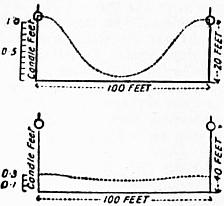

A form of reading lamp still in use is seen in section in fig. 2. The lamp is mounted on a standard on which it can be raised or lowered at will, and fixed by a thumb screw. The oil reservoir is in two parts, the upper ac being an inverted flask which fits into bb, from which the burner is directly fed through the tube d; h is an overflow cup for any oil that escapes at the burner, and it is pierced with air-holes for admitting the current of air to the centre tube of the Argand burner. The lamp is filled with oil by withdrawing the flask ac, filling it, and inverting it into its place. The under reservoir bb fills from it to the burner level ee, on a line with the mouth of ac. So soon as that level falls below the mouth of ac, a bubble of air gets access to the upper reservoir, and oil again fills up bb to the level ee.

|

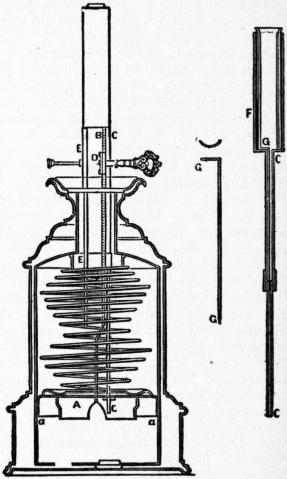

| Fig. 3.—Section of Moderator Lamp. |

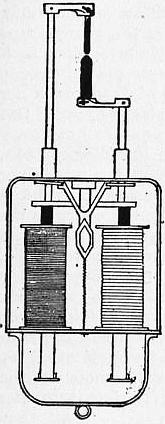

The moderator lamp (fig. 3), invented by Franchot about 1836, from the simplicity and efficiency of its arrangements rapidly superseded almost all other forms of mechanical lamp for use with animal and vegetable oils. The two essential features of the moderator lamp are (1) the strong spiral spring which, acting on a piston within the cylindrical reservoir of the lamp, serves to propel the oil to the burner, and (2) the ascending tube C through which the oil passes upwards to the burner. The latter consist of two sections, the lower fixed to and passing through the piston A into the oil reservoir, and the upper attached to the burner. The lower or piston section moves within the upper, which forms a sheath enclosing nearly its whole length when the spring is fully wound up. Down the centre of the upper tube passes a wire, “the moderator,” G, and it is by this wire that the supply of oil to the burner is regulated. The spring exerts its greatest force on the oil in the reservoir when it is fully wound up, and in proportion as it expands and descends its power decreases. But when the apparatus is wound up the wire passing down the upper tube extends throughout the whole length of the lower and narrower piston tube, obstructing to a certain extent the free flow of the oil. In proportion as the spring uncoils, the length of the wire within the lower tube is decreased; the upward flow of oil is facilitated in the same ratio as the force urging it upwards is weakened. In all mechanical lamps the flow is in excess of the consuming capacity of the burner, and in the moderator the surplus oil, flowing over the wick, falls back into the reservoir above the piston, whence along with new supply oil it descends into the lower side by means of leather valves a, a. B represents the rack which, with the pinion D, winds up the spiral spring hard against E when the lamp is prepared for use. The moderator wire is seen separately in GG; and FGC illustrates the arrangement of the sheathing tubes, in the upper section of which the moderator is fixed.

As early as 1781 the idea was mooted of burning naphtha, obtained by the distillation of coal at low temperatures, for illuminating purposes, and in 1820, when coal gas was struggling into prominence, light oils obtained Mineral oils. by the distillation of coal tar were employed in the Holliday lamp, which is still the chief factor in illuminating the street barrow of the costermonger. In this lamp the coal naphtha is in a conical reservoir, from the apex of which it flows slowly down through a long metal capillary to a rose burner, which, heated up by the flame, vaporizes the naphtha, and thus feeds the ring of small jets of flame escaping from its circumference.

It was in 1847 that James Young had his attention drawn to an exudation of petroleum in the Riddings Colliery at Alfreton, in Derbyshire, and found that he could by distillation obtain from it a lubricant of considerable value. The commercial success of this material was accompanied by a failure of the supply, and, rightly imagining that as the oil had apparently come from the Coal Measures, it might be obtained by distillation from material of the same character, Young began investigations in this direction, and in 1850 started distilling oils from a shale known as the “Bathgate mineral,” in this way founding the Scotch oil industry. At first little attention was paid to the fitness of the oil for burning purposes, although in the early days at Alfreton Young attempted to burn some of the lighter distillates in an Argand lamp, and later in a lamp made many years before for the consumption of turpentine. About 1853, however, it was noticed that the lighter distillates were being shipped to Germany, where lamps fitted for the consumption of the grades of oil now known as lamp oil were being made by Stohwasser of Berlin; some of these lamps were imported, and similar lamps were afterwards manufactured by Laidlaw in Edinburgh.

In Pennsylvania in 1859 Colonel E. L. Drake’s successful boring for petroleum resulted in the flooding of the market with oil at prices never before deemed possible, and led to the introduction of lamps from Germany for its consumption. Although the first American patent for a petroleum lamp is dated 1859, that year saw forty other applications, and for the next twenty years they averaged about eighty a year.

English lamp-makers were not behind in their attempts to improve on the methods in use for producing the highest results from the various grades of oil, and in 1865 Hinks introduced the duplex burner, while later improvements made in various directions, by Hinks, Silber, and Defries led to the high degree of perfection to be found in the lamps of to-day. Mineral oil for lamps as used in England at the present time may be defined as consisting of those portions of the distillate from shale oil or crude petroleum which have their flash-point above 73° F., and which are mobile enough to be fed by capillarity in sufficient quantity to the flame. The oil placed in the lamp reservoir is drawn up by the capillarity of the wick to the flame, and being there volatilized, is converted by the heat of the burning flame into a gaseous mixture of hydrogen and hydrocarbons, which is ultimately consumed by the oxygen of the air and converted into carbon dioxide and water vapour, the products of complete combustion.

To secure high illuminating power, together with a smokeless flame and only products of complete combustion, strict attention must be paid to several important factors. In the first place, the wick must be so arranged as to supply the right quantity of oil for gasification at the burner-head—the flame must be neither starved nor overfed: if the former is the case great loss of light is occasioned, while an excess of oil, by providing more hydrocarbons than the air-supply to the flame can completely burn, gives rise to smoke and products of incomplete combustion. The action of the wick depending on the capillary action of the microscopic tubes forming the cotton fibre, nothing but long-staple cotton of good quality should be employed; this should be spun into a coarse loose thread with as little twist in it as possible, and from this the wick is built up. Having obtained a wick of soft texture and loose plait, it should be well dried before the fire, and when put in position in the lamp must fill the wick-holder without being compressed. It should be of sufficient length to reach to the bottom of the oil reservoir and leave an inch or two on the bottom. Such a wick will suck up the oil in a regular and uniform way, provided that the level of the oil is not allowed to fall too low in the lamp, but it must be remembered that the wick acts as a filter for the oil, and that if any sediment be present it will be retained by and choke the capillaries upon which the action of the wick depends, so that a wick should not be used for too long a time. A good rule is that the wick should, when new, trail for 2 in. on the bottom of the oil vessel, and should be discarded when these 2 in. have been burnt off.

