Bellows

From Britannica 11th Edition (1911)

From Britannica 11th Edition (1911) Bellows and BLOWING MACHINES, appliances used for producing currents of air, or for moving volumes of air from one place to another. Formerly all such artificially-produced currents of air were used to assist the combustion of fires and furnaces, but now this purpose only forms a part of the uses to which they are put. Blowing appliances, among which are included bellows, rotary fans, blowing engines, rotary blowers and steam-jet blowers, are now also employed for forcing pure air into buildings and mines for purposes of ventilation, for withdrawing vitiated air for the same reason, and for supplying the air or other gas which is required in some chemical processes. Appliances of this kind differ from air compressors in that they are primarily intended for the transfer of quantities of air at low pressures, very little above that of the atmosphere, whereas the latter are used for supplying air which has previously been raised to a pressure which may be many times that of the atmosphere (see Power Transmission: Pneumatic).

Among the earliest contrivances employed for producing the movement of air under a small pressure were those used in Egypt during the Greek occupation. These depended upon the heating of the air, which, being raised in pressure and bulk, was made to force water out of closed vessels, the water being afterwards employed for moving some kind of mechanism. In the process of iron smelting there is still used in some parts of India an artificial blast, produced by a simple form of bellows made from the skins of goats; bellows of this kind probably represent one of the earliest contrivances used for producing currents of air.

The bellows1 now in use consists, in its simplest form, of two flat boards, of rectangular, circular or pear shape, connected round their edges by a wide band of leather so as to include an air chamber, which can be increased or diminished in volume by separating the boards or bringing them nearer together. The leather is kept from collapsing, on the separation of the boards, by several rings of wire which act like the ribs of animals. The lower board has a hole in the centre, covered inside by a leather flap or valve which can only open inwards; there is also an open outlet, generally in the form of a pipe or nozzle, whose aperture is much smaller than that of the valve. When the upper board is raised air rushes into the cavity through the valve to fill up the partial vacuum produced; on again depressing the upper board the valve is closed by the air attempting to rush out again, and this air is discharged through the open nozzle with a velocity depending on the pressure exerted.

The current of air produced is evidently not continuous but intermittent or in puffs, because an interval is needed to refill the cavity after each discharge. In order to remedy this drawback the double bellows are used. To understand their action it is only necessary to conceive an additional board with valve, like the lower board of the single bellows, attached in the same way by leather below this lower board. Thus there are three boards, forming two cavities, the two lower boards being fitted with air-valves. The lowest board is held down by a weight and another weight rests on the top board. In working these double bellows the lowest board is raised, and drives the air from the lower cavity into the upper. On lowering the bottom board again a fresh supply of air is drawn in through the bottom valve, to be again discharged when the board is raised. As the air passes from the lower to the upper cavity it is prevented from returning by the valve in the middle board, and in this way a quantity of air is sent into the upper cavity each time the lowest board is raised. The weight on the top board provides the necessary pressure for the blast, and at the same time causes the current of air delivered to be fairly continuous. When the air is being forced into the upper cavity the weight is being raised, and, during the interval when the lowest board is descending, the weight is slowly forcing the top board down and thus keeping up the flow of air.