When the lamp is lighted the oil burns with a heavy, smoky flame, because it is not able to obtain sufficient oxygen to complete the combustion, and not only are soot flakes produced, but products of incomplete combustion, such as carbon monoxide and even petroleum vapour, escape—the first named highly injurious to health, and the second of an offensive odour. To supply the necessary amount of air to the flame, an artificial draught has to be created which shall impinge upon the bottom of the flame and sweep upwards over its surface, giving it rigidity, and by completing the combustion in a shorter period of time than could be done otherwise, increasing the calorific intensity and thus raising the carbon particles in the flame to a far higher incandescence so as to secure a greater illuminating power. This in practice has been done in two ways, first by drawing in the air by the up-suck of the heated and expanded products of combustion in a chimney fitted over the flame, and secondly by creating a draught from a small clockwork fan in the base of the lamp. It is necessary to break the initial rush of the draught: this is mostly effected by disks of perforated metal in the base of the burner, called diffusers, while the metal dome which surrounds and rises slightly above the wick-holder serves to deflect the air on to the flame, as in the Wanzer lamp. These arrangements also act to a certain extent as regenerators, the air passing over the heated metal surfaces being warmed before reaching the flame, whilst disks, cones, buttons, perforated tubes, inner air-tubes, &c., have been introduced to increase the illuminating power and complete the combustion.

Table I.

| Type. | Name. | Grains of Oil per candle-power per hour. | Total Candle-power. | ||

| American. | Russian. | American. | Russian. | ||

| Circular wick | Veritas, 60-line | 64.5 | 112.5 | 122.5 | 78 |

| Veritas, 30-line | 42.5 | 50. | 60 | 60 | |

| Veritas, 20-line | 43.75 | 58.5 | 40 | 35 | |

| Ariel, 12-line center draught | 52.8 | 70.9 | 18 | 18 | |

| Reading, 14-line | 97.9 | 85.4 | 12 | 12 | |

| Kosmos, 10-line | 63.9 | 97.2 | 9 | 9 | |

| Wizard, 15-line | 56.9 | 51.3 | 18 | 19 | |

| Flat wick, single | Wanzer, no glass | 42.6 | 48.3 | 17 | 17 |

| Solid slip, gauze and cone | 84.4 | 84.4 | 8 | 8 | |

| Old slip, fixed gauze | 60.9 | 89.3 | 7 | 7 | |

| Flat wick, duplex | Feeder wick | 56.2 | 55.7 | 20 | 22 |

| Ordinary | 51.2 | 46.6 | 20 | 22 | |

| American oil—Sp. gr. 0.7904; flash-point, 110°F. Russian oil—Sp. gr. 0.823; flash-point, 83° F. | |||||

According to Sir Boverton Redwood, duplex burners which give a flame of 28 candle-power have an average oil consumption of 50 grains per candle per hour, while Argand flames of 38 candle-power consume about 45 grains of oil per candle per hour. These figures were obtained from lamps of the best types, and to obtain information as to the efficiency of the lamps used in daily practice, a number of the most popular types were examined, using both American and Russian oil. The results obtained are embodied in Table 1. The first noteworthy point in this table is the apparent superiority of the American over Russian oil in the majority of the lamps employed, and there is no doubt that the bulk of the lamps on the market are constructed to burn American or shale oil. A second interesting point is that with the flat-flame lamps the Russian oil is as good as the American. We have Redwood’s authority, moreover, for the fact that after prolonged burning the Russian oil, even in lamps least suited to it, gives highly improved results. Although the average consumption with these lamps is close upon 60 grains per candle with American oil, yet some of the burners are so manifestly wasteful that 50 grains per candle-power per hour is the fairest basis to take for any calculation as to cost.

The dangers of the mineral oil lamp, which were a grave drawback in the past, have been very much reduced by improvements in construction and quality, and if it were possible to abolish the cheap and dangerous rubbish sold in poor neighbourhoods, and to prevent the use of side-fillers and glass reservoirs in lamps of better quality, a still larger reduction in the number of accidents would take place. In the use of the lamp for domestic purposes only soft well-fitting wicks should be employed, and the lamp should be filled with oil each day so as never to allow it to burn too low and so leave a large space above the surface of the oil in the reservoir. The lamp should never be moved whilst alight, and it should only be put out by means of a proper extinguisher or by blowing across the top instead of down the chimney. By these means the risk of accident would be so reduced as to compare favourably with other illuminants.

Candles, oil and coal gas all emit the same products of complete combustion, viz. carbon dioxide and water vapour. The quantities of these compounds emitted from different illuminants for every candle of light per hour will be seen from the following table:

| Cubic Feet per Candle. | ||

| Illuminant. | Carbon Dioxide. | Water Vapour. |

| Sperm candle | 0.41 | 0.41 |

| Oil lamp | 0.24 | 0.18 |

| Gas—Flat flame | 0.26 | 0.67 |

| Argand | 0.17 | 0.45 |

| Regenerative | 0.07 | 0.19 |

| Incandescent | 0.03 | 0.08 |

From these data it appears that if the sanitary condition of the air of a dwelling-room be measured by the amount of carbon dioxide present, as is usually done, candles are the most prejudicial to health and comfort, oil lamps less so, and gas least, an assumption which practical experience does not bear out. The explanation of this is to be found in these facts: First, where we illuminate a room with candles or oil we are contented with a less intense and more local light than when we are using gas, and in a room of ordinary size would be more likely to use a lamp or two candles than the far higher illumination we should demand if gas were employed. Secondly, the amount of water vapour given off during the combustion of gas is greater than in the case of the other illuminants, and water vapour absorbing radiant heat from the burning gas becomes heated, and, diffusing itself about the room, causes great oppression. Also the air, being highly charged with moisture, is unable to take up so rapidly the water vapour which is always evaporating from the surface of our skin, and in this way the functions of the body receive a slight check, resulting in a feeling of depression.

A very successful type of oil lamp for use in engineering is represented by the Lucigen, Doty, and Wells lights, in which the oil is forced from a reservoir by air-pressure through a spiral heated by the flame of the lamp, and the heated Oil-spray lamps. oil, being then ejected partly as vapour and partly as spray, burns with a large and highly luminous flame. The great drawback to these devices is that a certain proportion of the oil spray escapes combustion and is deposited in the vicinity of the light. This form of lamp is often used for heating as well as lighting; the rivets needed for the Forth Bridge were heated in trays by lamps of this type at the spot where they were required. The great advantage of these lamps was that oils of little value could be employed, and the light obtained approximated to 750 candles per gallon of oil consumed. They may to a certain extent be looked upon as the forerunners of perhaps the most successful form of incandescent oil-burner.

As early as 1885 Arthur Kitson attempted to make a burner for heating purposes on the foregoing principle, i.e. by injecting oil under pressure from a fine tube into a chamber where it would be heated by the waste heat escaping Oil applied to incandescent lighting. from the flame below, the vapour so produced being made to issue from a small jet under the pressure caused by the initial air-pressure and the expansion in the gasifying tube. This jet of gas was then led into what was practically an atmospheric burner, and drew in with it sufficient air to cause its combustion with a non-luminous blue flame of great heating power. At the time when this was first done the Welsbach mantle had not yet reached the period of commercial utility, and attempts were made to use this flame for the generation of light by consuming it in a mantle of fine platinum gauze, which, although giving a very fine illuminating effect during the first few hours, very soon shared the fate of all platinum mantles—that is, carbonization of the platinum surface took place, and destroyed its power of light emissivity. It was not until 1893 that the perfecting of the Welsbach mantle enabled this method of consuming the oil to be employed. The Kitson lamp, and also the Empire lamp on a similar principle, have given results which ought to ensure their future success, the only drawback being that they need a certain amount of intelligent care to keep them in good working order.