|

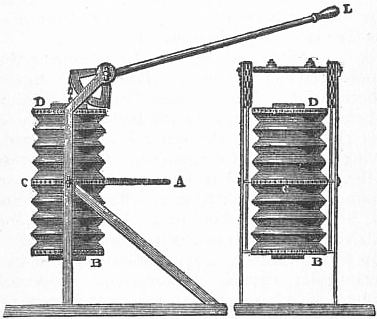

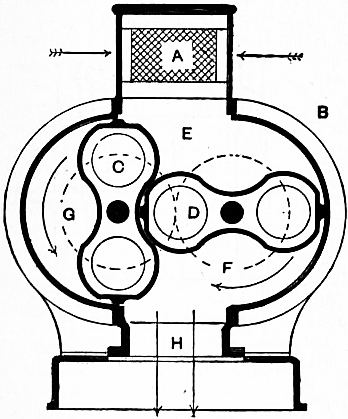

| Figs. 1 and 2.—Common Smiths’ Bellows. |

Hand-bellows for domestic use are generally shaped like a pear, with the hinge at the narrow end. The same shape was adopted for the older forms of smiths’ bellows, with the difference that two bellows were used superposed, in a manner similar to that just described, so as to provide for a continuous blast. In the later form of smiths’ bellows the same principle is employed, but the boards are made circular in shape and are always maintained roughly parallel to one another. These are shown on figs. 1 and 2. Here A is the blast pipe, B the movable lowest board, C the fixed middle board, close to which the pipe A is inserted, and D is the movable uppermost board pressed upon by the weight shown. The board B is raised by means of a hand lever L, through either a chain or a connecting rod, and lowered by a weight. The size of the weight on D depends on the air pressure required. For instance, if a blast pressure of half a pound per square inch is wanted and the boards are 18 in. in diameter, and therefore have an area of 254 sq. in., on each of the 254 sq. in. there is to be a pressure of half a pound, so that the weight to balance this must be half multiplied by 254, or 127 ℔ The diameter of the air-pipe can be varied to suit the required conditions. Instead of bellows with flexible sides, a sliding arrangement is sometimes used; this consists of what are really two boxes fitting into one another with the open sides both facing inwards, as if one were acting as a lid to the other. By having a valve and outlet pipe fitted as in the bellows and sliding them alternately apart and together, an intermittent blast is produced. The chief defect of this arrangement is the leakage of air caused by the difficulty in making the joint a sufficiently good fit to be air-tight.

Blowing Engines.—Where larger quantities of air at higher pressures than can conveniently be supplied by bellows are required, as for blast furnaces and the Bessemer process of steel-making, what are termed “blowing engines” are used. The mode of action of a blowing engine is simple. When a piston, accurately fitting a cylinder which has one end closed, is forcibly moved towards the other end, a partial vacuum is formed between the piston and the blank end, and if this space be allowed to communicate with the outer atmosphere air will flow in to fill the vacuum. When the piston has completed its movement or “stroke,” the cylinder will have been filled with air. On the return of the piston, if the valve through which the air entered is now closed and a second one communicating with a chamber or pipe is opened, the air in the cylinder is expelled through this second valve. The action is similar to that of the bellows, but is carried out in a machine which is much better able to resist higher pressures and which is more convenient for dealing with large quantities of air. The valves through which the atmosphere or “free” air is admitted are called “admission” or “suction” valves, and those through which the air is driven from the cylinder are the “discharge” or “delivery” valves. Formerly one side only of the blowing piston was used, the engine working “single-acting”; but now both sides of the piston are utilized, so that when it is moving in either direction suction will be taking place on one side and delivery on the other. All processes in connexion with which blowing engines are used require the air to be above the pressure of the outer atmosphere. This means that the discharge valves do not open quite at the beginning of the delivery stroke, but remain closed until the air in the cylinder has been reduced in volume and so increased in pressure to that of the air in the discharge chamber.

The power used to actuate these blowing-engines is in most cases steam, the steam cylinder being placed in line or “tandem” with the air cylinder, so that the steam piston rod is continuous with or directly joined to the piston rod of the air cylinder. This plan is always adopted where the cylinders are placed horizontally, and often in the case of vertical engines. The engines are generally built in pairs, with two blowing cylinders and one high-pressure and one low-pressure steam cylinder, the piston rods terminating in connecting rods which are attached to the pins of the two cranks on the shaft. In the centre of this shaft, midway between the two engines, there is usually placed a heavy flywheel which helps to maintain a uniform speed of turning. Some of the largest blowing engines built in Great Britain are arranged as beam engines; that is to say, there is a heavy rocking beam of cast iron which in its middle position is horizontal. One end of this beam is linked by a short connecting rod to the end of the piston rod of the blowing cylinder, while the other end is similarly linked to the top of the steam piston rod, so that as the steam piston comes up the air piston goes down and vice versa. At the steam end of the beam a third connecting rod works the crank of a flywheel shaft.