Oil gas and oil vapours differ from coal gas merely in the larger proportion and greater complexity of the hydrocarbon molecules present, and to render the oil flame available for incandescent lighting it is only necessary to Incandescent table-lamps. cause the oil gas or vapour to become mixed with a sufficient proportion of air before it arrives at the point of combustion. But with gases so rich in hydrocarbons as those developed from oil it is excessively difficult to get the necessary air intimately and evenly mixed with the gas in sufficient proportion to bring about the desired result. If even coal gas be taken and mixed with 2.27 volumes of air, its luminosity is destroyed, but such a flame would be useless with the incandescent mantle, as if the non-luminous flame be superheated a certain proportion of its luminosity will reappear. When such a flame is used with a mantle the superheating effect of the mantle itself very quickly leads to the decomposition of the hydrocarbons and blackening of the mantle, which not only robs it of its light-giving powers, but also rapidly ends its life. If, however, the proportion of air be increased, the appearance of the flame becomes considerably altered, and the hydrocarbon molecules being burnt up before impact with the heated surface of the mantle, all chance of blackening is avoided.

On the first attempts to construct a satisfactory oil lamp which could be used with the incandescent mantle, this trouble showed itself to be a most serious one, as although it was comparatively easy so to regulate a circular-wicked flame fed by an excess of air as to make it non-luminous, the moment the mantle was put upon this, blackening quickly appeared, while when methods for obtaining a further air supply were devised, the difficulty of producing a flame which would burn for a considerable time without constant necessity for regulation proved a serious drawback. This trouble has militated against most of the incandescent oil lamps placed upon the market.

It soon became evident that if a wick were employed the difficulty of getting it perfectly symmetrical was a serious matter, and that it could only be utilized in drawing the oil up to a heating chamber where it could be volatilized to produce the oil gas, which on then being mixed with air would give the non-luminous flame. In the earlier forms of incandescent oil lamps the general idea was to suck the oil up by the capillarity of a circular wick to a point a short distance below the opening of the burner at which the flame was formed, and here the oil was vaporized or gasified by the heat of the head of the burner. An air supply was then drawn up through a tube passing through the centre of the wick-tube, while a second air current was so arranged as to discharge itself almost horizontally upon the burning gas below the cap, in this way giving a non-luminous and very hot flame, which if kept very carefully adjusted afforded excellent results with an incandescent mantle. It was an arrangement somewhat of this character that was introduced by the Welsbach Company. The lamps, however, required such careful attention, and were moreover so irregular in their performance, that they never proved very successful. Many other forms have reached a certain degree of perfection, but have not so far attained sufficient regularity of action to make them commercial successes. One of the most successful was devised by F. Altmann, in which an ingenious arrangement caused the vaporization of oil and water by the heat of a little oil lamp in a lower and separate chamber, and the mixture of oil gas and steam was then burnt in a burner-head with a special arrangement of air supply, heating a mantle suspended above the burner-head.

The perfect petroleum incandescent lamp has not yet been made, but the results thus obtained show that when the right system has been found a very great increase in the amount of light developed from the petroleum may be expected. In one lamp experimented with for some time it was easy to obtain 3500 candle hours per gallon of oil, or three times the amount of light obtainable from the oil when burnt under ordinary conditions.

Before the manufacture of coal-gas had become so universal as it is at present, a favourite illuminant for country mansions and even villages where no coal-gas was available was a mixture of air with the vapour of very volatile Air-gas. hydrocarbons, which is generally known as “air-gas.” This was produced by passing a current of dry air through or over petroleum spirit or the light hydrocarbons distilled from tar, when sufficient of the hydrocarbon was taken up to give a luminous flame in flat flame and Argand burners in the same way as coal-gas, the trouble being that it was difficult to regulate the amount of hydrocarbon held in suspension by the air, as this varied very widely with the temperature. As coal-gas spread to the smaller villages and electric lighting became utilized in large houses, the use of air-gas died out, but with the general introduction of the incandescent mantle it again came to the front. In the earlier days of this revival, air-gas rich in hydrocarbon vapour was made and was further aerated to give a non-luminous flame by burning it in an atmospheric burner.

One of the best illustrations of this system was the Aerogene gas introduced by A. I. van Vriesland, which was utilized for lighting a number of villages and railway stations on the continent of Europe. In this arrangement a revolving coil of pipes continually dips into petroleum spirit contained in a cylinder, and the air passed into the cylinder through the coil of pipes becomes highly carburetted by the time it reaches the outlet at the far end of the cylinder. The resulting gas when burnt in an ordinary burner gives a luminous flame; it can be used in atmospheric burners differing little from those of the ordinary type. With an ordinary Welsbach “C” burner it gives a duty of about 30 candles per foot of gas consumed, the high illuminating power being due to the fact that the gas is under a pressure of from 6 to 8 in. With such a gas, containing a considerable percentage of hydrocarbon vapour, any leakage into the air of a room would give rise to an explosive mixture, in the same way that coal-gas would do, but inasmuch as mixtures of the vapour of petroleum spirit and air are only explosive for a very short range, that is, from 1.25 to 5.3%, some systems have been introduced in which by keeping the amount of petroleum vapour at 2% and burning the gas under pressure in a specially constructed non-aerating mantle burner, not only has it been found possible to produce a very large volume of gas per gallon of spirit employed, but the gas is itself non-explosive, increase in the amount of air taking it farther away from the explosive limit. The Hooker, De Laitte and several other systems have been based upon this principle.

2. Gas Lighting

In all measurements of illuminating value the standard of comparison used in England is the light yielded by a sperm candle of the size known as “sixes,” i.e. six to the pound, consuming 120 grains of sperm per hour, and although in photometric work slight inequalities in burning have led to the candle being discarded in practice, the standard lamps burning pentane vapour which have replaced them are arranged to yield a light of ten candles, and the photometric results are expressed as before in terms of candles.

When William Murdoch first used coal-gas at his Redruth home in 1779, he burnt the gas as it escaped from the open end of a small iron tube, but soon realizing that this plan entailed very large consumption of gas and gave a very small amount of light, he welded up the end of his tube and bored three small holes in it, so arranged that they formed three divergent jets of flame. From the shape of the flame so produced this burner received the name of the “cockspur” burner, and it was the one used by Murdoch when in 1807 he fitted up an installation of gas lighting at Phillips & Lee’s works in Manchester. This—the earliest form of gas burner—gave an illuminating value of a little under one candle per cubic foot of gas consumed, and this duty was slightly increased when the burner was improved by flattening up the welded end of the tube and making a series of small holes in line and close together, the jets of flame from which gave the burner the name of the “cockscomb.” It did not need much inventive faculty to replace the line of holes by a saw-cut, the gas issuing from which burnt in a sheet, the shape of which led to the burner being called the “batswing.” This was followed in 1820 by the discovery of J. B. Neilson, of Glasgow, whose name is remembered in connexion with the use of the hot-air blast in iron-smelting, that, by allowing two flames to impinge upon one another so as to form a flat flame, a slight increase in luminosity was obtained, and after several preliminary stages the union jet or “fishtail” burner was produced. In this form of burner two holes, bored at the necessary angle in the same nipple, caused two streams of gas to impinge upon each other so that they flattened themselves out into a sheet of flame. The flames given by the batswing and fishtail burners differed in shape, the former being wide and of but little height, whilst the latter was much higher and more narrow. This factor ensured for the fishtail a greater amount of popularity than the batswing burner had obtained, as the flame was less affected by draughts and could be used with a globe, although the illuminating efficiency of the two burners differed little.