About the end of the 19th century an important development took place which consisted in using the waste gas from blast furnaces to form with air an explosive mixture, and employing this mixture to drive the piston of the actuating cylinder in precisely the same manner as the explosive mixture of coal gas and air is used in a gas engine. Since the majority of blowing engines are used for providing the air required in iron blast furnaces, considerable saving should be effected in this way, because the gas which escapes from the top of the furnace is a waste product and costs nothing to produce.

|

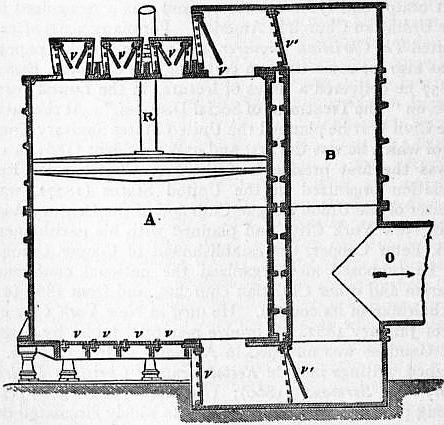

| Fig. 3.—Section of Cylinder of Early Blowing Engine (1851). |

The general action of a blowing engine may be illustrated by the sectional view shown on fig. 3, which represents the internal view of one of the blowing cylinders of the engines erected at the Dowlais Ironworks as far back as 1851. Many of the details are now obsolete, but the general scheme is the same as in all blowing engines. Here A is the air cylinder; in this is a piston whose rod is marked R; this piston is usually made air-tight by some form of packing fitted into the groove which runs round its edge. In this particular case the cylinder is placed vertically and its piston rod is actuated from the end of a rocking beam. The top and bottom ends are closed by covers and in these are a number of openings controlled by valves opening inwards so that air can flow freely in but cannot return. The piston is shown moving downwards. Air is now being drawn into the space above the piston through the valves v at the top, and the air in the space A below the piston, drawn in during the previous up-stroke, is being expelled through the valve v′ into the discharge chamber B, thence passing to the outlet pipe O. The action is reversed on the up-stroke. Thus it will be seen that air is being delivered both during the up-stroke and the down-stroke, and therefore flows almost continuously to the furnaces. There must, however, be momentary pauses at the ends of the strokes when the direction of movement is changed, and as the piston, though worked from an evenly rotating crank shaft, moves more quickly at the middle and slows down to no speed at the ends of its travel, there must be a considerable variation in the speed of delivery of the air. The air is therefore led from O into a large storage chamber or reservoir, whence it is again taken to the furnace; if this reservoir is made sufficiently large the elasticity of the air in it will serve to compensate for the irregularities, and a nearly uniform stream of air will flow from it. The valves used in this case and in most of the older blowing engines consist of rectangular metal plates hinged at one of the longer edges; these plates are faced with leather or india rubber so as to allow them to come to rest quietly and without clatter and at the same time to make them air-tight. It will be seen that some of these valves hang vertically and others lie flat on the bottom of the cover. The Dowlais cylinder is very large, having a diameter of 12 ft. and a piston stroke of 12 ft., giving a discharge of 44,000 cub. ft. of air per minute, at a pressure of 4¼ ℔ to the square inch.

|

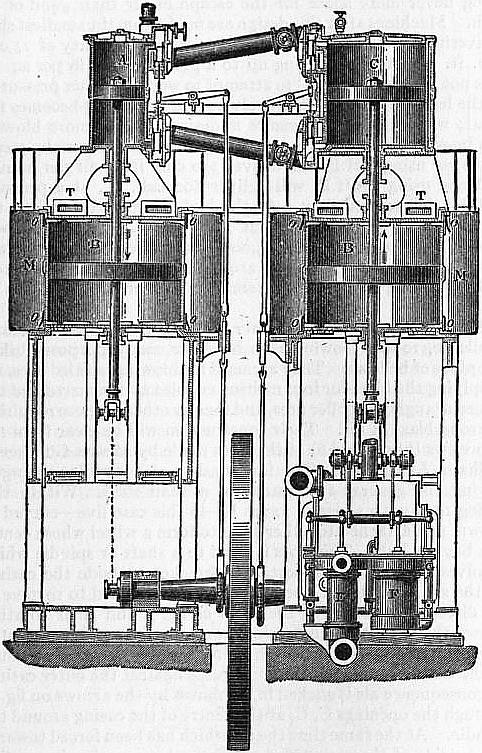

| Fig. 4.—Vertical Section of Lackenby Blowing Engines (1871). |

A later design of blowing engine, built in 1871 for the Lackenby iron-works, Middlesbrough, is shown in section in fig. 4, and is of a type which is still the most common, especially in the north of England. Here A, the high-pressure steam cylinder, and C, the low-pressure one, are placed in tandem with the air cylinders B, B, whose pistons they actuate. In these blowing cylinders the inlet valves in the bottom are circular disk valves of leather, eighteen in number; the inlet valves T on the top of the cylinder are arranged in ten rectangular boxes, having openings in their vertical sides, inside which are hung leather flap valves. The outlet valves O are ten in number at each end of the cylinders, and are hung against flat gratings which are arranged round the circumference. The blast is delivered into a wrought iron casing M which surrounds the cylinder. The combined area of the inlet valves is 860 sq. in., or one-sixth the area of the piston. The speed is twenty-four revolutions per minute and the air delivered at this speed is 15,072 cubic ft. per minute, the horse-power in the air cylinders being 258. The circulating pump E, air pump F, and feed pumps G, G, are worked off the cross-head on the low-pressure side.