In a lecture at the Royal Institution on the 20th of May 1853, Sir Edward Frankland showed a burner he had devised for utilizing the heat of the flame to raise the temperature of the air supply necessary for the combustion Regenerative burner. of the gas. The burner was an Argand of the type then in use, consisting of a metal ring pierced with holes so as to give a circle of small jets, the ring of flame being surrounded by a chimney. But in addition to this chimney, Frankland added a second external one, extending some distance below the first and closed at the bottom by a glass plate fitted air-tight to the pillar carrying the burner. In this way the air needed for the combustion of the gas had to pass down the space between the two chimneys, and in so doing became highly heated, partly by contact with the hot glass, and partly by radiation. Sir Edward Frankland estimated that the temperature of the air reaching the flame was about 500°F. In 1854 a very similar arrangement was brought forward by the Rev. W. R. Bowditch, and, as a large amount of publicity was given to it, the inception of the regenerative burner was generally ascribed to Bowditch, although undoubtedly due to Frankland.

The principle of regeneration was adopted in a number of lamps, the best of which was brought out by Friedrich Siemens in 1879. Although originally made for heating purposes, the light given by the burner was so effective and superior to anything obtained up to that time that it was with some slight alterations adapted for illuminating purposes.

Improvements followed in the construction and design of the regenerative lamp, and when used as an overhead burner it was found that not only was an excellent duty obtained per cubic foot of gas consumed, but that the lamp could be made a most efficient engine of ventilation, as an enormous amount of vitiated air could be withdrawn from the upper part of a room through a flue in the ceiling space. So marked was the increase in light due to the regeneration that a considerable number of burners working on this principle were introduced, some of them like the Wenham and Cromartie coming into extensive use. They were, however, costly to install, so that the flat flame burner retained its popularity in spite of the fact that its duty was comparatively low, owing to the flame being drawn out into a thin sheet and so exposed to the cooling influence of the atmosphere. Almost at the same time that Murdoch was introducing the cockscomb and cockspur burners, he also made rough forms of Argand burner, consisting of two concentric pipes between which the gas was led and burnt with a circular flame. This form was soon improved by filling in the space between the tubes with a ring of metal, bored with fine holes so close together that the jets coalesced in burning and gave a more satisfactory flame, the air necessary to keep the flame steady and ensure complete combustion being obtained by the draught created by a chimney placed around it. When it began to be recognized that the temperature of the flame had a great effect upon the amount of light emitted, the iron tips, which had been universally employed, both in flat flame and Argand burners, were replaced by steatite or other non-conducting material of similar character, to prevent as far as possible heat from being withdrawn from the flame by conduction.

In 1880 the burners in use for coal-gas therefore consisted of flat flame, Argand, and regenerative burners, and the duty given by them with a 16-candle gas was as follows:—

| Burner. | Candle units per cub. ft. of gas. |

| Union jet flat flame, No. 0 | 0.59 |

| ” ” 1 | 0.85 |

| ” ” 2 | 1.22 |

| ” ” 3 | 1.63 |

| ” ” 4 | 1.74 |

| ” ” 5 | 1.87 |

| ” ” 6 | 2.15 |

| ” ” 7 | 2.44 |

| Ordinary Argand | 2.90 |

| Standard Argand | 3.20 |

| Regenerative | 7 to 10 |

The luminosity of a coal-gas flame depends upon the number of carbon particles liberated within it, and the temperature to which they can be heated. Hence the light given by a flame of coal-gas can be augmented by (1) increasing the number of the carbon particles, and (2) raising the temperature to which they are exposed. The first process is carried out by enrichment (see Gas: Manufacture), the second is best obtained by regeneration, the action of which is limited by the power possessed by the material of which burners are composed to withstand the superheating. Although with a perfectly made regenerative burner it might be possible for a short time to get a duty as high as 16 candles per cubic foot from ordinary coal-gas, such a burner constructed of the ordinary materials would last only a few hours, so that for practical use and a reasonable life for the burner 10 candles per cubic foot was about the highest commercial duty that could be reckoned on. This limitation naturally caused inventors to search for methods by which the emission of light could be obtained from coal-gas otherwise than by the incandescence of the carbon particles contained within the flame itself. A coal-gas flame consumed in an atmospheric burner under the conditions necessary to develop its maximum heating power could be utilized to raise to incandescence particles having a higher emissivity for light than carbon. This led to the gradual evolution of incandescent gas lighting.

Long before the birth of the Welsbach mantle it had been known that when certain unburnable refractory substances were heated to a high temperature they emitted light, and Goldsworthy Gurney in 1826 showed that a Incandescent gas light. cylinder of lime could be brought to a state of dazzling brilliancy by the flame of the oxy-hydrogen blowpipe, a fact which was utilized by Thomas Drummond shortly afterwards in connexion with the Ordnance Survey of Ireland. The mass of a lime cylinder is, however, relatively very considerable, and consequently an excessive amount of heat has to be brought to bear upon it, owing to radiation and conduction tending to dissipate the heat. This is seen by holding in the flame of an atmospheric burner a coil of thick platinum wire, the result being that the wire is heated to a dull red only. With wire of medium thickness a bright red heat is soon attained, and a thin wire glows with a vivid incandescence, and will even melt in certain parts of the flame. Attempts were accordingly made to reduce the mass of the material heated, and this form of lighting was tried in the streets of Paris, buttons of zirconia and magnesia being heated by an oxy-coal-gas flame, but the attempt was soon abandoned owing to the high cost and constant renewals needed. In 1835 W. H. Fox Talbot discovered that even the feeble flame of a spirit lamp is sufficient to heat lime to incandescence, provided the lime be in a sufficiently fine state of division. This condition he fulfilled by soaking blotting-paper in a solution of a calcium salt and then incinerating it. Up to 1848, when J. P. Gillard introduced the intermittent process of making water-gas, the spirit flame and oxy-hydrogen flame were alone free from carbon particles. Desiring to use the water-gas for lighting as well as heating purposes Gillard made a mantle of fine platinum gauze to fit over the flame, and for a time obtained excellent results, but after a few days the lighting value of the mantle fell away gradually until it became useless, owing to the wire becoming eroded on the surface by the flame gases. This idea has been revived at intervals, but the trouble of erosion has always led to failure.

The next important stage in the history of gas lighting was the discovery by R. W. von Bunsen about 1855 of the atmospheric burner, in which a non-luminous coal-gas flame is obtained by causing the coal-gas before its combustion to mix with a certain amount of air. This simple appliance has opened up for coal-gas a sphere of usefulness for heating purposes as important as its use for lighting. After the introduction of the atmospheric burner the idea of the incandescent mantle was revived early in the eighties by the Clamond basket and a resuscitation of the platinum mantle. The Clamond basket or mantle, as shown at the Crystal Palace exhibition of 1882-1883, consisted of a cone of threads of calcined magnesia. A mixture of magnesium hydrate and acetate, converted into a paste or cream by means of water, was pressed through holes in a plate so as to form threads, and these, after being moulded to the required shape, were ignited. The heat decomposed the acetate to form a luting material which glued the particles of magnesium oxide produced into a solid mass, whilst the hydrate gave off water and became oxide. The basket was supported with its apex downwards in a little platinum wire cage, and a mixture of coal-gas and air was driven into it under pressure from an inverted blowpipe burner above it.

The Welsbach mantle was suggested by the fact that Auer von Welsbach had been carrying out researches on the rare earths, with constant use of the spectroscope. Desiring to obtain a better effect than that produced by heating his material on a platinum wire, he immersed cotton in a solution of the metallic salt, and after burning off the organic matter found that a replica of the original thread, composed of the oxide of the metal, was left, and that it glowed brightly in the flame. From this he evolved the idea of utilizing a fabric of cotton soaked in a solution of a metallic salt for lighting purposes, and in 1885 he patented his first commercial mantle. The oxides used in these mantles were zirconia, lanthania, and yttria, but these were so fragile as to be practically useless, whilst the light they emitted was very poor. Later he found that the oxide of thorium—thoria—in conjunction with other rare earth oxides, not only increased the light-giving powers of the mantle, but added considerably to its strength, and the use of this oxide was protected by his 1886 patent. Even these mantles were very unsatisfactory until it was found that the purity of the oxides had a wonderful effect upon the amount of light, and finally came the great discovery that it was a trace of ceria in admixture with the thoria that gave the mantle the marvellous power of emitting light.

Certain factors limit the number of oxides that can be used in the manufacture of an incandescent mantle. Atmospheric influences must not have any action upon them, and they must be sufficiently refractory not to melt or even soften to any extent at the temperature of the flame; they must also be non-volatile, whilst the shrinkage during the process of “burning off” must not be excessive. The following table gives the light-emissivity from pure and commercial samples of the oxides which most nearly conform to the above requirements; the effect of impurity upon the lighting power will be seen to be most marked.

| Pure. | Commercial. | |

| Metals— | ||

| Zirconia | 1.5 | 3.1 |

| Thoria | 0.5 | 6.0 |

| Earth metals— | ||

| Cerite earths—Ceria | 0.4 | 0.9 |

| Lanthania | 6.0 | |

| Yttrite earths—Yttria | 3.2 | |

| Erbia | 0.6 | 1.7 |

| Common earths—Chromium oxide | 0.4 | 0.4 |

| Alumina | 0.6 | 0.6 |

| Alkaline earth metals— | ||

| Baryta | 3.3 | 3.3 |

| Strontia | 5.2 | 5.5 |

| Magnesia | 5.0 | 5.0 |

Of these oxides thoria, when tested for shrinkage, duration and strength, stands pre-eminent. It is also possible to employ zirconia and alumina. Zirconia has the drawback that in the hottest part of the flame it is liable not only to shrinkage and semi-fusion, but also to slow volatilization, and the same objections hold good with respect to alumina. With thoria the shrinkage is smaller than with any other known substance, and it possesses very high refractory powers.

The factor which gives thoria its pre-eminence as the basis of the mantle is that in the conversion of thorium nitrate into thorium oxide by heat, an enormous expansion takes place, the oxide occupying more than ten times the volume of the nitrate. This means that the mass is highly spongy, and contains an enormous number of little air-cells which must render it an excellent non-conductor. A mantle made with thoria alone gives practically no light. But the power of light-emissivity is awakened by the addition of a small trace of ceria; and careful experiment shows that as ceria is added to it little by little, the light which the mantle emits grows greater and greater, until the ratio of 99% of thoria and 1% of ceria is reached, when the maximum illuminating effect is obtained. The further addition of ceria causes gradual diminution of light, until, when with some 10% of ceria has been added, the light given by the mantle is again almost inappreciable. When cerium nitrate is converted by heat into cerium oxide, the expansion which takes place is practically nil, the ceria obtained from a gramme of the nitrate occupying about the same space as the original nitrate. Thus, although by weight the ratio of ceria to thoria is as 1:99, by volume it is only as 1:999.

The most successful form of mantle is made by taking a cylinder of cotton net about 8 in. long, and soaking it in a solution of nitrates of the requisite metals until the microscopic fibres of the cotton are entirely filled Manufacture of mantles. with liquid. A longer soaking is not advantageous, as the acid nature of the liquid employed tends to weaken the fabric and render it more delicate to handle. The cotton is then wrung out to free it from the excess of liquid, and one end is sewn together with an asbestos thread, a loop of the same material or of thin platinum wire being fixed across the constricted portion to provide a support by which the mantle may be held by the carrying rod, which is either external to the mantle, or (as is most often the case) fixed centrally in the burner head. It is then ready for “burning off,” a process in which the organic matter is removed and the nitrates are converted into oxides. The flame of an atmospheric burner is first applied to the constricted portion at the top of the mantle, whereupon the cotton gradually burns downwards, the shape of the mantle to a great extent depending on the regularity with which the combustion takes place. A certain amount of carbon is left behind after the flame has died out, and this is burnt off by the judicious application of a flame from an atmospheric blast burner to the interior. The action which takes place during the burning off is as follows: The cellulose tubes of the fibre are filled with the crystallized nitrates of the metals used, and as the cellulose burns the nitrates decompose, giving up oxygen and forming fusible nitrites, which in their semi-liquid condition are rendered coherent by the rapid expansion as the oxide forms. As the action continues the nitrites become oxides, losing their fusibility, so that by the time the organic matter has disappeared a coherent thread of oxide is left in place of the nitrate-laden thread of cotton. In the early days of incandescent lighting the mantles had to be sent out unburnt, as no process was known by which the burnt mantle could be rendered sufficiently strong to bear carriage. As the success of a mantle depends upon its fitting the flame, and as the burning off requires considerable skill, this was a great difficulty. Moreover the acid nature of the nitrates in the fibres rapidly rotted them, unless they had been subjected to the action of ammonia gas, which neutralized any excess of acid. It was discovered, however, that the burnt-off mantle could be temporarily strengthened by dipping it in collodion, a solution of soluble gun-cotton in ether and alcohol together with a little castor-oil or similar material to prevent excessive shrinkage when drying. When the mantle was removed from the solution a thin film of solid collodion was left on it, and this could be burned away when required.

After the Welsbach mantle had proved itself a commercial success many attempts were made to evade the monopoly created under the patents, and, although it was found impossible to get the same illuminating power with anything but the mixture of 99% thoria and 1% ceria, many ingenious processes were devised which resulted in at least one improvement in mantle manufacture. One of the earliest attempts in this direction was the “Sunlight” mantle, in which cotton was saturated with the oxides of aluminium, chromium and zirconium, the composition of the burnt-off mantle being:—

| Alumina | 86.88 |

| Chromium oxide | 8.68 |

| Zirconia | 4.44 |

| ——— | |

| 100.00 |

The light given by these mantles was entirely dependent upon the proportion of chromium oxides present, the alumina playing the part of base in the same way that the thoria does in the Welsbach mantle, the zirconia being added merely to strengthen the structure. These mantles enjoyed considerable popularity owing to the yellowish pink light they emitted, but, although they could give an initial illumination of 12 to 15 candles per foot of gas consumed, they rapidly lost their light-giving power owing to the slow volatilization of the oxides of chromium and aluminium.