A more modern form of blowing engine erected at the Dowlais works about the end of the 19th century, may be taken as typical of the present design of vertical blowing engine in use in Great Britain. The two air cylinders are placed below and in tandem with the steam cylinders as in the last case. The piston rods also terminate in connecting rods working on to the crank shaft. The air cylinders are each 88 in. in diameter, and the high and low pressure cylinders of the compound steam engine are 30 in. and 64 in. respectively, while the common stroke of all four is 60 in. The pressure of the air delivered varies from 4½ to 10 ℔ per sq. in. and the quantity per minute is 25,000 cub. ft. Each engine develops about 1200 horse-power. It is to be noted that flap valves such as those used in the 1851 Dowlais engine have in most cases given place to a larger number of circular steel disk valves, held to their seats by springs.

|

| Fig. 5.—Richardsons, Westgarth & Co.’s Blowing Engine. |

In a large blowing engine built in 1905 by Messrs Davy Bros. of Sheffield for the North-Eastern Steel Company at Middlesbrough (see Engineering, January 6, 1905) the same arrangement was adopted as in that just described. The two air cylinders are each 90 in. diameter and have a stroke of 72 in. The capacity of this engine is 52,000 cub. ft. of air per minute, delivered at a pressure of from 12½ to 15 ℔ per sq. in. when running at a speed of thirty-three revolutions per minute. The air valves consist of a large number of steel disks resting on circular seatings and held down by springs, which for the delivery valves are so adjusted in strength that they lift and release the air when the desired working pressure has been reached. It is worthy of note that in this engine no attempt is made to make the air pistons air-tight in the usual way by having packing rings set in grooves round the edge, but the piston is made deeper than usual and turned so as to be a very good fit in the cylinder and one or two small grooves are cut round the edge to hold the lubricant.

To illustrate a blowing engine driven by a gas engine supplied with blast furnace gas, fig. 5 gives a diagrammatic view of the blowing cylinder of an engine built by Messrs Richardsons, Westgarth & Co. of Middlesbrough about 1905. The gas cylinder is not shown. It will be seen that the air cylinder is horizontal, and it is arranged to work in tandem with the gas motor cylinder. The chief point of interest is to be found in the arrangement of the details of the air cylinder. Its diameter is 86½ in. and the length of piston stroke 55 in. As to the arrangement of the valves, if the piston be moving in the direction shown, on the left side of the piston at A air is being discharged, and follows the course indicated by the arrows, so as first to pass into the annular chamber which forms a continuation of the space A, and thence, through the spring-controlled steel disk valves v′, into the discharge chamber C, which ultimately leads to the blast pipe. It will be seen that the valves v on the other side of the annular chamber are closed. At the same time a partial vacuum is being formed in the space B, to be filled by the inflow of air through the valves v which are now open, the corresponding discharge valves v′ being closed. These valves on the inside and outside of the annular spaces referred to are arranged so as to form a circle round the ends of the barrel of the cylinder. The free air, instead of being drawn into the valves v direct from the air of the engine house, is taken from an enclosed annular chamber E, which may be in communication with the clean, cool air outside. It will be seen that the piston is made deep so as to allow for a long bearing surface in the cylinder. Two metal packing rings are provided to render the piston air-tight. The horse-power of this engine, which is designed on the Cockerell system, is 750.

Air valves of other types than those which have been mentioned have been tried, such as sliding grid valves, rotatory slide valves and piston valves, but it has been found that either flap or disk lift valves are more satisfactory for air on account of the grit which is liable to get between slide valves and their seatings. In some of the blowing engines made by Messrs Fraser & Chalmers (see Engineer, June 15, 1906), sheets of flexible bronze act as flap valves both for admission and delivery, the part which actually closes the opening being thickened for strength.