Another method of making the mantle was first to produce a basis of thoria, and, having got the fabric in thorium oxide, to coat it with a mixture of 99% thoria and 1% ceria. This modification seems to give an improvement in the initial amount of light given by the mantle. In the Voelker mantle a basis of thoria was produced, and was then coated by dipping in a substance termed by the patentee “Voelkerite,” a body made by fusing together a number of oxides in the electric furnace. The fused mass was then dissolved in the strongest nitric acid, and diluted with absolute alcohol to the necessary degree. A very good mantle having great lasting power was thus produced. It was claimed that the process of fusing the materials together in the electric furnace altered the composition in some unexplained way, but the true explanation is probably that all water of hydration was eliminated.

The “Daylight” mantle consisted of a basis of thoria or thoria mixed with zirconia, dipped in collodion containing a salt of cerium in solution; on burning off the collodion the ceria was left in a finely divided condition on the surface of the thoria. In this way a very high initial illuminating power was obtained, which, however, rapidly fell as the ceria slowly volatilized.

Perhaps the most interesting development of the Welsbach process was dependent upon the manufacture of filaments of soluble guncotton or collodion as in the production of artificial silk. In general the process consisted in forcing a thick solution of the nitrated cellulose through capillary glass tubes, the bore of which was less than the one-hundredth of a millimetre. Ten or twelve of the expressed fibres were then twisted together and wound on a bobbin, the air of the room being kept sufficiently heated to cause the drying of the filaments a few inches from the orifice of the tube. The compound thread was next denitrated to remove its extreme inflammability, and for this purpose the skeins were dipped in a solution of (for instance) ammonium sulphide, which converted them into ordinary cellulose. After washing and drying the skeins were ready for the weaving machines. In 1894 F. de Mare utilized collodion for the manufacture of a mantle, adding the necessary salts to the collodion before squeezing it into threads. O. Knöfler in 1895, and later on A. Plaissetty, took out patents for the manufacture of mantles by a similar process to De Mare’s, the difference between the two being that Knöfler used ammonium sulphide for the denitration of his fabric, whilst Plaissetty employed calcium sulphide, the objection to which is the trace of lime left in the material. Another method for making artificial silk which has a considerable reputation is that known as the Lehner process, which in its broad outlines somewhat resembles the Chardonnet, but differs from it in that the excessively high pressures used in the earlier method are done away with by using a solution of a more liquid character, the thread being hardened by passing through certain organic solutions. This form of silk lends itself perhaps better to the carrying of the salts forming the incandescent oxides than the previous solutions, and mantles made by this process, known as Lehner mantles, showed promise of being a most important development of De Mare’s original idea. Mantles made by these processes show that it is possible to obtain a very considerable increase in life and light-emissivity, but mantles made on this principle could not now be sold at a price which would enable them to compete with mantles of the Welsbach type.

The cause of the superiority of these mantles having been realized, developments in the required direction were made. The structure of the cotton mantle differed widely from that obtained by the various collodion processes, and this alteration in structure was mainly responsible for the increase in life. Whereas the average of a large number of Welsbach mantles tested only showed a useful life of 700 to 1000 hours, the collodion type would average about 1500 hours, some mantles being burnt for an even longer period and still giving an effective illumination. This being so, it was clear that one line of advance would be found in obtaining some material which, whilst giving a structure more nearly approaching that of the collodion mantle, would be sufficiently cheap to compete with the Welsbach mantle, and this was successfully done.

By the aid of the microscope the structure of the mantle can be clearly defined, and in examining the Welsbach mantle before and after burning, it will be noticed that the cotton thread is a closely twisted and plaited rope of myriads of minute fibres, whilst the collodion mantle is a bundle of separate filaments without plait or heavy twisting, the number of such filaments varying with the process by which it was made. This latter factor experiment showed to have a certain influence on the useful light-giving life of the mantle, as whereas the Knöfler and Plaissetty mantles had an average life of about 1500 hours, the Lehner fabric, which contained a larger number of finer threads, could often be burnt continuously for over 3000 hours, and at the end of that period gave a better light than most of the Welsbach after as many hundred.

It is well known that plaiting gave the cotton candle-wick that power of bending over, when freed from the binding effect of the candle material and influenced by heat, which brought the tip out from the side of the flame. This, by enabling the air to get at it and burn it away, removed the nuisance of having to snuff the candle, which for many centuries has rendered it a tiresome method of lighting. In the cotton mantle, the tight twisting of the fibre brings this torsion into play. When the cotton fibres saturated with the nitrates of the rare metals are burnt off, and the conversion into oxides takes place, as the cotton begins to burn, not only does the shrinkage of the mass throw a strain on the oxide skeleton, but the last struggle of torsion in the burning of the fibre tends towards disintegration of the fragile mass, and this all plays a part in making the cotton mantle inferior to the collodion type.

If ramie fibre be prepared in such a way as to remove from it all traces of the glutinous coating, a silk-like fabric can be obtained from it, and if still further prepared so as to improve its absorbent powers, it can be formed into mantles having a life considerably greater than is possessed by those of the cotton fabric. Ramie thus seemed likely to yield a cheap competitor in length of endurance to the collodion mantle, and results have justified this expectation. By treating the fibre so as to remove the objections against its use for mantle-making, and then making it into threads with the least possible amount of twist, a mantle fabric can be made in every way superior to that given by cotton.

The Plaissetty mantles, which as now manufactured also show a considerable advance in life and light over the original Welsbach mantles, are made by impregnating stockings of either cotton or ramie with the nitrates of thorium and cerium in the usual way, and, before burning off, mercerizing the mantle by steeping in ammonia solution, which converts the nitrates into hydrates, and gives greater density and strength to the finished mantle. The manufacturers of the Plaissetty mantle have also made a modification in the process by which the saturated fabric can be so prepared as to be easily burnt off by the consumer on the burner on which it is to be used, in this way doing away with the initial cost of burning off, shaping, hardening and collodionizing.

Since 1897 inventions have been patented for methods of intensifying the light produced by burning gas under a mantle and increasing the light generated per unit volume of gas. The systems have either been self-intensifying Intensifying systems. or have depended on supplying the gas (or gas and air) under an increased pressure. Of the self-intensifying systems those of Lucas and Scott-Snell have been the most successful. A careful study has been made by the inventor of the Lucas light of the influence of various sizes and shapes of chimneys in the production of draught. The specially formed chimney used exerts a suction on the gas flame and air, and the burner and mantle are so constructed as to take full advantage of the increased air supply, with the result that the candle power given by the mantle is considerably augmented. With the Scott-Snell system the results obtained are about the same as those given by the Lucas light, but in this case the waste heat from the burner is caused to operate a plunger working in the crown of the lamp which sucks and delivers gas to the burner. Both these systems are widely used for public lighting in many large towns of the United Kingdom and the continent of Europe.