The pressure of the air supplied by blowing engines depends upon the purposes for which it is to be used. In charcoal furnaces the pressure is very low, being less than 1 ℔ per sq. in.; for blast furnaces using coal an average value of 4 ℔ is common; for American blast furnaces using coke or anthracite coal the pressure is as high as 10 ℔; while for the air required in the Bessemer process of steel-making pressures up to 25 or 30 ℔ per sq. in. are not uncommon. According to British practice one large blowing engine is used to supply several blast furnaces, while in America a number of smaller ones is used, one for each furnace.

|

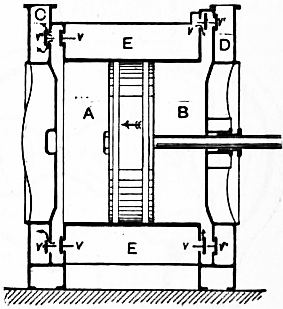

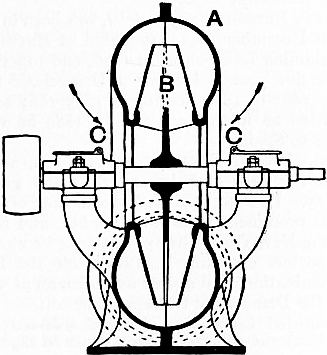

| Fig. 6.—Thwaites’ Improved Roots’ Blower. |

Rotary blowers occupy a position midway between blowing engines and fan blowers, being used for purposes requiring the delivery of large volumes of air at pressures lower than those of blowing engines, but higher than those of fan blowers. The blowing engine draws in, compresses and delivers its air by the direct action of air-tight pistons; the same effect is aimed at in a rotary blower with the difference that the piston revolves instead of moving up and down a cylinder.

Two of the best-known machines of this kind are Roots’ and Baker’s, both American devices. The mode of action of Roots’ blower, as made by Messrs Thwaites Bros. of Bradford, will be clear from the section shown on fig. 6. The moving parts work in a closed casing B, which consists of half-cylindrical curved plates placed a little more than their own radius apart, the ends being enclosed by two plates. Within the casing, and barely touching the curved part of the casing and each other, revolve two parts C, D, called “revolvers,” the speed of rotation of which is the same, but the direction opposite. They are compelled to keep their proper relative positions by a pair of equal spur wheels fixed on the ends of the shafts on which they run. The free air enters the casing through a wire screen at A and passes into the space E.

As the space E increases in volume owing to the movement of the revolvers, air is drawn in; it is then imprisoned between D and the casing, as shown at G, and is carried round until it is free to enter F, from which it is in turn expelled by the lessening of this space as the lower ends of the revolvers come together. In this way a series of volumes of air is drawn in through A, to be afterwards expelled from H in an almost perfectly continuous stream, this result being brought about by the relative variation in volume of the spaces E, F and G. In their most improved form the revolvers are made hollow, of cast iron, and accurately machined to a form such that they always keep close to one another and to the end casing without actually touching, there being never more space for the escape of air than 1⁄32nd of an inch. Machines after this design are made from the smallest size, delivering 25 cub. ft., to the largest, with a capacity of 25,000 cub. ft. per minute working up to a pressure of 3 ℔ per sq. in. It is not found economical to attempt to work at higher pressures, as the leakage between the revolvers and the casing becomes too great; where a higher pressure is desired two or more blowers can be worked in series, the air being raised in pressure by steps. A blower using 1 H.P. will deliver 350 cub. ft. of air per minute and one using 2¾ H.P. will deliver 800 cub. ft., at a pressure suitable for smiths’ fires. At the higher pressure required for cupola work—somewhere about ¾ ℔ per sq. in.—6½ H.P. will deliver 1300, and 123 H.P. 25,000 cub. ft. per minute. In the Baker blower three revolvers are used—a large one which acts as the rotating piston and two smaller ones forming air locks or valves.

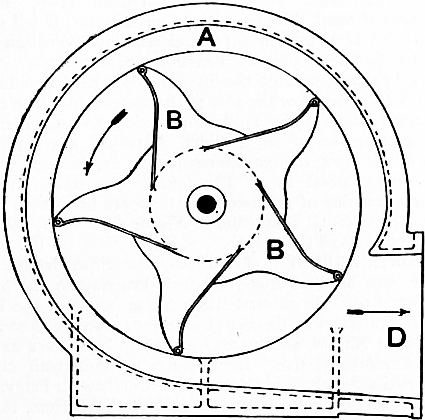

Rotary Fans.—Now that power for driving them is so generally available, rotary blowing fans have for many purposes taken the place of bellows. They are used for blowing smiths’ fires, for supplying the blast for iron melting cupolas and furnaces and the forced draught for boiler fires, and for any other purpose requiring a strong blast of air. Their construction will be clear from the two views (figs. 7 and 8) of the form made by Messrs Günther of Oldham, Lancashire. The fan consists of a circular casing A having the general appearance of a snail shell. Within this casing revolves a series of vanes B—in this case five—curved as shown, and attached together so as to form a wheel whose centre is a boss or hub. This boss is fixed to a shaft or spindle which revolves in bearings supported on brackets outside the casing. As the shaft is rotated, the vanes B are compelled to revolve in the direction indicated by the arrow on fig. 7, and their rotation causes the air within the casing to rotate also. Thus a centrifugal action is set up by which there is a diminution of pressure at the centre of the fan and an increase against the outer casing. In consequence air is sucked in, as shown by the arrows on fig. 8, through the openings C, C, at the centre of the casing around the spindle. At the same time the air which has been forced towards the outside of the casing and given a rotary motion is expelled from the opening at D (fig. 8). All blowing fans work on the same principle, though differences in detail are adopted by different makers to meet the variety of conditions under which they are to be used. Where the fan is to be employed for producing a delivery or blast of air the opening D is connected to an air pipe which serves to transmit the current of air, and C is left open to the atmosphere; when, however, the main object is suction, as in the case where the fan is used for ventilation, the aperture C is connected through a suction pipe with the space to be exhausted, D being usually left open. Günther fans range in size from those which have a diameter of fan disk of 8 in. and make 5500 revolutions per minute, to those which have a diameter of 50 in. and run at from 950 to 1200 revolutions per minute. For exhausting the fans are run less quickly than for blowing, the speed for a fan of 10 in. diameter being 4800 revolutions for blowing and 3300-4000 for exhausting, while the 50-in. fan only runs at 550-700 when exhausting. These two exhausting fans remove 400-500 and 12,000-15,000 cub. ft. of air per minute respectively.

|

| Fig. 7.—Günther’s Blowing Fan. |

|

| Fig. 8.—Günther’s Blowing Fan. |

The useful effect of rotary fans, that is to say the proportion of the total power used to drive the fan which is actually utilized in producing the current of air, is very low for the smaller sizes, but may rise to 30-70% in sizes above 5 ft. in diameter. It has its maximum value for any given fan at a certain definite speed. Fans are most suitable in cases where it is required to move or deliver comparatively large volumes of air at pressures which are little above that of the atmosphere. Where the pressure of the current produced exceeds a quarter of a pound on the square inch the waste of work becomes so great as to preclude their use. The fan is not the most economical form of blower, but it is simple and inexpensive, both in first cost and in maintenance. The largest fans are used for ventilating purposes, chiefly in mines, their diameters rising to 40 or even 50 ft. The useful effect of some of these larger fans, as obtained from experiments, is as high as 75%. In the case of the Capell fan, which differs from other forms in that it has two series of blades, inner and outer, separated by a curved blank piece between the inner wings, dipping into the fan inlet, and the outer wings, very high efficiencies have been obtained, being as great as 90% in some cases. Capell fans are used for ventilating mines, buildings, and ships, and for providing induced currents for use in boiler furnaces. In the larger fans the casing, instead of having a curved section, is more often built of sheet steel and is given a rectangular section at right angles to the periphery. The Sirocco blowing fan, of Messrs Davidson of Belfast, has a larger number of blades, which are relatively narrow as measured radially, but wide axially. It can be made much smaller in diameter than fans of the older designs for the same output of air—a great advantage for use in ships or in buildings where space is limited—and its useful effect is also said to be superior. (See also Hydraulics, § 213.)