The other method of obtaining high light-power from incandescent gas burners necessitates the use of some form of motive power in order to place the gas, or both gas and air, under an increased pressure. The gas compressor is worked by a water motor, hot air or gas engine; a low pressure water motor may be efficiently driven by water from the main, but with large installations it is more economical to drive the compressor by a gas engine. To overcome the intermittent flow of gas caused by the stroke of the engine, a regulator on the floating bell principle is placed after the compressor; the pressure of gas in the apparatus governs automatically the flow of gas to the engine. With the Sugg apparatus for high power lighting the gas is brought from the district pressure, which is equal to about 2½ in. of water, to an average of 12 in. water pressure. The light obtained by this system when the gas pressure is 9½ in. is 300 candle power with an hourly consumption of 10 cub. ft. of gas, equivalent to 30 candles per cubic foot, and with a gas pressure equal to 14 in. of water 400 candles are obtained with an hourly consumption of 12½ cub. ft., which represents a duty of 32 candles per cubic foot of gas consumed. High pressure incandescent lighting makes it possible to burn a far larger volume of gas in a given time under a mantle than is the case with low pressure lighting, so as to create centres of high total illuminating value to compete with arc lighting in the illumination of large spaces, and the Lucas, Keith, Scott-Snell, Millennium, Selas, and many other pressure systems answer most admirably for this purpose.

The light given by the ordinary incandescent mantle burning in an upright position tends rather to the upward direction, because owing to the slightly conical shape of the mantle the maximum light is emitted at an angle a Inverted burners. little above the horizontal. Inasmuch as for working purposes the surface that a mantle illuminates is at angles below 45° from the horizontal, it is evident that a considerable loss of efficient lighting is brought about, whilst directly under the light the burner and fittings throw a strong shadow. To avoid this trouble attempts have from time to time been made to produce inverted burners which should heat a mantle suspended below the mouth of the burner. As early as 1882 Clamond made what was practically an inverted gas and air blowpipe to use with his incandescent basket, but it was not until 1900-1901 that the inverted mantle became a possibility. Although there was a strong prejudice against it at first, as soon as a really satisfactory burner was introduced, its success was quickly placed beyond doubt. The inverted mantle has now proved itself one of the chief factors in the enormous success achieved by incandescent mantle lighting, as the illumination given by it is far more efficient than with the upright mantle, and it also lends itself well to ornamental treatment.

When the incandescent mantle was first introduced in 1886 an ordinary laboratory Bunsen burner was experimentally employed, but unless a very narrow mantle just fitting the top of the tube was used the flame could Burners. not be got to fit the mantle, and it was only the extreme outer edge of the flame which endowed the mantle fabric with the high incandescent. A wide burner top was then placed on the Bunsen tube so as to spread the flame, and a larger mantle became possible, but it was then found that the slowing down of the rate of flow at the mouth of the burner owing to its enlargement caused flashing or firing back, and to prevent this a wire gauze covering was fitted to the burner head; and in this way the 1886-1887 commercial Welsbach burner was produced. The length of the Bunsen tube, however, made an unsightly fitting, so it was shortened, and the burner head made to slip over it, whilst an external lighting back plate was added. The form of the “C” burner thus arrived at has undergone no important further change. When later on it was desired to make incandescent mantle burners that should not need the aid of a chimney to increase the air supply, the long Bunsen tube was reverted to, and the Kern, Bandsept, and other burners of this class all have a greater total length than the ordinary burners. To secure proper mixing of the air and gas, and to prevent flashing back, they all have heads fitted with baffles, perforations, gauze, and other devices which oppose considerable resistance to the flow of the stream of air and gas.

In 1900, therefore, two classes of burner were in commercial existence for incandescent lighting—(1) the short burner with chimney, and (2) the long burner without chimney. Both classes had the burner mouth closed with gauze or similar device, and both needed as an essential that the mantle should fit closely to the burner head.

Prior to 1900 attempts had been made to construct a burner in which an incandescent mantle should be suspended head downwards. Inventors all turned to the overhead regenerative gas lamps of the Wenham type, or the inverted blowpipe used by Clamond, and in attempting to make an inverted Bunsen employed either artificial pressure to the gas or the air, or to both, or else enclosed the burner and mantle in a globe, and by means of a long chimney created a strong draught. These burners also were all regenerative and aimed at heating the air or gas or mixture of the two, and they had the further drawback of being complicated and costly. Regeneration is a valuable adjunct in ordinary gas lighting as it increases the actions that liberate the carbon particles upon which the luminosity of a flame is dependent, and also increases the temperature; but with the mixture of air and gas in a Bunsen regeneration is not a great gain when low and is a drawback when intense, because incipient combination is induced between the oxygen of the air and the coal-gas before the burner head is reached, the proportions of air and gas are disturbed, and the flame instead of being non-luminous shows slight luminosity and tends to blacken the mantle. The only early attempt to burn a mantle in an inverted position without regeneration or artificial pressure or draught was made by H. A. Kent in 1897, and he used, not an inverted Bunsen, but one with the top elongated and turned over to form a siphon, so that the point of admixture of air and gas was below the level of the burner head, and was therefore kept cool and away from the products of combustion.

In 1900 J. Bernt and E. Cérvenka set themselves to solve the problem of making a Bunsen burner which should consume gas under ordinary gas pressure in an inverted mantle. They took the short Bunsen burner, as found in the most commonly used upright incandescent burners, and fitted to it a long tube, preferably of non-conducting material, which they called an isolator, and which is designed to keep the flame at a distance from the Bunsen. They found that it burnt fairly well, and that the tendency of the flame to burn or lap back was lessened, but that the hot up-current of heated air and products of combustion streamed up to the air holes of the Bunsen, and by contaminating the air supply caused the flame to pulsate. They then fixed an inverted cone on the isolator to throw the products of combustion outwards and away from the air holes, and found that the addition of this “deflecting cone” steadied the flame. Having obtained a satisfactory flame, they attacked the problem of the burner head. Experiments showed that the burner head must be not only open but also of the same size or smaller than the burner tube, and that by projecting it downwards into the mantle and leaving a space between the mantle and the burner head the maximum mantle surface heated to incandescence was obtained. It was also found that the distance which the burner head projects into the mantle is equivalent to the same amount of extra water pressure on the gas, and with a long mantle it was found useful under certain conditions to add a cylinder or sleeve with perforated sides to carry the gas still lower into the mantle. The principles thus set forth by Kent, Bernt and Cérvenka form the basis of construction of all the types of inverted mantle burners which so greatly increased the popularity of incandescent gas lighting at the beginning of the 20th century, whilst improvements in the shape of the mantle for inverted lighting and the methods of attachment to the burner have added to the success achieved.

The wonderful increase in the amount of light that can be obtained from gas by the aid of the incandescent gas mantle is realized when one compares the 1 to 3.2 candles per cubic foot given by the burners used in the middle of the 19th century with the duty of incandescent burners, as shown in the following table:—

Light yielded per cubic foot of Gas.

| Burner. | Candle power. |

| Low pressure upright incandescent burners | 15 to 20 candles |

| Inverted burners | 14 to 21 ” |

| Kern burners | 20 to 24 ” |

| High pressure burners | 22 to 36 ” |

3. Electric Lighting.

Electric lamps are of two varieties: (1) Arc Lamps and (2) Incandescent or Glow Lamps. Under these headings we may briefly consider the history, physical principles, and present practice of the art of electric lighting.

1. Arc Lamps.—If a voltaic battery of a large number of cells has its terminal wires provided with rods of electrically-conducting carbon, and these are brought in contact and then slightly separated, a form of electric discharge takes place between them called the electric arc. It is not quite certain who first observed this effect of the electric current. The statement that Sir Humphry Davy, in 1801, first produced and studied the phenomenon is probably correct. In 1808 Davy had provided for him at the Royal Institution a battery of 2000 cells, with which he exhibited the electric arc on a large scale.