Helical or screw blowers, often called “air propellers,” are used where relatively large volumes of air have to be moved against hardly any perceptible difference in pressure, chiefly for purposes of ventilation and drying. Most often the propeller is used to move air from one room or chamber to another adjoining, and is placed in a light circular iron frame which is fixed in a hole in the wall through which the air is to be passed. The propeller itself consists of a series of vanes or wings arranged helically on a revolving shaft which is fixed in the centre of the opening. The centre line of the shaft is perpendicular to the plane of the opening so that when the vanes revolve the air is drawn towards and through the opening and is propelled away from it as it passes through. The action is similar to that of a steamship screw propeller, air taking the place of water. Such blowers are often driven by small electric motors working directly on the end of the shaft. For moving large volumes of air against little pressure and suction they are very suitable, being simpler than fans, cheaper both in first cost and maintenance for the same volume of air delivered, and less likely to fail or get out of order. To obtain the best effect for the power used a certain maximum speed of rotation must not be exceeded; at higher speeds a great deal of the power is wasted. For example, a propeller with a vane diameter of 2½ ft. was found to deliver a volume of air approximately proportional to the speed up to about 700 revolutions per minute, when 8000 cub. ft. per minute were passed through the machine; but doubling this speed to 1400 revolutions per minute only increased delivery by 1000 cub. ft. to 9000. At the lower of these speeds the horse-power absorbed was 0.6 and at the higher one 1.6.

Other Appliances for producing Currents of Air.—In its primitive form the “trompe” or water-blowing engine adopted in Savoy, Carniola, and some parts of America, consists of a long vertical wooden pipe terminating at its lower end in an air chest. Water is allowed to enter the top of the pipe through a conical plug and, falling down in streamlets, carries with it air which is drawn in through sloping holes near the top of the pipe. In this way a quantity of air is delivered into the chamber, its pressure depending on the height through which the water falls. This simple arrangement has been developed for use in compressing large volumes of air at high pressures to be used for driving compressed air machinery. It is chiefly used in America, and provides a simple and cheap means of obtaining compressed air where there is an abundant natural supply of water falling through a considerable height. The pressure obtained in the air vessel is somewhat less than half a pound per square inch for every foot of fall.

Natural sources of water are also used for compressing and discharging air by letting the water under its natural pressure enter and leave closed vessels, so alternately discharging and drawing in new supplies of air. Here the action is the same as in a blowing engine, the water taking the place of the piston. This method was first thoroughly developed in connexion with the Mt. Cenis tunnel works, and its use has since been extended.

|

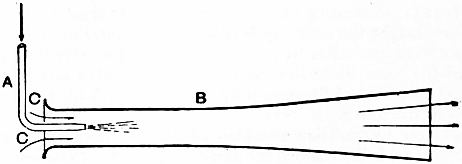

| Fig. 9.—Steam-jet Blower. |

In the jet blower (fig. 9) a jet of steam is used to induce a current of air. Into one end of a trumpet-shaped pipe B projects a steam pipe A. This steam pipe terminates in a small opening, say, one-eighth of an inch, through which the steam is allowed to flow freely. The effect is to cause a movement of the air in the pipe, with the result that a fresh supply is drawn in through the annular opening at C, C, and a continuous stream of air passes along the pipe. This is the form of blower made by Messrs Meldrum Bros. of Manchester, and is largely used for delivering air under the fire bars of boiler and other furnaces. In some cases the jets of steam are allowed to enter a boiler furnace above the fire, thus inducing a current of air which helps the chimney draught and is often used to do away with the production of smoke; they are also used for producing currents of air for purposes other than those of boiler fires, and are very convenient where considerable quantities of air are wanted at very low pressures and where the presence of the moisture of the steam does not matter.

Sometimes jets of high-pressure air flowing at great velocities are used to induce more slowly-moving currents of larger volumes of air at low pressures.

1 The Old English word for this appliance was blástbaelig, i.e. “blow-bag,” cf. German Blasebalg. By the 11th century the first part of the word apparently dropped out of use, and baelig, bylig, bag, is found in early glossaries as the equivalent of the Latin follis. Baelig became in Middle English bely, i.e. “belly,” a sack or bag, and so the general word for the lower part of the trunk in man and animals, the stomach, and another form, probably northern in origin, belu, belw, became the regular word for the appliance, the plural “bellies” being still used till the 16th century, when “bellows” appears, and the word in the singular ceases to be used. The verb “to bellow” of the roar of a bull, or the low of a cow, is from Old English bellan, to bell, roar.

↧ Download as ZWI file | Last modified: 11/17/2022 15:24:02 | 24 views

☰ Source: https://oldpedia.org/article/britannica11/Bellows | License: Public domain in the USA. Project Gutenberg License

ZWI signed:

ZWI signed: KSF

KSF