The electric arc may be produced between any conducting materials maintained at different potentials, provided that the source of electric supply is able to furnish a sufficiently large current; but for illuminating purposes pieces of hard graphitic carbon are most convenient. If some source of continuous electric current is connected to rods of such carbon, first brought into contact and then slightly separated, the following facts may be noticed: With a low electromotive force of about 50 or 60 volts no discharge takes place until the carbons are in actual contact, unless the insulation of the air is broken down by the passage of a small electric spark. When this occurs, the space between the carbons is filled at once with a flame or luminous vapour, and the carbons themselves become highly incandescent at their extremities. If they are horizontal the flame takes the form of an arch springing between their tips; hence the name arc. This varies somewhat in appearance according to the nature of the current, whether continuous or alternating, and according as it is formed in the open air or in an enclosed space to which free access of oxygen is prevented. Electric arcs between metal surfaces differ greatly in colour according to the nature of the metal. When formed by an alternating current of high electromotive force they resemble a lambent flame, flickering and producing a somewhat shrill humming sound.

Electric arcs may be classified into continuous or alternating current arcs, and open or enclosed arcs, carbon arcs with pure or chemically impregnated carbons, or so-called flame arcs, and arcs formed with metallic or oxide electrodes, such as magnetite. A continuous current arc is formed with an electric current flowing always in the same direction; an alternating current arc is formed with a periodically reversed current. An open arc is one in which the carbons or other material forming the arc are freely exposed to the air; an enclosed arc is one in which they are included in a glass vessel. If carbons impregnated with various salts are used to colour or increase the light, the arc is called a chemical or flame arc. The carbons or electrodes may be arranged in line one above the other, or they may be inclined so as to project the light downwards or more in one direction. In a carbon arc if the current is continuous the positive carbon becomes much hotter at the end than the negative, and in the open air it is worn away, partly by combustion, becoming hollowed out at the extremity into a crater. At the same time the negative carbon gradually becomes pointed, and also wears away, though much less quickly than the positive. In the continuous-current open arc the greater part of the light proceeds from the highly incandescent positive crater. When the arc is examined through dark glasses, or by the optical projection of its image upon a screen, a violet band or stream of vapour is seen to extend between the two carbons, surrounded by a nebulous golden flame or aureole. If the carbons are maintained at the right distance apart the arc remains steady and silent, but if the carbons are impure, or the distance between them too great, the true electric arc rapidly changes its place, flickering about and frequently becoming extinguished; when this happens it can only be restored by bringing the carbons once more into contact. If the current is alternating, then the arc is symmetrical, and both carbons possess nearly the same appearance. If it is enclosed in a vessel nearly air-tight, the rate at which the carbons are burnt away is greatly reduced, and if the current is continuous the positive carbon is no longer cratered out and the negative no longer so much pointed as in the case of the open arc.

Davy used for his first experiments rods of wood charcoal which had been heated and plunged into mercury to make them better conductors. Not until 1843 was it proposed by J. B. L. Foucault to employ pencils Carbons. cut from the hard graphitic carbon deposited in the interior of gas retorts. In 1846 W. Greener and W. E. Staite patented a process for manufacturing carbons for this purpose, but only after the invention of the Gramme dynamo in 1870 any great demand arose for them. F. P. É. Carré in France in 1876 began to manufacture arc lamp carbons of high quality from coke, lampblack and syrup. Now they are made by taking some specially refined form of finely divided carbon, such as the soot or lampblack formed by cooling the smoke of burning paraffin or tar, or by the carbonization of organic matter, and making it into a paste with gum or syrup. This carbon paste is forced through dies by means of a hydraulic press, the rods thus formed being subsequently baked with such precautions as to preserve them perfectly straight. In some cases they are cored, that is to say, have a longitudinal hole down them, filled in with a softer carbon. Sometimes they are covered with a thin layer of copper by electro-deposition. They are supplied for the market in sizes varying from 4 or 5 to 30 or 40 millimetres in diameter, and from 8 to 16 in. in length. The value of carbons for arc lighting greatly depends on their purity and freedom from ash in burning, and on perfect uniformity of structure. For ordinary purposes they are generally round in section, but for certain special uses, such as lighthouse work, they are made fluted or with a star-shaped section. The positive carbon is usually of larger section than the negative. For continuous-current arcs a cored carbon is generally used as a positive, and a smaller solid carbon as a negative. For flame arc lamps the carbons are specially prepared by impregnating them with salts of calcium, magnesium and sodium. The calcium gives the best results. The rod is usually of a composite type. The outer zone is pure carbon to give strength, the next zone contains carbon mixed with the metallic salts, and the inner core is the same but less compressed. In addition to the metallic salts a flux has to be introduced to prevent the formation of a non-conducting ash, and this renders it desirable to place the carbons in a downward pointing direction to get rid of the slag so formed. Bremer first suggested in 1898 for this purpose the fluorides of calcium, strontium or barium. When such carbons are used to form an electric arc the metallic salts deflagrate and produce a flame round the arc which is strongly coloured, the object being to produce a warm yellow glow, instead of the somewhat violet and cold light of the pure carbon arc, as well as a greater emission of light. As noxious vapours are however given off, flame arcs can only be used out of doors. Countless researches have been made on the subject of carbon manufacture, and the art has been brought to great perfection.

Special manuals must be consulted for further information (see especially a treatise on Carbon making for all electrical purposes, by F. Jehl, London, 1906).

| |

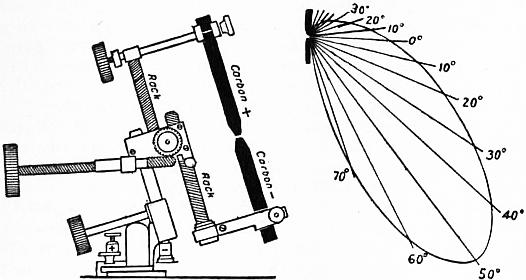

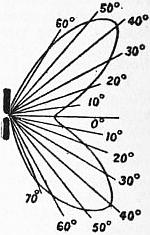

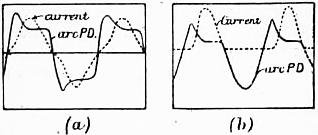

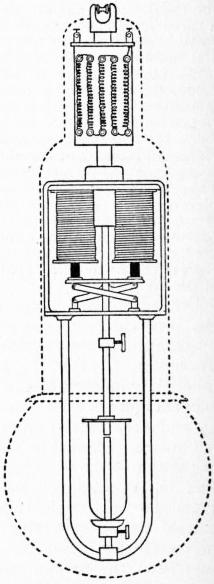

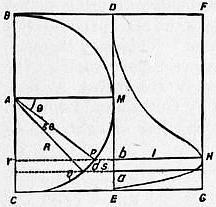

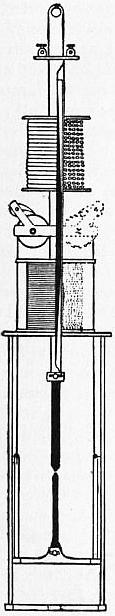

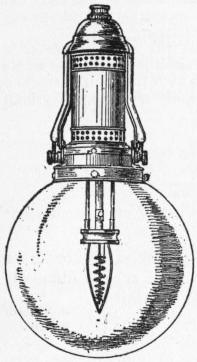

| Fig. 4. | Fig. 5. |